71%(7)71% found this document useful (7 votes)

2K views89 pagesSACS Training Material

Training material for SACS program

Uploaded by

Yadi PermadiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

71%(7)71% found this document useful (7 votes)

2K views89 pagesSACS Training Material

Training material for SACS program

Uploaded by

Yadi PermadiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

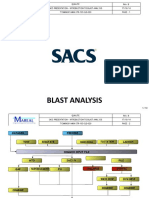

- SACS Training Project: Overview of the SACS training project including materials used, structure, and design codes.

- Structural Modeling: Instructions for setting up and modeling offshore structures using SACS software.

- Linear Static Analysis: Procedures for running a linear static analysis on the model using SACS.

SHRAD Services Sdn, Bhd. Training Brief 2012

SACS

BASIC TRAINING 3°°-5™ Oct. 2012

SINGAPORE

OFFSHORE STRUCTURAL DESIGN & ANALYSIS SYSTEM

SHRAD SERVICES SDN. BHD.

Design specifcation- 1

SHRAD Services Sdn. Bhd. Training Brief 2012

SACS Training project

This project provides the general information for the SACS training. The material can be

used for basic and advanced SACS training seminar. All the data and drawings included

in this document are for training proposes only, and none of them can be used in any

real design project.

Structure

The training project is a four legged wellhead platform with four conductors and a two-

lever deck located in an unknown area with water depth of 79.5 meters, see drewings

included in this document.

Design codes

API RP 2A 21" Edition with Supplement1, 2 and 3 published in 2007

AISC 9" Edition

Design loads

Equipment loads:

There are four equipment skids on the decks and the locations are shown in Drawing

201. The weights of the equipment are listed in the following table.

No. Equipment 1D Weight C.G height™

(kN) (mr;

i SKIDI 7112.05 3.0

2 SKID2 667.23 2.5

3 SKID3 444.82 2.0

4 SKID4 155.587 4.0

*C.G height is in +Z direction, relative to the surface of the skid.

Deck loads:

The main deck area load: 0.75kN/m*2

Cellar deck area load: —0.5kN/m*2

Live loads:

The main deck live load: 5.0kNim*2

The Cellar deck live load: 2.5kN/m*2

Appurtenant structure loads:

Design specifcation- 2

SHRAD Services Sdn. Bhd, Training Brief 2012

Walkway & staircase on the main and cellar decks are equally distributed weight at

weight value of 2.773 kN/m on the east side of both the cellar & main deck members.

A pedestal crane is located on the northeast leg at the main deck at a weight of

88.964kN

A firewall is located between on the cellar deck north legs at 1.5m north of the lags with

total weight of 45 kN that can be equally distributed as concentrated load of 15kN on the

support beams.

Four jacket lifting padeyes each weighing 2kN are to be installed on the jacket at

elevation 3m above the mean sea level.

The sea deck walkway at boat landing elevation (EL 2.0m) are supported by alll the

members at EL 2.0 plan except the wellbay members with a uniform distributed weight

of 1.5kN/m and assumed density of 1.5ton/m?3 for buoyancy calculation.

The jacket is protected from corrosion using zinc anodes weighing 2.5 kN each and 2

anodes installed on all primary structural members below the splash zone confined by

the highest X-brace center in the splash zone.

The weights of the appurtenant structures should be included in the model including the

unmodelled J-tubes and risers.

Environmental loads:

Still water depth: 79.5m

High tide: 4.5m

Marine growth:

Distance from Mudline(m) Thickness(cm) Dry density (T/m*3)

0-60 25 14

60-79.5 5.0 1.4

Current:

Distance from Mudline(m) Veloci 1)

7 Year" 100 Years

Bottom 0514 I 0.514

Surface a 1.029 [ 4.081

Wind:

45.17,

Design specification- 3

SHRAD Services Sdn. Bhd. Training Brief 2012

Wave:

Year 100 Years

Wave Height(m) | Period{sec) | Wave Height(m) Period(sec)

6.10 12.00 12.19 15.0

Wave Scat diagram:

Table | 0.0 direction Occurrence: 30%

Bee eet ignificant Wave Height (M)

ieee 0.0-0.6 06-14 14-26

10-20 ous 0.10 0.10

20-40 0.10 0.19 ou

| 40-60 90s 0.08 0.05

60-100 0.02 0.03 0.02

Table 2 45.0 direction Occurrence: 40%

beeaicsepesal Significant Wave Height (M)

caer 00-06 06-14 14-26

10-20 0.10 013 0.08

20-40 os 0.13 0.10

40-60 0.08 0.08 0.07

60-100 0.03 0.02 0.03

Design specification- 4

SHRAD Services Sdn. Bhd,

Training Brief 2012

Table 3 90.0 degree Oceurrence: 30%

ese Significant Wave Height (M)

oe 00-06 06-14 14-26

10-20 0.13 0.10 0.08

20-40 03 ois 0.10

40-60 “006 0.09 0.08

60-100 0.03, 0.03 0.02

Earthquake:

The maximum horizontal ground acceleration: 0.159

Response spectrum: APB spectrum should be adopted

Soil data:

The soil data used for this training project are made up data and they are not from any

soil report. The units of the data in the table is detail

das following}

Design specification- 5

9 -uoyeoyloeds uBiseq

ra aa

ra ra isan ws

ite [eet ra F650 TELL Har as

ii 960 Lt fer ws

oH a Score as

oo

4 x aA

ro ‘9 FO Fad 00

WW cundep 'Wo/N> td “WO: aIuN 20°0=10108} Z $pS'Z=1019B} A “2p A-d

al Le oe I LEE

00 00 00 00

3° Z o Zz

ssr sw

Wi cundap 'ZyWO/NA 2D "WI:Z AUN ——_ SL000°0=40198J © “pS'Z=10}98} Z “IEP Z-0

€L90 | 160 | 6ETO | VFO [Lor | 16S0 | eL90| Toso [sro [16s | Pew | 16s | e190 | 6s0

EL7O | FEED | GeO | FOE | LOTT | FEED | ELV | FEO [SLO | FOEO | POND | POE | CLI | Foro

voro | 9ec0 | vero | 9ec0 | 810 | 9ee0 | Foro | 9ec0 [s¥O | 90 | DES | VECO | FOF | 9ETO

toro | siro | Lo | RIO | SEO | RITO | coro | S110 | seco | SIO | 89z0 | SFO | coro | sIFO

oo [oo [oo [oo [oo [oo [oo [oo [oo [oo [oo [oo [oo [oo [oo [oo

Alice [Rez Eee Fe ez ll Mie [ee [cob cep cee] ce ef eee eee eee ea

Fer a we corer FOr 1 ws 00

wu cundep ‘ZywWoyny 1 ‘WH 2790'0=40108} | “pg Z=s0}e} Z “IEP Z-1

ClO Fone SuTUTEA PUA UPS STIS CVUHS

Member Label= Group

818980181 081 190316480

4780701010871 bB03L7 «80

Hb ssp

*qott 4037

3%

301P 31033104 303L

Xam "303?

203%

x

+ 203L

apap

101P. 11031104 1038 .

ATOTL ne

u= Ley

r2 Tle

pe foare

(2 candice,

Bar

3027

*302L

vO2L

*102P

oan

2102

402x

x

sox

x

j_iine

204P

Yana,

104P,,

* 0a

BOIL goat

Aba, HR ‘

“E01l ’ “402i

1x

apap \\a00P

“SIL o *a02u

201K

ae atk za.

anit “202°

re 101

iz :

303L 3100 304P

‘quae ———*

*a04

2100 204

* *204p

12x

x

i100 1oap, =

oa

Bin - Plans, View - -79.500

102

Bin - Plans, View - -79.500

Member Label= Group

Plan at -50.000

2100 at

Hr fat

2108

el

SS

fal

Py

Yel

“2010 Wr

Plan at -50.000

Member Label= Group

H

Plan at -21.000

Wa

303L 3100

3106

2uie au oo

*201T 302

XS

Plan at 2.000

Al

ana 4100

“4050

aa

n

anos 4108 a2 ano} |ato6

sore [> so8e

aes] saure| “nec

[aia Hay aud

405F 4o6c

*405c *406F

4107 au aioa [ais

ye

so1F aio

Xai

40a

‘4047

402F

402.

Plan at 2.000

Member Label= Group

H41

H

H4

H41

4

Plan at 15.300

80 7 er

7102 [7108

Neos Q

a wor

moa rus ruts mn

7108 7110

wy

\ “ol

rou 7101 m0}

60 ni00 nat

Toa,

7o2L

71D

Plan at 15.300

Member Label= Group

Plan at 23.000

B0aL 8104 an4L

8110 8113 aus gil

sins [e112 alld

82F0

8100 810

Plan at 23.000

Member Label= Group

woe

W

WwO02

WW

SHRAD Services Sdn, Bhd. Training 2012

Section 1 Starting a model

In windows file explorer create a directory called “Training Project”, and a subdirectory called

“Structural Modeling”

Launch SACS Executive and go to “SACS Settings\Units Settings” and set default un ts 10

“Metric KN Force”. Then click on the “OK” button. See picture below.

ee i =

Set current working directory to “Structural Modeling” and launch Precede program ty

clicking on “Modeler” icon in “Interactive” window of Executive (See picture below’.

Click here to launch

Precede

Structural Modeling Page - 1

SHRAD Services Sdn, Bhd. Training 20)2

Select “Create New Model” and click ok. Then select “Start Structure Definition Wi

and click ok.(See two pictures below).

New Model Options heim

Start Options

© startbank made

{Click here to create the

ew model

PRECEDE

& start Sbuctre Defcon Wizard

‘at Units

| Kreseiranoss © nah

eit a force

© Weick force

| canes

Section2 Defining the jackevpile and conductor model

Define the jack/pile based on the drawing 101

Elevations:

Water depth 79.5 m

Working point elevation: 4.0 m

Pile connecting elevation: 3.0 m

Mudline elevation, pile stub elevation, and leg extension elevation: -79.5m

Other intermediate elevations: -50.0, -21.0, 2.0, 15.3 (cellar deck), 23.0m (main deck)

(See picture below)

=)

Structural Modeling Page - 2

SHRAD Services Sdn. Bhd. ‘Training 2012

Keep “Generate Seastate hydrodynamic data” checked to create hydrodynamic data, such as pile

and w.b., overrides.

Legs:

Click on the “Legs” Tab to enter the data for the jacket legs.

Number of legs: 4

Leg type: Ungrouted

Leg spacing at wor 5m, YI=10 m.

Row Labeling: Define the Row label to match the drawing

Pile/Leg Batter: Row | (leg 1 and leg 3, 1" Y Row) is single batter in Y

Row 2 (leg 2 and leg 4, 2" Y Row) is double batter

(See picture below for the details of the input)

Click here to define leg

spacing at the working point,

Conductors:

Click on the “Conductors” Tab and then click on “Add/Edit Conductor Data” to enter the data

for the conductors.

One conductor well bay that has four conductors

‘The top conductor elevation: 15.3m

First conductor number: 5

Number of conductors in X direction: 2

Number of conductors in Y direction: 2

The location of first conductor (LL): X= -4.5m, Y= -1.0m (See drawing 102/104)

‘The distance between conductors: 2.0m in both X and Y directions,

‘onnected elevations: -79.5m, 3.0m, and 4.0m,

Structural Modeling Page - 3

SHRAD Services Sdn. Bhd. ‘Training 2012

(See picture bel

v for the details of the conductor data input)

Tate] dete [te cen |

sattacrtetee |

sonar 3]

temanemein we [BE

See osama fee

ke

Click-on “Apply” to create the leg/pile and conductor model as shown below.

Save model:

Go to File/Save As, click “O.K” from prompted window and give file name sacinp.dat_01

Structural Modeling Page - 4

SHRAD Services Sdn. Bhd. Training 20:2

Define properties of leg members:

On the Precede toolbar select “Property” >

“Member Group”. The Member Group

Manage Window will show up (See picture

on the right)

‘The Undefined Group window shows all

group IDs which are assigned to members,

but their properties have not been defined.

The IDs will be moved to Defined Groups

Window afier properties are defined,

Click “LG1” from Undefined Groups window and then click on “Add” Tab to define the section

and material properties of LG1. This group is segmented and the data can be found in Drawing

101

Segment 1: D 1.75in, F

Segment 2: D Loin,

Segment 3: D = 48.Sin, T= 1.75in, Fy

Member is flooded

4.50 kN/em’, Segment Length = 1.0 m.

24.80 kN/em?

4.50 kN/cm?, Segment Length = 1.0 m

The unit of each input filed can be modified to use available data, In the pictures below the unit

of Outside Diameter and Thickness are changed to English (in). The segment length will be

designed late. See the pictures below for the details of the LGI group data input.

a

Repeat above to define LG2 and LG3 group, the data can be found in Drawing 101.

Define group LG4, DL6, DL7, CON, PL* and Wishbone groups, find the section dimensions,

from Drawing 101

Structural Modeling Page - $

SHRAD Services Sdn. Bhd. ‘Training 2012

LG4 = 48.5"x1.75"

DL6 = 42°x1.5

DL7=42°x1.5

CON = 30"x1" flooded

PL*=42"x1.

W.B. = 30°x1" flooded

To define those non-segmented groups click

the group ID from Undefined Group

Window and then click on “Add” Tab; enter

the data and “Apply”. The picture on the

right shows the LG4 data.

Allabove groups have section type of

Tubular, and both the geometry and material

data can be defined in Group Manage

window

Save model:

File/Save As, and name the file to sacinp.dat_02.

‘Member groups defined at this time shall look like the following:

GRUPCON 76.200 2.540 20.007.72234.50 1 1.01.00 0,500F7.8490

GRUP DL6 —_ 106.68 3.810 20.007.72234.501 1,001.00 0.500 7.8490

GRUP DL7 106.68 3.810 20.007.72234.50 1 1.001.00 0.500 7.8490

GRUPLGI 123.19 4.445 20.007.72234.50 1 1.001.00 0.500F7.84901.00

GRUPLGI _ 119.38 2.540 20.007.72224.80 1 1.001.00 0.500F7.8490

GRUPLGI 123.19 4.445 20.007.72234.50 1 1.001.00 0.500F7.84901.00

GRUPLG2 123.19 4.445 20.007.72234.50 1 1.001.00 0.500F7.84901.00

GRUPLG2 119.38 2.540 20.007.72224.80 1 1,001.00 0.500F7.8490

GRUPLG2 123.19 4.445 20.007.72234.50 1 1,001.00 _0.500F7.84901,00

GRUPLG3 123.19 4.445 20.007.72234.50 1 1.001.00 _0.500F7.84901,00

GRUPLG3 —_ 119.38 2,540 20.007.72224.80 1 1,001.00 0.500F7.8490

GRUPLG3 —_ 123.19 4.445 20.007.72234.50 1 1.001.00 _0.500F7.84901.00

GRUP LG4 48.500 1.750 20.007.72234.501 1.001.00 0.500 7.8490

GRUPPLI —_ 106.68 3.810 20.007.72234.50 1 1.001.00 0.500 7.8490

GRUP PL2 106.68 3.810 20.007.72234.501 1,001.00 0.500 7.8490

GRUP PL3 —_ 106.68 3.810 20.007.72234.50 1 1.001.00 0.500 7.8490

Structural Modeling Page - 6

SHRAD Services Sdn. Bhd. Training 2012

GRUP PL4 —_ 106.68 3.810 20.007.72234.50 1 1.001.00 0.500 7.8490

GRUP PLS —_ 106.68 3.810 20.007,72234.50 1 1.001.00 0.500 7.8490

GRUP W.B 76.200 2.540 20.007.72234.501 1,001.00 0.500F7.8490

Seetion3 Create the horizontal framings of the jacket

Open file sacinp.dat_02 or continue from last section.

Step I Select the View

Go to “Display” > “Plan” and pick -79.5 to ereate the framing at the mudline elevation. The

Exclude selected

grours from the view

The model of the plan after built will be

shown in the model plot Plan at EL-79.5,

Go to “Display” > “Group Selection” to

exclude Pile and Wishbone elements from.

the current view. See picture on the right f

details

You should only see the joints on the jacket

legs and conductors in the current view.

Will use best available dimensions from the

drawing and use “Member Divide” feature

to create the new joints and members

Uncheck here to

remove unattached

Step 2 Add horizontal members to connect the legs

Go to “Member” > “Add” to get dialog box shown below.

Click on 101L and 102L and enter “HII” as Repeat to create member 101L-102L, 102L-

group ID. Then click on “Apply” or Right- {O4L and 103L-104L.

click to add the member. See picture on the

right

Structural Modeling Page - 7

SHRAD Services Sdn. Bhd. Training 20:2

sone reat

Grn te a JS

eae ecaaeere]

F Addinmedite seh ins

sane

oot 12 sete

DalneDetaas | [ Ase cue |

Step 3. Divide the members by ratio

‘The joint 1100, 1101 and 1102 can be added by divide member by ratio since the joints are at the

mid points of the beams

To create joint 1100, go to “Member” >

“Divide” > “Ratio” to get the dialog box

shown on the lef

Click-on Member 103L-104L.

° Enter 0.5 to “Ratio from joint A”

[omeipratnenpetneeel Enter new joint name 1100

Cctteroayeaueenea Check on “Use next available...”

aa Leave others blank

tata Click Apply to create the joint

o_o | see

=|) _o |

You will be getting a new joint and two new elements, the original member 103L-104L has been

replaced by two new created members.

Repeat this step to create joint 1101 and 1102.

Step 4 Divide the member by length

Joint 1103 and 1104 can be defined by using Divide by Distance based on the available

dimensions on Drawing 101

Structural Modeling Page - 8

SHRAD Services Sdn. Bhd. Training 2012

To create joint 1103, go to “Member” >

“Divide” > “Length” to get the dialog box

shown on the left.

metas tte r— Click to select member 101L-103L

exon siete Enter 11.35m to “Length from Joint A”

F sectemratenlibeeteniaeentit New Joint name should be 1103

[cvecouyeunttconne Keep “Use next available name” checked

ste Leave others blank

ee | tt | oo Joint }§04 can be added same way with

o_o | distance = 4.0m,

Step 5 Connect diagonal brace members

Add a member connecting Joint 1101-1100, and define group label as “H12”

Add the members connecting J

define group ID as “H13”.

1101-1102, 1102-1100, 1104-1100 and 1101-1103, and

Step 6 Create well head frame members

Joint 1105 and 1106 can be defined by using Divide by Length based on the available

dimensions on Drawing 101, same as Joint 1103 and 1104.

To create joint 1105, go to “Member” >

a tt faa) “Divide” > “Length” to get the dialog box

teat ema ae) [ER on the left.

tevpece r=

eee Click to select member 1101-1100

mck nteamse Enter 11.35m to “Length from Joint A”

Puttteren pntisjonthemenbe when fet New Joint name should be 1105

inne ReaD: Keep “Use next available name” checked

eee Leave others blank

Joint 1006 can be added the same way with

distance = 4.0m.

Add member 1104-1106 and 1103-1105, Group ID should be “H13"

Use “Member” > “Divide” > “Length” to create Joint 1107, 1108, 1109 and 1110. The

distances can be found in the drawing, See pictures below for adding Joint 1107 and 1110.

Structural Modeling Page - 9

SHRAD Services Sdn, Bhd.

‘Training 2012

Add Member 1107-1108 and 1109-1110 with Group ID H14.

Step 7 Define member group properties

Define the group properties to H11, H12, H13 and H14, the dimensions and material can be

found in the drawing. The pictures below show the sample of H11 and H12 definition,

Note that the unit of each input can be changed to match available data. The following pictures

show the diameter and thickness being changed to an English Unit so the data from the drawing

can be input directly. *Make sure units chosen are correct.

sect f

Oise 2)

ny en

cnet (REBT)

seni r ol

aie

setae ot

cece)

ou oth

sermowi 3 |

Tearawenbhewl

toroeel | tren Fae

Structural Modeling Page - 10

SHRAD Services Sdn, Bhd. Training 2012

Repeat all the steps in Section 3 to create horizontal plans at elevation -50.0m, -21.0m and 2.0m,

All the data and dimensions needed to build the model can be found in Drawings 102 and 103,

The joint name and group ID can be found in model plots Plan at EL-S0, Plan at EL-20and Plan

at EL+2 PDF files.

Section 4 Create conductor guide framing

Use Plan at EL-50.0 as a sample:

Step 1 Create the joints to connect the conductor guide

Divide members 2107-2109, 2108-2110 by ratios to create joints 2111 and 2112;

Add members 2107-2108, 2109-2110, and 2111-2112 and then divide them by ratios to create

joint 2113, 2114, and 2115.

Connect members 2113-2115 and 2115-2114.

Step 2 Define member group for conductor guide frame

Use “Property” > “Member Group” to define the group property for the conductor guide

frame. The conductor and frame connection model is shown in the picture below.

Slessseeo oe) visemes Oey

SE adel Oo

Repeat the steps above to build the conductor connections at elevation -21.0 and 2.0.

Save the file to SACINP.dat_03,

Structural Modeling Page - 11

SHRAD Services Sdn, Bhi,

Section 5

Step |

Training 2012

Create diagonal members on jacket rows

Open sacinp.dat_03 with Precede and go to “Display” > “Face” and pick “Row A”.

Step 2

Go to “Display” > “Group Selections” to turn off the Pile and Wishbone elements from the

view

Step 3:

Tum on the Joint and Group label by clicking on the “J” and “G” icon on the toolbar.

Step 4

Define the X-brace between clevation ~

79.5m and -50,0m

Go to “Member” > “X-Brace” to get the

dialog box on the right, and enter the data:

Center joint name 101X

Pick four joints 1011, 202L, 201L and 102L.

(Pick the joints diagonally)

Enter BR1 as group ID of through members

(101L-202L)

Enter BR2 as the group of other members

Use 0.9 as the K factor

Click on “Apply”

Step 5

Define the X-brace between elevation -

50.0m and -21.0m

Go to “Member” > “X-Brace” to get the

dialog box on the right, and enter the data:

ete ete

txidnorueerte, BE

Otero ttf

covamaneen A _|

Ge dnt 2 — |

tease)

1 hada

1 Das fete se

ox |e] oom

Center joint name 201X

Pick four joints 202L, 301L, 302L, and

201L (Pick the joints diagonally)

Structural Modeling Page - 12

SHRAD Services Sdn. Bhd. Training 20:2

Enter BR3 as group ID for through members,

(2021-3011)

ner BR4 as the group for the other

members

Use 0.9 as the K factor

Click on “Apply”

entpet lal

FF Urnnet ate rane shove rane ite

Erde ramets

aed seta

frdcteetusnsas iE

Oneredct na nants

Geancticente ERT

|S!

8)

Kiewataslsiee) BE

FF hats

FF Odea tune Int sey et)

ox _| [ioe ee

Step 6

Repeat Step 5 to build the X-brace between Elevation -21.0m and 2.0m. The new center joint

name should be 301X; group IDs should be BRS for through members and BR6 for others.

The locations of center joints 101X, 201X and 301X are automatically calculated by the

program,

Step 7

Repeat Step 1 to Step 6 to build X-braces on Row B, Row | and Row 2; use same Grow IDs and

the center joint ID starts from 102X on Row B, 103X on Row 1 and 104X on Row 2.

Step 8

Define the group properties for the X-brace members. BR1, BR3, and BRS are through members

which are segmented. BR2, BR4, and BR6 are non-segmented members. The dimensions of all

members can be found in Drawing 101

Save model and give a new name sacinp.dat_04,

Structural Modeling Page - 13

SHRAD Services Sdn. Bhd. Training 2012

Section6 Creating deck frame

Step 1 Cellar Deck (E1+15.30m)

Go to “Pile” > “Structure Definition” and click on the “Deck Girders” Tab. Then click on

“Add/Edit Deck Girder Data”, You should see the following window below.

Deck elevation: 15.30

Deck extension 4.0m at structure North and South

Click “Apply” to apply the input information to the model.

Gooner [sen ae come ses]

aacens|

Check-on here to add the

deck extension beams

Step 2 Main deck (El+23.0m)

Click on “Add/Edit Deck Girder Data”

Deck elevation: 23.00

Deck extension 4.0m at structure North and South, 5.0m at structure East

Click “Apply” or “OK” to apply to model. By clicking ok it will apply to the model ané also

close out the structure definition box.

Structural Modeling Page - 14

SHRAD Services Sdn. Bhd. ‘Training 20.2

Check-on here to add the

deck extension beams

Step 3

Go to “Display” > “Plan” and select Plan at 15.3. Then go to “Display” > “Labeling” >

“Special” and turn off “Show jacket rows” to get a larger view. Turn on the Joint and Group

Label from Toolbar icon.

Step 4

Change the member group ID to WO1 and WO2 as shown in model plot Plan at 15,3, go to

“Member” > “Details/Modify” and select the elements to change.

Step 5

‘The Member divide feature can be used to simplify modeling, Joint and group names stould be

defined as shown in the model plot Plan at 15.3. The dimensions needed to build the model can

be found in Drawing 202. The functions recommended to build the frame model are:

“Member">“Divide">"Distance”

“Member">“Divide">"Ratio”

“Member” >“Divide”>"Perpendicular”

‘The new created joints naming should start from 7100, Alll the distances and ratios can be found

in the drawing. The conductor guide should be connected to the deck using dummy members.

This is the same as the ones in the jacket.

Structural Modeling Page - 15

SHRAD Services Sdn. Bhd. Training 2012

Step 6

Repeat Step 3 to Step 5 to build the frame in EL 23,00 plan, and the modeling results are shown.

n the model plot Plan at 23.0.

Step 7

Define the properties for group W01 and W02; the sections should be selected from the AISC 9"

edition Library.

Fe — [ae

fromthe Select wide

Library flange only

The above three pictures is a sample of how to define WO1 (From Left to Right). Repect it to

define the properties for W02.

Deck member groups defined at this time shall look like the following:

GRUP W0l W24X162 20.007.72224.80 1 1.001.00 7.8490

GRUP Wo2 W24X131 20.007.72224.80 1 1.001.00 7.8490

Save the model as sacinp.dat_0S

Structural Modeling Page - 16

SHRAD Services Sdn, Bhd. Training 2012

Section 7 Joint connect

Step 1

Include only the jacket in the current active window. Exelude the deck, piles, conductors, and

wishbone element from the current view.

Go to “Display” > “Group Selections” and

exclude group PL1-PLS, W01, W02, CON,

DL6-DL7, and W.B. Check offshow

unattached joints” and then click on

“Apply”. Refer to the picture on the right.

Step 2

Go to “Joint” > “Connection” > “Automatic Design”. Check the box “Offset braces to

outside of chord”. For “Gapping option” use “Move Brace”, and for “Brace Move” use “Along

Chord”. Set Gap = 5 cm and Gap size option to “Minimum only”. Select “Use existing offsets if

gap criteria is met”

Structural Modeling Page - 17

SHRAD Services Sdn, Bhd.

Dene tbeceeres

Genet [emo

ies

Sespr9 comer, [Mowtace =)

sacnoe egies]

a

Training 2012

Dera beste

I Up ssn pos cone

Canlaghecte Pe nnieneaiane

Saenger a) J

ieee teat

Irowsadehancenet (a 2

Mormmctodsertd J [

Under joint Can/Chord options select “Update segmented groups can lengths” and set “Can

length option” to “API minimum requirements”, Select “Increase joint can lengths only”, See

above two pictures for the detail options to be selected and click on “Apply” to create the joint

can model.

The leg member's segment lengths are automatically updated and the member end offsets of

each brace member are created automatically.

Step 3

Create dummy members to connect the guide joint to the framing joint created in last step. The

conductor and frame connection model is shown in the picture below.

DUM = 12.75" x 375”

Structural Modeling Page - 18

SHRAD Services Sdn. Bhd, Training 2012

Repeat the steps above to build the conductor connection elevation -21.0, 2.0 and 15.3,

Save the model to sacinp.dat_06.

The final updated Can length for legs shall look like the following:

GRUPLGI 123.19 4.445 20.007.72234.50 1 1,001.00 0.500F7.84902.10

GRUPLG1 119.38 2.540 20.007.72224.80 1 1.01.00 0.500F7.8490

GRUPLG1 123.19 4.445 20.007.72234.50 1 1,001.00 0.500F7.84901.76

GRUP LG2 123.19 4.445 20.007.72234.50 1 1.001.00 0.500F7.84902.16

GRUP LG2 119.38 2.540 20.007.72224.80 1 1,001.00 _0.500F7.8490

GRUP LG2 123.19 4.445 20.007.72234.50 11,001.00 0.500F7.84901.63

GRUPLG3 123.19 4.445 20.007.72234.50 1 1.001.00 0.500F7.84902.33

GRUP LG3_—__119.38 2.540 20.007.72224.80 1 1.01.00 _0.500F7.8490

GRUP LG3_—_ 123.19 4.445 20.007.72234.50 1 1,001.00 0.500F7.84901.60

GRUP LG4 123.19 4.445 20.007.72234.50 1 1,001.00 0.500 7.8490

Section8 Define deck beam offsets

Step 1

Go to “Display” > “Plan” and select plan at 15.3m, Exclude group W.B and CON from current

view.

Step 2

Go to “Member” > “Offsets...” and drag a (Selected members will be highlighted in

window to pick all members in current view red).

Structural Modeling Page - 19

SHRAD Services Sdn, Bhi. Training 2012

Change “Offset Type” to “Top of Stee!”

Click on “Apply” to create the offsets.

Refer fo picture on the right.

Note: The deck beam properties must be

defined before you can define the offset type

to “Top of Steel”

Step 3

Repeat above two steps to define the offset for the beams at Plan EL 23.00m.

Save the model to sacinp.dat_06.

Section Define member code check properties

Define Ky/Ly for horizontal framings:

Use “Property” > “K Factor” > “Ky” to modify Ky factor for HL members

79.50 mand H21 members in XY plane Z = -50.0 m

XY plane Z =~

Use “Property” > “Effective Length” > “Ly” to modify Ly factor for H32 members in XY

plane Z = -21.0 mand H42 members in XY plane Z = 2.0 m

Section 10 Define deck weight (Area weight)

Step 1 Add cellar deck surface weight ID (CELLWT1)

Using “Weight” > “Surface Definition” input “CELLWT1” for Surface ID, pick up jeint

TIBD, 71ED, and 74BD for local coordinate joints. Input 0.5 for Tolerance, and pick up 71 BD,

TIED, 74ED and 74BD by holding CTRL key for Boundary joints. Select load direction to

“Members in local Y” and then click Apply to add this surface ID definition.

Structural Modeling Page - 20

SHRAD Services Sdn. Bhd.

a

safer [LTT

add © eat

Ist ont fon)

ed nnn fod)

‘3d.ont ocd)

Tole (a) =]

asd jt fre

ote: sce unbuunded

bendy pevsd70

Step 2 Add main deck surface weight ID (MAINWT1)

Training 2012

Using “Weight” > “Surface Definition” input *MAINWT1” for Surface ID. Pick up joint

81BD, 81FD and 84BD for local coordinate joints, input 0.5 for Tolerance, and pick 81BD,

81ED, 84D and 84BD by holding CTRL key for Boundary joints. Select load direction to

“Local Y" and then click Apply to add this surface ID definition.

see [FORT |) oetay

© ads eat

ssemmetaom [30

2st focal)

dont eal)

Tolan) 2}

ood tution decton [Nebesnicel¥drecion >]

ound ots

Note: sree nrboandedaeey

boundary jis af

order acd re BSP

States

rele,

bested

Step 3 Add weight group AREA by adding surface weight for deck

Structural Modeling Page - 21

SHRAD Services Sdn. Bhd. ‘Training 2012

Using “Weight” > “Surface Weight” jnput AREA as Weight Group and AREAWT as Weight

1D, input weight pressure of 0,5 kN/m for the cellar deck and move CELLWTI to “Included.

Surface IDs”and click “Apply”. Then input a weight pressure of 0.75 KN/m* for the main deck

and move MAINWTI to “Included Surface IDs” and click “Apply”

ee PT pom omar GF :

eoaneanen te coor tens [+

Step 4 Add weight group LIVE by adding surface weight

Add weight group LIVE by using surface weight feature as in step 3. Weight ID MAINLIVE

includes the main deck weight pressure of 5.0 kN/m? and ID CELLLIVE includes the cellar

deck weight pressure = 2.5 kN/m*

Structural Modeling Page - 22

SHRAD Services Sdn. Bhd. Training 20:2

The added surface IDs and surface weights shall look like following:

SURFID CELLWTI LY 71BD 71ED 74BD_ 0.500

SUREDR 71BD 71ED 74ED 74BD

SURFID MAINWTI LY 81BD 81FD 84BD 0.500

SURFDR 81BD 81FD 84FD 84BD

SUREWTAREA 0.500AREAWT —_1.001.001.00CELLWTI

SUREWTAREA 0.750AREAWT —_1.001.001.00MAINWT1

SURFWTLIVE 2.S00CELLLIVE —1.001,001,00CELLWT1

SUREWTLIVE 5.000MAINLIVE —_1,001.001.00MAINWTI

Section 11 Define deck weight (Equipment weight)

Step 1 Define Skid

Use “Weight” > “Footprint Weight”

Weight group is EQPT and Footprint ID is SKID1;

Weight = 1112.05 kN; Footprint center (5.0, 2.0, 23.0); Relative weight center (0, 0, 3.0)

Skid Length = 6 m; Skid Width = 3 m; 2 skid beams in X direction (longitudinal)

— =

eran sens [F

tenner a

femener Ee —

tin [Fett [Fe

=

Click Apply and the summation of forces will be shown on a pop-up window. To save the input

footprint weight select Keep.

Step 2 Define Skid2

Structural Modeling Page - 23

SHRAD Services Sdn. Bhd. ‘Training 2012

Weight group is EQPT and Footprint ID is SKID2

Weight = 667.23 KN; Footprint center (-5.0, -7.0, 23.0); Relative weight center (0, 0,

Skid Length ~ 6 m; Skid Width = 2.5 m; 2 skid beams in X direction (longitudinal)

me wrott ab

nn

Step 3 Define Skid4

Weight group ID is EQPT and Footprint ID is SKID4

Weight = 155.587 kN; Footprint center (10.0, 6.0, 23.0); Relative weight center (0, 0, 4.0)

Skid Length = 6 m; Skid Width=3 m; 3 skid beams in X direction (longitudinal)

Senn

Structural Modeling Page - 24

SHRAD Services Sdn, Bhi. Training 20 2

Step 4 Define Skid3

Weight group is EQPT and Footprint weight ID is SKID

Weight = 444.82 kN; Footprint center (5.0, 0.0, 15.3); Relative weight center (0, 0, 2.0)

Skid Length = 6 m; Skid Width = 2.5 m; 2 skid beams in X direction

‘The added EQPT footprint weights shall looks like following:

WGTFP EQPTI112.05SKIDI 5.000 2.00023.000R 3.0006.0003.000 2

WGTFP2 —1.001.001.00.152L.

WGTFP EQPT667.230SKID2 —_-5.000-7.00023.000R, 2.5006,0002.500 2

WGTFP2 _1.001.001.00.152L

WGTEP EQPT155.587SKID4 10.000 6.00023.000R 4,0006.0003.000 3

WGTFP2 _1.001.001.00.152L

WGTFP EQPT444.820SKID3_ 5.000 15.300R 2.0006.0002.500 2

WGTFP2 —1.001.001.00.152L.

Section 12 Define mise weight on the deck and the jacket

Step 1 Walkway on the deck

Go to “Weight” > “Member Weight” and

hold control key to select all members on the

east side of the decks, and enter the

following data:

Structural Modeling Page - 25

SHRAD Services Sdn. Bhd, Training 20°2

Weight group MISC

Weight ID: Walkway

Weight Category: Distribute

Coordinate system: Global

Initial weight value: 2.773 kN/m

Final weight value: 2.773 KN/m

Load dir. factors: Defaults

Click on “Apply” and keep the w

Step 2. Enter crane weight

Go to “Weight” > “Joint

Weight” and pick up joint

8041 and enter the data:

Weight Group: MISC

Weight ID: CRANEWT

Weight: 88.964kN

Load dir. Factors: Defaults

coef.

l ee ee

eens in

Click on “Apply” then =

select “Keep”, See pictures

on the right.

Step 3 Enter the Firewall weight

Go to “Weight” > “Member weight” and select the following members: 703L-74BD, 7102-

7103, 7106-7107, and then enter the following data:

Structural Modeling Page - 26

SHRAD Services Sdn. Bhi, Training 2012

Weight Group: MISC aa os

Weight ID: | FIREWALL Poco oeeee

Weight Cate: Concentrated Die Ee |

Coord system: Global ese os }

Concen. Weight: 15.0kN 7

Distance: 1.5m aa

Load factors: Defaults =e

Click on “Apply” and rod

select to “Keep” the ——

weight. See pictures on the <<

right for details,

Step 4 Enter Padeye weight on the jacket

Go to “Weight” > “Joint Weight” and pick up joint 501L, 502L, S03L and SO4L, and enter the

following data:

Weight group: LPAD

Weight ID: PADEYE

Weight: 2.0kN

Check on “Include

‘buoyancy :

Density: 7.849 tonne/m*3 soc — jmowermah a}

‘EE

Click on “Apply” and

Keep”. See pictures on

right for details.

Step 5 Enter the walkway weight at boat landing elevation (EL 2.0m)

Go to “Weight” > “Member Weight” and pick all the members at EL 2.0 plan except the

wellbay members and then enter the data as following:

Structural Modeling Page - 27

SHRAD Services Sdn, Bhd. Training 2012

Group ID: WKWY

Weight ID: WLKWAY

Weight Category: Distributed

Coord. System: Global

Initial weight: 1.5kN/m

Final weight: 1.5kN/m_

Load dir. Factors: Defaults Se

Include buoyancy seme

& wave load: Checked “omen

Density: 1.5 tonne/m’3

Click on “Apply” and “Keep” the data. See

picture on the right for details.

Step 6 Define Anode weight

Go to “Display” > “Volumes” and select Type of volume to “Volumes to include”. Select joint

101L to get the min, Z-coordinate and select joint 301X to get the max. Z-coordinate, and then

click Apply. This will display only the part of jacket with anode protection.

Go to “Display” > “Group selection” to exclude group PLI-PLS, W.B, CON, H13-HI4, H23-

H24 and H32-H33. This will exclude the wishbone, conductor, pile, and horizontal elements

from the current view.

Go to “Weight” > “Anode Weight” and drag a window to select all the members in the current

view and enter the data as following:

Weight group ID: ANOD

Weight ID: ‘Anode

Anode weight: -2.5KN =

# Anodes: 2/Member semen sf

‘Anode space’ Equal Patina i

Include Buoyancy: On

Density: 2.70 tonne/m”3

Click on “Apply” and “Keep” the weight.

See picture on right for details.

Save the mode to Sacinp.dat_07.

Part of jacket weights shall look like following:

WGTMEMANODIOIL101X 6.003 2.500 1.001.001.00GLOBCONC 2.700ANODE,

Structural Modeling Page - 28

SHRAD Services Sdn, Bhd.

WGTMEMANODIOILIOIX 12.007 2.500

WGTMEMANODI03L102X. 6.003 2.500

WGTMEMANOD103L102X 12.007 2.500

WGTMEMANOD103L103X. 6.673 2.500

WGTMEMANOD103L103X 13.345 2.500

WGTMEMANODI04L104X. 6.694 2.500

WGTIT LPAD 2.000PADEYE SOIL 7.849

WGTIT LPAD 2.000PADEYE 502L 7.849

WGTJT LPAD 2.000PADEYE 503L 7.849

WGTIT LPAD 2.000PADEYE S04L 7.849

WGTMEMWKWY4102404L 1.500

WGTMEMWKWY402L4102 1.500

WGTMEMWKWY4101402L 1.500

Section 13 Deck Loads

Training 2012

1,001.001.00GLOBCONC 2.700ANODE

1.001,001,00GLOBCONC 2.700ANODE,

1.001,001.00GLOBCONC 2.700ANODE,

1,001.001.00GLOBCONC 2.700ANODE

1,001.001.00GLOBCONC 2.700ANODE

1,001.001.00GLOBCONC 2.700ANODE

1,0001,0001.000

1,0001.0001.000

1,0001.0001.000

1.0001.0001.000

1,5001,001.001.00GLOBUNIF 1.500WLKWAY,

1,5001,001.001.00GLOBUNIF 1.S00WLKWAY

1.5001.001.001.00GLOBUNIF 1.500WLKWAY,

To create inertia loads from various weights defined on deck structure three steps need ‘0 be

performed:

Step 1

Define the center of the acceleration: Go to

“Weight” > “Center of Roll”, and define

center ID CENI at (0.0, 0.0, 0.0) location.

Then select “Appl

Structural Modeling Page - 29

SHRAD Services Sdn. Bhd,

y 2012

Step 2

Define the accelerations: Use

“Environmental” > “Loading” >

“Weight”: Check off Acceleration and

define 1.0g in Z direction for load condition

AREA, EQPT, LIVE and MISC.

Picture on the right shows the sample of

load case AREA.

Step 3

Use the weight groups to create the loads:

“Environmental” > “Loading” >

“Weight”: Check off Include weight group.

Select weight group AREA, EQPT, LIVE

and MISC to be included in load case. Use

Load condition AREA, EQPT, LIVE and

MISC respectively.

Note: EQPT, LIVE, and MISC will already

have acceleration defined from above, but

included weight group needs to be added

also.

‘The picture shows the load case AREA

definition,

Save the model to Sacinp.dat_08

Weights defined on the jacket will be added to the environmental load conditions to account for

the possible buoyancy and possible wave loads

‘The added inertia load cases shall look like following:

LOADCNAREA

INCWGT AREA

ACCEI 1.00000 NCENI

Structural Modeling Page - 30

SHRAD Services Sdn. Bhd. Training 2012

LOADCNEQPT

INCWGT EQPT

ACCEL 1.00000 NCENI

LOADCNLIVE

INCWGT LIVE

ACCEL 1.00000 NCENI

LOADCNMISC

INCWGT MISC

ACCEL 1.00000 NCENI

Section 14 Environmental Loading

Step 1 Define drag and mass coefficients

Use “Environmental” > “Global Parameters” > “Drag/Mass Coefficient” to define the data

(Shown in the picture).

Cd=0.6 and Cm=1.2 for both clean and

fouled members. All the members have

same Cd and Cm,

Step 2 Define marine growths

Go to “Environment” > “Global

Parameters” > “Marine growth” to enter

the data shown in the picture on the right.

The added marine growth override lines shall look like following:

MGROV.

MGROV 0,000 60.000 2.500 1.400

MGROV 60,000 79.500. 5.000 1.400

Structural Modeling Page - 31

SHRAD Services Sdn. Bhd. Training 2012

Step 3 Hydrodynamic modeling

Go to “Environment” > “Global

Parameters” > “Member Group

Overrides”

Override the jacket leg members with group

ID LGI-LG3 That need to take into account

the load increase due to the appurtenant

structures like J-tubes and Risers.

Highlight groups LG1-Lg3 that the

overrides need to be added to. The picture occa eee

on the right indicates that the drag and mass ream |

coefficients have been factored by 1.5 to =

account for the load increases.

The hydrodynamic model data should look like following:

GRPOV

GRPOVAL —LGI 1,501,501.501.50

GRPOVAL — LG2 1,501,501,501.50

GRPOVAL —LG3 1,501,501.501.50

GRPOVAL —PLINN 0.001 0.001 0.001

GRPOVAL — PL2NN 0.001 0.001 0.001

GRPOVAL — PL3NN 0.001 0.001 0.001

GRPOVAL — PL4NN 0.001 0.001 0.001

GRPOV —_W.BNF 0.001 0.001 0.001 0.001 0.001

Step 4 Environmental loading

Operating Storm (three directions considered: 0.00, 45.00, 90.00): load case P000, P045, PO90

Jacket weight groups ANOD and WKWY should be included in all three load cases by using

“Environment” > “Loading” > “Weight” > “Include Weight Group” to account for weight,

buoyancy and wave/current loads.

Go to “Environment” > “Loading” > “Seastate” to define the wave, current, wind and

dead/buoyaney load parameters. The data can be found in the design specification, and the

pictures below show the details of load case PO00,

Structural Modeling Page - 32

SHRAD Services Sdn, Bhd.

ey

wag 2}

1 Pode ee)

Fgh tf

oe tn 2h

1 eect el 2 [a

Frese (hc)

elec

vied ata pe

eve GBS ASI)

Vindavesmg pel 2 eh) (oe

irate =f

——

|

Training 20:2

i i oe

or enn ei gh

stv ovie

Maen innit

Pein [Maman

Poe Pind Ramet oentind Foy

noncredit dvb

ovate coe

thot soon eee i=)

‘te et ve =)

Meresatmovenie hls} |

aw ey ede Grn)

‘ay Oe cn ea fe nb

Structural Modeling Page - 33

SHRAD Services Sdn. Bhd. Training 2012

xe | |] dome ff

cue | | ene cen os

useeevcinorts 2} [| Jerse tn

Face sedartense ph Bteteote

ne natn

‘The 3 operating storm load case lines shall look like following:

LOADCNPOOO

INCWGT ANODWKWY

WAVE

WAVEL.OOSTRE 6.10 12.00 0.00 D_——-20.00 18MS101

WIND

WIND D 25.720 0.00 APOS:

CURR

CURR — 0.000 0.514 0.000 -5,000BC LN

CURR 79.500 1.029

DEAD

DEAD -Z M BML

LOADCNPO4S

INCWGT ANODWKWY

WAVE

WAVELOOSTRE 6.10 12.00 45.00 D 20.00 18MS101

WIND

WIND D 25.720 45.00 APOS,

CURR

CURR — 0.000 0.514 45.000 -5.000BC LN

CURR 79.500 1.029 45,000

DEAD

DEAD ~Z MBML

LOADCNPO90

INCWGT ANODWKWY

Structural Modeling Page - 34

SHRAD Services Sdn, Bhd. Training 2012

WAVE

WAVEL.O0STRE 6.10 12.00 90.00 D 20.00 18MS101

WIND

WINDD 25.720 90.00 APOS

CURR

CURR 0.000 0.514 90.000 -5.000BC LN

CURR 79.500 1.029 90.000

DEAD

DEAD M BML

Extreme Storm (three directions considered: 0,00, 45.00, 90,00): load case $000, S045 end $090

Extreme storm load cases can be defined similar as the operating storm load eases, except 100-

year storm criteria are used to generate the environmental forces, Jacket weight groups ANOD

and WKWY should be included in all three load cases. The water depth should be overridden to

consider the high tide. The following pictures show the detailed input data from the

Specification.

eaten [587 —

vet [vive a | it ar ar ea | 2

weet eo

1 aie es

oe cn bg

FF eeacasin ey

inde ie

Ie ea poston ig Ig =) -——

Woe etn ee

te hove

Meee desencvete

Preagin— emmere ——3]

ee aa)

Structural Modeling Page - 35

SHRAD Services Sdn, Bhd.

—

eh

ose

1 vey fe =f a

pence B=

aoa]

anther cotan

vars PDH) 2]

ind hn

=)

ee

aes

Training 2012

we] ae | snd} Gar ent

fergie ki

Nenoncevey a3) PO

1] ve || et | art amr eat

Sonecrontnd are aba z

creamatay :—

eater

Yi drove arn

[a

=

-——

‘erry Oven aod wef a ey rene

‘The 3 extreme storm load case lines shalll look like following:

LOADCNSO00

INCWGT ANODWKWY

WAVE

WAVEL.OOSTRE 12.19 81.00 15.00

D 20,00 18MS10 1

Structural Modeling Page - 36

SHRAD Services Sdn. Bhd. Training 2012

WIND

WIND D 45.170 0.00 APOs

CURR

CURR — 0.000 0.514 0.000 -5.000BC LN

CURR 81.000 1.801

DEAD

DEAD -Z 81.000 MBML

LOADCNS045

INCWGT ANODWKWY

WAVE

WAVELOOSTRE 12.19 81.00 15.00 45.00 D 20.00 18MSI01

WIND

WINDD 45.170 45.00 APOS

DEAD

DEAD -Z 81.000 M BML,

CURR

CURR 0,000 0.514 45.000 -5.000BC LN

CURR — 81.000 1.801 45.000

LOADCNS090

INCWGT ANODWKWY

WAVE

WAVEL.OOSTRE 12.19 81.0015.00 90.00 D 20,00 18MS101

WIND

WINDD 45.170 90.00 APO8

CURR

CURR — 0,000 0.514 90.000 -5.000BC LN

CURR — 81.000 1.801 90.000

DEAD

DEAD -Z 81.000 MBML_

Section 15 Load combination and code check options

Step 1 Load combination

Six load combinations OPR1, OPR2, OPR3, STM1, STM2 and STM3 will be added into the

model. Three of them are corresponding to operating storms and the other three are

corresponding to extreme storms. Load factor of 1.1 will be used for environmental loads. The

live load will be included with a factor of 0.75 in extreme storm load combinations.

Go to “Load” > “Combine load conditions” to define the load combinations. The following

two pictures show the combinations of operating and extreme storm conditions,

Structural Modeling Page - 37

SHRAD Services Sdn. Bhd. ‘Training 2012

The load combination lines shall look like following:

LCOMB.

LCOMB OPRI AREA!.0000EQPT1.0000LIVE1,0000MISC1.0000P0001.1000

LCOMB ORP2 AREA1,0000EQPT1.0000LIVE1,0000MISC1.0000P0451.1000

LCOMB ORP3 AREA1.0000EQPT1.0000LIVE1.0000MISC 1.0000P0901.1000

LCOMB STMI AREA1.0000EQPTI.0000MISCI.000011VF0.7500S0001,1000

LCOMB STM? AREA1.0000EQPTI.0000MISCI.0000L1VE0.7500S045 1.1000

LCOMB STM3 AREA1.0000EQPT1.0000MISC1.0000LIVE0.7500S0901.1000

Step 2 Analysis load case selection

Go to “Options"> “Load condition

selection” to select all the load

combinations to analyze and report. The

picture on the right shows the input.

Lesteotionatein oe SE]

ott

Step 3 Allowable stress modification factor (AMOD)

Allowables can be increased by 1/3 based on API code, and this should be entered using the

AMOD line. Go to “Options” > “Allowable stress/Mat Factor” and enter the data as shown in

the picture below.

Structural Modeling Page - 38

SHRAD Services Sdn. Bhd.

Training 2012

Add unity check partition line (UCPART). Go to “Options” > “Unity Check Ranges” and

enter the data as shown in the picture below.

| SEES

owe | a] oe |

‘The LCSEL, UCPART and AMOD lines shall look like following’

LCSEL ST — OPRI ORP2 ORP3 STM1 STM2 STM3

UCPART —_0.5000.5001.0001.000300.0

AMOD,

AMOD STMI 1,330STM2 1.330STM3 1.330

Save the model to Sacinp.dat_09

Structural Modeling Page - 39

SHRAD Services Sdn Bhd Training 2012

Linear Static Analysis

Section 1 Create the static analysis d

‘ctory and separate the model file.

Step 1 Create the directory for stat

nalysis

Under “Training Project”, create “Static” subdirectory; copy sacinp.dat_09 to the directory, and

make this directory current.

Step 2 Separate the model

Open sacinp.dat_09 with Precede and then go to File/Save As and select “Model data only”, and

click-on “OK™ to save the model file to sacinp.dat. See picture below

|

‘Output file contents fi *

Output nts [fetianforce =)

1 Sertdtain alphanumeric order rather than order read or ated

Not: Sortng may cause comments tobe rearranged h model fe.

TF Outputint coorinatesin meters ony ater than meters aed ens

Note: Mis could couse some oes of acaracy njnt coordinates.

ee

Step 3 Separate the Environmental load

Go to File/Save As and select “Seastate data only”, click on “OK” to save the separated seastate

input file to seainp dat. See picture below.

Output fle contents E x

Output units [mewicnni Force I

TT Sort data in alphanumeric order rather than order read or created

Note: Sorting may cause comments to be rearranged in model fle.

T Output joint coordinates in meters only rather than meters and ons.

Note: This could cause some los of acuracy in int coordinates,

Ox

Linear Static Aralysis - 1

SHRAD Services Sdn Bhd Training 2012

Section2 Create a Joint Can input file

Step I Using Datagen to create file

Click on datagen and select to create a new file. Then

click on Post Processing tab and select Joint Can Input file

and click OK. See picture to right.

Click on Insert Input Line and select Joint Can Options

card and select OK. On the line assistant specify “API”

Select “R" for Allowable Limit. Minimum gap allowed

should be 5 cm. Leave the rest as default. See pictures

below.

yaa

Under Reports tab select “Max” as UC Order and Joint Can Output Report Options. Type END as

the end line command.

Linear Static Analysis - 2

SHRAD Services Sdn Bhd

Save as jeninp inp

Joint Can File

appear as the following:

JCNOPT APT 1 c mp vata

zB

Section3 Create the static analysis run file

Step I Select the analysis type and sub-type

Click on “Analysis Generator” from the Executive window and select “Static” for Type and “Basic

Static Analysi

on oe oe

Boo — = 2 =

Linear Static Analysis - 3

SHRAD Services Sdn Bhd. Training 20:2

Step 2 Select the Seastate analysis option

Check and click on “Edit Environmental Loading Options” to active the Seastate program and get

the Seastate Analysis Options shown on right.

Select the option to match the definition in the picture below.

Click on “O.K” to save the option.

tea Ope

Step 3 Select member code check option

Click on “Edit Element Check Options” to get the code check option window and set the options

Detailed as following:

Use Post input file: “No”

Code criteria: API21" edition

Stress/code check location: 2/2

Report option: Override the mode!

Following report should be tumed on:

Joint deflection

Joint reaction

Member end forces

UC range

Click on “OK” to save the options

Linear Static Analysis - 4

SHRAD Services Sdn Bhd Training 2012

Step 4 Select Tubular Joint Check Options

Check and click on “Edit Tubular Joint Check Options” to get the tubular joint check window shown,

below.

For joint can input file select jeninp inp file. See Picture.

Section 4 Run the analysis and review the results

Step 1 Define/change the result file extension name

Change the file ID to “DAT” and click on “ID” icon to apply.

Step 2. Select model input file, the model file is saved in step 2 of Section 1

Step 3 Select or check the Seastate input file

Linear Static Analysis - 5

SHRAD Services Sdn Bhd

Training 2012

Step 4 Select or check the Joint Can input file

Step $ Run the analysis.

See below picture for the location of above options.

‘Type in or select

the file ID here

Check here for the file

extension change

Step 6 Check results

Click here to run

the analysis

Click here to select

‘model input file

Linear Static Analysis - 6

SHRAD Services Sdn Bhi. Training 2012

Static Analysis with Non-Linear Foundation

Section] Create a PSI input data file

Step 1 Create a new folder and name it ‘Static PSI”, and then make it the current folder.

Copy SACINP.DAT and SEAN

DAT files from *Static” directory to current folder

Step 2 Create PSI input data file

and

Click-on “Data file” icon to launch Datagen program, and select “Create new data fil

click-on OK to get the second window pop-up, as shown below; select “Pile Soil Intera:

Input File” as the file type and select the unit is Metric KN

Step 3 Define analysis options

Go to “Insert Input Line” tool and select to input PSI Option as below.

sf@e

oe Pee eee |

Ensure units are in MN and select Final Pile Analysis option to “EX”. Keep other options to

default values.

Static analysis with non-linear foundation- 4

SHRAD Services Sdn Bhd. ‘Training 20:2

Step 4 Select the results to plot

Select the PLTRQ card to get Plot Option window and select the options shown below.

Step 5 Define pile group

Create the PLGRUP header line by adding the PLGRUP card. Under the PLGRUP header card,

insert the first PLGRUP card to define the first of two pile groups and one conductor group using

PLGRUP card, the pile group ID ="PL1” and “PL2”; conductor group ID ="CND”, Pile and

conductor details are as follows:

Pile OD.: 106.68 cm. Conductor OD.: 106.68 cm

1° Segment Wall thickness: 2.54 em Wall thickness: 2.54 cm

2"! Segment Wall thickness: 1.50 em Yield Strength: 24.821 kn/em*2

Yield Strength: 24.821 kN/em’2 Elastic Modulus: 20000 kN/em’2

Elastic Modulus: 20000 kN/em*2 Shear Modulus: 8000 kN/em”2

Shear Modulus: 8000 kN/em*2 Available End Bearing Area: 0.454 cm*2

1" Segment Length: 10m

2" Segment Length: 30m

Available End Bearing Area: 0.656 m2

Continue adding or copy the PLGRUP card to add the segments or groups until you finish

defining the pile and conductor group definition, See below for input guide & click “NEXT” to

g0 to the next step:

Static analysis with non-linear foundation- 2

SHRAD Services Sdn Bhd. ‘Training 2012

Step 6 Define the piles

Insert PILE header card followed by PILE cards to define the pile head joint, batter joirt, pile

‘group ID and soil ID as shown in below picture for the four piles, and repeat to define

conductors,

Click-on “Next” fo finish the pile definition and get to next step,

Static analysis with non-linear foundation- 3

SHRAD Services Sdn Bhd ‘Training 2012

Step 7 Define T-Z data type

Insert the SOIL card to begin definition of the soil characteristics. This should be immediately

followed by the SOIL card for axial adhesion properties.

To define the axial spring representation for the piles skin adhesion, several type of axicl data

options are available in SACS system as below (please refer manual for more info):

Linear Springs

User defined adhesion.

API generated adhesion.

User defined T-Z curves,

API generated T-Z curves

yeeee

‘The data for the training is T-Z data, thus please select and insert “SOIL TZAXIAL HEAD (T-Z.

Soil Axial)”

Step 8 Define T-Z axial header data

‘The header data defines the total number of soil strata, Z-factor, Soil ID and the maximam data

point of any T-Z curves. The data should be from the Design Specification for this training, and

is shown in following picture.

Click-on next to get to next line

Static analysis with non-linear foundation- 4

SHRAD Services Sdn Bhd. Training 2012

Step 9 Define T-Z soil stratum data

‘This step defines the soil stratum information followed by soil data of cach stratum (Step 10), the

data needs to be defined is number of point of the curve, stratum location and T factors;

following picture shows the stratum definition of the top soil.

Step 10 Define the soil data of the stratum

‘The data is from the project specification document, the picture on right shows the soil at 0.0m

location.

Repeat Step 9 and 10 to enter all § soil T-Z curves.

Static analysis with non-linear foundation- 5

SHRAD Services Sdn Bhd ‘Training 2012

Step 11 Define end bearing data

On completion of step 10 and input of axial adhesion characteristics, the next step is to input soil

bearing data. The bearing input shall be initiated by the input of “SOIL BEARING HEAD (T-Z

AXIAL Bearing) to enter the Q-Z axial header data as shown below.

ae

See

oareocitn

Beas piesa

ees

Eergecet

berate

ESBS eer itu

ieeraceamer

a

FF sethatesaty

Define the Q-T axial header data shown in below picture, click-on “Next” to accept the data and

get to soil stratum data.

Loni

Define the soil stratum data as shown in following two pictures and repeat it for all the stratums.

Static analysis with non-linear foundation- 6

SHRAD Services Sdn Bhd. Training 2012

Step 12 Torsional data

The torsional stiffness of the soil can be defined as linear spring, following picture gives the

detail of the input.

Static analysis with non-linear foundation- 7

SHRAD Services Sdn Bhd, Training 2012

Step 13 P-Y data input

The P-Y data input is similar to Axial T-Z data, follow the direction of Step 7 to 10 an¢ get the

data from the soil report to finish the input.

Following two pictures show the soil type selection and P-Y header definition.

a =

a

Following picture show the stratum and soil data definition at 0.0m location, repeat the input to

define all the P-Y soils at rest locations. Include the END card upon completion of all stratum,

input.

Static analysis with non-linear foundation- 8

SHRAD Services Sdn Bhd ‘Training 2012

SS

Save the file and name it PSIINP.DAT.

Section2 Static analysis with PSI

Your current directory should have three input files: SEAINP.DAT containing the loading

condition, SACINP.DAT containing the model information includes the weight definition and

PSIINP.DAT containing the pile model information.

Step I Select analysis type and options

File ID: dat

Analysis type: Static

Analysis subtype: Static analysis with Pile/Soil Interaction

Analysis options: selections are shown in the picture below

Static analysis with non-linear foundation- 9

SHRAD Services Sdn Bhd. Training 2012

ET a

Step 2. Edit analysis options

Click-on to get the window shown below and make

selections as shown in the window, click-on “OK” when finish; Click-on to define the code option shown in below window on right:

Code option: API RP 2A 21th edition/AISC 9" edition

Segment to be checked: 2 for both segmented and non-segmented member

Override the report to include Joint deflection, Joint reaction, Member end forces and te UC

range report.

Static analysis with non-linear foundation- 10

SHRAD Services Sdn Bhd.

©) secs.

oe

me

Step 3 Define input files and run the analysis

Training 2012

Select the input files as shown in below window and check the output file names, click-on “Run

Analysis” Tab to run the analysis.

SHRAD Services Sdn Bhd, Training 2012

Static analysis with nor-linear foundation- 12

€L -uonepunoy se9ul-uoU ym sisfjeue ONES,

zago oubrE = gua 0ST Ores po"ers- Trre- oz"OI- E6"9Ez- 0D" Oe 1 com Ttoa-aste

ewao 06670 666°0 ores ST o°z Twao zoo" zon rr18-0118

Tao ses" voor Szet sree oor ewan) zon Twos-T208

e¥ao ose’ eet obo rat os twa. Tom Troe-soTe

rer) t eer 9nm9 68 O'S eyso oSz"T 10K SoTe-baTe

euao e64"T Togs erat 6e°98G- 16"P- I6*T1- €S°99z~ OE"L- OST GET TOM TzOR-EOTE

zaa0) t sevt 9799 grat parsot €b°0 — g6°z> OZ"TST €6°9= 0S ENO BRITE —10m COTe-zoTe

go 9eT'T Zao orm grat EL"6EZ B6'E- SPE CO"ZLT- 00"0~— 0D EMO LOT —TOM aaes-ThOB

Tago 166" Wao BET «999 TAT oz'zsz ze'S- OS"1T9"9PT- 95°S- 070 -—-EBAO_GOT"T —TOM vaLa-TEOR

aez zuao. op oer eL"09e 65°S~ €6°28t= LO“L= 070 HAO. HET — TOM -zaTeTTOR

‘noo no No gaan ZhW/N NS “ONO AMINO GL

yor n gu/zT A/a za xa 2 SS@MIS WOW Noo GaNTaWOO anows — ¥ahaH

ESGHOTH-GHINL ISaHOTH-aNODES SOMO UVES — SSTULS ON: WIXY STO GVOT MNNTxYH

S837 GNY 00" T NVILL WALWEYO SOB ALIN = ITT anous

RUVHANS SONVY YOSHI ALINN WIEHEH —AI-SOWS

zt 3ova Esa S1#Z5700 aNIL ZT0Z-LO0-T0 ava vorqrutzeq yex020

us Nas saDrAWaS owsHS (esa) 1 sersaszosias Tea sows

mo[9q 298 ‘astqriep anarsog 40 apy Bust] Sod roy payxsayo aq ED sINSAL 9949 209 19.

Ww

syinsoa siséyeur ay y90y—_-¢ woND9g

clog au

‘yl -uonepunoy se9uy-uoU ym sisfjeuR ONES.

Loz't 96-ziz~ zz. ovo userroro 1s702 $570 ag“ 18S

OBS 0 9L"eB~ Be ovo Eeacoo"o Is7eorr0S*e BL

Z19°0 15796- PS" ovo oosto0-0 | ze"z = Le"0 "tes

995"0 T9"98- 8g" oo peozoo"o os" = zev0 ZS cia avar

1 1c092~ 98" ovo 205600°0 42°91 09°0 orm

0 9806T- 05" 0-0 £16600°0 0S"eI_2z"0 18"053

0 spraet 19 oro SL0t0"0 98°02 I"O~ egr9te

D gereri~ tar avo a68z00"0 99"t —«GE"0 az"93z

sO ZL"Lk~ Ob oro 662Z00"0 T6°"z —GZ°0 Livre

“0 ¥9°9F- 08 oro Uzzzoo"o Lz THO serser vie acor

68 ovo 9968000 Ltto- 9 orzes

zs oro ° ozo te"PT9

¥6 oro 0 ¥s"0 62°69

29° Brot 0 poo 9 oe" tez

f° oro “0 error 1z'98t

of oro oz6t00"0 zo 9" 6r'69t eta azo

99'st torent Serer 0°0 S9s600"0 L6"9T ot"o- —z*zt0E ¥0"999

serot OIveeL gs"0s "0 46260070 LO"9T Lz"0- "S082 eb'099

Sorat SErLST p9"HZ 0°0 oseoto"o otroz Etvo- Evite 0s"soe,

the zz} se"ez- 0°0 O6ee00"0 6t'y © ETO "B06 96° 10E euso

sz"t 66"ee- Le"s= FrOT guezoo"0 98°z = 9070 "645, 90°902 zago

es" Zev G9"Tz- 00 eetz00"0 sz) tO L's2g to"ser Tago 11a atot

coceceeeneee zany ove wo no new 4 wo

was 28a NOLLWON “WHSLYT TVIXY INGNOd = TVWauWT = IXY aya ac

+ MOMHO ALINA “XY IV SUESTUIS seeennseres + SUNSHEDWIASIO QVHSTIA + sereees SEDO QVANTIA +eee04 ayo1 amo stra

has KUVWHNS HOTHO KLING WOHIXVHW ZTId eae

voratutsed i=x9e°

99) gv Isa cI!z9!00 WIL zT0Z-490-T0 aLva uovarurzaq 199900

ols Nas saoznwas ovwHs (sa) 1 sovsesuostas Tea sovs

“ayy Sunsy isd uz parsy] aue sypnsay yoyo oILq

Zhog Baur, “PUR UPS SPONDS CVUHS

1 -uonepunoy Jeeul-uoU YM sisfjeuE ONES,

tte 6z

ble uz

bre 92

6

6z

oz

62

uz:

sz

ze- 62

be- 62

ase Z

ue 6z

eI uz

bie 82

av- 62

bb- 62

zs- az

ute 62"

fI- 92

vie 32

aze~ 10"

nee te

fe

ee

a

ge

te

ie

ot

a

et

Hi

=

ie

a

"6-0"

Szt- 0

veetoo

teor00

esoro0

19900"

Lseroo"

918500"

teetoo

ee0r00"

psoro0"

9p9%00"

e0t00"

psor00"

oxav00"

zeevo0"

£08500"

suetoo

s90t00"

zsor00

06800

vese00"

0

Foro

a

0

365

96s.

Lorocr- caso

SL'6zr- Zao

LS'6z= —Tido NOD De0T

6p nas

6s aus

ee twas

20-081 ego

ustezr- Zao

Fer — TtaO NOD LOT

ehrotr- Has

estotr- — cHus

es ‘Olr- THUS

Su6zb- euao

Us6zb- ao

Ls'6zb- Tado Nod 9901

oporr- ews

e901 — zHIS

eccotp: THIS

Se'ezr- GO

obezr- — zuao

EE'6ZP- TIO NOD DgOT

uer9poc- HAS

Le-6se0I- cas

Zloz Bue,

PUE UPS SOMIMDG CVAHS.

91, -uonepunoy seeul-uoU YIM sisfjeue OnEIS

oan

AuINA

“eHt09

99°

zawayn

aad

XYW IY SESSRULS veeeesseeey

suo

awix ctoz-490-10 aava

Bree Ists- 9°z 699¥00"0

16"ae | 1S"s-9°Z 958400°0

66°F ObS- BZ pzeso0'0

8 owe

Kad TWIXY Hidza—NOILWION

a

oe

on

rn

1

+ SaNsHaoWTasTa avat

z poro sere

Zoro ovate

z poo toe

wo 01

1 avEXY — aNaHOH

KLIN WoWIX¥H

voratutzed 12998"

ona Nas sso1AWas avis

sereres SHQMOE QVEHETIG +e eenes

oprote- ena

ostotr- zHIs

es'ote- THIS

wi no

TWisLvT = TWIXY—as¥o te

avot ana at1a

aita sas

oa aexoer.

(e'Ga) 1 seraaszganas ten so¥s

Tioc sue,

PUR UPS SAOININS GVUHS

You might also like

- Frequency Domain Approach for Transportation AnalysisNo ratings yetFrequency Domain Approach for Transportation Analysis25 pages

- SACS Analysis: Structures and Load Modeling100% (1)SACS Analysis: Structures and Load Modeling2 pages

- Tutorial #1 KL4120 Offshore Platform Ocean Engineering ITB 201567% (3)Tutorial #1 KL4120 Offshore Platform Ocean Engineering ITB 201513 pages

- SACS Offshore Structural Design TrainingNo ratings yetSACS Offshore Structural Design Training68 pages

- L2 - Introduction Course Part A and Assignment - YPX 2024No ratings yetL2 - Introduction Course Part A and Assignment - YPX 202428 pages

- Offshore Jacket Inplace Analysis For Beginners With Sacs 1614129844100% (3)Offshore Jacket Inplace Analysis For Beginners With Sacs 161412984463 pages

- SACS Jacket Type Structure - Modeling The Loads Using The Load Feature ReferenceNo ratings yetSACS Jacket Type Structure - Modeling The Loads Using The Load Feature Reference30 pages

- Machine Elements and Design II Course OutlineNo ratings yetMachine Elements and Design II Course Outline3 pages

- Functional Description: 3D/2D Modelling Suite For Integral Water SolutionsNo ratings yetFunctional Description: 3D/2D Modelling Suite For Integral Water Solutions46 pages

- Naval Architecture & Ship Construction IINo ratings yetNaval Architecture & Ship Construction II4 pages

- Seakeeping Analysis Using CFD TechniquesNo ratings yetSeakeeping Analysis Using CFD Techniques26 pages

- Class 1 Introduction To Engineering Section 1No ratings yetClass 1 Introduction To Engineering Section 183 pages