Professional Documents

Culture Documents

Pub139 26

Pub139 26

Uploaded by

satnam0 ratings0% found this document useful (0 votes)

3 views1 pageCopper-nickel alloys have a high natural resistance to marine biofouling. When freely exposed or electrically insulated from other materials, copper-nickel can reduce fouling buildup on structures like pipes and condensers. Studies showed that copper-nickel sheathing reduced biofouling on pilings by 44-56% compared to bare steel after 5-10 years, even when electrically connected to steel. With insulation, fouling was reduced by over 98% compared to bare steel. Long-term exposure can lead to thick microfouling layers, but these periodically slough off or can be removed with light scraping.

Original Description:

pub139_26

Original Title

pub139_26

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopper-nickel alloys have a high natural resistance to marine biofouling. When freely exposed or electrically insulated from other materials, copper-nickel can reduce fouling buildup on structures like pipes and condensers. Studies showed that copper-nickel sheathing reduced biofouling on pilings by 44-56% compared to bare steel after 5-10 years, even when electrically connected to steel. With insulation, fouling was reduced by over 98% compared to bare steel. Long-term exposure can lead to thick microfouling layers, but these periodically slough off or can be removed with light scraping.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pagePub139 26

Pub139 26

Uploaded by

satnamCopper-nickel alloys have a high natural resistance to marine biofouling. When freely exposed or electrically insulated from other materials, copper-nickel can reduce fouling buildup on structures like pipes and condensers. Studies showed that copper-nickel sheathing reduced biofouling on pilings by 44-56% compared to bare steel after 5-10 years, even when electrically connected to steel. With insulation, fouling was reduced by over 98% compared to bare steel. Long-term exposure can lead to thick microfouling layers, but these periodically slough off or can be removed with light scraping.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

12.

0 Biofouling Resistance

Copper-nickel’s natural properties have a

high resistance to marine macrofouling.

This quality can be exploited to reduce

cleaning of pipework or condensers,

decrease wave drag and reduce fouling

removal costs of platform structures.

Optimum biofouling resistance requires

the alloy to be freely exposed or electrically

insulated from less noble alloys.

In offshore sheathing, neoprene or

concrete have been used to insulate the

sheathing from the cathodically protected

(CP) structures. However, it is now known

that some fouling reduction is obtained

even when CP is applied. Table 7 shows

the results of 10-year studies at LaQue

Corrosion Services in North Carolina. The

isolated pilings show negligible build up.

When directly connected to the steel,

with or without cathodic protection, the

fouling rate was only 44% of that on the

plain steel piling. Similar results have

been found in service. A light scraping

action can readily remove any biofouling

attachment which does form.

Exposure panels (left to right in above picture): steel, 90-10 copper-nickel sheathed steel,

copper-nickel - all three protected with aluminium anodes - and freely exposed copper-nickel.

Long-term exposure of copper-nickel

After 12 months exposure at Langstone Harbour, UK, there was no macrofouling on the freely

to quiet or stagnant seawater can lead

exposed panel.

to a thickening of microfouling (slimes)

sufficient to allow some colonisation of

macrofoulants. As these will not be as

rigorously attached as on many other Table 7 – Biofouling Mass on Copper-nickel Sheathed Test Pilings After 5 and 10 Years’ Exposure

substrates, experience has shown that they Piling Biofouling Mass Percentage of

will periodically slough away or can be kg/m2 Area Covered

removed by a light scraping.

Bare steel control (not sheathed)

5 year removal 18 100

10 year removal 12 100

Concrete insulated

5 year removal 0.36 1.9

10 year removal 0.14 1.2

Directly welded

5 year removal 7.95 44.3

10 year removal 4.43 36.8

Rubber insulated

5 year removal 0.26 1.4

10 year removal 0.62 5.3

24 | Copper-Nickel Welding and Fabrication

75

You might also like

- Reinforcement of Elastomers 2016Document9 pagesReinforcement of Elastomers 2016ibrahim sugarNo ratings yet

- Tabla de Caracteristicas de Los PlasticosDocument12 pagesTabla de Caracteristicas de Los PlasticosBetty JadueNo ratings yet

- Hexoloy SA Silicon Carbide: Technical DataDocument4 pagesHexoloy SA Silicon Carbide: Technical DatagldiasNo ratings yet

- Weathering of Anodized AluminiumDocument7 pagesWeathering of Anodized AluminiumShahid PerwezNo ratings yet

- Kirloskar Presentation - KCPL Products For Pumps, Pipes, StructuresDocument61 pagesKirloskar Presentation - KCPL Products For Pumps, Pipes, Structuresvinay1999No ratings yet

- Guidelines For Selection of Bridge Deck Overlays, Sealers and TreatmentsDocument61 pagesGuidelines For Selection of Bridge Deck Overlays, Sealers and Treatmentssong112358No ratings yet

- Cikocrete Micro: Technical DataDocument3 pagesCikocrete Micro: Technical DataMuhammathu Anver AbdullahNo ratings yet

- Erection Method StatementDocument1 pageErection Method StatementsathiyanNo ratings yet

- 11138.0997 Cathodic Protection of Surface Storage Tank BottomsDocument7 pages11138.0997 Cathodic Protection of Surface Storage Tank Bottomsoussama somraniNo ratings yet

- Fibretron BrochureDocument13 pagesFibretron Brochureravi kumarNo ratings yet

- Zinc Silicate or Zinc Epoxy As The Preferred High Performance Pri PDFDocument10 pagesZinc Silicate or Zinc Epoxy As The Preferred High Performance Pri PDFAi Ha100% (1)

- Giúdice, 2004, Combinational Use of Extenders With Lamellar ZincDocument14 pagesGiúdice, 2004, Combinational Use of Extenders With Lamellar Zinccyclo DreamNo ratings yet

- Co Axial CablesDocument4 pagesCo Axial CablesKCTV NEWS PUNGANURNo ratings yet

- Los Angeles Abrasion Test PDFDocument3 pagesLos Angeles Abrasion Test PDFBarijit 650% (1)

- Zahraaalturaihee, Production Editor, 1Document8 pagesZahraaalturaihee, Production Editor, 1Данило ГадайчукNo ratings yet

- Life Cycle Cost Per Kilometre: Option - 1Document1 pageLife Cycle Cost Per Kilometre: Option - 1rjg_vijayNo ratings yet

- Chloride Permeability and Impact Resista PDFDocument8 pagesChloride Permeability and Impact Resista PDFJulián MartínezNo ratings yet

- Clock Spring: Application Note Cathodic Protection and Electrical Properties of Clock Spring®Document3 pagesClock Spring: Application Note Cathodic Protection and Electrical Properties of Clock Spring®tran hungNo ratings yet

- SoR 2011 12Document21 pagesSoR 2011 12MuraliKrishna NaiduNo ratings yet

- The Big TEGO. Products Services Data Sheets-151-224Document74 pagesThe Big TEGO. Products Services Data Sheets-151-224DWI RAHMASARI FATMAWATINo ratings yet

- Kabelindo NYM PDFDocument3 pagesKabelindo NYM PDFDenzo RyugaNo ratings yet

- S.N. Bhobe Associates Pvt. Ltd. Banking Complex No - II, Unit No.10, Plot No.9&10, Sec-19A, Vashi, Navi Mumbai-400705. 14Document1 pageS.N. Bhobe Associates Pvt. Ltd. Banking Complex No - II, Unit No.10, Plot No.9&10, Sec-19A, Vashi, Navi Mumbai-400705. 14afzal taiNo ratings yet

- Surface Condition of Steel ReinforcementDocument2 pagesSurface Condition of Steel ReinforcementLuis Antonio GuerraNo ratings yet

- Surface Condition of Steel ReinforcementDocument2 pagesSurface Condition of Steel ReinforcementLuis Antonio GuerraNo ratings yet

- (Alontm) Optical Ceramic: Recent Advances in Aluminum OxynitrideDocument8 pages(Alontm) Optical Ceramic: Recent Advances in Aluminum OxynitrideErick CuyaNo ratings yet

- Fly Ash Based Geopolymer ConcreteDocument8 pagesFly Ash Based Geopolymer ConcreteSharad KumarNo ratings yet

- cp:19990791Document5 pagescp:19990791AynamawNo ratings yet

- Experimental Investigation of Copper Slag Replacement of Fine AggregateDocument27 pagesExperimental Investigation of Copper Slag Replacement of Fine AggregateUDAYA M.E.T COLLEGE75% (4)

- C-Purlins Wall Wall Angle Roofing D. Furring Hardi Lite Flashin GDocument1 pageC-Purlins Wall Wall Angle Roofing D. Furring Hardi Lite Flashin GRamilArtatesNo ratings yet

- Substrates Quartz & AluminaDocument2 pagesSubstrates Quartz & AluminaBin LadenNo ratings yet

- Surlon KE Datasheet Hard Ceramic Hard Anodizing With Lubrication 29AUG17Document8 pagesSurlon KE Datasheet Hard Ceramic Hard Anodizing With Lubrication 29AUG17Giacomo ZammattioNo ratings yet

- Monolithic Membrane 6125: PremiumDocument8 pagesMonolithic Membrane 6125: PremiumSam YoonNo ratings yet

- Relation Friction Visco ElasticDocument18 pagesRelation Friction Visco ElasticsiritapeNo ratings yet

- Absolute Roughness (MM) Coefficient of Maning Hazen Williams (C)Document6 pagesAbsolute Roughness (MM) Coefficient of Maning Hazen Williams (C)Cesar PachacamaNo ratings yet

- Table of Standards 1 Voc Limits Grams of VOC Per Liter of Coating, Less Water and Less Exempt CompoundsDocument3 pagesTable of Standards 1 Voc Limits Grams of VOC Per Liter of Coating, Less Water and Less Exempt CompoundsphassornNo ratings yet

- Materials and Corrosion ProtectionDocument11 pagesMaterials and Corrosion ProtectionRajasekaran MuruganNo ratings yet

- Climate Resistant Safer Hill Roads: "My Country Was Never So Rich That It Could Afford Poor Roads"Document33 pagesClimate Resistant Safer Hill Roads: "My Country Was Never So Rich That It Could Afford Poor Roads"amanNo ratings yet

- Bill of Quantities: No. Job No. DRG No. Sheet No. 1 of 1 Rev. Designed Checked DateDocument2 pagesBill of Quantities: No. Job No. DRG No. Sheet No. 1 of 1 Rev. Designed Checked DateSitche ZisoNo ratings yet

- Cement by Fly AshDocument7 pagesCement by Fly AshganapathyNo ratings yet

- Emaco S88 Ci: Sprayable, Fiber-Reinforced Structural Repair Mortar With Integral Corrosion InhibitorDocument4 pagesEmaco S88 Ci: Sprayable, Fiber-Reinforced Structural Repair Mortar With Integral Corrosion Inhibitormohamed ayadNo ratings yet

- Cellular Light Weight Concrete Manufacturing Process & Properties Full DetailsDocument4 pagesCellular Light Weight Concrete Manufacturing Process & Properties Full Detailskinley dorjee100% (1)

- DM SSSDocument5 pagesDM SSSiitmpdNo ratings yet

- City DesignDocument15 pagesCity DesignjoshpovashNo ratings yet

- Tacsil f20 Flex PCB TapeDocument4 pagesTacsil f20 Flex PCB Tapeccr-scribdNo ratings yet

- A Detail Study On Autoclave Aerated Concrete: International Research Journal of Engineering and Technology (IRJET)Document3 pagesA Detail Study On Autoclave Aerated Concrete: International Research Journal of Engineering and Technology (IRJET)Velmurugan Siva KamarajNo ratings yet

- Wear Resistant Coatings Carbon Fibre Composites: T Kääriäinen, M Rahamathunnisa, M Tanttari and D C CameronDocument14 pagesWear Resistant Coatings Carbon Fibre Composites: T Kääriäinen, M Rahamathunnisa, M Tanttari and D C Camerontamilselvan416No ratings yet

- Hard Anodising Info TR-17 Revision F 0Document11 pagesHard Anodising Info TR-17 Revision F 0LucasNo ratings yet

- 1994 - Corrosion of Thin Hard PVD CoatingsDocument4 pages1994 - Corrosion of Thin Hard PVD Coatingspr194537No ratings yet

- ClothDocument2 pagesClothRajulapati VinodkumarNo ratings yet

- Colmonoy: Colmonoy 88 Extends Wear of Parts, Components, and Equipment in A Variety of IndustriesDocument3 pagesColmonoy: Colmonoy 88 Extends Wear of Parts, Components, and Equipment in A Variety of IndustriesgersomNo ratings yet

- Ppt-Sugarcane Bagasse AshDocument27 pagesPpt-Sugarcane Bagasse AshHegdeVenugopalNo ratings yet

- Wrinkle of FoilDocument48 pagesWrinkle of FoilLuận NgôNo ratings yet

- OK Band/Flux For Stainless SteelDocument2 pagesOK Band/Flux For Stainless SteelSadashiva sahooNo ratings yet

- Vertical Coal Mill Classifier Air Seal ConditionsDocument20 pagesVertical Coal Mill Classifier Air Seal ConditionsMohammed El rajyNo ratings yet

- Kimmco Clean Liner (KCL)Document8 pagesKimmco Clean Liner (KCL)FARIDNo ratings yet

- Construction Monitoring Modular Accomplishment Based On NTP NTP No: No of Units: 3Document7 pagesConstruction Monitoring Modular Accomplishment Based On NTP NTP No: No of Units: 3Rhobbie NolloraNo ratings yet

- Rec Erc 84 320Document1 pageRec Erc 84 320Alireza KhodabandehNo ratings yet

- Wear of Metals: International Series in Materials Science and TechnologyFrom EverandWear of Metals: International Series in Materials Science and TechnologyRating: 4 out of 5 stars4/5 (2)

- Mechanics of Optimal Structural Design: Minimum Weight StructuresFrom EverandMechanics of Optimal Structural Design: Minimum Weight StructuresNo ratings yet

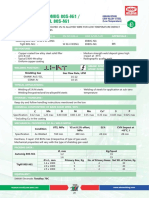

- Tigfil Cuni: Classification: ApprovalsDocument1 pageTigfil Cuni: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 1100: Classification: Aws A/Sfa 5.10Document1 pageAUTOMIG 1100: Classification: Aws A/Sfa 5.10satnamNo ratings yet

- CWC-BookletF1 59Document1 pageCWC-BookletF1 59satnamNo ratings yet

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Document1 pageAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNo ratings yet

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocument1 pageAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamNo ratings yet

- CWC-BookletF1 17Document1 pageCWC-BookletF1 17satnamNo ratings yet

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDocument1 pageAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamNo ratings yet

- Automig Cusn-A: Classification: Aws A/Sfa 5.7Document1 pageAutomig Cusn-A: Classification: Aws A/Sfa 5.7satnamNo ratings yet

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocument1 pageAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNo ratings yet

- Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060Document1 pageAutomig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060satnamNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocument1 pageAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNo ratings yet

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Document1 pageAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNo ratings yet

- CWC-BookletF1 12Document1 pageCWC-BookletF1 12satnamNo ratings yet

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 pageAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 pageTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNo ratings yet

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- CWC-BookletF1 10Document1 pageCWC-BookletF1 10satnamNo ratings yet

- CWC-BookletF1 9Document1 pageCWC-BookletF1 9satnamNo ratings yet

- CWC-BookletF1 9Document1 pageCWC-BookletF1 9satnamNo ratings yet

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Document1 pageTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNo ratings yet

- CWC-BookletF1 5Document1 pageCWC-BookletF1 5satnamNo ratings yet

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 pageTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNo ratings yet

- CWC-BookletF1 3Document1 pageCWC-BookletF1 3satnamNo ratings yet

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- CWC-BookletF1 4Document1 pageCWC-BookletF1 4satnamNo ratings yet

- CWC-BookletF1 2Document1 pageCWC-BookletF1 2satnamNo ratings yet

- Biodata TemplateDocument16 pagesBiodata TemplateB. Srini VasanNo ratings yet

- Moltistoreyed Building - DT 15.09.17Document14 pagesMoltistoreyed Building - DT 15.09.17V.m. RajanNo ratings yet

- Classic CNC Milling Machine Center CatlogDocument7 pagesClassic CNC Milling Machine Center Catlogmario diego simeonNo ratings yet

- 18cv34 - Vinod B R CivilDocument188 pages18cv34 - Vinod B R CivilOlawale AdebesinNo ratings yet

- Organometallic Compounds and Applications. (Presentation) and Notes XDocument15 pagesOrganometallic Compounds and Applications. (Presentation) and Notes XHanzala LabeebNo ratings yet

- EN Thalachrome S PDFDocument1 pageEN Thalachrome S PDFthyskieNo ratings yet

- Solar Photovoltaics: Basics: Mpepb@nus - Edu.sgDocument37 pagesSolar Photovoltaics: Basics: Mpepb@nus - Edu.sg김동욱No ratings yet

- MOM Chapter 03 New-EditedDocument22 pagesMOM Chapter 03 New-Editednur yusufNo ratings yet

- Elaskon 30 SDS CDN-en v2,7Document7 pagesElaskon 30 SDS CDN-en v2,7Konstantinos SynodinosNo ratings yet

- Bel NotesDocument7 pagesBel NotesUsama JanNo ratings yet

- A Textbook Organic Chemistry - CompressedDocument1,224 pagesA Textbook Organic Chemistry - CompressedEJ CUBERNo ratings yet

- انتاج اوكسيد الاثيلينDocument53 pagesانتاج اوكسيد الاثيلينسرى العبيديNo ratings yet

- Engineering Properties of RocksDocument10 pagesEngineering Properties of RocksSachin Singh JatNo ratings yet

- Glass StructureDocument116 pagesGlass StructureArion Dan67% (3)

- API 510 Question Bank Sets IDocument4 pagesAPI 510 Question Bank Sets IMd Asif FaizanNo ratings yet

- Extra High Voltage XLPE Cables: LntrodllctiollDocument3 pagesExtra High Voltage XLPE Cables: LntrodllctiollNika ThaiNo ratings yet

- Irc 112-2011-1Document2 pagesIrc 112-2011-1Anonymous HJ7hmihhNo ratings yet

- Wavi Strong Installation GuideDocument44 pagesWavi Strong Installation Guideumer.shariff87No ratings yet

- Case Study-Failure in SolebarDocument24 pagesCase Study-Failure in SolebardonendrajNo ratings yet

- Production RatesDocument4 pagesProduction RatesAmanda LongNo ratings yet

- NCCT-MEP-CS0003 - ITP Check Sheet - Cable Tray and Bracket InstallationDocument2 pagesNCCT-MEP-CS0003 - ITP Check Sheet - Cable Tray and Bracket InstallationJamie CannellNo ratings yet

- Behaviour of Concrete On The Use of Quarry Dust and Superplasticizer To Replace SandDocument6 pagesBehaviour of Concrete On The Use of Quarry Dust and Superplasticizer To Replace SandNeeraj SinghNo ratings yet

- Biogeochemical CyclesDocument5 pagesBiogeochemical Cyclesjaimejeannepoot.martinezNo ratings yet

- Energies 14 02369 v2Document22 pagesEnergies 14 02369 v2Cavidan IbrahimliNo ratings yet

- PRECAST CONCRETE Floor SystemDocument13 pagesPRECAST CONCRETE Floor SystemBenjie MonasqueNo ratings yet

- Procedure Checklist ASTM C430/AASHTO T192 Fineness of Hydraulic Cement by 325 SieveDocument1 pageProcedure Checklist ASTM C430/AASHTO T192 Fineness of Hydraulic Cement by 325 SieveanbertjonathanNo ratings yet

- Physics Investigatory Project LIGHT DEPEDocument21 pagesPhysics Investigatory Project LIGHT DEPEragg ss100% (1)

- SikaPlast 2014 NS BDDocument2 pagesSikaPlast 2014 NS BDTaposh Paul100% (1)

- Safety Data Sheet Product IdentificationDocument5 pagesSafety Data Sheet Product IdentificationHayu Atuh 1No ratings yet

- May 2010 TZ2 Paper 2 PDFDocument10 pagesMay 2010 TZ2 Paper 2 PDFleanne yangNo ratings yet