Professional Documents

Culture Documents

Los Angeles Abrasion Test PDF

Uploaded by

Barijit 65Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Los Angeles Abrasion Test PDF

Uploaded by

Barijit 65Copyright:

Available Formats

Determination of Los Angeles Abrasion Value

Theory:

Los Angeles abrasion test on aggregates is the measure of aggregate toughness and abrasion resistance

such as crushing, degradation and disintegration. This test is carried out by AASHTO T 96 or ASTM C

131: Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los

Angeles Machine. The aggregate used in surface course of the highway pavements are subjected to

wearing due to movement of traffic. When vehicles move on the road, the soil particles present between

the pneumatic tyres and road surface cause abrasion of road aggregates. The steel rimmed wheels of

animal driven vehicles also cause considerable abrasion of the road surface. Therefore, the road

aggregates should be hard enough to resist abrasion. Resistance to abrasion of aggregate is determined in

laboratory by Los Angeles test machine. The principle of Los Angeles abrasion test is to produce abrasive

action by use of standard steel balls which when mixed with aggregates and rotated in a drum for specific

number of revolutions also causes impact on aggregates. The percentage wear of the aggregates due to

rubbing with steel balls is determined and is known as Los Angeles Abrasion Value.

The Los Angeles abrasion test on aggregates are done for following purposes:

1. To determine the Los Angeles abrasion value.

2. To find the suitability of aggregates for use in road construction.

Apparatus for Los Angeles Test

The apparatus as per IS: 2386 (Part IV) - 1963 consists of:

1. Los Angeles Machine

2. Abrasive charge: Cast iron or steel balls, approximately 48mm in diameter and each

weighing between 390 to 445 g; six to twelve balls are required.

3. Sieve: 1.70, 2.36, 4.75, 6.3, 10, 12.5, 20, 25, 40, 50, 63, 80 mm IS Sieves.

4. Balance of capacity 5 kg or 10 kg

5. Drying oven

6. Miscellaneous like tray

Dept. of Civil Engineering. BGI-SDET

Procedure for Los Angeles Test

The test sample consists of clean aggregates dried in oven at 105° - 110°C. The sample should

conform to any of the gradings shown in table 1.

1. Select the grading to be used in the test such that it conforms to the grading to be used in

construction, to the maximum extent possible.

2. Take 5 kg of sample for gradings A, B, C & D and 10 kg for gradings E, F & G.

3. Choose the abrasive charge as per Table 2 depending on grading of aggregates.

4. Place the aggregates and abrasive charge on the cylinder and fix the cover.

5. Rotate the machine at a speed of 30 to 33 revolutions per minute. The number of

revolutions is 500 for gradings A, B, C & D and 1000 for gradings E, F & G. The

machine should be balanced and driven such that there is uniform peripheral speed.

6. The machine is stopped after the desired number of revolutions and material is

discharged to a tray.

7. The entire stone dust is sieved on 1.70 mm IS sieve.

8. The material coarser than 1.7mm size is weighed correct to one gram.

Table 1: Grading of Test Samples - *Tolerance of ± 12 percent permitted.

Sieve size

Weight of test

(square

sample in gm

hole)

Passing Retained on

A B C D E F G

(mm) (mm)

80 63 2500*

63 50 2500*

50 40 5000* 5000*

40 25 1250 5000* 5000*

25 20 1250 5000*

20 12.5 1250 2500

12.5 10 1250 2500

10 6.3 2500

6.3 4.75 2500

4.75 2.36 5000

Dept. of Civil Engineering. BGI-SDET

Table 2: Selection of Abrasive Charge

Grading No of Steel balls Weight of charge in gm.

A 12 5000 ± 25

B 11 4584 ±25

C 8 3330 ± 20

D 6 2500 ± 15

E 12 5000 ± 25

F 12 5000 ± 25

G 12 5000 ± 25

Observations of Los Angeles Test

Original weight of aggregate sample = W1 g; Weight of aggregate sample retained = W2 g;

Weight passing 1.7mm IS sieve = W1 - W2 g; Abrasion Value = (W1 - W2 ) / W1 X 100

Recommended Los Angeles Test Values for Pavements

Los Angeles test is commonly used to evaluate the hardness of aggregates. The test has more

acceptability because the resistance to abrasion and impact is determined simultaneously.

Depending upon the value, the suitability of aggregates for different road constructions can be

judged as per IRC specifications as given:

Sl.

Type of Pavement Max. permissible abrasion value in %

No.

1 Water bound macadam sub base course 60

2 WBM base course with bituminous surfacing 50

3 Bituminous bound macadam 50

4 WBM surfacing course 40

5 Bituminous penetration macadam 40

Bituminous surface dressing, cement concrete

6 35

surface course

7 Bituminous concrete surface course 30

Watch Video: Los Angeles Abrasion Test

Dept. of Civil Engineering. BGI-SDET

You might also like

- Los AngelesDocument2 pagesLos AngelesAbdulelah SNo ratings yet

- Abrasion Test of AggregatesDocument5 pagesAbrasion Test of AggregatesNorhazerahYussop100% (1)

- LabEx No. 7 Los Angeles Abrasion TestDocument4 pagesLabEx No. 7 Los Angeles Abrasion TestianzkieeNo ratings yet

- Addis Ababa Housing Project Geotechnical ReportDocument32 pagesAddis Ababa Housing Project Geotechnical ReportMinilik Tikur SewNo ratings yet

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985From EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No ratings yet

- BCE 3107 Transportation Engineering PDFDocument118 pagesBCE 3107 Transportation Engineering PDFmoradNo ratings yet

- Highway Engineering: Subject Code - CE 2255Document43 pagesHighway Engineering: Subject Code - CE 2255HanafiahHamzahNo ratings yet

- Theory Costant Head MethodDocument4 pagesTheory Costant Head MethodsyathirohNo ratings yet

- Shape Test Determines Flakiness IndexDocument8 pagesShape Test Determines Flakiness IndexShivpreet SharmaNo ratings yet

- A1 SolutionDocument7 pagesA1 SolutionhamzaNo ratings yet

- Minor ProjectDocument17 pagesMinor Projectपाँशुल जम्वाल राजपूतNo ratings yet

- Chapter 1 (Sandy Lean Clay)Document17 pagesChapter 1 (Sandy Lean Clay)John Raymund TanugaNo ratings yet

- Highway Lab ReportDocument23 pagesHighway Lab ReportGayan WaidyaratneNo ratings yet

- Liquid Limit and Plastic Limit Tests - Lab ExperimentsDocument8 pagesLiquid Limit and Plastic Limit Tests - Lab ExperimentsbilalNo ratings yet

- Concrete Mix Design Report PDFDocument32 pagesConcrete Mix Design Report PDFMohamed AhmedNo ratings yet

- 114Document22 pages114Mohamad Tomindug BauloNo ratings yet

- Final PPT An Experimental Study On Mechanical PropertiesDocument31 pagesFinal PPT An Experimental Study On Mechanical PropertiesMohd JunaidNo ratings yet

- Lab 3 (Level 2) - Road and Building Setting OutDocument3 pagesLab 3 (Level 2) - Road and Building Setting OutMohd Yusri100% (1)

- Soil InvestigationDocument45 pagesSoil InvestigationMelano ArjayNo ratings yet

- CE 121 LAB REPORT DENSITY & SPECIFIC GRAVITYDocument14 pagesCE 121 LAB REPORT DENSITY & SPECIFIC GRAVITYNatsu RefilNo ratings yet

- Soundness Test of Cement Using Autoclave MethodDocument3 pagesSoundness Test of Cement Using Autoclave MethodPritha DasNo ratings yet

- AGGREGATE ABRASION TEST VALUESDocument6 pagesAGGREGATE ABRASION TEST VALUESAbdur RazzakNo ratings yet

- Determination of Fineness of Cement by Dry SievingDocument2 pagesDetermination of Fineness of Cement by Dry SievingMaterial LabNo ratings yet

- Compaction Test PDFDocument6 pagesCompaction Test PDFACTION plusNo ratings yet

- Experiment 3 Compaction TestDocument5 pagesExperiment 3 Compaction TestAnis Nurfarahanim Abdul Halim0% (1)

- Bahir Dar University construction equipment assignmentDocument7 pagesBahir Dar University construction equipment assignmentComputer Maintainance Hardware and softwareNo ratings yet

- AGGREGATE SHAPE TEST RESULTSDocument9 pagesAGGREGATE SHAPE TEST RESULTSBeman EasyNo ratings yet

- LAB 3 - Traffic Volume (Method 1) OEL 1Document5 pagesLAB 3 - Traffic Volume (Method 1) OEL 1saraa sharanNo ratings yet

- Design of timber compression membersDocument28 pagesDesign of timber compression membersPablo CartagenaNo ratings yet

- Determination of Elongation IndexDocument8 pagesDetermination of Elongation IndexAnonymous 5soodVRnNo ratings yet

- Assignment - 3: Highway Engineering-II 2011 E.CDocument4 pagesAssignment - 3: Highway Engineering-II 2011 E.CABexample GgideyNo ratings yet

- Marshall method design bituminous mixturesDocument26 pagesMarshall method design bituminous mixturesKEZIAH JANE SULAPASNo ratings yet

- L1-Physical Characteristic of SoilDocument78 pagesL1-Physical Characteristic of SoilTAN PANG ZORNo ratings yet

- Determination of Aggregate CrushingDocument8 pagesDetermination of Aggregate CrushingPoovan Rajaratnam100% (2)

- Failure analysis of retaining wall in VisakhapatnamDocument4 pagesFailure analysis of retaining wall in VisakhapatnamRaghavNo ratings yet

- Concrete Lab Manual Normal Consistency TestDocument3 pagesConcrete Lab Manual Normal Consistency TestKamran AliNo ratings yet

- Name: Yanik Lubin CVNG 3009 - Marshall Mix Design Lab I.D.#: 809100024Document17 pagesName: Yanik Lubin CVNG 3009 - Marshall Mix Design Lab I.D.#: 809100024Deoraj ToolsieNo ratings yet

- Tut 1 - Port, Air & RailDocument81 pagesTut 1 - Port, Air & RailJia SingNo ratings yet

- D2488 - Description and Identification of Soils (Visual-Manual Procedure) PDFDocument11 pagesD2488 - Description and Identification of Soils (Visual-Manual Procedure) PDFNachoNo ratings yet

- Soil Stablization Using Shredded Rubber TyreDocument4 pagesSoil Stablization Using Shredded Rubber TyremahakNo ratings yet

- 1 PT CBRDocument18 pages1 PT CBRmihiretu TeferaNo ratings yet

- Standard Proctor Compaction Test ResultsDocument12 pagesStandard Proctor Compaction Test Resultsaidil adhaNo ratings yet

- Soil Mechanics FundamentalsDocument12 pagesSoil Mechanics Fundamentalsmichalakis483No ratings yet

- Plasticity of SoilDocument4 pagesPlasticity of SoilJommarVocalTagalog100% (1)

- (COMPLETE) Ring Ball and Penetration Test PDFDocument10 pages(COMPLETE) Ring Ball and Penetration Test PDFAthirah DinataNo ratings yet

- Falling Head Permeability Lab ReportDocument11 pagesFalling Head Permeability Lab ReportfatinNo ratings yet

- Experiment No. Liquid Limit of Soil by Satic Cone PenetrometerDocument2 pagesExperiment No. Liquid Limit of Soil by Satic Cone PenetrometerOpu DebnathNo ratings yet

- Bitumen Extraction Test PDFDocument4 pagesBitumen Extraction Test PDFAyat ANo ratings yet

- Test 1 - Concrete Mix Design DishanDocument20 pagesTest 1 - Concrete Mix Design DishanYasndra AbeygunewardhaneNo ratings yet

- Determination of Flakiness and Elongation Index For The Given Aggregate Sample.Document4 pagesDetermination of Flakiness and Elongation Index For The Given Aggregate Sample.Huma AliNo ratings yet

- SIWES Buk 500 - FinakDocument45 pagesSIWES Buk 500 - FinakUmar James YakubuNo ratings yet

- Determine Fineness Modulus of Fine AggregateDocument10 pagesDetermine Fineness Modulus of Fine AggregateMathangi Prathap KumarNo ratings yet

- M.E QuestionsDocument7 pagesM.E QuestionsStephen John ClementeNo ratings yet

- Consolidation TestDocument2 pagesConsolidation TestTenzinKesang100% (1)

- Classifying Roads and Calculating Pavement DesignDocument9 pagesClassifying Roads and Calculating Pavement DesignLeo Albert MaputiNo ratings yet

- Determining Affinity Between Aggregate and BitumenDocument7 pagesDetermining Affinity Between Aggregate and BitumenJohn Prashanth VadlapatiNo ratings yet

- Crushing Test PDFDocument4 pagesCrushing Test PDFAshishJamadarNo ratings yet

- Chapter 5Document62 pagesChapter 5Mo Kops100% (1)

- Thesis Presentation Edited&FinalDocument49 pagesThesis Presentation Edited&FinalJafar AhamadNo ratings yet

- Los Angeles Abrasion Test PDFDocument6 pagesLos Angeles Abrasion Test PDFAshishJamadar100% (1)

- To The Postmaster : For Use of Post OfficeDocument2 pagesTo The Postmaster : For Use of Post OfficeSuvodip EtcNo ratings yet

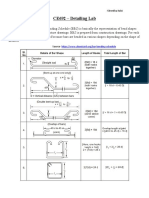

- Notes On Detailing Lab - CE692Document3 pagesNotes On Detailing Lab - CE692Barijit 65No ratings yet

- Excercise 2Document1 pageExcercise 2Nishok INo ratings yet

- Aptitude questions with explanationDocument32 pagesAptitude questions with explanationBarijit 65No ratings yet

- Civil Final Upto 4th Year Syllabus 14.03.14Document51 pagesCivil Final Upto 4th Year Syllabus 14.03.14Suryasis DasguptaNo ratings yet

- KYCDocument2 pagesKYCRamkumarNo ratings yet

- Product Panel of EseDocument4 pagesProduct Panel of EseBarijit 65No ratings yet

- Introduction To Highway EngineeringDocument8 pagesIntroduction To Highway EngineeringBarijit 65No ratings yet

- HU-601 Principles of Management Module 1 PDFDocument12 pagesHU-601 Principles of Management Module 1 PDFSriparna guhaNo ratings yet

- Highway & Transportation Engineering Lab Viva QuestionsDocument1 pageHighway & Transportation Engineering Lab Viva QuestionsBarijit 6550% (2)

- Chemistry Honours Cbcs Draft Syllabus PDFDocument87 pagesChemistry Honours Cbcs Draft Syllabus PDFBarijit 65No ratings yet

- Chemistry Honours Cbcs Draft Syllabus PDFDocument87 pagesChemistry Honours Cbcs Draft Syllabus PDFBarijit 65No ratings yet

- COLORMATCHING GUIDELINES FOR DEMI-PERMANENT HAIR COLORDocument1 pageCOLORMATCHING GUIDELINES FOR DEMI-PERMANENT HAIR COLORss bbNo ratings yet

- Biology 1090 Exam 1 Study GuideDocument5 pagesBiology 1090 Exam 1 Study GuideAmandaNo ratings yet

- Югоизточна Европа под османско владичество 1354-1804Document531 pagesЮгоизточна Европа под османско владичество 1354-1804auroradentataNo ratings yet

- A Lesson Plan in English by Laurence MercadoDocument7 pagesA Lesson Plan in English by Laurence Mercadoapi-251199697No ratings yet

- Pharmaco-pornographic Politics and the New Gender EcologyDocument14 pagesPharmaco-pornographic Politics and the New Gender EcologyMgalo MgaloNo ratings yet

- Itm Guia Rapida Tds 600 Tipo4 Ed1 EspDocument148 pagesItm Guia Rapida Tds 600 Tipo4 Ed1 Espcamel2003No ratings yet

- Global Detection - Electronic and Electromechanical Sensors Catalogue 2006.10 PDFDocument800 pagesGlobal Detection - Electronic and Electromechanical Sensors Catalogue 2006.10 PDFSarah RichardNo ratings yet

- Woody Plant Seed Manual - CompleteDocument1,241 pagesWoody Plant Seed Manual - CompleteJonas Sandell100% (1)

- Roke TsanDocument53 pagesRoke Tsanhittaf_05No ratings yet

- Understanding Heavy Lifting Operations and Vessel StabilityDocument15 pagesUnderstanding Heavy Lifting Operations and Vessel StabilitygeorgesagunaNo ratings yet

- Manual vs Air Rotor Stripping SEM EvaluationDocument8 pagesManual vs Air Rotor Stripping SEM Evaluationlocos3dNo ratings yet

- Ergonomía y Normatividad en 3Document5 pagesErgonomía y Normatividad en 3Rogers DiazNo ratings yet

- Prepare Egg Dishes GuideDocument5 pagesPrepare Egg Dishes GuideRuth CesistaNo ratings yet

- Attendance: Umut KurtoğluDocument2 pagesAttendance: Umut KurtoğluHavvaNo ratings yet

- PreciControl CMV IgG Avidity - Ms - 05942322190.V4.EnDocument2 pagesPreciControl CMV IgG Avidity - Ms - 05942322190.V4.EnARIF AHAMMED PNo ratings yet

- Solid State Device Analysis ApproximationsDocument34 pagesSolid State Device Analysis Approximationsmrd9991No ratings yet

- Compare and Contrast History EssayDocument9 pagesCompare and Contrast History EssayGiselle PosadaNo ratings yet

- Creative 2nd QuarterDocument6 pagesCreative 2nd QuarterJanice CordovaNo ratings yet

- CẤU TẠO TỪ VÀ TỪ LOẠIDocument15 pagesCẤU TẠO TỪ VÀ TỪ LOẠIccnsdNo ratings yet

- Arnold Jacobs: His Global Influence: Midwest Clinic, Thursday, December 17 12:00-1:00pmDocument17 pagesArnold Jacobs: His Global Influence: Midwest Clinic, Thursday, December 17 12:00-1:00pmAlex MoralesNo ratings yet

- Important Characteristics of an Ideal InductorDocument4 pagesImportant Characteristics of an Ideal Inductorsreekantha reddyNo ratings yet

- Ngāti Kere: What 87 Can Achieve Image 500Document17 pagesNgāti Kere: What 87 Can Achieve Image 500Angela HoukamauNo ratings yet

- I. VHF CommunicationsDocument12 pagesI. VHF CommunicationsSamuel OyelowoNo ratings yet

- Paratech Brochures RSSDocument12 pagesParatech Brochures RSSTatiana Andrea Carvajal GutierrezNo ratings yet

- ECF/SSF : 08 : 11: Rotex Double Rack and Pinion Actuator SeriesDocument20 pagesECF/SSF : 08 : 11: Rotex Double Rack and Pinion Actuator SeriesProcess Controls & ServicesNo ratings yet

- 2Tafseer2019Sep4 17 24oc1 8 29nov5 262020jan7 21F11 18 25Document96 pages2Tafseer2019Sep4 17 24oc1 8 29nov5 262020jan7 21F11 18 25Aroob YaseenNo ratings yet

- Unofficial Fanbook Made With Permission - Incar-NationDocument24 pagesUnofficial Fanbook Made With Permission - Incar-NationBrockPetersdorf-Nelson100% (1)

- Loveology: God. Love. Marriage. Sex. and The Never-Ending Story of Male and Female. by John Mark Comer, SamplerDocument32 pagesLoveology: God. Love. Marriage. Sex. and The Never-Ending Story of Male and Female. by John Mark Comer, SamplerZondervan40% (5)

- Training EvaluationDocument15 pagesTraining EvaluationAklima AkhiNo ratings yet

- HBR - Michael Porter - Redefining Competition in Healthcare - 2004 PDFDocument14 pagesHBR - Michael Porter - Redefining Competition in Healthcare - 2004 PDFYusfin DelfitaNo ratings yet