Professional Documents

Culture Documents

MSA Case Studies

Uploaded by

MuthuswamyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSA Case Studies

Uploaded by

MuthuswamyCopyright:

Available Formats

MSA 4th Edition Case Studies & Guidelines

MSA CASE STUDIES

BIAS

Difference between observed average

of measurements and reference value.

Reference Value

Reference value, also known as

accepted reference value or master

value, is a value that serves as an

agreed upon reference for measured

values.

A reference value can be determined

Observed Average by

averaging several measurements

Value with a

higher level of measuring equipment.

BIAS WORK INSTRUCTION & CASE STUDY:

The inside diameter of a coupling is measured fifteen times repeatedly by the same

operator. The data is given below. The reference value is 6.00.

Average (X-bar) = Trials OD Values Individual Bias

1. 5.8

2. 5.7

3. 5.9

4. 5.9

5. 6.0

6. 6.1

7. 6.0

8. 6.1

9. 6.4

Nathan & Nathan Consultants Pvt. Ltd., Page No. 1

MSA 4th Edition Case Studies & Guidelines

10. 6.3

11. 6.0

12. 6.1

13. 6.2

14. 5.6

15. 6.0

DRAW HISTOGRAM FOR THE INDIVIDUAL BIAS & INTERPRET FOR

NORMALITY

Compute the average bias of the n readings.

Avg. bias = (Sum of Bias) / n

Compute the repeatability standard deviation

Sigma repeatability = σ r = sqrt{(Sum ( Xi – X-bar) 2) / (n-1)}

If a GRR study is available (and valid), the repeatability standard deviation should

be based on the study results.

Determine if the repeatability is acceptable by calculating the

%EV = 100 (EV/TV) = 100 (σ r / TV)

Nathan & Nathan Consultants Pvt. Ltd., Page No. 2

MSA 4th Edition Case Studies & Guidelines

If the % EV is large, then the measurement system variation may be

unacceptable. Since the bias analysis assures that the repeatability is acceptable,

continuing the analysis with a measurement system with a large %EV will lead to

misleading and confusing results.

CALCULATE SIGMA BIAS = SIGMA r / SQRT n

Bias is acceptable at the α level, if

Zero falls within the 1- α confidence bounds based on the bias value. (Use the t-

distribution table).

Average Bias – [σb (tν, 1 – α/2)] ≤ 0 ≤ Average Bias + [σb (tν, 1 – α/2)]

Where ν = n-1, tν, 1 – α/2 from t - table

REPEATABILITY

Variation in measurements

obtained with one measurement

instrument when used several

times by one Appraiser while

measuring identical characteristic

on same part.

Repeatability

REPRODUCIBILITY

Variation in average of

measurements made

by different Appraisers Appraiser B

using same measuring

instrument when

measuring identical

characteristic on same Appraiser C

part.

Nathan & Nathan Consultants Pvt. Ltd., Page No. 3

Appraiser A

Reproducibility

MSA 4th Edition Case Studies & Guidelines

GAGE R & R STUDY ( X bar and R method)

GAGE R & R WORK INSTRUCTIONS

1. Select three appraisers who are users of the measurement system

2. Obtain a sample of 10 parts that represent actual or expected range of process

variation

3. Number parts 1 through 10 so that numbers are not visible to appraisers

4. Calibrate gage if this is part of the normal gauging procedures

5. Measure 10 parts in random order by appraiser a, with an observer recording

results

6. Repeat step 5 with other appraisers, conceal other appraisers readings

7. Repeat step 5 and 6 using a different random order of measurement

8. Calculate the average and ranges for all readings for each appraiser

9. Using the attached GR & R report, enter part averages and range averages

10. Calculate repeatability for equipment variation

11. Calculate reproducibility for appraiser variation

12. Calculate GR & R

Nathan & Nathan Consultants Pvt. Ltd., Page No. 4

MSA 4th Edition Case Studies & Guidelines

13. Calculate part variation.

14. Calculate % EV, %AV, % R&R against TV or tolerance based on the following

guidelines:

(i) Using process variation

Process variation, taken from the parts in GRR study itself

Use when the selected sample represents the expected process

variation (preferred option)

(ii) Surrogated process variation

Use when sufficient samples to represent the process are not

available but an existing process with similar process variation

is available

(iii) Pp (or Ppk) target value

Use when sufficient samples to represent the process are not

available and an existing process with similar process variation

is not available or the new process is expected to have less

variability than an existing process

Formula to be used –

Pp = (USL-LSL) / (6*σp) = (USL-LSL) / (6*TV)

Therefore, TV = (USL-LSL) / (6*Pp)

(iv) Specification tolerance

Use When the measurement system is to be used to sort the

process, and the process has a Pp < 1.0

15. Calculate number of distinct data categories

GR & R ACCEPTANCE GUIDELINES

Acceptance criteria based on estimated value of R&R of system

GRR Decision Comments

Under Generally considered to be Recommended, especially useful when trying

10% an acceptable measurement to sort or classify parts or when tightened

system process control is required

10% to May be acceptable for some Decision should be based upon, for example,

Nathan & Nathan Consultants Pvt. Ltd., Page No. 5

MSA 4th Edition Case Studies & Guidelines

30% applications importance of application measurement, cost

of measurement device, cost of rework or

repair.

Should be approved by the customer

Over Considered to be Every effort should be made to improve the

30% unacceptable measurement system.

This condition may be addressed by the use

of an appropriate measurement strategy; for

example, using the average result of several

readings of the same part characteristic in

order to reduce final measurement variation.

No. of distinct data categories NDC > 5

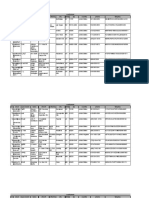

GAGE REPEATABILITY AND REPRODUCIBILITY DATA SHEET

VARIABLE DATA RESULTS

Part Number : Guage Name : Appraiser A :

Part Name : Guage Number : Appraiser B :

Characteristic Range Guage Type Appraiser C :

Characteristic Classification Trials Parts Appraisers Date Performed

APPRAISER/ PART AVERAGE

TRIAL # 1 2 3 4 5 6 7 8 9 10

1. A 1

2. 2

3. 3

4. AVE X-bar a =

5. R R-bar a =

6. B 1

7. 2

8. 3

9. AVE X-bar b =

10. R R-bar b =

11. C 1

12. 2

13. 3

Nathan & Nathan Consultants Pvt. Ltd., Page No. 6

MSA 4th Edition Case Studies & Guidelines

14. AVE X-bar c =

15. R R-bar c =

16. PART X double bar =

AVE ( Xp ) Rp=

17. (R-bara + R-barb + R-barc) / (# OF APPRAISERS) = R d-bar=

(Max X-bar – Min X-bar) =

18. X barDIFF=

R d-bar x D4*

19. = UCLR=

* D4 =3.27 for 2 trials and 2.58 for 3 trials; UCLR represents the limit of individual R’s. Circle those that are

Beyond this limit. Identify the cause and correct. Repeat these readings using the same appraiser and unit as originally used or dis-

card values and re-average and recompute R-dbar and the limiting value from the remaining observations.

Notes:

GAGE REPEATABILITY AND REPRODUCIBILITY DATA SHEET

VARIABLE DATA RESULTS

Part Number Gage Name Appraiser A

Part Name Gage Number Appraiser B

Characteristic Gage Type Appraiser C

Characteristic Classification Trials Parts Appraisers Date Performed

Measurement Unit Analysis % TV

Repeatability – Equipment Variation (EV)

EV =R d-bar x K1 Trials K1 % EV =100 (EV/ TV)

= 2 0.8862 =

= 3 0.5908 =

Reproducibility – Appraiser Variation (AV)

AV ={(x barDIFF x K2)2 – (EV2/nr)}1/2 % AV =100 (AV/ TV)

= =

= Appraisers 2 3 =

n = number of

parts, r = number of trials K2 0.70710.5231

Repeatability & Reproducibility (GRR)

GRR ={(EV2 + AV2)}1/2 Parts K3 % GRR =100 (GRR/ TV )

= 2 0.7071 =

= 3 0.5231 =

Part Variation (PV) 4 0.4467

Nathan & Nathan Consultants Pvt. Ltd., Page No. 7

MSA 4th Edition Case Studies & Guidelines

PV =RP x K3 5 0.4030

= 6 0.3742 % PV =100 (PV/ TV )

= 7 0.3534 =

Total Variation 8 0.3375 =

TV ={(GRR2 + PV2)}1/2 9 0.3249 ndc =1.41(PV/GRR)

= 10 0.3146 =

= =

Nathan & Nathan Consultants Pvt. Ltd., Page No. 8

MSA 4th Edition Case Studies & Guidelines

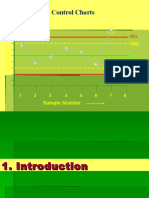

CONTROL PLAN

Prototype Pre-launch Production Key Contact / Phone Date (Org.) Date (Rev.)

Control Plan Number S. Specs 555-8888

Part Number / Latest Change Level Core Team Customer Engg. Approval/Date (if Reqd.)

Part Name / Description Supplier / Plant Approval Date Customer Quality Approval / Date (if reqd.)

Supplier / Plant Supplier Code Other Approval Date (if reqd.) Other Approval Date (if reqd.)

Part/ Process Name / Machine, Characteristics Special Methods Reaction

Process Operation Description Device, No. Product Process Char. Product/Process Evaluation Sample Control Plan

Number Jig. Tools specification / Measurement Size Freq Method

For Mfg. Tolerance Technique .

20 Turning CNC 1 O.D 275 +/- 0.1 H – GAGE 1 hr Self SOP

Inspn VE/SOP/

2 THICK 47 +/- 0.1 E – GAGE 1 hr Self 08

inspn.

3 BORE * 50 +0.05 BORE DIAL 5 hr X bar &

( 0.001) R chart

Nathan & Nathan Consultants Pvt. Ltd., Page No. 9

MSA 4th Edition Case Studies & Guidelines

t-Distribution Table

Α 0..6 0.75 0.90 0.95 0.975 0.99 0.995 0.9975 0.999 0.9995

1 0.325 1.000 3.078 6.314 12.706 31.821 63.657 127.320 318.310 636.620

2 0.289 0.816 1.886 2.920 4.303 6.965 9.925 14.089 23.326 31.598

3 0.277 0.765 1.638 2.353 3.182 4.541 5.841 7.453 10.213 12.924

4 0.271 0.741 1.533 2.132 2.776 3.747 4.604 5.598 7.173 8.610

5 0.267 0.727 1.476 2.015 2.571 3.365 4.032 4.773 5.893 6.869

6 0.265 0.718 1.440 1.943 2.447 3.143 3.707 4.317 5.208 5.959

7 0.263 0.711 1.415 1.895 2.365 2.998 3.499 4.029 4.785 5.408

8 0.262 0.706 1.397 1.860 2.306 2.896 3.355 3.833 4.501 5.041

9 0.261 0.703 1.383 1.833 2.262 2.821 3.250 3.690 4.297 4.781

10 0.260 0.700 1.372 1.812 2.228 2.764 3.169 3.581 4.144 4.587

11 0.260 0.697 1.363 1.796 2.201 2.718 3.106 3.497 4.025 4.437

12 0.259 0.695 1.356 1.782 2.179 2.681 3.055 3.428 3.930 4.318

13 0.259 0.694 1.350 1.771 2.160 2.650 3.012 3.372 3.852 4.221

14 0.258 0.692 1.345 1.761 2.145 2.624 2.977 3.326 3.787 4.140

15 0.258 0.691 1.341 1.753 2.131 2.602 2.947 3.286 3.733 4.073

16 0.258 0.690 1.337 1.746 2.120 2.583 2.921 3.252 3.686 4.015

17 0.257 0.689 1.333 1.740 2.110 2.567 2.898 3.222 3.646 3.965

18 0.257 0.688 1.330 1.734 2.101 2.552 2.878 3.197 3.610 3.922

19 0.257 0.688 1.328 1.729 2.093 2.539 2.861 3.174 3.579 3.883

20 0.257 0.687 1.325 1.725 2.086 2.528 2.845 3.153 3.552 3.850

21 0.257 0.686 1.323 1.721 2.080 2.518 2.831 3.135 3.527 3.819

22 0.256 0.686 1.321 1.717 2.074 2.508 2.819 3.119 3.505 3.792

23 0.256 0.685 1.319 1.714 2.069 2.500 2.807 3.104 3.485 3.767

24 0.256 0.685 1.318 1.711 2.064 2.492 2.797 3.091 3.467 3.745

25 0.256 0.684 1.316 1.708 2.060 2.485 2.787 3.078 3.450 3.725

26 0.256 0.684 1.315 1.706 2.056 2.479 2.779 3.067 3.435 3.707

27 0.256 0.684 1.314 1.703 2.052 2.473 2.771 3.057 3.421 3.690

28 0.256 0.683 1.313 1.701 2.048 2.467 2.763 3.047 3.408 3.674

29 0.256 0.683 1.311 1.699 2.045 2.462 2.756 3.038 3.396 3.659

30 0.256 0.683 1.310 1.697 2.042 2.457 2.750 3.030 3.385 3.646

40 0.255 0.681 1.303 1.684 2.021 2.423 2.704 2.971 3.307 3.551

60 0.254 0.679 1.296 1.671 2.000 2.390 2.660 2.915 3.232 3.460

120 0.254 0.677 1.289 1.658 1.980 2.358 2.617 2.860 3.160 3.373

0.253 0.674 1.282 1.645 1.960 2.326 2.576 2.807 3.090 3.291

ν - degrees of freedom

Nathan & Nathan Consultants Pvt. Ltd., Page No. 10

You might also like

- 5S ManualDocument60 pages5S ManualMun Hein ZawNo ratings yet

- Gage R RDocument8 pagesGage R Rshobhit2310No ratings yet

- Captiva 2013 Systema Electric 3.0Document13 pagesCaptiva 2013 Systema Electric 3.0carlos martinez50% (2)

- Attribute Gage R&R Effectiveness ReportDocument10 pagesAttribute Gage R&R Effectiveness ReportCésar MezaNo ratings yet

- Advanced Process CapabilityDocument11 pagesAdvanced Process Capabilitycheqjieja100% (1)

- Copper Standards Handbook Guide to Terminology and Product ClassificationDocument36 pagesCopper Standards Handbook Guide to Terminology and Product ClassificationMuthuswamyNo ratings yet

- Customer: Id Email Password Name Street1 Street2 City State Zip Country Phone TempkeyDocument37 pagesCustomer: Id Email Password Name Street1 Street2 City State Zip Country Phone TempkeyAgus ChandraNo ratings yet

- How to Analyze and Improve Measurement System Capability with Expanded Gage R&RDocument10 pagesHow to Analyze and Improve Measurement System Capability with Expanded Gage R&Rmassman02143No ratings yet

- Lesson Plan SETS 2 PDFDocument10 pagesLesson Plan SETS 2 PDFHelmi Tarmizi83% (6)

- MSA-R&R Training Program GuideDocument25 pagesMSA-R&R Training Program GuideHarshad KulkarniNo ratings yet

- Control Charts3Document103 pagesControl Charts3Emad EmadNo ratings yet

- Complete PPAP OverviewDocument166 pagesComplete PPAP OverviewblkdirtymaxNo ratings yet

- Measuring Measurement: An Introduction to MSADocument134 pagesMeasuring Measurement: An Introduction to MSAVikram Billal100% (2)

- Measurement System Analysis How-To Guide - Workbook: August 2013Document25 pagesMeasurement System Analysis How-To Guide - Workbook: August 2013trsmrsNo ratings yet

- Msa 4th Edition ChangesDocument3 pagesMsa 4th Edition ChangesNasa00No ratings yet

- MeasurementSystemsAnalysis PDFDocument37 pagesMeasurementSystemsAnalysis PDFJorge MartinezNo ratings yet

- MSA StudyDocument22 pagesMSA StudyNarayanKavitakeNo ratings yet

- Msa (NDC)Document7 pagesMsa (NDC)rkshpanchalNo ratings yet

- Sample DFMEA - Full PackageDocument7 pagesSample DFMEA - Full Packageabhisheksen.asindNo ratings yet

- Root Cause & Corrective Action Corrective Action (RCCA) (RCCA)Document37 pagesRoot Cause & Corrective Action Corrective Action (RCCA) (RCCA)Bisma Masood100% (1)

- 4.statistical Process ContorlDocument47 pages4.statistical Process ContorlMinhajul Haque SarkarNo ratings yet

- CSIR NET December 2019 Admit CardDocument1 pageCSIR NET December 2019 Admit CardDevendra Singh RanaNo ratings yet

- Measurement System Analysis LabDocument32 pagesMeasurement System Analysis LabAnonymous 3tOWlL6L0U100% (1)

- Quality Control and Acceptance SamplingDocument15 pagesQuality Control and Acceptance SamplingMark Ortiz Luis OllerNo ratings yet

- How Are They Related ?Document39 pagesHow Are They Related ?MURALIDHRANo ratings yet

- Measurement System AnalysisDocument42 pagesMeasurement System Analysisazadsingh1No ratings yet

- MSA PresentationDocument37 pagesMSA Presentationelifexp100% (1)

- Attribute MSA TrainingDocument21 pagesAttribute MSA TrainingDisha ShahNo ratings yet

- Msa PDFDocument111 pagesMsa PDFClaudiu NicolaeNo ratings yet

- The Application of Gage R&R Analysis in S Six Sigma Case of ImproDocument83 pagesThe Application of Gage R&R Analysis in S Six Sigma Case of ImproDLNo ratings yet

- Cycle1 Parta GettingtoknowyourstudentsDocument7 pagesCycle1 Parta Gettingtoknowyourstudentsapi-295073409No ratings yet

- Gage R&RDocument1 pageGage R&Rshobhit2310No ratings yet

- Piperack Design PhiloshipyDocument10 pagesPiperack Design PhiloshipyGautam PaulNo ratings yet

- Training in MSA PQ Systems Training Material PDFDocument109 pagesTraining in MSA PQ Systems Training Material PDFsaby aroraNo ratings yet

- MSA-Gage RRDocument9 pagesMSA-Gage RRbmyertekinNo ratings yet

- GR&R Training DraftDocument53 pagesGR&R Training DraftLOGANATHAN VNo ratings yet

- APQP FormsDocument23 pagesAPQP FormsJOECOOL670% (1)

- Msa PresentationsDocument17 pagesMsa PresentationsNarasimharaghavanPuliyurKrishnaswamyNo ratings yet

- MSA Presentation by M Negi 31.01.09Document76 pagesMSA Presentation by M Negi 31.01.09Mahendra100% (2)

- GM Apqp Manual PDFDocument57 pagesGM Apqp Manual PDFBenito GerardoNo ratings yet

- Meet Customer Requirements with Process CapabilityDocument30 pagesMeet Customer Requirements with Process CapabilityAniket Jain100% (2)

- Risk Assessment: Overall RatingDocument3 pagesRisk Assessment: Overall RatingandirizaNo ratings yet

- CpkGuide 0211 TECH1Document11 pagesCpkGuide 0211 TECH1d_flamarich7358No ratings yet

- Circuit Breaker GTSDocument31 pagesCircuit Breaker GTScpandey01_688066930No ratings yet

- PPAP Webinar Core ToolsDocument62 pagesPPAP Webinar Core ToolsDLNo ratings yet

- MSA & Destructive TestDocument4 pagesMSA & Destructive Testanon_902607157100% (1)

- DLP 6 LO2 Safe Disposal of Tools and MaterialsDocument13 pagesDLP 6 LO2 Safe Disposal of Tools and MaterialsReybeth Tahud Hamili - Matus100% (2)

- Process and Measurement System Capability AnalysisDocument18 pagesProcess and Measurement System Capability AnalysisUtkarsh MittalNo ratings yet

- Attribute Gauge R&RDocument5 pagesAttribute Gauge R&Rhel2905No ratings yet

- Statistic ProcessDocument39 pagesStatistic ProcessxredjokerxNo ratings yet

- SPCDocument59 pagesSPCadibhai06100% (2)

- Six Sigma Control PDFDocument74 pagesSix Sigma Control PDFnaacha457No ratings yet

- MSA Sample PresentationDocument9 pagesMSA Sample PresentationTom@GGCNo ratings yet

- The Polo GT TDI and TSI: VolkswagenDocument6 pagesThe Polo GT TDI and TSI: VolkswagenSheril ChandraboseNo ratings yet

- SC Project Closeout Report v6Document27 pagesSC Project Closeout Report v6SateeshIngoleNo ratings yet

- PPAP TRGDocument102 pagesPPAP TRGArivazhagan Art100% (1)

- A Is Called The Base and N Is Called The Exponent: Grade 7 Math Lesson 21: Laws of Exponents Learning GuideDocument4 pagesA Is Called The Base and N Is Called The Exponent: Grade 7 Math Lesson 21: Laws of Exponents Learning GuideKez MaxNo ratings yet

- Uop Teuop-Tech-And-More-Air-Separation-Adsorbents-Articlech and More Air Separation Adsorbents ArticleDocument8 pagesUop Teuop-Tech-And-More-Air-Separation-Adsorbents-Articlech and More Air Separation Adsorbents ArticleRoo FaNo ratings yet

- Measurement System Analysis (MSA) GuideDocument30 pagesMeasurement System Analysis (MSA) Guideshukumar_24No ratings yet

- Measurement Systems Analysis: Total Quality ManagementDocument17 pagesMeasurement Systems Analysis: Total Quality ManagementkhamaludinNo ratings yet

- Capability Analysis and MSA IntroductionDocument27 pagesCapability Analysis and MSA IntroductionJosé María MorenoNo ratings yet

- Basic SPC Training GuideDocument44 pagesBasic SPC Training Guidekalam2k2No ratings yet

- Destructive R&RDocument19 pagesDestructive R&RKalyan SrinivasNo ratings yet

- Measurement System Analysis (MSA) : Validating Your Measurement Systems Gy yDocument16 pagesMeasurement System Analysis (MSA) : Validating Your Measurement Systems Gy yHesham MahdyNo ratings yet

- Presentation On MSA by TS16949 Auditors From UL IndiaDocument16 pagesPresentation On MSA by TS16949 Auditors From UL IndiaJetesh DevgunNo ratings yet

- GRR Studies On CMM Accuracy HexDocument31 pagesGRR Studies On CMM Accuracy HexSylvia FischerNo ratings yet

- Software ReliabilityDocument211 pagesSoftware Reliabilityapi-3775463100% (1)

- Presentation On MSA by TS16949 Auditors From UL IndiaDocument16 pagesPresentation On MSA by TS16949 Auditors From UL Indiavish12321No ratings yet

- One-Way Analysis of Variance by Abhishek VijayvargiyaDocument2 pagesOne-Way Analysis of Variance by Abhishek VijayvargiyaVipul GuptaNo ratings yet

- ANPQP - DRBFM (Design Review Based On Failure Mode) WORKSHEETDocument1 pageANPQP - DRBFM (Design Review Based On Failure Mode) WORKSHEETrenato fabbri100% (1)

- Kistler 4503BDocument12 pagesKistler 4503BMuthuswamyNo ratings yet

- Engineering Thermoplastics: Products and GradesDocument20 pagesEngineering Thermoplastics: Products and GradesmadkatteNo ratings yet

- Duct CutterDocument2 pagesDuct CutterMuthuswamyNo ratings yet

- Design of Solar Vehicle and Material Handling MechanismDocument8 pagesDesign of Solar Vehicle and Material Handling MechanismMuthuswamyNo ratings yet

- Springs 170929232513Document58 pagesSprings 170929232513MuthuswamyNo ratings yet

- 0381-05 EbkDocument318 pages0381-05 EbkMuthuswamyNo ratings yet

- UG Information Brochure 2020 EnglishDocument70 pagesUG Information Brochure 2020 EnglishMuthuswamyNo ratings yet

- Driving Directions From CoimbatoreDocument2 pagesDriving Directions From CoimbatoreMuthuswamyNo ratings yet

- Asus P7P55D: Strongly Recommended For Building A Future-Proof Mid - Range Gaming PCDocument1 pageAsus P7P55D: Strongly Recommended For Building A Future-Proof Mid - Range Gaming PCMuthuswamyNo ratings yet

- Adhesive TapeDocument1 pageAdhesive TapeMuthuswamyNo ratings yet

- 01 Iboco2Document1 page01 Iboco2MuthuswamyNo ratings yet

- Adhesive Tape 2Document1 pageAdhesive Tape 2MuthuswamyNo ratings yet

- Dupont ZYTEL70G33L Material DataDocument4 pagesDupont ZYTEL70G33L Material DataMuthuswamyNo ratings yet

- MicrometerDocument2 pagesMicrometerMuthuswamyNo ratings yet

- Manufacturer of Extension, Torsion & Compression Springs in Satara, MaharashtraDocument5 pagesManufacturer of Extension, Torsion & Compression Springs in Satara, MaharashtraMuthuswamyNo ratings yet

- OSHA Exposure To LeadDocument2 pagesOSHA Exposure To LeadMuthuswamyNo ratings yet

- Adhesive Tape 1Document1 pageAdhesive Tape 1MuthuswamyNo ratings yet

- Shelf Life Document For Medical Grade TPU - FinalDocument3 pagesShelf Life Document For Medical Grade TPU - FinalMuthuswamyNo ratings yet

- An Engineers Guide To Specify The Right ThermoplasticDocument63 pagesAn Engineers Guide To Specify The Right ThermoplasticChithiran CullenNo ratings yet

- Geza MaroczyDocument1 pageGeza MaroczyMuthuswamyNo ratings yet

- Plastic Material Selection GuideDocument7 pagesPlastic Material Selection GuideThanachai TengjirathanapaNo ratings yet

- Halogen FreeDocument8 pagesHalogen FreeMarko IvanečkiNo ratings yet

- How To Save Tax For Fy 2018 19 PDFDocument45 pagesHow To Save Tax For Fy 2018 19 PDFsenthilkumarkskNo ratings yet

- CPS Boards Drive Visual ManagementDocument1 pageCPS Boards Drive Visual ManagementMuthuswamyNo ratings yet

- TDS - On - Salary 2018-19Document84 pagesTDS - On - Salary 2018-19Jitender BhardwajNo ratings yet

- 6 Big Losses PresentationDocument21 pages6 Big Losses PresentationMuthuswamyNo ratings yet

- Polo-Ebrochure May 2018 PDFDocument17 pagesPolo-Ebrochure May 2018 PDFMuthuswamyNo ratings yet

- VW Polo India-EbrochureDocument17 pagesVW Polo India-EbrochurecolourhutNo ratings yet

- MDP Module 2Document84 pagesMDP Module 2ADITYA RAJ CHOUDHARYNo ratings yet

- Tutorial Chapter 1 Thermochemistry QuestionsDocument4 pagesTutorial Chapter 1 Thermochemistry Questionssiti nur masyitah nasaruddinNo ratings yet

- L. M. Greenberg - Architects of The New Sorbonne. Liard's Purpose and Durkheim's RoleDocument19 pagesL. M. Greenberg - Architects of The New Sorbonne. Liard's Purpose and Durkheim's Rolepitert90No ratings yet

- QBD Dry PowdersDocument13 pagesQBD Dry PowdersTausif AlamNo ratings yet

- Hve r13Document1 pageHve r13aleem_201sNo ratings yet

- E-Ship Assignment 2 Utkarsh Surjey MBA-FT-EDocument3 pagesE-Ship Assignment 2 Utkarsh Surjey MBA-FT-Eutkarsh surjeyNo ratings yet

- LPDocument5 pagesLPHeizyl ann VelascoNo ratings yet

- Identifying The Orders of AR and MA Terms in An ARIMA ModelDocument11 pagesIdentifying The Orders of AR and MA Terms in An ARIMA ModelNeha GillNo ratings yet

- Tema Line Solutions BrochureDocument8 pagesTema Line Solutions BrochureUmair Mushtaq SyedNo ratings yet

- UID Module Wise TopicsDocument3 pagesUID Module Wise TopicsPavan KumarNo ratings yet

- MSC Dissertation Gantt ChartDocument6 pagesMSC Dissertation Gantt ChartProfessionalPaperWritingServiceUK100% (1)

- I/O Buffer Megafunction (ALTIOBUF) User GuideDocument54 pagesI/O Buffer Megafunction (ALTIOBUF) User GuideSergeyNo ratings yet

- Vidya Mandir Public School Class 11 Computer Science String Assignment SolutionsDocument5 pagesVidya Mandir Public School Class 11 Computer Science String Assignment SolutionsArun SharmaNo ratings yet

- Operation and Maint Manual Swill Hydraulic PlateformDocument16 pagesOperation and Maint Manual Swill Hydraulic Plateformmicell dieselNo ratings yet

- Agricrop9 ModuleDocument22 pagesAgricrop9 ModuleMaria Daisy ReyesNo ratings yet

- G8 - Light& Heat and TemperatureDocument49 pagesG8 - Light& Heat and TemperatureJhen BonNo ratings yet

- ASM Product Opportunity Spreadsheet2Document48 pagesASM Product Opportunity Spreadsheet2Yash SNo ratings yet