Professional Documents

Culture Documents

Manual Wiltec 3/1 Macerator Toilet Pump System Article 50741

Uploaded by

Titu A FaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Wiltec 3/1 Macerator Toilet Pump System Article 50741

Uploaded by

Titu A FaCopyright:

Available Formats

Manual

WilTec 3/1 Macerator Toilet Pump System

Article 50741

Read and follow the operating instructions and safety information before using for the first time.

Technical changes reserved!

Due to further developments, illustrations, functioning steps and technical data can differ insignifi-

cantly.

Updating the documentation

If you have suggestions for improvement or have found any irregularities please contact us.

© by WilTec Wildanger Technik GmbH Seite 16

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de

The information contained in this document is subject to change without prior notice. No part of this

document can be copied or duplicated in another form without the prior written consent of WilTec Wil-

danger Technik GmbH. The WilTec Wildanger Technik GmbH assumes no liability for any errors in

this user manual or the connection diagram.

Although WilTec Wildanger Technik GmbH has made every effort to make sure that this user manual

is complete, accurate and updated, errors cannot always be avoided. In the event of problems with

this user manual please complete and send this form back to us.

FAX-notification (+++49 2403 55592-15),

from: ________________________________________

Name: ________________

Firm:_____________________

Tel/Fax:__________________

I would like to report the following mistakes:

___________________________________________________________________

Customer Service WilTec Wildanger Technik GmbH

e-mail: service@WilTec.info

Tel:++ +49 2403 55592-0

Introduction

Thank you for purchasing this quality product. To minimize the risk of injury by means of fire or

electric shock we urge that our clients take some basic safety precautions when using this

device. Please read the operation instructions carefully and make sure you have understood its

content.

Always use a grounded power connection with the appropriate mains voltage. You can find the corre-

sponding mains voltage on the type plate. If you have any doubts about the connection being

grounded, have it checked by a qualified professional. Never use a faulty electric cable.

Do not inspect the electrical part of the pressure pond filter in a wet or damp environment or when you

are wet yourself and protect it from direct sunlight. Install this device in a safe location so that nobody

can step on the cable, fall over or damage it. Disconnect the power plug before cleaning it and use

only a damp cloth for cleaning. Avoid using cleaning agents and make sure that no liquid enters the

electrical part of the pump.

The electric part of the device contains no parts that can be inspected or serviced by the user. Leave

the maintenance, adjustment and repair to qualified technical personnel. In case of unauthorised inter-

vention the 2-year warranty is no longer valid! Keep these operation instructions safe.

© by WilTec Wildanger Technik GmbH Seite 17

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de

The user is responsible for the compliance with location specific safety and installing regula-

tions. (Ask an electrician).

Consequential damage arising from flooded rooms caused by dysfunctions of the appliance

must be avoided by means of the appropriate measures. (installing an alarm system, reserve

pump).

In case of malfunction the repair work can be carried out only by a qualified electrician or the

WilTec-service.

The appliance must not run dry or with a completely closed intake port. The manufacturer’s

guarantee is no longer valid if the damage is caused by dry running.

The unit cannot be used for swimming pools.

The device cannot be employed for potable water circuits.

The conveyance of aggressive fluids like abrasive liquids must be avoided.

The pump must be protected against frost.

The pump must be protected from run drying.

WARNING:

Read carefully all the safety guidelines and instructions. Non-compliance with the safety rules and

regulations can lead to an electric shock, fire and/or serious injury.

Keep the instructions and the safety guidelines in a safe place in case you need them in the future.

Stability

To ensure the macerator’s long working life, the user should make sure that only organic toilet sew-

age, water and toilet paper are removed with the toilet waste pump. The max. temperature of the

pumped fluid should not exceed +50°C in permanent operation.

This pump must not transport flammable, gas-emitting or explosive liquids. It cannot be used for other

fluids, like fuels, cleaning agents and other chemical products!

Installation

The macerator is installed according to the EN-12056-4 directive.

The unit can be operated on every standard toilet with a horizontal outflow. The midpoint of the hori-

zontal drainage must comply with the EU-Standard: 18cm above the floor (Rohrbau/pipework: 18cm

above the ground according to FFB).

If a washing machine is connected to the macerator, the drainage pipe/hose must not be directly con-

nected to the macerator but it has to be led/coupled via a vented pipe system. If connected directly to

the macerator, the collecting tank may crack and this does not fall under warranty.

ATTENTION:

Pay attention when installing the unit, the pump must not be mounted freely suspended from

the pressure pipe or the power cable.

© by WilTec Wildanger Technik GmbH Seite 18

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de

Functional principle

The macerator comprises a tank that storages the waste water and an electrical pump which is auto-

matically controlled and operated via a pressure switch.

The conveying/transporting function is activated when the flushing is operated, just like in the case of a

normal toilet.

The substances to be removed by pumping are collected in the tank (A). The air chamber (B) meas-

ures the air pressure that flows through the pipe (C) in order to activate/operate the pressure switch

(D). The pressure switch starts the engine (E) that activates the turbine (F). The sewage is transported

and removed through the outlet (G).

This mechanism is easy and the unit is made of high quality materials. The operating principle is

based on a proven concept.

Control Component

1 Pressure Switch

Mechanism Components

- 1 electric motor

- 1 turbine

Control components and safety device

- 1 manual override switch

- 1 Check valve

© by WilTec Wildanger Technik GmbH Seite 19

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de

Discharging the toilets

d) Connect the horizontal departure of the toilet bowl with the rubber cuff of the pump system

and stretch the connection with the enclosed bell. Take care that you if necessary use a

lubricant, so that the rubber connection does not break.

e) Join the drain pipe with the rubber connection piece, the pipe should have a diameter of

40 or 32 mm. Seal the connection with the clamping piece.

Check the installation of the non-return valve

f) If the sewage should be transported / pumped upwards install the non-return valve as

close as possible to the macerator.

Discharging waste form toilet and other appliances

Connect the discharge pipes of the other appliances to the rubber connectors provided and clamp with

the pipe.

For bath or shower waste water, check that the slope from the Siphon has a gradient of at least 1 cm

per meter so that the waste flows by gravity to the Macerator. If other appliances are connected along

the discharge line near to the macerator, install check valves on their discharge pipes in order to pre-

vent waste return.

The slope of the horizontal parts of the discharge line must have a gradient of 1 cm per meter.

Pressure switch inspection

Plug the pressure tap chamber located in the rubber tank, press it down to create pressure and listen

to hear if there is a click indicating that the motor has switched on. If there is no click, also that the air

chamber of the pressure switch pipe nozzle does not leak.

If the appliance is switched on, the motor should start running.

Before performing this operation, check that the opening or inside of the pressure tap chamber are not

blocked.

© by WilTec Wildanger Technik GmbH Seite 20

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de

Review the pressure switch

You trim this one to fastenings in the rubber container at, you push the excrement tank to below,

around pressure to in the inner one you produce and pay attention on this, whether you hear a click

noise. Clicking is switching the push button switch, this means that the engine would start. If you do

not hear any click noise, you make sure that the air cell of the push button switch pipe does not have

any leak or the excrement tank is leaky.

One can by also easy the push button switch puffs into the transparent tube, which leads to the push

button switch trigger, one hears, one the switch switches and the engine must call if click. No water

may be in the transparent tube and the push button switch! Otherwise push button switches dry or

replace.

Cleaning the unit

The toilet pump macerator must be cleaned from the outside only with mild cleaning agents like damp

cloth and soapy water. Damage caused by inappropriate cleaning agents does not fall under warranty.

Installing possibilities:

© by WilTec Wildanger Technik GmbH Seite 21

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de

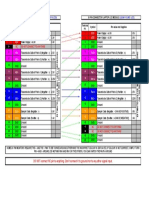

Troubleshooting

This device is only suitable for removing faeces and toilet paper. Perhaps, other small constituent can

be pumped; bigger constituents can clog the pump. This is the main reason for malfunctions that is

encountered by our customer service.

The appliance works but Causes Remedies

Is not powerful enough or too Discharge pipes too long or too Recalibrate the pipes

slow to discharge the waste high

Discharge pipe diameter too Recalibrate the pipes

small

Partial blockage Actuate the pump with manual

override switch. If the problem

persists, the pump must be

blocked check the pump

Emits a humming noise but Pump blocked Check the pump

does not discharge the waste Check valve installed the wrong Reinstall it the right way round

way round

Starts running and discharging Check valve defect Check the valve

accidentally Leak in the flushing tank that Repair the leak

causes water to flow into the

macerator and sets it running

intermittantly

Runs continually Vertical discharge without Install the check valve

cecke valve

Check valve defect Check the valve

Pressure switch defect Check the pressure switch

No humming noise Electrical connection defect Check the connection

Pressure switch Press the manual override

Motor switch several times, if the ap-

pliance starts running check the

electrical connection of the

pressure switch line. Pressing

the manual override switch has

no effect. Check the motor

Detailed error descriptions and solutions

Residual water in the shower

Should order the lifting equipment at the discharge of waste water turns clean the feeding waste water

line have a slope of at least 2-3% and a height difference of at least 20cm from the siphon to the en-

trance of the pumping system .

This is both necessary so that the pressure switch in the toilet lift system works properly, the lifting unit

turns on and pumps out the water. Possible error if this is not taken into account is that the lifting sta-

tion does not empty the water or getting into the shower tray is too high residual in the pipes or possi-

bly back .

© by WilTec Wildanger Technik GmbH Seite 22

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de

Loud noises , engine running or not hard at , water is not discharged

These are the symptoms of a blockage of the lifting system .

If the system is clogged with toilet paper and faeces , it is sufficient in most cases , carefully rinse the

system backwards with water. To do that, the output of the lifting station just a little water pressure, eg

so that the residues are flushed out of the pump body back to the lifting unit with a garden hose.

Please make sure that no water pressure comes on the collection of the lifting system. Otherwise, the

pressure switch of the lifting unit is damaged and the automatic on / off does not work properly any-

more .

With stronger obstructions / blockages by solid bodies that have jammed in the pump body , an open-

ing of the pump may be necessary so that the solids can be removed.

For strong shocks through the solids in the pumping system , it may even happen that the motor bear-

ings damaged. In this case, the motor of the lifting unit must be opened and the bearing be replaced.

This error is usually expressed after removing or flushing of larger solids. The lifting unit can then be

rotated by hand still free, but once you try to start the engine it blocked and only hums .

The flushing out of the lifting equipment requires no technical knowledge . Opening for cleaning should

be left to a qualified technician . In this case, you can contact us happy . We will then prompt you to

clean the lifting plant thoroughly and send it to our workshop.

Pump system does not pump out and is in the jog

This problem occurs with macerators (toilet pump systems), which were shut down (no electrical pow-

er) but still supplied water; pressurized wastewater from a dishwasher or washing machine was sup-

plied, or it had more intake water than the pump could convey. As a result the pump system was

"overfilled".

In this connection it can happen, that water penetrates in the pressure switch of the macerator and its

proper functioning is impaired. Then the toilet pump system either runs permanently or no longer

switches on automatically. This problem can be quickly solved and does not affect the guarantee.

You should proceed as follows

1. Disconnect the macerator from the mains voltage (pull out the plug).

2. Release the two screws (narrow sides) from the cover lid of the macerator

and remove it. (the cover)

3. Empty the small transparent hose which connects the big "tank" with the small black "control box".

Dry up the pressure switch in the small black box. (put it on the heating system or in the sun.)

4. After it had dried up, assembly the unit again in the reverse order.

5. Put the macerator into operation.

If you do not trust yourself to carry out this work, our technical service can do this for you. However I

would like to remind you that this case of malfunction does not fall under manufacturer’s warranty and

the costs for work and transportation will be borne by the customer.

© by WilTec Wildanger Technik GmbH Seite 23

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de

Partlist

1 Push Button (50741-2)

2

3 Cover Lide Case Box (50741-4)

4 Screw

5

6 Depressurization float

7 Vent valve

8

9

10 Tank (50741-6)

11 Case box (50741-4)

12 Rubber feet

13 Seal

14 Steel Clamp

15 Drain pipe (plastic / rubber)

16 Steel Clamp

17 Screw

18

19

20

21

22 Engine

23

24

25

26

27

28 Capacitor

29

30

31 Pressure switch (50741-1)

32

33

34

35 Transparent compressed air line (pressure switch)

36 Plastic Clamps

© by WilTec Wildanger Technik GmbH Seite 24

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de

© by WilTec Wildanger Technik GmbH Seite 25

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de

Disposal regulations

EU guidelines regarding the disposal of scrap electric appliances (WEEE, 2002/96/EC) were imple-

mented in the law related to electrical and electronic equipment and appliances.

All WilTec electric devices that fall under the WEEE regulations are labelled with the crossed-out

wheeled waste bin logo. This logo indicates that this electric equipment must not be disposed with the

domestic waste.

The company WilTec Technik GmbH has been registrated in the German registry EAR under the

WEEE-registration number DE45283704.

Disposal of used electrical and electronic appliances

(intended for use in the countries of the European

Union and other European countries with a separate

collection system for these appliances).

The logo on the article or on its packaging points out

that this article must not be treated as normal house-

hold waste but must be disposed to a recycling collec-

tion point for electronic and electrical waste equip-

ment. By contributing to the correct disposal of this

article you protect the environment and the health of

your fellow men. Environment and health are threat-

ened by inappropriate disposal.

Materials’ recycling helps reduce the consumption of raw materials.

Additional information on recycling this article can be provided by your local community, municipal

waste disposal facilities or the store where you purchased the article.

Address:

WilTec Wildanger Technik GmbH

Königsbenden 12 / 28

D-52249 Eschweiler

Important notice:

The reprint or reproduction, even of excerpts, and any commercial use, even in part of this instructions

manual require the written permission of WilTec Wildanger Technik GmbH.

© by WilTec Wildanger Technik GmbH Seite 26

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Oertzen E500 30Document16 pagesOertzen E500 30yulizardNo ratings yet

- Ariston Hot PointDocument84 pagesAriston Hot Pointromanianpaul3033100% (1)

- Washing Machine Manual for Models WNF 7301 WE20 WNF 7321 AE20 WNF 7341 AE20 WNF 7361 AE20Document68 pagesWashing Machine Manual for Models WNF 7301 WE20 WNF 7321 AE20 WNF 7341 AE20 WNF 7361 AE20Afasyr AmicaleNo ratings yet

- Hotpoint Ariston WML 601 Eu PDFDocument48 pagesHotpoint Ariston WML 601 Eu PDFDaliborka Burtić100% (1)

- Operation Instructions Airbrush Compressor AS186: ARTICLE 34208Document9 pagesOperation Instructions Airbrush Compressor AS186: ARTICLE 34208njaydopeNo ratings yet

- Instructions for use Washing MachineDocument36 pagesInstructions for use Washing MachinegsaviNo ratings yet

- Lavadora Hotpoint Ariston WMG 922b InstruccionesDocument72 pagesLavadora Hotpoint Ariston WMG 922b InstruccionesCristina Parra LópezNo ratings yet

- Instructions for use WASHING MACHINEDocument60 pagesInstructions for use WASHING MACHINETiberiu IonescuNo ratings yet

- Wash machine quick start guideDocument8 pagesWash machine quick start guidetibi_sandorNo ratings yet

- Washing Machine EssentialsDocument52 pagesWashing Machine EssentialsAgustnNo ratings yet

- valveIT Storage and Maintainance Generic PDFDocument5 pagesvalveIT Storage and Maintainance Generic PDFsami maNo ratings yet

- Class 430 / 630: Operation InstructionsDocument7 pagesClass 430 / 630: Operation InstructionsFernanda Novoa VelozoNo ratings yet

- Hotpoint FMSF 702 enDocument24 pagesHotpoint FMSF 702 engabi_george_1No ratings yet

- Adaptable Waste Pump For Toilet: WarningDocument7 pagesAdaptable Waste Pump For Toilet: WarningJason TingNo ratings yet

- GB It FR PL Es PTDocument72 pagesGB It FR PL Es PTcristinacristeNo ratings yet

- Washing machine instructionsDocument28 pagesWashing machine instructionsИван АлексиевNo ratings yet

- Bosch Washing Machine WAS32461GB 90004608573Document6 pagesBosch Washing Machine WAS32461GB 90004608573David GoldNo ratings yet

- GB FR de Es PT TR PDFDocument72 pagesGB FR de Es PT TR PDFfaac88No ratings yet

- Instructions For Use: Washing MachineDocument24 pagesInstructions For Use: Washing MachineOliver ZsokNo ratings yet

- Gorenje Washing Machine User Manual PDFDocument32 pagesGorenje Washing Machine User Manual PDFNoel Fernando67% (3)

- GB CZ Hu Ro Eu Ua RuDocument84 pagesGB CZ Hu Ro Eu Ua RuNegoescu Mihai CristianNo ratings yet

- GB de CZ EuDocument60 pagesGB de CZ EuConstantin AndreeaNo ratings yet

- User Guide Hotpoint WMSD 723Document36 pagesUser Guide Hotpoint WMSD 723Andreea PatricheNo ratings yet

- BDW 209 Dishwasher InstructionsDocument12 pagesBDW 209 Dishwasher InstructionsClaudiu Anton VitanNo ratings yet

- Instructions For Use: Washing MachineDocument32 pagesInstructions For Use: Washing MachineSoowkskkadjj DidiwkwjaoNo ratings yet

- Masina de Spalat - WML 621Document48 pagesMasina de Spalat - WML 621Budulan RaduNo ratings yet

- Instructions For Use: Washing MachineDocument72 pagesInstructions For Use: Washing MachineAdriana OlteanuNo ratings yet

- Quick Install and Use GuideDocument72 pagesQuick Install and Use GuideSandraBorja-SantosNo ratings yet

- Uk Usa Aus Hu CZ Eu Ro ItDocument72 pagesUk Usa Aus Hu CZ Eu Ro ItDani StoianNo ratings yet

- Sanicom & Sanitop Installation GuideDocument9 pagesSanicom & Sanitop Installation GuideSimona Maria PruteanuNo ratings yet

- 1 - 2820522086 Lavadora BekoDocument72 pages1 - 2820522086 Lavadora BekocesarNo ratings yet

- Hotpoint Ariston 846Document48 pagesHotpoint Ariston 846Rock'n Rose CoutureNo ratings yet

- Hotpoint-Ariston RSG 825 JSDocument72 pagesHotpoint-Ariston RSG 825 JSAlin BalasoiuNo ratings yet

- Quick guide to installing and using washing machineDocument24 pagesQuick guide to installing and using washing machinejoanae_borgesNo ratings yet

- Masina Za Ves - UputstvoDocument84 pagesMasina Za Ves - UputstvoHamza MavricNo ratings yet

- WML 803Document24 pagesWML 803giorgos1978No ratings yet

- Operation Manual: To Be Read Carefully Before Start-Up!Document17 pagesOperation Manual: To Be Read Carefully Before Start-Up!FOXX AHMNo ratings yet

- Beko WMB 51021 SDocument52 pagesBeko WMB 51021 SEmbyAnandaNo ratings yet

- Gorenje WS53125Document32 pagesGorenje WS53125Mihai TatuNo ratings yet

- Ariston WMD 763 Mosógép PDFDocument48 pagesAriston WMD 763 Mosógép PDFAdam RajczyNo ratings yet

- Spitwater 10120Document11 pagesSpitwater 10120Brendon Stanley100% (1)

- Oil Free Vacuum Pump ManualDocument27 pagesOil Free Vacuum Pump ManualMartin Fco EncinasNo ratings yet

- Washing Machine: WL712HDW User ManualDocument28 pagesWashing Machine: WL712HDW User ManualNelson BantoloNo ratings yet

- FUST NOVOMATIC 1268.3_051306Document27 pagesFUST NOVOMATIC 1268.3_051306Asemota OghoghoNo ratings yet

- Wash machine installation guideDocument12 pagesWash machine installation guideValentin IlieNo ratings yet

- 3 Manuel BTA-5160220-000-01Document16 pages3 Manuel BTA-5160220-000-01louis666frNo ratings yet

- (En) Masina de Spalat Zanussi ZWF 185W - ManualDocument29 pages(En) Masina de Spalat Zanussi ZWF 185W - Manualziggo88No ratings yet

- Gorenje Wa 50120Document28 pagesGorenje Wa 50120Simina SpiridonNo ratings yet

- DC68-04480M-00 IB Dryer DV5000C D.LED ENDocument28 pagesDC68-04480M-00 IB Dryer DV5000C D.LED ENWinstonNo ratings yet

- PureFlo 6, 12 & 18 Installation and OperationDocument19 pagesPureFlo 6, 12 & 18 Installation and OperationDesy HelnandaNo ratings yet

- User Manual Electrolux Ew878fDocument21 pagesUser Manual Electrolux Ew878fwidhiantoNo ratings yet

- Hotpoint-Ariston ARXXL 105Document60 pagesHotpoint-Ariston ARXXL 105Florentina NichitovNo ratings yet

- Im0902-He0406-04 He20 30 40 60 80 12 ProgramsDocument80 pagesIm0902-He0406-04 He20 30 40 60 80 12 Programsdaovanthanh_bk200775% (4)

- Dryer Secadora Asciugatrice Secador: Downloaded From Manuals Search EngineDocument56 pagesDryer Secadora Asciugatrice Secador: Downloaded From Manuals Search EnginecopsimanNo ratings yet

- Tài liệu lắp đặt máy giặt vắt công nghiệp MWHEDocument82 pagesTài liệu lắp đặt máy giặt vắt công nghiệp MWHEÁnh Dâu100% (1)

- Samsung Wf8604ng-02607a EnxeuDocument36 pagesSamsung Wf8604ng-02607a EnxeuijsmckayNo ratings yet

- Advanced Plumbing Techniques: A Comprehensive Guide to Tackling Complex Projects for the DIY Enthusiast: Homeowner Plumbing Help, #3From EverandAdvanced Plumbing Techniques: A Comprehensive Guide to Tackling Complex Projects for the DIY Enthusiast: Homeowner Plumbing Help, #3No ratings yet

- 001 - DNG SeriesDocument62 pages001 - DNG SeriesTitu A FaNo ratings yet

- Ricetta - Sugar WashDocument2 pagesRicetta - Sugar WashTitu A FaNo ratings yet

- Distillation - How It WorksDocument8 pagesDistillation - How It WorksOmar KallufNo ratings yet

- StillDragon The Gin Basket Operation Manual v1 1 20140116Document46 pagesStillDragon The Gin Basket Operation Manual v1 1 20140116draganNo ratings yet

- Moonlight & Roses PDFDocument63 pagesMoonlight & Roses PDFTitu A FaNo ratings yet

- Palatable spirit from palatable fermentationsDocument3 pagesPalatable spirit from palatable fermentationsArren HawksworthNo ratings yet

- L 025wnotesDocument10 pagesL 025wnotesTitu A FaNo ratings yet

- L 025Document2 pagesL 025Titu A FaNo ratings yet

- GinDocument22 pagesGinTitu A FaNo ratings yet

- The Joint Rolling HandbookDocument66 pagesThe Joint Rolling HandbookRomascu AlexandruNo ratings yet

- Liber 31: Sacred Texts ThelemaDocument18 pagesLiber 31: Sacred Texts ThelemaZoth Bernstein100% (1)

- Going Electric: The Magazine For Hobby DistillersDocument10 pagesGoing Electric: The Magazine For Hobby DistillersTitu A FaNo ratings yet

- Books For Magic BeginnersDocument2 pagesBooks For Magic BeginnersNeena ThurmanNo ratings yet

- L 010Document2 pagesL 010Titu A FaNo ratings yet

- L 003Document3 pagesL 003Titu A FaNo ratings yet

- L 021Document4 pagesL 021Titu A FaNo ratings yet

- (Survival - Text) - Plants - Edible and Medicinal Plants (T-Y)Document9 pages(Survival - Text) - Plants - Edible and Medicinal Plants (T-Y)cleverizedNo ratings yet

- 14 Chapter 11 - Virtue and The Soul in Greek and Gnostic TeachingDocument15 pages14 Chapter 11 - Virtue and The Soul in Greek and Gnostic TeachingTitu A FaNo ratings yet

- Benjamin Rowe - The Essential Skills of MagickDocument12 pagesBenjamin Rowe - The Essential Skills of MagickMwagaVumbiNo ratings yet

- ReadmeDocument1 pageReadmeTitu A FaNo ratings yet

- L 335Document20 pagesL 335Titu A FaNo ratings yet

- British Legal SystemDocument7 pagesBritish Legal SystemValentin TriponescuNo ratings yet

- Liber A'ash Vel Capricorni PDFDocument6 pagesLiber A'ash Vel Capricorni PDFibarzabalNo ratings yet

- (Health) Natural Remedies For Toothache and GumDocument4 pages(Health) Natural Remedies For Toothache and Gumcleverized100% (1)

- (Health) Natural Remedies For Toothache and GumDocument4 pages(Health) Natural Remedies For Toothache and Gumcleverized100% (1)

- L 120v3Document10 pagesL 120v3Titu A FaNo ratings yet

- L 341Document4 pagesL 341Titu A FaNo ratings yet

- Acwk-V3 As2Document123 pagesAcwk-V3 As2Titu A FaNo ratings yet

- Supreme Court: Arsenio C. Villalon, Jr. For Petitioner. Labaguis, Loyola, Angara & Associates For Private RespondentDocument43 pagesSupreme Court: Arsenio C. Villalon, Jr. For Petitioner. Labaguis, Loyola, Angara & Associates For Private RespondentpiaNo ratings yet

- Accounting for Business CombinationsDocument52 pagesAccounting for Business CombinationsEliza BethNo ratings yet

- LCD PinoutsDocument1 pageLCD PinoutsPablo Daniel MagallanNo ratings yet

- PRACTICA (1) (1) - Páginas-2-4Document3 pagesPRACTICA (1) (1) - Páginas-2-4EDDY POLICARPIO BRAVO HUAMANINo ratings yet

- JKM320PP-72 305-320 Watt Poly Crystalline Solar Module Technical SpecificationsDocument2 pagesJKM320PP-72 305-320 Watt Poly Crystalline Solar Module Technical SpecificationsRonal100% (1)

- PSE Archery2015 RecurveDocument10 pagesPSE Archery2015 RecurvecarlheindlNo ratings yet

- ABB Surge Arrester POLIM-H SD - Data Sheet 1HC0075860 E02 ABDocument4 pagesABB Surge Arrester POLIM-H SD - Data Sheet 1HC0075860 E02 ABHan HuangNo ratings yet

- Vodacom Fibre - Application Form CPD - 23 August 2018Document8 pagesVodacom Fibre - Application Form CPD - 23 August 2018Mla Emmanuel ZondoNo ratings yet

- Municipal Profile of Umingan, PangasinanDocument51 pagesMunicipal Profile of Umingan, PangasinanGina Lee Mingrajal Santos100% (1)

- Binders For: Architectural CoatingsDocument8 pagesBinders For: Architectural CoatingsAPEX SON100% (1)

- Police Report Hearing RightsDocument7 pagesPolice Report Hearing RightsYatn BangadNo ratings yet

- DSRD Ar05Document132 pagesDSRD Ar05djon888No ratings yet

- Ram SAP MM Class StatuscssDocument15 pagesRam SAP MM Class StatuscssAll rounderzNo ratings yet

- LeCroy 1996 Catalog (Reduced Size) PDFDocument196 pagesLeCroy 1996 Catalog (Reduced Size) PDFpetrocelliNo ratings yet

- Tipster Job AdvertDocument3 pagesTipster Job AdvertDatateq ConsultancyNo ratings yet

- Research On HIBADocument9 pagesResearch On HIBAPixel GeekNo ratings yet

- FCPP Fiberglass Coated ConcreteDocument20 pagesFCPP Fiberglass Coated ConcretemahdiNo ratings yet

- Blueprint of Banking SectorDocument33 pagesBlueprint of Banking SectormayankNo ratings yet

- FLIX Booking 1068813091Document2 pagesFLIX Booking 1068813091Pavan SadaraNo ratings yet

- Ligot v. MathayDocument1 pageLigot v. MathayJoyce BaylonNo ratings yet

- CH 15 QuizDocument8 pagesCH 15 QuizNelano EastNo ratings yet

- DC Motor Load Characteristics ExperimentDocument6 pagesDC Motor Load Characteristics Experimentbilalkhan3567No ratings yet

- Nursing Grand Rounds Reviewer PDFDocument17 pagesNursing Grand Rounds Reviewer PDFAlyssa Jade GolezNo ratings yet

- Global CityDocument3 pagesGlobal Citycr lamigoNo ratings yet

- REMMLOTDocument53 pagesREMMLOTarpit saraswat100% (1)

- Balcony AnalysysDocument4 pagesBalcony AnalysysKory EstesNo ratings yet

- Case 14. G.R. No. 144104 Lung Center of The Phil V. Ortigas G.R. No. 144104 June 29, 2004Document2 pagesCase 14. G.R. No. 144104 Lung Center of The Phil V. Ortigas G.R. No. 144104 June 29, 2004Jay Kent RoilesNo ratings yet

- ERecon Software Development at Hospital Corporation of America-1553395398 PDFDocument11 pagesERecon Software Development at Hospital Corporation of America-1553395398 PDFKaren CarranzaNo ratings yet

- LSRetailDataDirector UserGuideDocument89 pagesLSRetailDataDirector UserGuideRock Lee60% (5)

- Spirax-Sarco - Boiler Controls and SystemsDocument8 pagesSpirax-Sarco - Boiler Controls and SystemstpqnhatNo ratings yet