Professional Documents

Culture Documents

SOP Pile Load Test PDF

Uploaded by

Soigne ConsultantsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP Pile Load Test PDF

Uploaded by

Soigne ConsultantsCopyright:

Available Formats

SOIGNE ENGINEERING CONSULTANTS

SCF 23, MM, MANIMAJRA, CHANDIGARH (U.T.)

Contact: 0172-4007236, +91 98761 67299

Website : www.soigneconsult.com

Email: info@soigneconsult.com

Doc No. SEC/DOC/XX PILE LOAD TEST PROCEDURE Section No.:

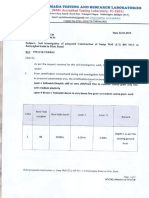

1. Purpose : To lay down the procedure for ascertain capacity of Pile by conducting load tests.

2. Scope : This standard (Part 4) covers the load test on all types of piles covered in

IS: 2911 (Part me /Sec 1).1979,

IS: 2911 (Part l/Sec 2)-1979,

IS: 2911 (Part l/Sec 3)-1979,

IS: 2911 (Part me /Sec 4)-198411,

IS: 2911 (Part 2)-1980 and

IS: 2911 (Part 3) 1980.

3. Responsibility: Site Engineer

4. Procedure

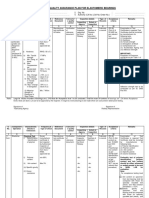

4.1. Vertical Load Test (Compression) :

General

In this type of test, compression load is applied to the pile top by means of a hydraulic

jack against rolled steel joist or suitable load frame capable of providing reaction and the

settlement is recorded by suitably positioned dial gauges.

Preparation of Pile Head

The pile bead should be shipped off to natural horizontal plane till sound concrete is met.

The projecting reinforcement should be cut off or bent suitably and the top finished

smooth and level with plaster of Paris or similar synthetic material where required.

A bearing plate with a hole at the centre should be placed on the head of the pile for

the jacks to rest.

Application of Load

Issue Date: 01.02.2019 Rev. No.: 00 Rev. Date: Nil Page 1 of 5

Prepared By: QM Approved By: Director

SOIGNE ENGINEERING CONSULTANTS

SCF 23, MM, MANIMAJRA, CHANDIGARH (U.T.)

Contact: 0172-4007236, +91 98761 67299

Website : www.soigneconsult.com

Email: info@soigneconsult.com

Doc No. SEC/DOC/XX PILE LOAD TEST PROCEDURE Section No.:

The test should be carried out by applying a series of vertical downward incremental load

each increment being of about 20% of safe load on the pile. For testing of raker piles it is

essential that loading is along the axis.

Reaction : The reaction may be obtained from the following

Kentledge placed on a platform supported clear of the test pile. In case of load test below

under-pinned structure, the existing structure if having, adequate weight and

suitable, construction may serve as kentledge. The centre of gravity of the kentledge

should generally be on the axis of the pile and the load applied by the jack should also

be coaxial with this pile..

Anchor piles with centre-to-centre distance with the test pile not less than 3 times

the test pile shaft diameter subject to minimum of 2 m, if the anchor piles are

permanent working piles, it should be ensured that their residual uplift is within

limits. Care should be exercised to ensure that the datum bar supports are not

affected by heaving up of the soil.

Rock anchors with distance from the nearest edge of the piles at rock level being 2 times

the test pile shaft diameter or 1.5 m whichever is greater.

The reaction to be made available for the test should be 25% more than the final test

load proposed to be applied.

Settlement

Settlement shall be recorded with minimum 2 dial gauges for single pile and 4 dial gauges

of 0·01 mm sensitivity for groups, each positioned at equal distance around the piles and

normally held by datum bars resting on immovable supports at a distance of 3D (subject

to minimum of 1·5 m) from the edge of the piles, where D is the pile stem diameter

Issue Date: 01.02.2019 Rev. No.: 00 Rev. Date: Nil Page 2 of 5

Prepared By: QM Approved By: Director

SOIGNE ENGINEERING CONSULTANTS

SCF 23, MM, MANIMAJRA, CHANDIGARH (U.T.)

Contact: 0172-4007236, +91 98761 67299

Website : www.soigneconsult.com

Email: info@soigneconsult.com

Doc No. SEC/DOC/XX PILE LOAD TEST PROCEDURE Section No.:

of circular piles or diameter of the circumscribing circle in the case of square or non-

circular piles.

SINGLE PILE : The safe load on single pile for the initial test should be the least of

the following:

Two-thirds of the final load at which the total displacement attains a value of 12

mm unless otherwise required in a given case on the basis of nature and type of

structure in which case, the safe load should be corresponding to the stated total

displacement permissible.

50% of the final load at which the total displacement equal 10% of the pile

diameter in case of uniform diameter piles and 7.5% of bulb diameter in case of

under-reamed piles.

Routine test shall be carried for a test load of at least one and half times the

working load and the maximum settlement of test loading in position being not

exceeding 12 mm.

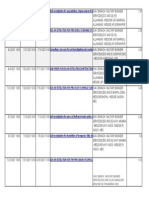

4.2. Lateral Load test on piles :

The test may be carried out by introducing a hydraulic jack with gauge between two piles

or pile groups under test or the reaction may be suitably obtained otherwise. If it is

conducted by jack located between two piles or groups, the full load imposed by the jack

shall be taken as the lateral resistance of each pile or group. The loading should be

applied in increments of about 20 percent of the estimated safe load.

The next increment should be applied after the rate of displacement is nearer to 0·1 mm

per 30 minutes.

Issue Date: 01.02.2019 Rev. No.: 00 Rev. Date: Nil Page 3 of 5

Prepared By: QM Approved By: Director

SOIGNE ENGINEERING CONSULTANTS

SCF 23, MM, MANIMAJRA, CHANDIGARH (U.T.)

Contact: 0172-4007236, +91 98761 67299

Website : www.soigneconsult.com

Email: info@soigneconsult.com

Doc No. SEC/DOC/XX PILE LOAD TEST PROCEDURE Section No.:

Displacements shall be read by using at least two dial gauges of 0·01 mm sensitivity spaced

at 30 cm and kept horizontally one above the other on the test pile and the displacement

interpolated at cut-off level from similar triangles where cut-off level is

unapproachable and for approachable cut-off level, however, one dial gauge placed

diametrically opposite to the jack shall directly measure the displacement. Where is not

possible to locate One of the dial gauges in the line of the jack axes, then two dial gauges

may be kept at a distance of 30 cm at a suitable height and the displacement interpolated

at load point from similar triangles.

Also one dial gauge should be placed on the firm support to verify displacement of the

firm support.

Note - One of the methods for keeping dial gauge on pile surface is to chip off uneven concrete on the

side of the pile and to fix a piece of glass 20 to 30 mm square. The dial gauges tips shall rest on the

central portion of the glass plate.

The safe lateral load on the pile shall be taken as the least of the following:

i. 50% of the lateral load at which the total displacement increase to 12 mm.

ii. Final load at which the total clip corresponds to 5mm.

iii. Load corresponding, to any other specified displacement as per performance requirements

Note - The displacement is at the cut-off level of the piles.

4.3. Pull Out test on the piles :

Uplift force may preferably be applied by means of hydraulic jack(s) with gauge using a

suitable pull-out set up.

Note - One of the method for pull out test that may be used is where hydraulic jack is made to rest on

rolled steel joint(s) resting on two supports on the ground. The jack reacts against a frame attached to the

Issue Date: 01.02.2019 Rev. No.: 00 Rev. Date: Nil Page 4 of 5

Prepared By: QM Approved By: Director

SOIGNE ENGINEERING CONSULTANTS

SCF 23, MM, MANIMAJRA, CHANDIGARH (U.T.)

Contact: 0172-4007236, +91 98761 67299

Website : www.soigneconsult.com

Email: info@soigneconsult.com

Doc No. SEC/DOC/XX PILE LOAD TEST PROCEDURE Section No.:

top of the test pile such that when the jack is operated, the pile gets pulled and the reaction is

transferred to the ground through the supports which are at least 2.5 D away from the test pile periphery

(where D is pile stem diameter of circular piles or diameter of the circumscribing circle in the case of

piles. The framework can be attached to the pile top with the reinforcement bars which may be

threaded or to which threaded bolts may be welded. As an alternative if it sometimes preferable to use

a central rod designed to take pile load and embedded centrally in the pile to a length equal to a bond

length load required. It will have threads at top for fixing it to the framework.

For larger loads the number of rods may have to be more and depending on the set-up these may be put

in a line or in any other symmetrical pattern. For routine tests, the framework is normally attached to

the reinforcing bars but a central rod may also be used in case the upper portion of the pile is required to

be built up.

The test pile shall have adequate steel to withstand pulling. In some cases, in order to allow for neck

tension in a pull out test, it may be necessary to provide additional reinforcement in the piles to be

tested.

The pull out load increments and consequent displacement readings shall be read as in the

case of vertical load test. The safe load shall be taken as the least of the following:

i. Two- third of the load at which the total displacement is 12 mm or the load

corresponding to a specified permissible uplift.

ii. Half of the load at which the load-displacement curve shows a clear break (downward

trend).

The initial test shall be carried out up to twice the estimated safe load or until the load

displacement curve shows a clear- break (downward trend).

Routine test shall be carried out to one-end-a-half times the estimated safe load or 12

mm total displacement whichever is earlier.

Issue Date: 01.02.2019 Rev. No.: 00 Rev. Date: Nil Page 5 of 5

Prepared By: QM Approved By: Director

You might also like

- Handbook Bandsaw BladeDocument82 pagesHandbook Bandsaw Bladewisnu_bayusaktiNo ratings yet

- NCC Spherical Bearing Method Statement DraftDocument23 pagesNCC Spherical Bearing Method Statement Draftrohit67% (3)

- PAPER+ +Collapse+of+Soil+in+Pile+Bore+and+Its+Stabilisation+Using+Bentonite+SuspensionDocument9 pagesPAPER+ +Collapse+of+Soil+in+Pile+Bore+and+Its+Stabilisation+Using+Bentonite+SuspensionPrashanth Seshamani Iyer100% (1)

- Manual de Servicio de AgilentDocument100 pagesManual de Servicio de Agilentjonathan_calixto_450% (2)

- Toyota Engine 1grfe 4 0 Repair ManualDocument7 pagesToyota Engine 1grfe 4 0 Repair Manualjames100% (49)

- Methodology - Well Sinking-Foundation PDF-1Document7 pagesMethodology - Well Sinking-Foundation PDF-1Tina J100% (1)

- Pile Load Test ProcedureDocument24 pagesPile Load Test ProcedureRamkumar K100% (4)

- Standard QA Plan (Elastomeric Bearings)Document8 pagesStandard QA Plan (Elastomeric Bearings)ghaghra bridgeNo ratings yet

- 1893-Part 1-2016-1 PDFDocument44 pages1893-Part 1-2016-1 PDFDarshit Vejani100% (3)

- 10 Cold Form SteelDocument24 pages10 Cold Form Steelbernaduscatur100% (1)

- The MAN B&W MC Engine VIT Fuel PumpDocument6 pagesThe MAN B&W MC Engine VIT Fuel PumpRickle Vincent PilongoNo ratings yet

- Pile Load Test Methodology - Kentledge Method - Cyclic-RoutineDocument10 pagesPile Load Test Methodology - Kentledge Method - Cyclic-RoutineHarshit DubeyNo ratings yet

- Pile Load Test Procedure-1Document5 pagesPile Load Test Procedure-1S GoudaNo ratings yet

- Pile Load Test MethodologyDocument4 pagesPile Load Test MethodologyAkhilesh Dwivedi100% (1)

- Amendment No.4 To Is 456-2000Document5 pagesAmendment No.4 To Is 456-2000kalpanaadhiNo ratings yet

- SOP of Pull Out, Lateral & Compression - REV01Document8 pagesSOP of Pull Out, Lateral & Compression - REV01Prince MittalNo ratings yet

- Pile Load Test PDFDocument11 pagesPile Load Test PDFAjit P. SinghNo ratings yet

- Methodology For Verticial Initial Cyclic Load Test by Reaction MethodDocument4 pagesMethodology For Verticial Initial Cyclic Load Test by Reaction MethodvivekNo ratings yet

- Pile - DMC Method PDFDocument19 pagesPile - DMC Method PDFAnonymous Ngcgbh00eNo ratings yet

- 114 - Method Statement For Bored Cast in Situ Pile - R2 PDFDocument42 pages114 - Method Statement For Bored Cast in Situ Pile - R2 PDFDadi YashwantNo ratings yet

- Is.14893.2001 Pile Integrity Test PDFDocument14 pagesIs.14893.2001 Pile Integrity Test PDFParth Patel100% (1)

- Lateral Pile Load Test For PilesDocument8 pagesLateral Pile Load Test For PilesSubrahmanaya S Murthy TATA100% (3)

- A Revolution To Stop Punching of Anchor Cone in PSC Girder 1659263632Document13 pagesA Revolution To Stop Punching of Anchor Cone in PSC Girder 1659263632Sanjay MishraNo ratings yet

- Method Statement For Initial and Routine Load Test - TP1-10.06.2019Document27 pagesMethod Statement For Initial and Routine Load Test - TP1-10.06.2019Manas BeheraNo ratings yet

- DMC PilingDocument19 pagesDMC PilingRaghav AroraNo ratings yet

- TDS - Polyalk CP 293+Document1 pageTDS - Polyalk CP 293+Anonymous ouZFaSBRNo ratings yet

- HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudDocument16 pagesHKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudRajesh GangwalNo ratings yet

- Methodology of Static Pile Load TestDocument33 pagesMethodology of Static Pile Load Testraju_420034520100% (1)

- Pile Load Test: IS: 2911 (Part 4) - 1985 IS: 14893-2001Document5 pagesPile Load Test: IS: 2911 (Part 4) - 1985 IS: 14893-2001Dwijendra Chanumolu100% (1)

- 26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodDocument16 pages26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodpdksubudhiNo ratings yet

- ECO DF Polymer PDFDocument5 pagesECO DF Polymer PDFDeepak GareraNo ratings yet

- Anchor Pile Load Test MethodologyDocument11 pagesAnchor Pile Load Test MethodologyHegdeVenugopal50% (4)

- Chisel N BailerDocument51 pagesChisel N BailerAmine Amroun67% (3)

- Cyclic Pile Load Test (Major Project)Document89 pagesCyclic Pile Load Test (Major Project)vidyaranya_b82% (11)

- Vertical Pile Load Test (Sabarmati Station Building)Document9 pagesVertical Pile Load Test (Sabarmati Station Building)Vipin Kumar ParasharNo ratings yet

- Is - 14687-1999 Falsework For Concrete StructuresDocument27 pagesIs - 14687-1999 Falsework For Concrete StructuresJarrod HarrellNo ratings yet

- Aggregate Impact Value (Is: 2386 (Part-Iv) )Document19 pagesAggregate Impact Value (Is: 2386 (Part-Iv) )ajit karandikarNo ratings yet

- Form Work, Reinforcement & Concreting - MethodologyDocument10 pagesForm Work, Reinforcement & Concreting - MethodologyRabnawaz ImamNo ratings yet

- Initial Load Test ReportDocument8 pagesInitial Load Test Reportarif_rubinNo ratings yet

- Test Pile MethodologyDocument7 pagesTest Pile MethodologyCOME TO KNOWNo ratings yet

- Schedule D - P2 - 14.09.2017Document190 pagesSchedule D - P2 - 14.09.2017Settipalli Ram SuryaNo ratings yet

- Pile Load TestDocument4 pagesPile Load TestRitesh Dahiya100% (1)

- Cast-In-Situ Bored Piling Works by ConventionalMethod1Document11 pagesCast-In-Situ Bored Piling Works by ConventionalMethod1jitendraNo ratings yet

- Bored Piling Pakubumi 2009 MechanicalDocument19 pagesBored Piling Pakubumi 2009 MechanicaljimdabrondNo ratings yet

- Method Statement For Conducting High Strain Dynamic Pile Testing of 1200Mm Dia R.C. Bored PilesDocument6 pagesMethod Statement For Conducting High Strain Dynamic Pile Testing of 1200Mm Dia R.C. Bored PilesFaisal RizwanNo ratings yet

- Method Statement of Routine Pile Load Test (Dynamic)Document3 pagesMethod Statement of Routine Pile Load Test (Dynamic)Akhilesh Dwivedi100% (1)

- Pile Load Test (DSTP)Document10 pagesPile Load Test (DSTP)Nazmul HassanNo ratings yet

- Format Pile Load TestDocument1 pageFormat Pile Load TestUmesh Mishra100% (1)

- What Are The Requirements of Bentonite (Powder and Suspension) Used in Piling Work As Per IS-2911Document2 pagesWhat Are The Requirements of Bentonite (Powder and Suspension) Used in Piling Work As Per IS-2911Pritha DasNo ratings yet

- Indian Standard: Specification For Plain WashersDocument13 pagesIndian Standard: Specification For Plain WashersrahulmechdceNo ratings yet

- Methodology For Emb With Pond AshDocument10 pagesMethodology For Emb With Pond Ashjitendra100% (4)

- Adoption of Geo-Composites in Construction of RE WallsDocument1 pageAdoption of Geo-Composites in Construction of RE WallsVijayakrishna SingamsettiNo ratings yet

- RE Wall DrawingDocument20 pagesRE Wall DrawingSamuel Gezahegn100% (1)

- Appendix - 1800 - III (Sfgop-Tcipc)Document8 pagesAppendix - 1800 - III (Sfgop-Tcipc)kvijayasok100% (1)

- 1786 2012 New Ammendments PDFDocument23 pages1786 2012 New Ammendments PDFS RamakrishnaNo ratings yet

- Well Foundation (Jack Down) - Method Statement-R0!07!08-201Document10 pagesWell Foundation (Jack Down) - Method Statement-R0!07!08-201SurinderPalSinghGillNo ratings yet

- Delhi Metro Paper On MonitoringDocument8 pagesDelhi Metro Paper On MonitoringTarun Kant GoyalNo ratings yet

- Vertical Cyclic Pile Load Test - Lec18Document15 pagesVertical Cyclic Pile Load Test - Lec18Sumit GhoseNo ratings yet

- Dynamic Load Test 1200mm DiaDocument6 pagesDynamic Load Test 1200mm DiaVB665100% (1)

- SP Fashion Fero Scan ReportDocument16 pagesSP Fashion Fero Scan ReportMd SohagNo ratings yet

- 0 Method Statement-Trench Cutter FinalDocument36 pages0 Method Statement-Trench Cutter FinalGobinath GovindarajNo ratings yet

- Method Statement FOR PDA TestDocument3 pagesMethod Statement FOR PDA TestMarivic D. SantosNo ratings yet

- FBDocument5 pagesFBbimal bhandariNo ratings yet

- Astm C78Document3 pagesAstm C78avrajan100% (3)

- Load Test On PilesDocument4 pagesLoad Test On PilesIftiNo ratings yet

- Methodology For Initial Load TestDocument2 pagesMethodology For Initial Load TestAnish PanchalNo ratings yet

- Tendernotice 1Document2 pagesTendernotice 1Soigne ConsultantsNo ratings yet

- E-In-C Branch - Military Engineer Services - Cesc and Ce (Af) Bangalore - Mes - Cwe (Af) Trivandrum - MesDocument1 pageE-In-C Branch - Military Engineer Services - Cesc and Ce (Af) Bangalore - Mes - Cwe (Af) Trivandrum - MesSoigne ConsultantsNo ratings yet

- SR - No. BHL No Depth Site Work Sample Location Testing Status Report StatusDocument1 pageSR - No. BHL No Depth Site Work Sample Location Testing Status Report StatusSoigne ConsultantsNo ratings yet

- DCS Addl Soil Investigation Type II RatnagiriDocument14 pagesDCS Addl Soil Investigation Type II RatnagiriSoigne ConsultantsNo ratings yet

- 114 - (Rainwater Harvesting Throught)Document42 pages114 - (Rainwater Harvesting Throught)Soigne ConsultantsNo ratings yet

- Rajasthan FinalDocument29 pagesRajasthan FinalSoigne ConsultantsNo ratings yet

- Annexure IIDocument1 pageAnnexure IISoigne ConsultantsNo ratings yet

- PRODUCTS Final 1Document133 pagesPRODUCTS Final 1Soigne ConsultantsNo ratings yet

- Navratna Korma, Veg Navratan Korma: IngredientsDocument1 pageNavratna Korma, Veg Navratan Korma: IngredientsSoigne ConsultantsNo ratings yet

- Fee Structure PDFDocument46 pagesFee Structure PDFSoigne ConsultantsNo ratings yet

- Fee Structure PDFDocument46 pagesFee Structure PDFSoigne ConsultantsNo ratings yet

- LetterDocument1 pageLetterSoigne ConsultantsNo ratings yet

- Punjab Government Telephone DirectoryDocument89 pagesPunjab Government Telephone DirectorySurendera M. Bhanot67% (3)

- GmadaDocument1 pageGmadaSoigne ConsultantsNo ratings yet

- Boundary Pillars QuoteDocument2 pagesBoundary Pillars QuoteSoigne ConsultantsNo ratings yet

- Katni SBCDocument7 pagesKatni SBCSoigne ConsultantsNo ratings yet

- Hyd LimePDS v03Document3 pagesHyd LimePDS v03Petros IosifidisNo ratings yet

- NotesDocument1 pageNotesSoigne ConsultantsNo ratings yet

- Boundary Pillars QuoteDocument2 pagesBoundary Pillars QuoteSoigne ConsultantsNo ratings yet

- Hawe PDFDocument262 pagesHawe PDFmadan mohan katta0% (1)

- Nissan Almera Manual PDFDocument276 pagesNissan Almera Manual PDFheartvadorNo ratings yet

- 2015 Frigidaire Laundry Center Service ManualDocument195 pages2015 Frigidaire Laundry Center Service ManualRiks GarcesNo ratings yet

- Bharat Heavy Electricals LTD - Station C & I and MMI-DASDocument5 pagesBharat Heavy Electricals LTD - Station C & I and MMI-DASmandar_paradkarNo ratings yet

- Refrigeration Systems Refrigeration SystemsDocument50 pagesRefrigeration Systems Refrigeration SystemsHafzal GaniNo ratings yet

- Single Disc Sample Grinder Polisher GP-1SDocument2 pagesSingle Disc Sample Grinder Polisher GP-1S周记伟No ratings yet

- Lectures On Kinetic Theory of Gases and Statistical Physics: Alexander A. SchekochihinDocument157 pagesLectures On Kinetic Theory of Gases and Statistical Physics: Alexander A. SchekochihinRoy VeseyNo ratings yet

- Suzuki Ignis Sport Part NumbersDocument58 pagesSuzuki Ignis Sport Part Numbersdimitrisroom20No ratings yet

- Service Bulletin: Washing 2520 - 2530Document16 pagesService Bulletin: Washing 2520 - 2530Łukasz KozlowskiNo ratings yet

- Milling Cutting Speeds & RPM CalculationsDocument3 pagesMilling Cutting Speeds & RPM CalculationsQuilerNo ratings yet

- Question and Answer On Steam TurbinesDocument33 pagesQuestion and Answer On Steam TurbineschunkyNo ratings yet

- Physics 14 HWDocument2 pagesPhysics 14 HWMelody KimNo ratings yet

- Radiation Heat Transfer: Amit KakkarDocument11 pagesRadiation Heat Transfer: Amit KakkarRupesh TiwariNo ratings yet

- Rigging GuideDocument142 pagesRigging GuideJB MadeleineNo ratings yet

- AAPL Capability StatementDocument41 pagesAAPL Capability StatementjsmnjasminesNo ratings yet

- Worksheet No.4 Paper 4Document37 pagesWorksheet No.4 Paper 4Timothy SilvaNo ratings yet

- U DiesDocument1 pageU DiesadrianNo ratings yet

- Classification of CNC Machine ToolsDocument7 pagesClassification of CNC Machine ToolsRajendra Kumar YadavNo ratings yet

- Arctic Cat 2012 150 Service ManualDocument8 pagesArctic Cat 2012 150 Service ManualedwardNo ratings yet

- Capaliiry Flow MethodDocument3 pagesCapaliiry Flow MethodDinesh Kumar MehraNo ratings yet

- Questions and Answers On The Marine Diesel EngineDocument272 pagesQuestions and Answers On The Marine Diesel Enginefarouk100% (1)

- Research of Road Bridge Composite Steel Girder For Different Load ConditionsDocument6 pagesResearch of Road Bridge Composite Steel Girder For Different Load ConditionsHabib Ur RahmanNo ratings yet

- Kinetic Model of Gases: Section 1.3 of Atkins, 6th Ed. Section 24.1 of Atkins, 7th Ed. Section 21.1 of Atkins, 8th EdDocument18 pagesKinetic Model of Gases: Section 1.3 of Atkins, 6th Ed. Section 24.1 of Atkins, 7th Ed. Section 21.1 of Atkins, 8th EdJerome JavierNo ratings yet

- Khan 2000Document18 pagesKhan 2000HIMANSHU YADAVNo ratings yet

- BV2025.en - 2004-041 (WAF 644-1963 Engels)Document72 pagesBV2025.en - 2004-041 (WAF 644-1963 Engels)Rick Van den BosNo ratings yet