Professional Documents

Culture Documents

Simmons PDF

Simmons PDF

Uploaded by

mcnortyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simmons PDF

Simmons PDF

Uploaded by

mcnortyCopyright:

Available Formats

The following article was published in ASHRAE Journal, August 2007.

©Copyright 2007 American Society of Heating, Refrigerating and

Air-Conditioning Engineers, Inc. It is presented for educational purposes only. This article may not be copied and/or distributed electronically

or in paper form without permission of ASHRAE.

Vibration

Isolation

By Robert Simmons, P.E., Member ASHRAE will is many times more.

All mechanical equipment used in

N

o matter how advanced the design, mechanical equipment HVAC&R systems vibrate to some de-

gree. The awareness of vibration prob-

will contribute to objectionable vibration and vibration- lems have increased over recent years for

a number of reasons:

induced noise in buildings. Building owners’ and tenants’ increasing • Economical, lightweight building

construction has replaced the heavy

demand for a comfortable and productive workspace, and the

construction of the past. These more

increased presence of sensitive, high-tech equipment requires flexible buildings are much more

susceptible to transmit and resonate

vibration control issues be considered. This article will examine if, vibration.

• Valuable floor space results in mechan-

why, or when vibration from HVAC&R equipment causes a problem ical systems located in smaller areas

near occupants. The closer proximity

in buildings, and some practical vibration isolation theory and to tenants means greater probability

of complaint. Equipment located on

installation guidelines. flexible above-grade floors results in a

greater risk of vibration transmission.

What’s the Buzz? tion isolator during design and installa- • The link between workplace comfort

We all remember that age old idiom, tion of equipment could prevent much and individual productivity necessi-

“penny wise and pound foolish.” A simi- more costly trouble later. It is not only

lar adaptation of this applies to vibration higher in direct costs to retrofit an isola- About the Author

isolation of typical HVAC&R equipment tion system (as much as 10 times more), Robert Simmons, P.E., is a vice president of engi-

and systems in buildings today. Attention but the cost in downtime, consulting to neering for Amber Booth, A VMC Group Company,

to a relatively small, inexpensive vibra- diagnose a problem, and customer bad Houston and Bloomingdale, N.J.

30 ASHRAE Journal ashrae.org August 2007

tates a noise and vibration-free environment. Classroom noise necessary to achieve a successful installation. All paths must be

criteria also is becoming more stringent as studies show a cut off, since vibration will take the path of least resistance. If one

link between learning and good room acoustics. piece of equipment is not isolated, or the connected pipe is not,

• The high-tech industry with high-precision production equip- then unwanted vibration may bleed through to the structure.

ment has an extremely low tolerance for vibration, so losing The receiver is the building occupant or equipment/process

millions of dollars in defective product caused by vibration that is affected by vibration. Complaints arising from transmit-

is a concern. ted vibration take the form of either a high level of vibration

• Advanced diagnostic or microsurgery medical equipment re- they perceive to be disturbing or alarming, or relatively small

quires a high-fidelity environment with low floor vibration. amounts of energy transmitted to building components (i.e.,

• R&D facilities with precision lasers and electron microscopes walls) that radiate as unacceptable noise. The more critical

require very low floor vibration to operate correctly. the occupant, the greater sensitivity to vibration or vibration

induced noise: vibration control is more critical in a conference

Source—Path—Receiver room or executive office than in a standard office; a hospital is

Vibration control can be broken in to three components: typically more critical than an office building; a concert hall

source, path and receiver. or performing arts center requires very low levels of vibra-

The source is the machinery or system producing the vibra- tion-induced noise; and classroom acoustics are increasingly

tion. Any type of equipment with rotating parts produces vibra- important (especially in early primary education). In today’s

tion. While HVAC equipment manufacturers are consistently high-tech world, vibration in the building interferes with the

improving their products, it is impractical and uneconomical proper operation of sensitive equipment and instruments.

to balance equipment beyond commercial tolerances. The Figure 2 compares acceptable occupant vibration levels with

amplitude of vibration that might be expected from typical expected levels generated by HVAC&R equipment. The source

new equipment maybe as low as 0.08 in./s (0.002 m/s) RMS level can be 10 to 1,000 times greater than acceptable receiver

velocity. Over the life of equipment, depending on the care and levels, depending on the equipment and type of occupancy.

maintenance, the vibration may increase due to normal wear Since the source and the receiver cannot be changed, it is most

(bearing wear, belt misalignment, etc.) to 0.2 in./s to 0.6 in./s practical to cut off the path with an isolation system as shown in

(0.005 to 0.015 m/s). Figure 3. An isolation system is the best inexpensive insurance

The pipe connected to the HVAC&R equipment also can be against unwanted vibration.

a source of vibration. Valves, pumps, pressure reducers, or a

pipe geometry with a number of bends can produce turbulent How Vibration Isolation Works

flow, which can generate enough vibration to exceed occupancy Properly isolated equipment is designed to transmit negli-

tolerance. Vibration from duct is not as common as pipe, but gible vibratory force and prevent the equipment from being

abrupt changes in direction or rough transitions can cause flow considered a problem source. To be assured of proper isola-

pulsations that create a source vibration. Figure 1 illustrates tion, it is necessary to apply the well established principles of

typical vibration sources. vibration control.

The path is the medium through which the vibration is trans- Vibration isolator is defined as a resilient material placed

ferred. Most building components (floors, beams, columns, between the equipment and the structure to create a low natural

walls, etc.) will transmit vibration. Pipe and duct are also very frequency support system for the equipment. Some common

good conduits of vibration. Lighter building construction, materials are elastomeric pads or mounts, helical steel springs,

lightweight roofs, and larger column spans (30+ ft [9 m]) can wire rope springs, and air springs. Often, materials are com-

be more flexible and contribute to easier transmission. The close bined to create desired results. The spring mass schematic in

proximity of valuable commercial space to equipment decreases Figure 4 is the simplified model used to represent equipment

the path length, which increases the likelihood of complaints. mounted on isolators.

Figure 1 demonstrates typical paths. Static deflection is how much the isolator (spring or elasto-

The only sure way to cut off the path of objectionable vibra- meric) deflects under the weight of the equipment. In general,

tion is with an isolation system. Note that a systems approach is larger static deflection gives better isolation.

August 2007 ASHRAE Journal 31

with resistance to fluid or airflow. Shock absorbers on a car

Pipe Transmits and Generates Vibration are an example of viscous damping. During normal equipment

operation, damping tends to reduce the isolator efficiency as

the breaking action transmits force to the structure. However,

during incidental large movements (temporary imbalance,

Structure Borne

Vibration Induced water hammer, temporary resonance, earthquake, etc.), the

by Machinery damping keeps movement from becoming too extreme, and

Airborne Sound out of control. Figure 5 graphically demonstrates the effect

Radiated by

Vibrating Structure of damping.

Objectionable Percent transmissibility, T, is the percentage of the total force

Vibration Transmitted transmitted to the supporting structure through the isolators.

Through Structure

Theoretical percent transmissibility can be calculated from the

formula shown in Figure 5 for damped and undamped isolators.

A steel coil spring can be assumed an essentially undamped

Figure 1: Typical vibration source, path and receiver. isolator. Many isolator materials such as elastomer-type isola-

tors and pad-type isolators possess inherent damping, which

Natural frequency, fn , is the frequency at which a vibration should be considered when using this formula.

isolator will naturally oscillate (bounce) when compressed and Isolation efficiency, E, is equal to 100% minus the percent

quickly released. See Figure 4 for an equation that gives the transmissibility and indicates what percent of the vibratory

natural frequency of a simple spring mass model in cycles per forces will not be transmitted to the supporting structure.

minute (cpm or rpm). Note that higher static deflection gives a Frequency or efficiency quotient, Eq , is equal to fd / fn, Figure

lower natural frequency, which provides better isolation. 5 shows the application of the frequency quotient. The higher

Disturbing frequency, fd , is defined as the lowest frequency of the ratio of the disturbing frequency to the natural frequency of

vibration generated by the equipment. There are usually one or the isolators, the lower the percent transmissibility of the vibra-

two dominant frequencies of vibration produced by equipment. tory forces. Thus, it is sometimes referred to as an efficiency

For example, in a fan, the slower of the fan wheel or motor rpm quotient. The higher this quotient, the higher the isolation

will produce the frequency of dominant vibrations. There may efficiency. As a general rule, for minimum vibration isolation

be other higher-mode vibration frequencies present in equip- this ratio should be a minimum of 3.5.

ment, depending on issues such as the rigidity of the equipment, Resonant amplification is a phenomenon that occurs when

its mass, the number of moving or rotating parts (blades, lobes, the disturbing frequency matches the natural frequency of the

pistons, etc.) and many other properties. However,

if we concentrate on proper isolation of the lowest

1,000,000

disturbing frequency, we typically also isolate the

higher frequencies. Therefore, the lowest operating 0.2 to 0.6 Range of Vibration

equipment speed defines, for our purpose, the design Level That May be Anticipated

Over Life of Equipment

disturbing frequency.

Amplitude, X ′, is the magnitude of vibration. 100,000

General Perceptable

For the purposes of this discussion vibration am- Annoyance

plitudes will be expressed in terms of velocity, X ′

(in./s or m/s RMS), as this is a common basis used

Velocity μin/s

in equipment vibration criteria and human response Offices

to vibration criteria. RMS (root mean square value 10,000

Schools

of the vibration averaged over a sample time, equals

Hospitals, Concert Halls

about 71% of peak for cyclical vibration) gives

a useful, nonzero, single number magnitude that

gives an effective value of the vibration. It’s the 1,000

amplitude one might feel if they placed their hand

on the equipment. Sensitive High-

Tech Equipment

Damping, ε, acts as the brakes for equipment

mounted on isolators and is an inherent property of

most isolator materials. Damping reduces or stops 100

1.25 2 3.15 5 8 12.5 20 31.5 50 80

motion by use of friction or viscous resistance. Fric-

One-Third Octave Band Center Frequency, Hz

tion damping occurs when the friction between slid-

ing parts slows down movement between the parts, Figure 2: Comparison of equipment vibration levels to acceptable vibration levels

similar to brakes on a car. Viscous damping occurs in the occupied space.

32 ASHRAE Journal ashrae.org August 2007

isolators, i.e., fd = fn . Under this condition, the isolators dra-

matically amplify the vibratory forces.

Spring Isolation for Pipe

Figure 5 is the graph of transmissibility versus frequency Spring Isolation Base

quotient. The effect of resonance and damping can be seen

from the curve. No Structure Borne

Vibration

Practical Application and Implementation

Although the formulas used to estimate vibration isolation

are fairly easy, the effort to wade through through the formulas No Objectionable

for many pieces of the equipment in a typical building can be Vibration Transmitted

Through Structure

time consuming. To simplify this process, the vibration trans-

missibility chart in Table 1, can be used to quickly determine

the static deflections required in an isolator to limit the trans- Isolated Concrete Inertia Base

mission of vibration.

This table is only accurate for practically undamped isolators

(e.g., steel springs, air springs). Elastomeric mounts and pads Figure 3: An isolation system helps provide a vibration-free envi-

have damping and produce higher dynamic stiffness. This results ronment.

in higher transmissibility. As a rough rule of thumb, double the

required deflection given in the table for an elastomeric-type iso- Note that if this tower were placed on pads at about 0.1 in.

lator. This factor may change as a result of dynamic characteristics (2.5 mm) deflection, the vibration transmission is off the chart.

of the elastomer (durometer, shape, formula, etc.) Contact the The pad natural frequency Fn would be between 600 and 800

isolator supplier if more exact damping properties are needed. cpm, resulting in a resonant condition that would amplify the

vibration. Therefore, indiscriminant use of isolation can make

Example the problem worse. The vibration isolator must be correctly

Assume, for example, that the wheel of a cooling tower fan tuned to the disturbing frequency.

rotates at 600 rpm (cpm), which is the lowest frequency of vibra- In addition to the static deflection, there are a few other im-

tion (disturbing frequency). The cooling tower will be placed on portant considerations when mounting equipment on vibration

steel spring isolators. To ensure negligible vibration enters the isolators in the field.

building, it is determined to keep the vibration transmissibility

below 5%. Using the chart in Table 1, the intersection of the How Much Isolation Is Needed?

600 rpm row and the 5% transmission column reveals that an The first consideration is the criticalness of the installation.

isolator with a static deflection of 2.1 in. (53 mm) is needed to The more critical the installation, the more efficient the isolation

obtain the desired isolation. Industry-supplied spring isolators must be. This is somewhat subjective, but some basic common

typically are available in static deflections of 1 in. (25 mm) in- sense usually can be applied to decide how critical an instal-

crements. Field variances make it impractical to expect an exact lation should be: equipment on grade, next to a warehouse

deflection of 2.1 in. (53 mm).Therefore, round up the specified would be noncritical; equipment in a general office building,

spring isolator to the next whole number. In this case, a 3 in. (76 but away from occupied areas could be considered an average

mm) rated deflection spring will meet our requirement. sensitive installation; if equipment is directly above or adjacent

to occupied rooms, it is usually considered sensitive; close

fn = 188 (1/d)1/2 (unit of RPM) proximity to classrooms, quiet environment tenants or confer-

RPM fn = 3.13 (1/d)1/2 (unit of Hz)

fd Vibration 20

RMS (in./s, RMS)

10 ε

T if =0.5

fd 7 ε

T if =0.2

5 ε

T if =0.05

1+ (2×ε×fd / fn)2

[ ]

1/2

3

T=

2

ε× fd /fn)2

Transmissibility

(1–fd2 / fn2)2+(2×

fn 1 Cycle 1

0.7

0.5

ε = Damping Ratio as a Proportion of Critical Damping (C/Cc)

0.3

0.2

= Isolator Stiffness (lb/in.)

0.1

= Damping = C/Cc 0.07

0.05

= Static Deflection (in.) 0.03 Assuming Negligible Damping

0.02

T =1/ ([fd / fn]2 –1)

0.01

0 2 4 6 8 10 12

fd/fn (Forced Frequency/Natural Frequency)

Figure 4: Spring-mass-damper model used to calculate properties

of an isolation system. Figure 5: Transmissibility versus frequency or efficiency quotient.

August 2007 ASHRAE Journal 33

ence rooms can create a more sensitive Vibration Transmission—Percentage

Equipment

nature; and theaters, performing arts,

Speed 0.50% 1% 2% 3% 5% 10% 15% 25% 40%

high-tech installations, and hospitals usu- (RPM)

Static Deflection Required for Isolator*

ally would be considered critical instal-

lations with little tolerance for vibration 3,600 0.55 0.27 0.14 0.09 0.06 0.03 0.02 0.01 0.01

or vibration-induced noise. As a general 2,400 1.2 0.62 0.31 0.21 0.13 0.07 0.05 0.03 0.02

guide, select isolators with a maximum 1,800 2.2 1.1 0.56 0.37 0.23 0.12 0.08 0.05 0.04

transmissibility of 3% for critical instal-

1,600 2.8 1.4 0.7 0.47 0.29 0.15 0.11 0.07 0.05

lations, 5% for sensitive installations

1,400 3.6 1.8 0.92 0.62 0.38 0.2 0.14 0.09 0.06

and 10% for nonsensitive. If in doubt, it

is usually a negligible cost to err on the 1,200 4.9 2.5 1.3 0.84 0.52 0.27 0.19 0.12 0.09

conservative side. 1,100 5.9 2.9 1.5 1.0 0.61 0.32 0.22 0.15 0.1

Once the maximum allowable trans- 1,000 7.1 3.6 1.8 1.2 0.74 0.39 0.27 0.18 0.12

missibility has been decided, use Table 900 8.8 4.4 2.2 1.5 0.92 0.48 0.34 0.22 0.15

1 to determine the minimum static de-

800 11.1 5.6 2.8 1.9 1.2 0.61 0.42 0.28 0.19

flection required to achieve the desired

efficiency. The static deflection of the 700 - 7.3 3.7 2.5 1.5 0.79 0.55 0.36 0.25

isolation system at the equipment op- 600 - 9.9 5.0 3.4 2.1 1.1 0.75 0.49 0.34

erating weight is something that can be 550 - 11.8 6.0 4.0 2.5 1.3 0.9 0.59 0.41

easily field verified. It is not practical for 400 - - 11.3 7.6 4.6 2.4 1.7 1.1 0.77

an installing contractor or inspector to try

350 - - - 9.9 6.1 3.2 2.2 1.4 1.0

to verify the isolator natural frequency

for isolated equipment. Therefore, the 300 - - - - 8.3 4.3 3.0 2.0 1.4

minimum static deflection becomes the 250 - - - - - 6.2 4.3 2.8 2.0

key factor to specify to obtain the needed *Table assumes negligible damping (open spring coil). Elastomeric type isolators will have inherent damping, resulting in

higher transmissibility. Increase required static deflection by a factor of 2 (or as recommended by the isolator manufactur-

isolation. ing) to account for damping.

Equipment Location and Substrate Table 1: Quick reference chart to determine isolator deflection required to limit vibration

Location, location, location. What is transmission.

true in real estate is true in designing for

low vibration transmission. The first and resonance with the vibration disturbing flections from 0.75 to 6.0 in. (19 to 152

best option is to locate equipment as far frequency. This requires greater isola- mm), yielding natural frequencies from

away from occupied or sensitive areas as tion than with a stiff structure. To avoid 4 to 1.3 Hz. Springs are an adjustable,

possible. If equipment must be located problems, it is a good rule of thumb to free-standing, open-spring mounting.

near occupied or sensitive areas, then use an isolator with a deflection of 10 The springs are fastened to an integral

try to place the equipment adjacent to times what the floor will deflect due to cup/base plate or welded to the spring

areas such as bathrooms, storage areas, or the equipment weight. It is helpful to mounting base plate and compression

hallways to create a buffer zone between locate heavy equipment near columns or plate for stability. The isolator is usually

the equipment and the more sensitive heavy-duty beams. designed for a minimum kx /ky (horizon-

locations. tal-to-vertical spring rate) of approxi-

Next, consider the support structure. Available Isolator Types mately 1.0, and with a minimum outside

Rigid structure is needed beneath the Once the isolator deflection is resolved, diameter to operating height of 0.8 to

isolated HVAC&R equipment to work it must be determined what type or style ensure stability.

properly. The stiffness is a function of the of isolator best suits the installation. All steel springs should be used with

column spacing, the structural material There are a number of isolator styles that elastomer pads or cup under the spring

used (wide flange, open web, pre-stressed can be used. The different styles address or base plate to provide anti-skid and a

or post-tensioned concrete), and the con- practical installation issues encountered barrier to high-frequency noise that might

struction. In general, heavier construction with various types of equipment. The pass directly through the steel spring.

(concrete deck with heavy wide flange following components are shown in Every steel spring has a surge frequency

or concrete beams) is more rigid than Figure 6. at which vibration passes through without

light weight construction (open web Open steel spring isolators provide being isolated. If you thump a spring, it

joist, shallow concrete or wood deck). In high efficiencies, adjustability, and long will resonate a ring tone (the surge fre-

some cases, especially lighter construc- maintenance-free life. These are the most quency). This is a very high frequency

tion roofing, the floor can be flexible, common isolators used in the commercial that is not usually an issue. However, on

and its natural frequency can be close to industry. They are available in static de- the off chance that there exists vibration

34 ASHRAE Journal ashrae.org August 2007

Advertisement formerly in this space.

in the equipment that resonates with the surge frequency, the mm) deflection, but inherent dampening in elastomers increases

pad under the base plate effectively isolates it. vibration transmission above theoretical. They are generally

Restrained spring isolators use the open steel spring isola- adequate for high frequencies and non-critical installations.

tor type, and incorporate built-in restraints to prevent outdoor Elastomeric pads are generally used for very high-speed

equipment from too much sway due to wind load. The restraint equipment or electrical (transformers, etc.) equipment and less

housing, which serves as a blocking device during equipment critical installations. The typical static deflection is from 0.05

installation, also has restraint bolts to limit vertical movement in. to 0.15 in. (1 mm to 4 mm). These materials are widely used

resulting from large load variations as when equipment is as barriers against high-frequency noise transmission, and are

filled or drained of water. This reduces strain on connections also used as decouplers in floating floors.

such as piping. The spring package is isolated from the hous- Spring and elastomeric hangers are used for isolating sus-

ing by an elastomeric pad beneath the spring or base plate for pended equipment pipe and duct. They consist of a steel box,

high-frequency vibration absorption at the base of the spring. coil spring, spring retainers and elastomeric element. To account

The spring assembly is typically removable with equipment for hangers that are out of plumb, the box may allow 30-degree

in place. This enables changing springs out if needed without rod misalignment.

lifting the equipment or removing the housings. Restraints must Wire ropes are isolators made up of helical, stranded-wire

have elastomeric grommets and adequate clearance to prevent rope held with metal retaining bars. This design provides excel-

shorting out the isolator. They are commonly available for loads lent shock and vibration isolation in a multiple range of appli-

from 15 to 25,000 lbs (67 to 111,200 N), and are customizable cations. These isolators offer specific response characteristics

for virtually any load. These are the most common isolator based on the diameter of the wire rope, the number of strands,

types used for HVAC&R equipment such as cooling towers the cable loop length and the number of loops per section. The

and chillers. large dynamic displacement attenuates vibration, while the

Housed telescoping isolator provides wind horizontal re- inherent damping provided by the sliding friction between the

straint and damping, but no vertical restraint. strands of the wire rope minimize post-shock noise and lower

Elastomer-type mountings provide 0.25 to 0.5 in. (6 to 13 resonant peaks.

Advertisement formerly in this space. Advertisement formerly in this space.

36 ASHRAE Journal ashrae.org August 2007

Air springs provide the ultimate in and tightening belt tension. Many equip- under wind or seismic loads. Thus, it

high efficiency and adjustability. They ment generic submittals show two wide is recommended to create a full base to

have long life, but they require a constant flange rails supporting the equipment. resist these loads.

compressed air source and maintenance This assumes the rails are rigidly attached Concrete inertia bases provide the

(such as a car tire). Air springs can be or mounted to structure or grade. When same advantages as a steel base, plus

designed to provide natural frequencies the wide flange is mounted on springs, providing a solid base with extra mass as

from 4 Hz down to as low as 1.0 Hz. This there is no longer a rigid attachment, needed to provide maximum stability. A

isolation media allows a minimum height and the rail is susceptible to twisting concrete inertia base provides:

for extremely high efficiencies. They are

not normally used in commercial instal-

lations as the expense and maintenance

is considerably higher than other isolator

types. They are used for extremely critical

installations.

Base and Rail Requirements

Often equipment is not designed to be

mounted on point-loaded isolators and

may not have the rigidity to be direct

mounted to isolators. If the equipment has

a high center of gravity and a narrow foot-

print, it may be susceptible to unstable

rocking when direct-mounted to isolators.

Some equipment can experience large

unbalanced forces that require a solid

mass support to stabilize and counteract

the forces. In such circumstances, the Advertisement formerly in this space.

equipment must be mounted on a prop-

erly designed base or rail, which is then

mounted on the vibration isolator. The

following are illustrated in Figure 7.

Rails may be used whenever equipment

simply needs a level bearing surface to

distribute the weight to the vibration

isolator support. Made from channels,

angles, wide flanges, and such, they are

typically used on smaller fans, AHU,

vent sets, packaged units, etc., that can-

not be point loaded. Note, rails are not

recommended for an installation that

may be subject to earthquake or heavy

wind loads, since the rails may tend to

twist when subject to seismic or high

wind loads.

Integral steel base is a welded steel

frame that provides extra rigidity to main-

tain proper drive alignment for equipment

such as belt-driven fans with separate

motor mounts. The added strength and

rigidity resists racking due to start-up

torque. Steel bases also can be designed

to withstand seismic and wind loading.

Bases are generally made from wide

flange, channel or angle, and can be pro-

vided with a motor slide rail for adjusting

August 2007 ASHRAE Journal 37

Spring Isolator Restrained Spring Elastomeric Elastomeric Elastomeric Pads With

Isolator Rubber Pads Rubber Mounts Glass Fiber

Rolling Lobe Bellows

Elastomeric Spring Hanger Wire Rope Air Springs Spherical Rubber Connector

Rubber Hanger

Flexible Bellows

Pipe Clamp

Clamped to

Welded to Pipe

Sleeve and Pipe

Rubber Expansion Joint Metal Hose Spring-Isolated Riser System Thrust Restraint

With Control Rods

Figure 6: Available isolator types.

• Increased rigidity for heavy and/or high horsepower equip- accepts isolator point support and seismic/wind restraint. The

ment; upper frame must be designed with positive fastening provi-

• A lower center of gravity and wider footprint to prevent rock- sions (welding or bolting) to anchor the rooftop unit to the

ing instability for tall, narrow equipment; and curb in a manner that will not affect waterproofing. There is

• Increased mass to prevent high momentary or cyclical un- a continuous air seal between the upper floating member and

balanced forces from causing too much movement in the the stationary bottom. A wood nailer is provided on the bottom

springs. portion for roofing/flashing. Spring locations have access ports

These types of bases are used with pumps, compressors, large with removable waterproof covers so isolators can be adjustable,

fans (40 in. [1 m] wheel diameter or more), etc. removable and interchangeable. These type of curbs typically

Roof curb isolation rail. Rooftop equipment often is have a means to allow roof insulation and sound attenuating

mounted on a roof curb. For this, a continuous roof curb isola- that act thermally outside and acoustically inside. Flexible

tion rail is mounted on top of the roof connectors must be used between the

curb. It consists of a top and bottom isolated unit and the duct. Most can be

weatherproofed aluminum or formed supplied with sound barrier packages

metal rails for mounting between the and plenums.

equipment and roof curb. It provides

a continuous air and water seal, which Equipment Schedule

is protected from accidental puncture Structural Rails Structural Bases To ensure that the right isolation

and direct sunlight by a weather shield. needed for the job is installed, it is es-

Rails incorporate spring isolators sential that all the disciplines involved

properly spaced and sized around the in the construction process know what

perimeter to maintain the specified is required. The design team, the me-

deflection, and contain built-in seis- chanical engineer, the contractor, and

mic/wind restraints. Flexible connec- the vendor must all be on the same

Concrete Bases Curb Isolation

tors must be used between the isolated page. The best way to accomplish this

unit and the duct. Most suppliers offer is via an equipment isolation schedule.

Figure 7: Support base options.

options for flexible duct supports and Table 2 shows a portion of the sug-

sound barrier packages. gested schedule from ASHRAE Handbook—HVAC Applica-

Integral isolation curb or pedestal. This type of rooftop tions, Chapter 47, Table 48. The minimum deflections, listed in

support combines the equipment curb and isolation into one Table 48, recommended isolator type, and base type, are good

package, and is used as a structural spring isolation curb capable recommendations for most HVAC equipment installations. The

of resisting strong seismic and wind loading. The upper frame selections are based on typical concrete equipment room floors

provides continuous support for the equipment. The lower frame with typical floor stiffness. Projects of a more sensitive or criti-

38 ASHRAE Journal ashrae.org August 2007

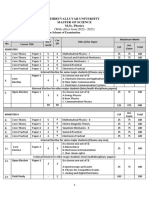

Table 48 Selection Guide for Vibration Isolation

Equipment Location (Note 1)

Floor Span

Slab on Grade Up to 20 ft 20 to 30 ft 30 to 40 ft

Min. Min. Min. Min.

Horsepower Base Isolator Defl., Base Isolator Defl., Base Isolator Defl., Base Isolator Defl., Reference

Equipment Type and Other RPM Type Type in. Type Type in. Type Type in. Type Type in. Notes

Refrigeration Machines and Chillers

Reciprocating All All A 2 0.25 A 4 0.75 A 4 1.50 A 4 2.50 2,3,12

Centrifugal, screw All All A 1 0.25 A 4 0.75 A 4 1.50 A 4 1.50 2,3,4,12

Open centrifugal All All C 1 0.25 C 4 0.75 C 4 1.50 C 4 1.50 2,3,12

Absorption All All A 1 0.25 A 4 0.75 A 4 1.50 A 4 1.50

Table 2: Excerpt from the Selection Guide for Vibration Isolation (see 2007 ASHRAE Handbook—HVAC Applications, Chapter 47, Table

48 for complete schedule).

cal nature or equipment, proximity to noise-sensitive areas may the first two hangers adjacent to the equipment may be the

require more isolation then listed. In such circumstances, an positioning or precompressed type to prevent load transfer to

acoustical professional is usually needed to design job specific the equipment flanges when the piping system is filled. The

isolation requirements. positioning hanger aids in installing large pipe, and therefore

Consider the following when using the table for isolator some use this type for all isolated pipe hangers for piping 8

selection and applications: in. (203 mm) and larger.

• For equipment mounted on upper floors with longer column Flexible connectors at equipment provide piping flexibility to

spans (30 – 40 ft [9 – 12 m]) or lightweight roof construction, protect equipment from strain due to misalignment or thermal

use the far right column. This column may also be used for movement of piping. They can also help attenuate noise and

equipment where isolation of the vibration is critical. vibration. Connectors are available in two common configura-

• Equipment located on upper floors with medium column tions for HVAC equipment: 1) The arched or expansion joint

spans (20 – 30 ft [6 – 9 m]) use the second column from the type, is a short-length connector with one or more large radius

right. This column would also be used for equipment located arches of an elastomer such as rubber, EDPM or PTFE (Figure

anywhere in close proximity to sensitive areas. 6). 2) The metal expansion joint types are convoluted stainless

• For upper floors that are stiff (10 – 20 ft [3 – 6 m] column hose with stainless braids (Figure 6). The elastomeric arched

spacing), use the second column from the left in the table. joints provide for axial, lateral and rotational movement, and

This may also be used for equipment on grade near noise attenuate vibration-induced noise transmitted to the pipe wall.

sensitive areas. Metal hose provide lateral movement. Two hose can be installed

• The first column is used for equipment located on grade in in an L-, U-, or V-shape to obtain multidirectional movement.

a nonsensitive location. Metal hose is not as acoustically effective for sound isolation

nor control of vibration-induced noise. They are commonly

Pipe used to provide for thermal movement, mechanical vibration,

Isolating piping is essential to completing the vibration isola- or differential movement experienced in earthquakes, and they

tion system. It also will accommodate thermal movement of the can be used at temperatures and pressures beyond the ability of

piping without imposing undue strain on the connections and elastomeric type. Check the flex manufacturer’s literature for

equipment. Therefore, the following is suggested to provide a proper application and for chemical compatibility to insure the

system that helps prevent vibration from leaking through the flex material is appropriate for the fluid or gas in the system.

piping system. Flex connectors should not be viewed as a substitute for pipe

Horizontal Pipe. Isolate all HVAC and plumbing pumped isolation hangers. When under pressure, they can become more

water, pumped condensate, glycol, refrigerant, and steam rigid and control rods can become heavily loaded in tension,

piping size 1¼ in. and larger within mechanical rooms . which can degrade the isolation. Since flex connectors do not

Outside equipment rooms this piping should be isolated for completely attenuate vibration and do not control flow-induced

the greater of 50 ft or 100 ft (15 or 30 m) pipe diameters from noise, resilient hangers or supports should still be used.

rotating equipment. To avoid degrading the isolation for the Isolate pipe risers using isolators similar to those shown in

equipment the first three support locations from equipment, Figure 6. This system eliminates the need for anchors or guides,

provide isolation hangers or floor mounts with the same de- and gives effective vibration isolation and acoustical break. In

flection as equipment isolators. All other piping within the totally floating risers, springs are carefully engineered to accom-

equipment rooms should be isolated with a ¾ in. (19 mm) modate the thermal movement, as well as, guide and support

minimum deflection isolator. Any piping below or adjacent the pipe. This system also results in more consistent loads on

to a noise-sensitive area should also be isolated with a com- the structure, as the springs allow the riser to float and move

bination spring and rubber hanger. For installation purposes, without a large change in load. Isolation of branch lies and riser

August 2007 ASHRAE Journal 39

take-offs must also be coordinated with the riser isolation to frequencies of standard isolation systems. This places the earth-

accommodate anticipated thermal displacement and to obtain quake accelerations close to the peak in Figure 5. The result

a system without excessive stress. is amplified forces that have been known to make equipment

All variable temperature vertical pipe risers 1¼ in. (32 mm) leap across a mechanical room and through a wall. Therefore,

and larger should be considered for spring support using floor- the isolated systems must be tied down. To prevent the shorting

mounted open steel springs or steel hangers. It is good practice out the isolators, restraints should be designed with about a ¼

to select a spring deflection that is a minimum of four times the in. (6.4 mm) gap so it is not engaged during normal operation.

anticipated deflection change with a ¾ in. (19 mm) minimum. Hanging equipment pipe or duct is typically accomplished

Typically, risers 12 in. (305 mm) or less can be supported at with restraint cables installed with slight slack to eliminate any

intervals of every third floor of the building. Pipe risers 14 in. dead load during normal operation, and minimize any vibration

(356 mm) and over may require support at closer intervals. transmission through the cable. For more complete information

Wall and floor penetrations often are overlooked as a vibra- see ASHRAE’s A Practical Guide to Seismic Restraint and

tion path. Significant acoustic energy can pass through a small ASHRAE Handbook—HVAC Applications, Chapter 53, Seismic

opening in a wall or floor. Therefore, it is very important to and Wind Restraint. In addition, industry guides can be obtained

seal openings with an acoustical barrier to prevent contact and from SMACNA and VISCMA.

decrease sound transmission. This can be done with an engi-

neered sleeve, as shown in figure or, by filling the annular space Summary

with fibrous material and non-hardening caulk. Wall sleeves for As with all equipment, HVAC&R equipment produces vibra-

take-offs from risers shall be sized for insulation O.D., plus two tion. As demonstrated in this paper, even the smoothest running

times the anticipated movement to prevent binding. equipment can produce vibration that is higher than the accept-

able range for many occupants. Building components and pipe

Duct provide conduits that effectively transmit vibration throughout

Similar to pipe, duct can experience vibration in the walls due the building, which results in complaints about felt vibration or

to flow pulsations and turbulence caused by abrupt changes in vibration-induced noise. Fortunately, the path of the vibration

direction or geometry. Although vibration is not as common a can be readily cut off with a properly designed vibration isola-

problem with duct, isolation hangers should be used in critical tion system. Following the basic isolation techniques presented

areas to ensure no vibration transmits through the hanger walls in this paper is recommended to help achieve an acceptable

and into the building. It is good practice to isolate the first 50 ft vibration environment. An isolation system installed with the

(15 m) from AHU or fan discharge and where the duct is sup- equipment can provide insurance against vibration-induced

ported beneath or adjacent to a vibration sensitive area. This complaints. Retrofitting after complaints develop is often far

is especially recommended for large duct with a velocity of 25 more expensive than an original installation—as “a penny of

fps or more. Spring or combination spring and rubber hangers prevention is worth a pound of cure.”

are recommended.

Flexible canvas and elastomeric duct connections should

also be used at fan and AHU discharge and intake. To prevent References

1. 2007 ASHRAE Handbook—HVAC Applications, Chapter 47,

the flex from being overextended or becoming rigid, and thus Sound and Vibration Control.

defeating its purpose, a spring thrust restraint as shown in Figure 2. Amber/Booth. A VMC Group Company, Houston. www.

6 should be considered when the static pressure is more than amberbooth.com.

2 in. (51 mm). 3. Ebbing, C., W. Blazier. 1998. Application of Manufacturers’ Sound

Data. Atlanta: ASHRAE.

4. GAO. 1992. Federal buildings—Many are threatened by earth-

Seismic Restraint Consideration

quakes.” GAO/GGD-92-62. Gaithersburg, Md.:U.S. General

Although restraint of equipment against earthquake loads is Accounting Office.

not the main focus of this article, it is imperative that seismic 5. Guckelberger, D. 2000. “Controlling noise from large rooftop

restraint be mentioned briefly as it pertains to isolation. Check units.” ASHRAE Journal, May 2000.

local building codes to determine if seismic restraint is required 6. Rivin, E. “Vibration isolation of precision objects.” Sound and

Vibration (7).

for equipment. Since the adoption of the IBC by most states, 7. Schaffer, M. 2005. A Practical Guide to Noise and Vibration

the requirement for seismic restraint has increased. Sixty to Control for HVAC Systems, Second Edition. Atlanta: ASHRAE.

seventy-five percent of the U.S. is now subject to some degree 8. Simmons, R. 2002. “Vibration control for cooling towers.” CTI

of seismic restraint. Journal Summer.

The design of equipment isolators must take into account 9. Tauby, J.R., et al. 1999. Practical Guide to Seismic Restraint.

Atlanta: ASHRAE.

special considerations if seismic restraint is required by the 10. The VMC Group. Vibration Mountings and Controls. Isolator

code. One common misconception is that the isolation system Products Catalog. www.thevmcgroup.com.

will isolate the earthquake from the equipment. In reality, an 11. Thornton, W., et al. 2006. “Vibration isolation of a medical facil-

earthquake has peak ground accelerations close to the resonant ity.” Sound and Vibration (12).

40 ASHRAE Journal ashrae.org August 2007

Advertisement formerly in this space.

You might also like

- LATERAL EARTH PRESSURE YanaDocument89 pagesLATERAL EARTH PRESSURE YanaTareq Al ShyoukhyNo ratings yet

- 3 Basics of Vibration Measurement by Torben LichtDocument138 pages3 Basics of Vibration Measurement by Torben LichtDragan LazicNo ratings yet

- Adre BrochureDocument12 pagesAdre BrochurenuesteNo ratings yet

- Identification of Torsional Vibration Features in Electrical Powered Rotating EquipmentDocument9 pagesIdentification of Torsional Vibration Features in Electrical Powered Rotating EquipmentHasan PashaNo ratings yet

- AA ARM2017 Vibration AnalysisDocument39 pagesAA ARM2017 Vibration Analysismahmoud fawzyNo ratings yet

- HydraulicsDocument36 pagesHydraulicsMark Lorenz DiolataNo ratings yet

- Vibration Isolation of Precision Objects: Eugene I. Rivin, Wayne State University, Detroit, MichiganDocument9 pagesVibration Isolation of Precision Objects: Eugene I. Rivin, Wayne State University, Detroit, MichiganYogesh Falak100% (1)

- Oil Distribution Within A Journal BearingDocument2 pagesOil Distribution Within A Journal BearingAnkit DedhiyaNo ratings yet

- 24 Vibration IsolatorDocument22 pages24 Vibration IsolatorNon Etabas Gadnatam100% (1)

- Iso 9614-1 - 1993 - 077291330811Document25 pagesIso 9614-1 - 1993 - 077291330811Hadi100% (1)

- Vibration IsolationDocument7 pagesVibration IsolationadbNo ratings yet

- The Practical Vibration PrimerDocument35 pagesThe Practical Vibration PrimerKroya HunNo ratings yet

- Dynamic Balancing ExpDocument10 pagesDynamic Balancing ExpSand Man Out100% (1)

- Vibration TechnologyDocument18 pagesVibration TechnologySakthimgsNo ratings yet

- Lubrication Guide - Ultrasonic Condition-Based LubricationDocument7 pagesLubrication Guide - Ultrasonic Condition-Based LubricationLLNo ratings yet

- Vibration: Core Body of Knowledge For The Generalist OHS ProfessionalDocument25 pagesVibration: Core Body of Knowledge For The Generalist OHS ProfessionalAlbert PerezNo ratings yet

- Fan VibrationDocument8 pagesFan Vibrationlafondejs100% (1)

- Antivibration MountsDocument6 pagesAntivibration MountsvldxbNo ratings yet

- Vibration PDFDocument48 pagesVibration PDFtruva_kissNo ratings yet

- 1-Cooling LoadDocument10 pages1-Cooling LoadJoão CavalcantiNo ratings yet

- Choosing The Right Accelerometer White Paper PDFDocument6 pagesChoosing The Right Accelerometer White Paper PDFRahulNo ratings yet

- Commissioning Fundamentals 2 - Pharmaceutical Commissioning and QualificationDocument13 pagesCommissioning Fundamentals 2 - Pharmaceutical Commissioning and QualificationJoão Cavalcanti100% (2)

- ASHRAE Filtration ComparisonDocument5 pagesASHRAE Filtration ComparisonTiago SilvaNo ratings yet

- 3 Axis AccelerometerDocument10 pages3 Axis AccelerometerTechqualcerNo ratings yet

- Technical Manual Centrifugal Axial FanDocument17 pagesTechnical Manual Centrifugal Axial Fanxichengren100% (2)

- Vibration Isolation TheoryDocument4 pagesVibration Isolation TheoryRa BalamuruganNo ratings yet

- EFRC RD Report Foundation Anchor Bolts Grouting October 19th 2017Document210 pagesEFRC RD Report Foundation Anchor Bolts Grouting October 19th 2017ahmadmortazaviNo ratings yet

- Thin-Walled Pressure Vessel PDFDocument3 pagesThin-Walled Pressure Vessel PDFNadlor Gasco OzausNo ratings yet

- Unlimited & G+12 DM Exam Rev.01Document15 pagesUnlimited & G+12 DM Exam Rev.01Lobna Tameem100% (2)

- Oil Whirl Whip PDFDocument9 pagesOil Whirl Whip PDFbwelz100% (2)

- GodaDocument22 pagesGodaLazaros NtoanidisNo ratings yet

- AGMADocument13 pagesAGMARizky MahendraNo ratings yet

- Isolator Selection GuideDocument30 pagesIsolator Selection GuideRaasik Jain100% (1)

- Installation of Vibration SensorsDocument8 pagesInstallation of Vibration SensorsnmguravNo ratings yet

- Avm Imnr50 17aDocument2 pagesAvm Imnr50 17aRani Hendrikus100% (1)

- Avm Imnr44 17aDocument2 pagesAvm Imnr44 17aRani HendrikusNo ratings yet

- VIB Booklet ENDocument36 pagesVIB Booklet ENPetra HeutsNo ratings yet

- Optimal Design of A Damped Dynamic Vibration AbsorberDocument21 pagesOptimal Design of A Damped Dynamic Vibration AbsorberShrikant DholeNo ratings yet

- Selection Guide VibrationDocument7 pagesSelection Guide VibrationLamija LamyNo ratings yet

- OrbitDocument12 pagesOrbitThair El-KabbaryNo ratings yet

- Noise Control EngineeringDocument12 pagesNoise Control EngineeringArindam Bhowmick100% (1)

- One Third Octave Vibration CriteriaDocument4 pagesOne Third Octave Vibration CriteriaMike100% (1)

- Fan Vibration Isolation ED1900 PDFDocument4 pagesFan Vibration Isolation ED1900 PDFsivajirao70No ratings yet

- Chapter-1: Downloaded FromDocument22 pagesChapter-1: Downloaded Fromsai ramanaNo ratings yet

- SMACNA HVAC Contractors Guide To Bidding Green Building ProjectsDocument40 pagesSMACNA HVAC Contractors Guide To Bidding Green Building ProjectsJoão CavalcantiNo ratings yet

- Coaching Table TennisDocument242 pagesCoaching Table TennisJoão CavalcantiNo ratings yet

- Centrifugal FanDocument9 pagesCentrifugal FanDTNgoNo ratings yet

- Smacna StandardsDocument2 pagesSmacna StandardsJoão Cavalcanti50% (6)

- Intro To Anti Vibration MountsDocument7 pagesIntro To Anti Vibration MountsmodvillamancaNo ratings yet

- Detection of Ski Slopes in Vibration SpectrumsDocument6 pagesDetection of Ski Slopes in Vibration SpectrumsJamie BNo ratings yet

- Vibration Isolation Selection GuideDocument5 pagesVibration Isolation Selection GuidearifzakirNo ratings yet

- Sound ReductionDocument11 pagesSound ReductionWilliam GrecoNo ratings yet

- Silencer Spark Arrestor CatalogueDocument10 pagesSilencer Spark Arrestor CatalogueBasem TamNo ratings yet

- API 670 MPS Overspeed DetectionDocument2 pagesAPI 670 MPS Overspeed DetectionPPMNo ratings yet

- Motor Vibration Analysis - Keeping It SimpleDocument2 pagesMotor Vibration Analysis - Keeping It SimplebwelzNo ratings yet

- Noise Control GuidelinesDocument11 pagesNoise Control GuidelinesRique BenitesNo ratings yet

- Silencers For HVACDocument12 pagesSilencers For HVACZaw Moe KhineNo ratings yet

- Pump InstallationDocument9 pagesPump InstallationYe tun KyawNo ratings yet

- Iso 8041-1 - 2017Document19 pagesIso 8041-1 - 2017Hi Tech Calibration ServicesNo ratings yet

- Tuned-Mass Absorber Case StudiesDocument14 pagesTuned-Mass Absorber Case StudieskenryouNo ratings yet

- 400 Don 4Document9 pages400 Don 4DarioNo ratings yet

- Gas Turbine Exhaust Systems Design ConsiderationsDocument8 pagesGas Turbine Exhaust Systems Design ConsiderationsArne AndersenNo ratings yet

- Pump RotorDocument54 pagesPump RotorYousefNo ratings yet

- Vibration AnalysisDocument17 pagesVibration AnalysispmagrawalNo ratings yet

- VibrationIsolation by Simmons PDFDocument10 pagesVibrationIsolation by Simmons PDFaruatscribdNo ratings yet

- SimmonsDocument12 pagesSimmonsGürelBaltalıNo ratings yet

- EEOMDocument15 pagesEEOMGillianne Mae VargasNo ratings yet

- Study of Vibration Isolators: By, Y.Shiva Kumar, K.Sudhir Kumar, S.VivekDocument12 pagesStudy of Vibration Isolators: By, Y.Shiva Kumar, K.Sudhir Kumar, S.Vivekvivek338No ratings yet

- VIBENGINEERINGDocument5 pagesVIBENGINEERINGCharlyn PandaNo ratings yet

- Essay in VibrationDocument7 pagesEssay in VibrationReynalene PanaliganNo ratings yet

- WWW Hvac Okstate EduDocument9 pagesWWW Hvac Okstate EduJoão CavalcantiNo ratings yet

- Compressed Air and MicroorganismsDocument5 pagesCompressed Air and MicroorganismsJoão CavalcantiNo ratings yet

- TTCAN Evaluation Toolkit 2016 enDocument59 pagesTTCAN Evaluation Toolkit 2016 enJoão CavalcantiNo ratings yet

- JBL - CADP2 Design Applications PDFDocument10 pagesJBL - CADP2 Design Applications PDFJoão CavalcantiNo ratings yet

- Guide To Minimizing Compressor-Based Cooling in Data CentersDocument19 pagesGuide To Minimizing Compressor-Based Cooling in Data CentersJoão CavalcantiNo ratings yet

- ISOPLAST - Catalogo Camaras Frigorificas IsoplastDocument8 pagesISOPLAST - Catalogo Camaras Frigorificas IsoplastJoão CavalcantiNo ratings yet

- Zsiga - Ch6-Physics of SoundDocument11 pagesZsiga - Ch6-Physics of SoundJoji Santa MariaNo ratings yet

- Vurgaftman Band 2001Document61 pagesVurgaftman Band 2001solidmasteryNo ratings yet

- Gravitational Collapse and Spacetime Singularities PDFDocument284 pagesGravitational Collapse and Spacetime Singularities PDFSachin Venkatesh100% (1)

- Lab 4 Electric PotentialDocument4 pagesLab 4 Electric PotentialJorge Tenorio0% (1)

- EE428 Industrial Process Control: Dr. Ammar HasanDocument27 pagesEE428 Industrial Process Control: Dr. Ammar HasanUmer ImranNo ratings yet

- IS800 2007 (Reaffirmed2017) Smx1mhtgqfgnyculmeemie1srmsd20230207100541Document155 pagesIS800 2007 (Reaffirmed2017) Smx1mhtgqfgnyculmeemie1srmsd20230207100541baubleNo ratings yet

- Design of Machine ElementsDocument5 pagesDesign of Machine ElementsjayadevakodiNo ratings yet

- 29-M.Sc. PhysicsDocument111 pages29-M.Sc. PhysicsM. BalakrishnanNo ratings yet

- Power System Stability Analysis Using MatlabDocument26 pagesPower System Stability Analysis Using MatlabAryan Pratap SinghNo ratings yet

- Design of Reinforced Concrete Elements: UsingDocument62 pagesDesign of Reinforced Concrete Elements: UsingISsa Qafa'itiNo ratings yet

- HCHCR1022T HCHCR1022P PDFDocument4 pagesHCHCR1022T HCHCR1022P PDFDIKSHA SARASWATNo ratings yet

- Electromagnetic Waves in Free SpaceDocument25 pagesElectromagnetic Waves in Free SpaceYuvan Raam ChandraNo ratings yet

- Aisc Member Dimensions and Properties ViewerDocument23 pagesAisc Member Dimensions and Properties ViewerMadara Uchija100% (1)

- Design and Control of An Active Knee Orthosis Driven by A Rotary Series Elastic ActuatorDocument12 pagesDesign and Control of An Active Knee Orthosis Driven by A Rotary Series Elastic ActuatorYazdan RastegarNo ratings yet

- BSC (Physics) SyllabusDocument16 pagesBSC (Physics) SyllabusAlok ThakkarNo ratings yet

- ENGR 4011 Resistance & Propulsion of Ships Assignment 3: 2018Document5 pagesENGR 4011 Resistance & Propulsion of Ships Assignment 3: 2018Luis De GraciaNo ratings yet

- Projectile MotionDocument14 pagesProjectile MotionAbel CruzNo ratings yet

- Capítulo 6Document83 pagesCapítulo 6fslsantosNo ratings yet

- Frank Herbert Attix (Auth.) Assorbimento Fotoni - Introduction To Radiological Physics and Radiation Dosimetry (1986) - 141-176-21Document1 pageFrank Herbert Attix (Auth.) Assorbimento Fotoni - Introduction To Radiological Physics and Radiation Dosimetry (1986) - 141-176-21EnricoBogoniNo ratings yet

- Fluid Motion.Document3 pagesFluid Motion.Oscar OchoaNo ratings yet

- Solidworks Simulation Premiun DYNAMICSDocument142 pagesSolidworks Simulation Premiun DYNAMICSTarcio TomNo ratings yet

- PHY 143 Course OutlineDocument3 pagesPHY 143 Course Outlinesurvanity wilsonNo ratings yet

- Q2 Curriculum Map GP1Document5 pagesQ2 Curriculum Map GP1Leonardo PigaNo ratings yet

- Torque NotesDocument3 pagesTorque NotesKudzai MashayaNo ratings yet