Professional Documents

Culture Documents

Comincashin Scania Problems

Uploaded by

Hani SweetieCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comincashin Scania Problems

Uploaded by

Hani SweetieCopyright:

Available Formats

16:07-02

Issue 1 en

Communication problems

Help when troubleshooting

? ?

?

? ?

135 489

Scania CV AB 2004, Sweden

Contents

Contents

Background .................................................................................. 3

Troubleshooting Preparations .............................................................. 4

SDP3 cannot establish contact with the vehicle ....... 5

SDP3 can only establish contact with systems

on the green CAN bus .............................................. 8

Communication problems in the vehicle .................. 9

CAN chart ................................................................................ 10

Scania CV AB 2004, Sweden

2 16:07-02

Background

Background

An electrical system with CAN communication

implies to some extent a new way of carrying

out troubleshooting, compared with a

conventional electrical system.

In most cases it is possible to carry out

troubleshooting within the vehicle electrical

system using SDP3. This assumes that

communication between the control units via

CAN cables is working and that SDP3 can

communicate with the vehicle control units.

In some cases faults may occur which can be

difficult to diagnose using SDP3.

Examples which may assist you when you are

searching for the causes of faults in the vehicle's

electrical system are provided below.

More detailed information about the electrical

system can be found in the booklet Electrical

system in P, R and T series, Introduction and

general troubleshooting.

The methods of measurement for the green

CAN bus which are described in the booklet can

also be used to troubleshoot the yellow CAN bus

and red CAN bus.

Scania CV AB 2004, Sweden

16:07-02 3

Troubleshooting

Troubleshooting

Preparations "no contact"

Before you start, you should know whether the In this case, however, it is not the fault

fault occurred in connection with some other codes that are most important, since it is

activity, e.g. connecting bodywork, installing the communication we want to test. If the

accessories, etc. or whether it just occurred for instrument cluster responds with "no

no apparent reason. errors", this means that communication is

working. Systems such as CTS (clock and

For troubleshooting you need: timer system), AHS (auxiliary heater

• SDP3 system) and AUS (audio system) must be

switched on in order to establish contact

• Multimeter with them.

• Chart showing how the control units are

connected to the CAN bus (see last page)

• Measuring adapter 99 508 (included in

measuring adapter kit 99 511)

• Fault code descriptions

If SDP3 cannot communicate with one or

more control units so that you cannot

obtain supplementary numbers or fault

codes within the program, you can obtain a

list of fault codes for each supplementary

number from SDP3 as follows:

Go to the menu under View and select

Search for fault code list.

You can obtain the supplementary number

via the IVD function on the instrument

cluster, provided that the instrument cluster

can establish contact with the control units

and that fault codes have been registered.

The instrument cluster always shows which

systems it expects to receive a response

from, i.e. which systems are fitted on the

vehicle.

If there are no fault codes registered in the

control unit, the instrument cluster

displays:

"no errors"

If the instrument cluster cannot establish

contact with the control unit, it displays:

Scania CV AB 2004, Sweden

4 16:07-02

Troubleshooting

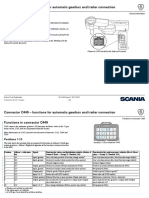

SDP3 cannot establish contact with the vehicle

When the program is started, a fault message

appears indicating that the program cannot find

any SOPS. When you enter the program, it is

"empty".

1 Check that VCI2 is connected.

Function of the lamps

PWR (green) The lamp lights up continuously when the

VCI2 is supplied with voltage both from the

vehicle and the PC.

The lamp flashes when the VCI2 is connected

to the PC.

USB (yellow) The lamp lights up (flashes rapidly) when data

is transmitted between the PC and VCI2 via

the USB key.

CAN (yellow) The light lights up (flashes rapidly) when data

is transmitted between the VCI2 and the

vehicle via the CAN bus.

Error (red) The lamp lights up when there is a

communication error on the CAN bus.

2 Try to start the program again.

3 Check using the IVD function on the

instrument cluster (diagnostic mode)

whether the ICL control unit can

communicate with systems on the green • If the ICL control unit has not established

CAN bus. contact with the green CAN bus, continue

troubleshooting as follows:

N.B. On low-specification vehicles, it is not

certain whether there will be any systems on

the green CAN bus.

Check via the instrument cluster which

systems should be available on the vehicle

and compare them with the CAN chart on

the last page.

• If the ICL control unit has established

contact with the green CAN bus, check

whether there is an open circuit somewhere

between the VCI2 and the junction box for

the green CAN bus (C479).

Scania CV AB 2004, Sweden

16:07-02 5

Troubleshooting

The junction blocks are concealed and located

on the right of the central electric unit area. They

are fitted in the holes without locking, which

means that they can easily be taken out.

135 385

135 386

2 1

1 Junction blocks for CAN Junction blocks taken out.

2 Junction block for earth.

1 Measure the voltage level between chassis

earth and the green CAN bus using a

multimeter.

• The voltage should be approximately

2.5V

135 388

Example of measuring on CAN high in relation

to chassis earth.

Scania CV AB 2004, Sweden

6 16:07-02

Troubleshooting

Note! During the following measurement, all

systems must be connected but not supplied

with voltage.

2 Measure the resistance on the CAN cable

between CAN high and CAN low.

• The resistance should be around

60 ohms.

135 387

3 Measure the resistance between CAN high With the junction blocks taken out, it is easy to

and chassis earth or between CAN low and measure, e.g. the resistance between CAN high

chassis earth to check that the resistance is and CAN low.

high enough.

• The resistance should be at least

1000 ohms, in most cases it is much

more.

4 If the resistance is too low, disconnect the

connector and measure on the junction box

for the green CAN bus for all cables in order

to find out which control unit is faulty.

5 Disconnect the control unit concerned in

order to determine whether there is a fault

on the control unit or in the cable harness.

6 If there is a fault in the cable harness,

troubleshoot according to the instructions

set out in "Electric system in P, R and T

series, Introduction and general

troubleshooting".

Scania CV AB 2004, Sweden

16:07-02 7

Troubleshooting

SDP3 can only establish contact with systems on the

green CAN bus

The ICL control unit has only established

contact with systems on the yellow (its own)

CAN bus.

1 Check the voltage supply to the coordinator.

Start by checking that the fuse for the

coordinator (fuse 19) is intact and that

voltage is supplied to it.

99 508 81 3

IMPORTANT! To avoid damaging the pins, you 79 80 81

2

3

1

should use the measuring adapter. No 60

61 62

41 42 43

5

measurement should be carried out directly on 22 23

5

the coordinator pins because they are very

sensitive.

2 Check using measuring adapter 99 508

whether the coordinator is receiving voltage

to pin connection 3 (30-supply) and pin

connection 81 (15-supply).

135 668

Measurement on pin 3 (30-supply)

• If the measurement shows that voltage is

being supplied to the coordinator, the

cause may be play in the coordinator

connector.

3 Test by connecting the coordinator again.

• If the fault persists, renew the

coordinator.

• If the fault disappears, inspect the

relevant pin in the connector and renew

it if necessary.

Scania CV AB 2004, Sweden

8 16:07-02

Troubleshooting

Communication problems in the vehicle

Faults which may cause the vehicle to engage

"limp home mode". All possible warnings

come on in the instrument cluster.

• If you can use SDP3, check the fault codes.

Also check whether there are inactive fault

codes which cause problems at low

voltage.

If you cannot use SDP3, try to read the

fault codes from the instrument cluster.

• If a control unit has a fault code for a low

supply voltage, measure the input voltage

and check the control unit earth connection

by, for example, measuring the voltage

drop on the earth lead.

• If there are fault codes implicating a

specific CAN bus, test by measuring the

voltage on the CAN bus by connecting a

multimeter between the CAN high cable

and chassis earth.

The voltage should be approximately 2.5V.

• If the multimeter shows an absurdly high

value, more than 5V, this may indicate

earthing problems on one or more control

units on the CAN bus which is being

measured.

• Dismantle the junction block and check

what is giving the incorrect voltage.

• Check any earthing problems by measuring

the voltage drop on the control unit.

Measure from the earth connection in the

control unit connector to a safe earthing

point, e.g. one of the cab earthing points.

Correctly operating earthing results in no

or very little voltage drop.

Scania CV AB 2004, Sweden

16:07-02 9

CAN chart

CAN chart

Diagnostic bus

K1

Red bus

COO

AUS Coordinator system

Audio system

GMS EMS BMS SMS

CSS Gearbox management Engine management Brake management Suspension

system system system management system

Crash safety system

ACC

Automatic climate

control LAS

Locking and alarm

system

WTA

Auxiliary heater

system water to air AWD

All wheel drive

system

ATA

Auxiliary heater ICL

system air to air Instrument cluster

system

CTS TCO

Clock and timer

Tachograph system

system

VIS

RTG

Road transport Visibility system

informatics gateway

APS

Air prosessing

RTI system

Road transport

informatics system

135 389

Green bus

BWS Body Builder

Body work system Truck

Yellow bus

Scania CV AB 2004, Sweden

10 16:07-02

You might also like

- Diagrama Electrico Caterpillar 3406E C10 & C12 & C15 & C16Document2 pagesDiagrama Electrico Caterpillar 3406E C10 & C12 & C15 & C16Gerardo Diesel83% (99)

- GRS 890 900 GR 801 900Document28 pagesGRS 890 900 GR 801 900Osmar Franco Pires100% (23)

- Clucth ScaniaDocument2 pagesClucth ScaniaNoeRtjahya Ahmad100% (1)

- Caterpillar ADEM II 3176C 3406E C10 C12 Completo PDFDocument2 pagesCaterpillar ADEM II 3176C 3406E C10 C12 Completo PDFOmar Garcia Cazares100% (3)

- Caterpillar ADEM II 3176C 3406E C10 C12 Completo PDFDocument2 pagesCaterpillar ADEM II 3176C 3406E C10 C12 Completo PDFOmar Garcia Cazares100% (3)

- Caterpillar ADEM II 3176C 3406E C10 C12 Completo PDFDocument2 pagesCaterpillar ADEM II 3176C 3406E C10 C12 Completo PDFOmar Garcia Cazares100% (3)

- Equilizer p410Document5 pagesEquilizer p410lilik sukristiantoNo ratings yet

- Cable Harness Connections For Additional Switches Cable Harness For Additional SwitchesDocument4 pagesCable Harness Connections For Additional Switches Cable Harness For Additional Switchesmbpaja100% (1)

- 16-75 BWE, Bodywork Electrical System: Overview - Sheet 1Document13 pages16-75 BWE, Bodywork Electrical System: Overview - Sheet 1lilik sukristianto100% (1)

- Opisanie KomponentovDocument299 pagesOpisanie KomponentovuserNo ratings yet

- WSM 0003159 ru-RUDocument134 pagesWSM 0003159 ru-RUCleiton aviNo ratings yet

- Scania P, G, R, T Series Workshop Manual - Removing A Manual GearboxDocument11 pagesScania P, G, R, T Series Workshop Manual - Removing A Manual GearboxFachrie50% (2)

- FPCDocument30 pagesFPCJohan RiemersmaNo ratings yet

- File WSM - 0000793 - 01.pdf From Thread Scania 124L 420HPi - Opticruise - Błąd E090 I E092 PDFDocument145 pagesFile WSM - 0000793 - 01.pdf From Thread Scania 124L 420HPi - Opticruise - Błąd E090 I E092 PDFBota NicusorNo ratings yet

- Connector C449 - Functions For Automatic Gearbox and Trailer Connection General InformationDocument3 pagesConnector C449 - Functions For Automatic Gearbox and Trailer Connection General InformationmbpajaNo ratings yet

- Scania Ebs5 WiringDocument1 pageScania Ebs5 WiringRafo CaceresNo ratings yet

- SCANIA Suspension BT300 Work DescDocument44 pagesSCANIA Suspension BT300 Work DescHeri SuryoNo ratings yet

- ISO 14121-2-2007 Risk AssessmentDocument1 pageISO 14121-2-2007 Risk AssessmentMancamiaicuruNo ratings yet

- Wiring Diagram Handbook: For LHD and RHD TrucksDocument168 pagesWiring Diagram Handbook: For LHD and RHD Trucksluis meza100% (3)

- Scania SuspensionDocument3 pagesScania SuspensionHeri SuryoNo ratings yet

- WSM - Maintenance Instruction Part - 1 Truk - en PDFDocument120 pagesWSM - Maintenance Instruction Part - 1 Truk - en PDFDul AdulNo ratings yet

- Trouble Shoot ScaniaDocument77 pagesTrouble Shoot ScaniaTjoa Gin Hao75% (4)

- Scania P, G, R, T Series Workshop Manual - Removing The Reductant Main UnitDocument1 pageScania P, G, R, T Series Workshop Manual - Removing The Reductant Main Unitmusharrf100% (1)

- Electric Throttle: Issue 1Document40 pagesElectric Throttle: Issue 1asesmen mekanik100% (1)

- XCOM User GuideDocument33 pagesXCOM User GuideAnonymous ljkiyqJt8MNo ratings yet

- Electric ComponentDocument299 pagesElectric ComponentHari100% (1)

- enDocument55 pagesenRegistr Registr100% (2)

- enDocument21 pagesenRegistr Registr100% (1)

- enDocument23 pagesenuser100% (3)

- Damper For Range Gear Changing GR801-900, GRS890-900 Work DescriptionDocument8 pagesDamper For Range Gear Changing GR801-900, GRS890-900 Work DescriptionfugegaNo ratings yet

- Wiring Diagrams Manual: For BusesDocument46 pagesWiring Diagrams Manual: For BusesModestasNo ratings yet

- Coordinator and Base System: Industrial Engines DC9, DC13, DC16 Marine Engines DI9, DI13, DI16Document51 pagesCoordinator and Base System: Industrial Engines DC9, DC13, DC16 Marine Engines DI9, DI13, DI16PIKO MOBNo ratings yet

- Electric Installation ManualDocument47 pagesElectric Installation ManualAbuhurairah MunshiNo ratings yet

- Pnumatic BrakeDocument19 pagesPnumatic BrakeClovis100% (1)

- dc16 SeriesDocument77 pagesdc16 SeriesRasheed SiddiquiNo ratings yet

- WSM 16 06-11-c enDocument26 pagesWSM 16 06-11-c eneko sunaryoNo ratings yet

- Scania Diagnos & Programmer 3 2.48.1Document7 pagesScania Diagnos & Programmer 3 2.48.1Jaya Pranata50% (2)

- Important Information: Operator's Manual DC9 EMS With S6/PDE Industrial EngineDocument60 pagesImportant Information: Operator's Manual DC9 EMS With S6/PDE Industrial Enginemmmm100% (1)

- Fuel System With Unit Injector PDE and EDC MS6: Issue 3Document55 pagesFuel System With Unit Injector PDE and EDC MS6: Issue 3Георгий222No ratings yet

- enDocument17 pagesenRegistr Registr60% (5)

- User Multi6 Parts en-GB SCANIADocument58 pagesUser Multi6 Parts en-GB SCANIAIsmael De Jesus Andrade100% (3)

- Catalogo Scania CromadosDocument96 pagesCatalogo Scania CromadosDusanMasle100% (1)

- Scania Inter AxleDocument14 pagesScania Inter AxleKharis Mahfudz100% (2)

- BWM - 0000388 - 01 - PTO OverviewsDocument14 pagesBWM - 0000388 - 01 - PTO OverviewsNoeRtjahya AhmadNo ratings yet

- Engine Data D12 PDFDocument20 pagesEngine Data D12 PDFClaudesson Nascimento Rodrigues100% (1)

- ZF As Tronic DescriptionDocument24 pagesZF As Tronic DescriptionBienvenu MassouanguiNo ratings yet

- Adjustable Parameters - EngineDocument33 pagesAdjustable Parameters - EnginescaniaNo ratings yet

- Switch General InformationDocument40 pagesSwitch General InformationmbpajaNo ratings yet

- CALIBRACIONDocument65 pagesCALIBRACIONNuñez JesusNo ratings yet

- P11X24EN Scania Opticruise and Retarder Tcm40 280864Document6 pagesP11X24EN Scania Opticruise and Retarder Tcm40 280864Ionut LefterNo ratings yet

- enDocument30 pagesenRegistr RegistrNo ratings yet

- Munication Area Network (CAN) TerbaruDocument19 pagesMunication Area Network (CAN) TerbaruKurniawan -No ratings yet

- Daf Ix Custom Par Pmci2Document12 pagesDaf Ix Custom Par Pmci2Mircea GilcaNo ratings yet

- Motorola ScaniaDocument7 pagesMotorola Scaniabob bobkaNo ratings yet

- BWM 0000004 01Document54 pagesBWM 0000004 01stefanovicana1No ratings yet

- Wartungsanweisungen Für Gruppe 7-9 P-, G-, R - Und T-SerieDocument24 pagesWartungsanweisungen Für Gruppe 7-9 P-, G-, R - Und T-SerieWeber BennyNo ratings yet

- Fms Prep ScaniaDocument80 pagesFms Prep Scaniaipdown4250% (2)

- Tacometro y Velocimetro ScaniaDocument48 pagesTacometro y Velocimetro ScaniaChristian Ramos Campos60% (5)

- Scania Basic General (4series & Cabs-Andi Ver 24 Mar 2005)Document39 pagesScania Basic General (4series & Cabs-Andi Ver 24 Mar 2005)Erik KrisdiyantoNo ratings yet

- A - Scania Basic GeneralDocument162 pagesA - Scania Basic GeneralEndraNo ratings yet

- 030201en PDFDocument64 pages030201en PDFMichael Davenport100% (1)

- B - Bledding Procedurre On Page 13Document35 pagesB - Bledding Procedurre On Page 13EndraNo ratings yet

- 01-05 Flywheel Housing: Fitting Flywheel Housing On 9, 11 and 12 Litre Engines With PDE or HPIDocument4 pages01-05 Flywheel Housing: Fitting Flywheel Housing On 9, 11 and 12 Litre Engines With PDE or HPIyordan baniaraNo ratings yet

- How To Instal1 Scania sdp3Document12 pagesHow To Instal1 Scania sdp3netoNo ratings yet

- 030402en PDFDocument55 pages030402en PDFdaniel_jorge_10No ratings yet

- 25 Words SilicaDocument5 pages25 Words SilicaJahRed FronterasNo ratings yet

- Vib 0000004 01Document36 pagesVib 0000004 01Hani SweetieNo ratings yet

- Diag DXi V2.25Document22 pagesDiag DXi V2.25Hani SweetieNo ratings yet

- Vib 0000004 01Document36 pagesVib 0000004 01Hani SweetieNo ratings yet

- Ec-Fao Partnership Programme (1998-2001) : European Commission Directorate-General Viii DevelopmentDocument15 pagesEc-Fao Partnership Programme (1998-2001) : European Commission Directorate-General Viii DevelopmentAbdulhamid IdrisNo ratings yet

- Comincashin Scania ProblemsDocument10 pagesComincashin Scania ProblemsHani SweetieNo ratings yet

- Ad at 380T44 WH PDFDocument2 pagesAd at 380T44 WH PDFHani SweetieNo ratings yet

- AD / AT 720T38 TH Tractor 6x4: WEIGHTS (KG.) G.V.W. G.C.W. Front Axle Rear AxleDocument2 pagesAD / AT 720T38 TH Tractor 6x4: WEIGHTS (KG.) G.V.W. G.C.W. Front Axle Rear AxleHani SweetieNo ratings yet

- AD / AT 190T38 H Rigid 4x2: WEIGHTS (KG.) G.V.W. G.C.W. Front Axle Rear AxleDocument2 pagesAD / AT 190T38 H Rigid 4x2: WEIGHTS (KG.) G.V.W. G.C.W. Front Axle Rear AxleHani SweetieNo ratings yet

- Diag DXi V2.25Document22 pagesDiag DXi V2.25Hani SweetieNo ratings yet

- Ad at 380T44 WH PDFDocument2 pagesAd at 380T44 WH PDFHani SweetieNo ratings yet

- Howo Trucks Fault Codes List - Table of Diagnostic Flashing Codes For Faults of The Fuel Pump System of Common Rail Diesel Engine PDFDocument15 pagesHowo Trucks Fault Codes List - Table of Diagnostic Flashing Codes For Faults of The Fuel Pump System of Common Rail Diesel Engine PDFLuciana Silveira80% (5)

- FactoryTalk Historian SE V4 - 0 Frequently Asked QuestionsDocument9 pagesFactoryTalk Historian SE V4 - 0 Frequently Asked QuestionsRidho AnjikoNo ratings yet

- How To Mix A Lead VocalDocument2 pagesHow To Mix A Lead VocalAntónio LopesNo ratings yet

- Dry Run 10Document4 pagesDry Run 10anshiNo ratings yet

- Cloud Assignment 2Document4 pagesCloud Assignment 2tiraNo ratings yet

- Marine Radar M-1835 - SerienDocument6 pagesMarine Radar M-1835 - SerienRifalMkNo ratings yet

- 01 DMBI Module 01 (Introduction) PPT-compressedDocument19 pages01 DMBI Module 01 (Introduction) PPT-compressedGunjan Narayan KiratkarNo ratings yet

- Online Gas Cylinder Booking System: Developed By: Jayesh AhirDocument22 pagesOnline Gas Cylinder Booking System: Developed By: Jayesh AhirZaharaddeen AbubuakarNo ratings yet

- Yusra Hanif: Lecturer Computer Science Concordia College SahiwalDocument21 pagesYusra Hanif: Lecturer Computer Science Concordia College SahiwalYusraNo ratings yet

- 15.1 Internet of ThingsDocument29 pages15.1 Internet of ThingsRakesh PogulaNo ratings yet

- CrashDocument4 pagesCrashzDarkCodexNo ratings yet

- New Directions in Wireless Communications Systems - From Mobile To 5G (PDFDrive) PDFDocument563 pagesNew Directions in Wireless Communications Systems - From Mobile To 5G (PDFDrive) PDFRandy LeeNo ratings yet

- Class DiagramDocument7 pagesClass Diagrammanognamanu802_10982No ratings yet

- History of Russian Monopulse Radar by LeonovDocument7 pagesHistory of Russian Monopulse Radar by LeonovDhimas AfihandarinNo ratings yet

- BCIT MANUAL - STUDENT COPY-Bio-Medical-31-36Document6 pagesBCIT MANUAL - STUDENT COPY-Bio-Medical-31-36Anonymous naEAR9adNo ratings yet

- Networking: PPT Requirement For Students As AprojectDocument22 pagesNetworking: PPT Requirement For Students As Aproject10chirag10100% (1)

- Embedded BMC IpmiDocument65 pagesEmbedded BMC Ipmid_i_mNo ratings yet

- MCC Final Exam QuestionsDocument3 pagesMCC Final Exam QuestionsKomal TuliNo ratings yet

- Epson Perfection V500 Photo SERVICE MANUALDocument69 pagesEpson Perfection V500 Photo SERVICE MANUALrendangenakNo ratings yet

- Microcontroller 8051Document72 pagesMicrocontroller 8051vaibhav sharmaNo ratings yet

- Pendahuluan: Rekayasa Trafik Sukiswo Sukiswo@elektro - Ft.undip - Ac.idDocument9 pagesPendahuluan: Rekayasa Trafik Sukiswo Sukiswo@elektro - Ft.undip - Ac.idBetson Ferdinal SaputraNo ratings yet

- Unit 4Document3 pagesUnit 4Saloni ChaudharyNo ratings yet

- Tejb9628 00Document64 pagesTejb9628 00DinaNo ratings yet

- CH 01Document23 pagesCH 01Karan MadaanNo ratings yet

- Diamond 1line TelephonesDocument2 pagesDiamond 1line TelephonesArmando RamirezNo ratings yet

- Bluetooth Based Smart HomeDocument21 pagesBluetooth Based Smart HomeSagarSinha100% (1)

- 365C 385C NPI Large Hydraulic Information IDocument18 pages365C 385C NPI Large Hydraulic Information IAnjelo Jeanhpool Hidalgo AlvaradoNo ratings yet

- How To Create A LAB of ADFS ServersDocument2 pagesHow To Create A LAB of ADFS ServersDisha1No ratings yet

- CeilAiR Engineering ManualDocument76 pagesCeilAiR Engineering Manualeselcosac100% (1)

- Controladora Sonido 32191-32196-32199Document1 pageControladora Sonido 32191-32196-32199janseta22No ratings yet