Professional Documents

Culture Documents

G-2150 / S-2150 Bolt Type Chain Shackles

Uploaded by

Sheikh Shoaib0 ratings0% found this document useful (0 votes)

12 views1 page80

Original Title

80

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document80

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 pageG-2150 / S-2150 Bolt Type Chain Shackles

Uploaded by

Sheikh Shoaib80

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Crosby® Bolt Type Shackles

SHACKLES

• Capacities 1/2 thru 85 metric tons, grade 6.

• Working Load Limit and grade “6” permanently shown on every shackle.

• Forged — Quenched and Tempered, with alloy pins.

• Hot Dip galvanized or self colored. (85, 120, and 150-metric ton shackles are all

hot dip galvanized bows and the bolts are Dimetcoted® and painted red).

• Sizes 3/8 inch and below are mechanically galvanized.

• Fatigue rated (1/2t - 55t).

• Shackles 25t and larger are RFID EQUIPPED.

• Approved for use at -40° C (-40 degrees F) to 204° C (400° F).

G-2150 / S-2150 • Meets or exceeds all requirements of ASME B30.26.

Bolt Type chain shackles

with thin hex head bolt - nut • Sizes 1/2 - 25t meet the performance requirements of EN13889:2003.

with cotter pin. Meets the • Shackles 55 metric tons and smaller can be furnished proof tested with certificate

performance requirements of

Federal Specification RR-C to designated standards, such as ABS, DNV, Lloyds, or other certification whe

271G, Type IVB, Grade A, Class requested at time of order.

3,except for those provisions

required of the contractor. • Type Approval certification in accordance with ABS 2016 Steel Vessel Rules and

For additional information,

see page 452.

2016 ABS Guide for Certification of Lifting Appliance. Certificates available when

requested at time of order and may include additional charges.

• All 2150 shackles can meet charpy requirements of 42 Joules (31 ft•lbf) avg at -20° C

(-4° F) upon special request.

• Look for the Red Pin® . . . the mark of genuine Crosby quality.

® SEE APPLICATION INFORMATION

On Page 92 of the General Catalog

Para Español: www.thecrosbygroup.com

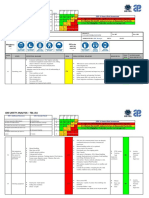

G-2150 / S-2150 Bolt Type Chain Shackles

Working Stock Dimensions Tolerance

Nominal Load No. Weight (in) +/-

Size Limit Each

(in) (t)* G-2150 S-2150 (lb) A B D F G K M P R G A

1/4 1/2 1019768 – .13 .47 .31 .25 .62 .91 1.59 .97 1.56 .25 .06 .06

5/16 3/4 1019770 – .23 .53 .38 .31 .75 1.07 1.91 1.15 1.82 .31 .06 .06

3/8 1 1019772 – .33 .66 .44 .38 .92 1.28 2.31 1.42 2.17 .38 .13 .06

7/16 1-1/2 1019774 – .49 .75 .50 .44 1.06 1.48 2.67 1.63 2.51 .44 .13 .06

1/2 2 1019775 1019784 .75 .81 .64 .50 1.18 1.66 3.03 1.81 2.80 .50 .13 .06

5/8 3-1/4 1019793 1019800 1.47 1.06 .77 .63 1.50 2.04 3.76 2.32 3.56 .63 .13 .06

3/4 4-3/4 1019819 1019828 2.52 1.25 .89 .75 1.81 2.40 4.53 2.75 4.15 .81 .25 .06

7/8 6-1/2 1019837 1019846 3.85 1.44 1.02 .88 2.10 2.86 5.33 3.20 4.82 .97 .25 .06

1 8-1/2 1019855 1019864 5.55 1.69 1.15 1.00 2.38 3.24 5.94 3.69 5.39 1.00 .25 .06

1-1/8 9-1/2 1019873 1019882 7.60 1.81 1.25 1.13 2.68 3.61 6.78 4.07 5.90 1.25 .25 .06

1-1/4 12 1019891 1019908 10.81 2.03 1.40 1.25 3.00 3.97 7.50 4.53 6.69 1.38 .25 .06

1-3/8 13-1/2 1019917 1019926 13.75 2.25 1.53 1.38 3.31 4.43 8.28 5.01 7.21 1.50 .25 .13

1-1/2 17 1019935 1019944 18.50 2.38 1.66 1.50 3.62 4.87 9.05 5.38 7.73 1.62 .25 .13

1-3/4 25 1019953 1019962 31.40 2.88 2.04 1.75 4.19 5.82 10.97 6.38 9.33 2.12 .25 .13

2 35 1019971 1019980 46.75 3.25 2.30 2.10 5.00 6.82 12.74 7.25 10.41 2.36 .25 .13

2-1/2 55 1019999 1020004 85.00 4.12 2.80 2.63 5.68 8.07 14.85 9.38 13.58 2.63 .25 .25

3 † 85 1020013 – 124.25 5.00 3.25 3.00 6.50 8.56 16.87 11.00 15.13 3.50 .25 .25

* NOTE: Maximum Proof Load is 2 times the Working Load Limit. Minimum Ultimate Strength is 6 times the Working Load Limit. For Working Load Limit reduction due to side loading ap-

plications, see page 94. † Individually Proof Tested with certification

80 Copyright © 2019 The Crosby Group LLC All Rights Reserved

You might also like

- Express Islamabad 05 OctDocument14 pagesExpress Islamabad 05 OctSheikh ShoaibNo ratings yet

- 60-Degree Bunsen Burner Test For Electric Wire: 4.1 ScopeDocument7 pages60-Degree Bunsen Burner Test For Electric Wire: 4.1 ScopeSheikh ShoaibNo ratings yet

- NBP RateSheet 18 11 2019Document1 pageNBP RateSheet 18 11 2019Bunny VirgoNo ratings yet

- Iso Noremark PDFDocument86 pagesIso Noremark PDFimran sheikh100% (1)

- Epoxy Iron Oxide Primer: DescriptionDocument1 pageEpoxy Iron Oxide Primer: DescriptionSheikh ShoaibNo ratings yet

- Westinghouse Technology Systems Manual Section 3.2 Reactor Coolant SystemDocument62 pagesWestinghouse Technology Systems Manual Section 3.2 Reactor Coolant SystemSheikh ShoaibNo ratings yet

- Epoxy Primer Technical Data SheetDocument2 pagesEpoxy Primer Technical Data SheetSheikh Shoaib100% (1)

- Industry Checklist CranesDocument4 pagesIndustry Checklist CranesoperationmanagerNo ratings yet

- Credit Card StatementDocument4 pagesCredit Card StatementSheikh ShoaibNo ratings yet

- Technical Data EPOXY PRIMER Grey OxideDocument2 pagesTechnical Data EPOXY PRIMER Grey OxideSheikh ShoaibNo ratings yet

- Asmeb30 26 35777Document5 pagesAsmeb30 26 35777ilmiNo ratings yet

- Total HeadDocument34 pagesTotal HeadHussainNo ratings yet

- DKPWDocument5 pagesDKPWMurad AlamNo ratings yet

- SEO-Optimized Title for Water Technology Chapter DocumentDocument96 pagesSEO-Optimized Title for Water Technology Chapter Documentdeep34No ratings yet

- Calibration BrochureDocument8 pagesCalibration BrochurehuidhyiuodghNo ratings yet

- Orbital Welding & Induction Machine ConsumablesDocument1 pageOrbital Welding & Induction Machine ConsumablesSheikh ShoaibNo ratings yet

- 11 Apr Express IslamabadDocument16 pages11 Apr Express IslamabadSheikh ShoaibNo ratings yet

- Pump PerformanceDocument18 pagesPump PerformanceKelvin XuNo ratings yet

- Astm A 324 73 r00Document3 pagesAstm A 324 73 r00Sheikh ShoaibNo ratings yet

- PIEAS - Computer Issued Offer LetterDocument3 pagesPIEAS - Computer Issued Offer LetterSheikh ShoaibNo ratings yet

- Tech Tip 2 PDFDocument5 pagesTech Tip 2 PDFcarlosorizabaNo ratings yet

- CreditCard Statement 04-02-2020T22 02 46Document1 pageCreditCard Statement 04-02-2020T22 02 46Sheikh Shoaib67% (3)

- Astm A 324 73 r00Document3 pagesAstm A 324 73 r00Sheikh ShoaibNo ratings yet

- PIEAS - Computer Issued Offer Letter PDFDocument3 pagesPIEAS - Computer Issued Offer Letter PDFSheikh ShoaibNo ratings yet

- Technical Data Sheet: Dynafor Range LLXHDocument2 pagesTechnical Data Sheet: Dynafor Range LLXHSheikh ShoaibNo ratings yet

- Wire Rope Slings Guide for Lifting ApplicationsDocument22 pagesWire Rope Slings Guide for Lifting ApplicationsMahmoud Al-SherbinyNo ratings yet

- Sound Meter HDDocument5 pagesSound Meter HDSheikh ShoaibNo ratings yet

- Setup a Simple Rankine Steam Cycle in HYSYS v8.6Document27 pagesSetup a Simple Rankine Steam Cycle in HYSYS v8.6ソーダ エドゥアルドNo ratings yet

- MTS 1.5 An: D 3.0 Meter Uniaxial Seismic SimulatorsDocument2 pagesMTS 1.5 An: D 3.0 Meter Uniaxial Seismic SimulatorsSheikh ShoaibNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Rigging Study & Lifting Plan For Oil Storage Tank at NaimatDocument15 pagesRigging Study & Lifting Plan For Oil Storage Tank at NaimatEngr Arfan Ali Dhamraho100% (4)

- Chapter GSK 8 Exam QuestionsDocument13 pagesChapter GSK 8 Exam QuestionsChandan PalNo ratings yet

- Decrease Rig #10 PDFDocument16 pagesDecrease Rig #10 PDFjokoNo ratings yet

- X 904 Recommended PracticeDocument4 pagesX 904 Recommended PracticemuralisunNo ratings yet

- Forestry and Logging Tools CatalogDocument16 pagesForestry and Logging Tools Catalogbman0051401No ratings yet

- Manual Duplex EDocument50 pagesManual Duplex E赵焕彪No ratings yet

- Huawei - Jaguar - Rigging MOP Rev005Document28 pagesHuawei - Jaguar - Rigging MOP Rev005Ronie MarxistNo ratings yet

- FEMA Heavy Equip and Rigging TrainingDocument22 pagesFEMA Heavy Equip and Rigging TrainingTimbo6808No ratings yet

- 07 Genpurp Mooring - QXD 27/1/12 12:48 PM Page 1Document9 pages07 Genpurp Mooring - QXD 27/1/12 12:48 PM Page 1Daniel0010No ratings yet

- Circuit Breaker Lockout: Reference GuideDocument16 pagesCircuit Breaker Lockout: Reference Guideangel_rojas_38No ratings yet

- Safe rigging practices for slings, ropes, chains and lifting hardwareDocument78 pagesSafe rigging practices for slings, ropes, chains and lifting hardwareanurag_4013100% (2)

- Job Safety Analysis for Pipeline LoadingDocument8 pagesJob Safety Analysis for Pipeline LoadingMoaatazz NouisriNo ratings yet

- Japan: EDI CT OF GovernmentDocument19 pagesJapan: EDI CT OF GovernmentHan Win AungNo ratings yet

- Crossby PinDocument1 pageCrossby PinHimura_No ratings yet

- Shackles Rev01.Document17 pagesShackles Rev01.Pudjiono APNo ratings yet

- HaGun Rigging Study and Lifting StudyDocument110 pagesHaGun Rigging Study and Lifting StudyGunawan HaGun100% (9)

- Basic RiggingDocument156 pagesBasic RiggingDoni Hardi100% (3)

- Shell Lifting AttachmentsDocument12 pagesShell Lifting AttachmentsjesusgameboyNo ratings yet

- Technical Data Sheet Bolt Diameter Tolerances For Crosby® S/G-2130/2140 ShacklesDocument1 pageTechnical Data Sheet Bolt Diameter Tolerances For Crosby® S/G-2130/2140 ShacklesozkanhasanNo ratings yet

- Guide to Ship Anchors and Ground TackleDocument77 pagesGuide to Ship Anchors and Ground TackleMaria VasileNo ratings yet

- My Industrial Rigging and CranesDocument203 pagesMy Industrial Rigging and CranesJShearer67% (6)

- Basic Rigging WorkbookDocument46 pagesBasic Rigging WorkbookMalcolm MooreNo ratings yet

- Crosby - G2130 ENGLISH PDFDocument1 pageCrosby - G2130 ENGLISH PDFtarun1976No ratings yet

- APLO Mobile Crane PDFDocument126 pagesAPLO Mobile Crane PDFFaiyazNo ratings yet

- D - D Ratio and The Effect On Sling Capacity - Unirope LTD PDFDocument3 pagesD - D Ratio and The Effect On Sling Capacity - Unirope LTD PDFalphadingNo ratings yet

- D&B - J Rigging ManualDocument34 pagesD&B - J Rigging ManualJairoGRNo ratings yet

- Rigging Safety Training: 4 Types of Slings and Inspection RequirementsDocument92 pagesRigging Safety Training: 4 Types of Slings and Inspection RequirementsD Srinivasa RaoNo ratings yet

- 01 - Lifting Personnel Basket - ADNOCDocument4 pages01 - Lifting Personnel Basket - ADNOCEmad ZakiNo ratings yet

- Truck Suspension Past Generation Products: AR 34K AR 38K HN 40K - 46K HN /HNT 40K - 46KDocument26 pagesTruck Suspension Past Generation Products: AR 34K AR 38K HN 40K - 46K HN /HNT 40K - 46Kgustavoemosquera5093No ratings yet

- Green Lift Checklist F1003Document2 pagesGreen Lift Checklist F1003Engr Arfan Ali Dhamraho67% (3)