Professional Documents

Culture Documents

Ultrasonic Machining, or Strictly Speaking The "Ultrasonic

Uploaded by

sudhanshu kumar0 ratings0% found this document useful (0 votes)

1 views1 pageUltrasonic machining is a manufacturing process that removes material from a part's surface through high-frequency, low-amplitude vibrations of a tool against the material in the presence of fine abrasive particles mixed in a water slurry. The tool vertically travels in small amplitudes against the part's surface while the abrasive grains in the slurry do the cutting work, allowing intricate shapes to be machined without leaving mechanical marks on the material.

Original Description:

Original Title

UM.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUltrasonic machining is a manufacturing process that removes material from a part's surface through high-frequency, low-amplitude vibrations of a tool against the material in the presence of fine abrasive particles mixed in a water slurry. The tool vertically travels in small amplitudes against the part's surface while the abrasive grains in the slurry do the cutting work, allowing intricate shapes to be machined without leaving mechanical marks on the material.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views1 pageUltrasonic Machining, or Strictly Speaking The "Ultrasonic

Uploaded by

sudhanshu kumarUltrasonic machining is a manufacturing process that removes material from a part's surface through high-frequency, low-amplitude vibrations of a tool against the material in the presence of fine abrasive particles mixed in a water slurry. The tool vertically travels in small amplitudes against the part's surface while the abrasive grains in the slurry do the cutting work, allowing intricate shapes to be machined without leaving mechanical marks on the material.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

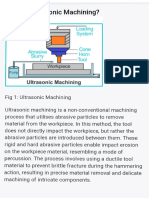

ULTRASONIC MACHINING

Ultrasonic machining, or strictly speaking the "Ultrasonic

vibration machining", is a subtraction manufacturing process that

removes material from the surface of a part through high

frequency, low amplitude vibrations of a tool against the material

surface in the presence of fine abrasive particles. The tool travels

vertically or orthogonal to the surface of the part at amplitudes of

0.05 to 0.125 mm (0.002 to 0.005 in.).[1] The fine abrasive grains

are mixed with water to form a slurry that is distributed across the

part and the tip of the tool. Typical grain sizes of the abrasive

material range from 100 to 1000, where smaller grains (higher

grain number) produce smoother surface finishes. [1]

You might also like

- Ultrasonic MachiningDocument14 pagesUltrasonic MachiningKeyur SoleNo ratings yet

- Surface Finishing ProcessDocument28 pagesSurface Finishing ProcessRavichandran GNo ratings yet

- VASCHE AD ULTRASUONI GB LowDocument16 pagesVASCHE AD ULTRASUONI GB Lowkaka punNo ratings yet

- Screening: Che-205 Particle TechnologyDocument31 pagesScreening: Che-205 Particle TechnologyInsiram NaveedNo ratings yet

- Ultrasonic MachiningDocument11 pagesUltrasonic Machininghyundai31050% (2)

- 215 Sample ChapterDocument23 pages215 Sample ChapterSreekumar RajendrababuNo ratings yet

- Ultrasonic CleaningDocument14 pagesUltrasonic CleaningAbhilash FulkarNo ratings yet

- The Use of Ultrasonic Cleaning in Dairy Industry: How Does It Work?Document3 pagesThe Use of Ultrasonic Cleaning in Dairy Industry: How Does It Work?Vetz clubNo ratings yet

- Machining Process: University of LahoreDocument3 pagesMachining Process: University of LahoreZain TabishNo ratings yet

- Modern Manufacturing ProcssesDocument24 pagesModern Manufacturing ProcssesAravind SudheesanNo ratings yet

- Ultrasonic MachiningDocument2 pagesUltrasonic MachiningDinesh NeshNo ratings yet

- USM Working PrincipleDocument3 pagesUSM Working PrincipleAnonymous dL8dsCncNo ratings yet

- Non-Traditional Machining - Ultrasonic Machining (USM)Document22 pagesNon-Traditional Machining - Ultrasonic Machining (USM)SyafiqAsyrafNo ratings yet

- Piezoelectric Actuator Ultrasonic: MechanismDocument2 pagesPiezoelectric Actuator Ultrasonic: Mechanism39 Mohit KumarNo ratings yet

- Working PrincipleDocument2 pagesWorking Principle39 Mohit KumarNo ratings yet

- Final Report 2Document16 pagesFinal Report 2Ravi PatelNo ratings yet

- Ultrasonic-Machining ProcessDocument16 pagesUltrasonic-Machining ProcessTrung Quoc LeNo ratings yet

- Ultrasonic MachiningDocument26 pagesUltrasonic MachiningEmanuel Nuñez ClavecillasNo ratings yet

- Ultrasonic Machining (USM) : Dr. Harlal Singh MaliDocument11 pagesUltrasonic Machining (USM) : Dr. Harlal Singh MaliPrashant Singh SankhalaNo ratings yet

- Ultrasonic Machining: Principle of USMDocument5 pagesUltrasonic Machining: Principle of USMmahammad kamaluddeenNo ratings yet

- 4D UsmDocument13 pages4D UsmHARSHVARDHAN SINGH RATHORENo ratings yet

- Ultrasonic Machining: Mechanisms of Material Removal in USMDocument4 pagesUltrasonic Machining: Mechanisms of Material Removal in USMGunabalan SellanNo ratings yet

- USM NotesDocument11 pagesUSM Notes18R21A0310 BIYYALA SHESHAGIRINo ratings yet

- Usm 139Document38 pagesUsm 139Shivaprasad bhNo ratings yet

- UsmDocument16 pagesUsmSatish Singh KunduNo ratings yet

- Ultrasonic MachiningDocument20 pagesUltrasonic MachiningKoushik Rao100% (1)

- Assignment#3 Group #2: Manufacturing Process Ultrasonic MachiningDocument16 pagesAssignment#3 Group #2: Manufacturing Process Ultrasonic MachiningThe Noob100% (1)

- Ultresonic MachiningDocument2 pagesUltresonic MachiningPrashant SinghNo ratings yet

- NON Conventional MachiningDocument26 pagesNON Conventional MachiningAdam PathanNo ratings yet

- Dinakaran 2 CMLDocument86 pagesDinakaran 2 CMLShashwarya ShashuNo ratings yet

- El-Hofy Fundamentals of Machining Processes Tema 10Document42 pagesEl-Hofy Fundamentals of Machining Processes Tema 10chompo83No ratings yet

- Ajm UsmDocument19 pagesAjm Usm0iamkaran0No ratings yet

- Ultrasonic Machining (Usm)Document17 pagesUltrasonic Machining (Usm)Prasad ChikkamNo ratings yet

- Ultra Sound MachiningDocument20 pagesUltra Sound MachiningVishalHarchandaniNo ratings yet

- Ultrasonic Machining Engineering Materials And Manufacuring Technology اشع ديعس نزام ديعس 0147566Document8 pagesUltrasonic Machining Engineering Materials And Manufacuring Technology اشع ديعس نزام ديعس 0147566Saeed AshaNo ratings yet

- Different Types of IsolationDocument29 pagesDifferent Types of IsolationLockon StratosNo ratings yet

- Ultrasonic Machining (USM)Document20 pagesUltrasonic Machining (USM)Prateek SharmaNo ratings yet

- Ultra Sonic MachiningDocument32 pagesUltra Sonic MachiningAshwin DevNo ratings yet

- Approximate Speed of Sound in Common Materials: Medium Sound Velocity (FT/S) M/sDocument3 pagesApproximate Speed of Sound in Common Materials: Medium Sound Velocity (FT/S) M/sJop GanancialNo ratings yet

- Lapping Is A: Machining AbrasiveDocument4 pagesLapping Is A: Machining AbrasiveRajesh AthishNo ratings yet

- Working Principle of Ultrasonic MachiningDocument7 pagesWorking Principle of Ultrasonic MachiningYogesh KandaNo ratings yet

- The Principles of Acoustical AttenuationDocument24 pagesThe Principles of Acoustical AttenuationNagwan QassemNo ratings yet

- Advanced Manufacturing ProcessDocument2 pagesAdvanced Manufacturing ProcessBiswadeep Roy ChoudhuryNo ratings yet

- Non-Traditional Machining: Mechanical Processes (USM, WJM, AWJM, IJM, MAF)Document61 pagesNon-Traditional Machining: Mechanical Processes (USM, WJM, AWJM, IJM, MAF)Yahya Abdelhameed AamerNo ratings yet

- Super Finishing ProcessesDocument2 pagesSuper Finishing ProcessesSamir BoseNo ratings yet

- Ultrasonic Machining by M.8601685.PowerpointDocument8 pagesUltrasonic Machining by M.8601685.PowerpointSheikh waleedNo ratings yet

- Blanking Piercing Forming DrawingDocument3 pagesBlanking Piercing Forming DrawingS.DharanipathyNo ratings yet

- Ignacio, Fernand Lui B. Generoso, John Michael IDocument18 pagesIgnacio, Fernand Lui B. Generoso, John Michael IAnonymous aWxiNE7w100% (1)

- Ultrasonic MachiningDocument12 pagesUltrasonic MachiningTumai Bau kiNo ratings yet

- Ultrasonic Machining (Usm) : TitleDocument12 pagesUltrasonic Machining (Usm) : TitleKiran KumarNo ratings yet

- USM Study of Parameters of USMDocument43 pagesUSM Study of Parameters of USMZoric BobbyNo ratings yet

- Unit 1 - AMTDocument38 pagesUnit 1 - AMTLavishNo ratings yet

- Vibro SifterDocument3 pagesVibro SifterRaj K SharmaNo ratings yet

- Ultrasonic Machining (Usm) : Brittle Fracture Cavitation Induced Erosion Chemical ErosionDocument26 pagesUltrasonic Machining (Usm) : Brittle Fracture Cavitation Induced Erosion Chemical ErosionRishiJpNo ratings yet

- Ultrasonic Machining (Usm) : Brittle Fracture Cavitation Induced Erosion Chemical ErosionDocument26 pagesUltrasonic Machining (Usm) : Brittle Fracture Cavitation Induced Erosion Chemical ErosionRishiJp100% (1)

- Ultrasonic Machining Process, Working Principles & AdvantagesDocument3 pagesUltrasonic Machining Process, Working Principles & AdvantagesCiprian-Dumitru CiofuNo ratings yet

- Unit-Ii Advanced Mechanical Processes Ultrasonic MachiningDocument14 pagesUnit-Ii Advanced Mechanical Processes Ultrasonic MachiningAbhishek KumarNo ratings yet

- Abdurehman (40931) Assign 1Document3 pagesAbdurehman (40931) Assign 1Abdurehman Ullah khanNo ratings yet

- Unit I: Abrasive GrindingDocument50 pagesUnit I: Abrasive GrindingVaibhav KumarNo ratings yet

- UNIT-2 Ultrasonic MachiningDocument73 pagesUNIT-2 Ultrasonic MachiningraghurockramNo ratings yet