Professional Documents

Culture Documents

Disassembly Instructions for ECblue External Rotor Motors

Uploaded by

Jose MarcamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Disassembly Instructions for ECblue External Rotor Motors

Uploaded by

Jose MarcamCopyright:

Available Formats

english

Instruction for disassembly

ECblue-external rotor motors of motor size

B (090), D (116) and G (152)

L-WAL-007-GB 1546 Index 001 Part.-No.

L-WAL007 Instruction for disassembly General notes

1 General notes

Instruction for disassembly and ecologically meaningful disposal of motor components of ECblue-

external rotor motors according to regulation (EU) No. 1253/2014. Valid for motor size “B” (090), “D”

(116) and “G” (152).

The used motor size is recognisable from the type designation ( rating plate).

Examples for type designations with motor size B = 90

Motors Type Axial fans type Centrifugal fans type

MK090 -_ I _ . _ _ . _ _ F _ _ _ _-_ I _. B _._ _ _ _ RH _ _ _-_ I _. B _._ _

GR _ _ _-_ I _. B _._ _

ER _ _ _-_ I _. B _._ _

2 Safety instructions

Attention!

• Observe the assembly instructions of the product! Ensure in particular compliance with all safety

specifications!

• The high magnetic forces of attraction between the rotor and the stator present a risk of injury.

L-WAL-007-GB 1546 Index 001 Part.-No.

2/10

L-WAL007 Instruction for disassembly Disassemble fan

3 Disassemble fan

Danger due to electric current

• The 5 electrical safety rules must be observed!

• When the motor runs independently due to air flowing through or if it continues to run down after

being turned off, dangerous voltages of over 50 V can arise on the motor internal connections

through operation of the generator.

• Through use of capacitors, danger of death exists even after switching off the device through

directly touching the energized parts or due to parts that have become energized due to faults.

• The controller housing may only be removed or opened when the power line has been switched off

and a period of three minutes has elapsed since switching it off.

Procedure

1. Turn off the line voltage and secure against switching back on.

2. Clean any external contaminations from the fan prior to disassembly.

3. Depending on the fan's construction, remove the external components like the wall ring (2) and

the protective grille (1), and check that these can be reused.

4. Wait for at least 3 minutes before removing the cover from the controller housing.

5. Check safe isolation from supply.

6. Disconnect all electrical cables.

L-WAL-007-GB 1546 Index 001 Part.-No.

3/10

L-WAL007 Instruction for disassembly Tools for disassembly

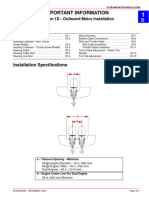

4 Tools for disassembly

The following tools are required for disassembly:

1 Bar extractor

2 Pliers for outer circlip

3 Pliers for inner circlip

4 Release toll for motor size D (116) and G (152)

5 For Motor size B (090) screwdriver TX20 (TR TX20 for security torx), for motor size D (116) and G (152) screwdriver TX25

6 Slotted screwdriver (e.g. 0.6) for motor size D (116) and G (152)

7 Withdrawal sleeve incl. round material for extracting the ball bearing on the stator side

Special tool available from ZIEHL-ABEGG

Motor size Release tool Bar extractor Extractor sleeve

Drawing num- Part numbers Drawing num- Part numbers Drawing num- Part numbers

ber ber ber

B (090) - - 6003-201 00280698 6003-212 00703644

D (116) 6003-019 00161068 6003-202 00280682 6003-209 00295437

G (152) 6003-019 00161068 6003-202 00280682 6003-211 00296476

L-WAL-007-GB 1546 Index 001 Part.-No.

4/10

L-WAL007 Instruction for disassembly Procedure for disassembly

5 Procedure for disassembly

5.1 Opening the motor

Remove the cover from the controller housing

" For motor size B (090)

– 2 x Torx of connection area cover solve with

screwdriver “5” TX20.

– 4 x Security Torx TR of controller cover solve

with screwdriver “5” TX20.

" For motor size D (116) solve 5 screws (combi

Torx T20) with screwdriver “5”.

" For motor size G (152) solve 6 screws (combi

Torx T20) with screwdriver “5”.

Illustration motor size G (152)

Motor size D (116) and G (152)

" Remove any add-on module present from its

slot.

" Loosen the locking bolts using the release tool

“4”.

Information

• Earlier versions are designed with a Torx T10

plastic screw, which must be loosened here.

" Push the retaining clips using the screwdriver

“6” and remove the black inner cover.

L-WAL-007-GB 1546 Index 001 Part.-No.

5/10

L-WAL007 Instruction for disassembly Procedure for disassembly

5.2 Disassemble the motor and remove ball bearings

" Remove the inner circlip using pliers “3” and

dispose of it.

Attention!

• Do not reuse the circlip due to the risk of

overstretching.

" Remove and dispose of the plastic washer.

Information

• The plastic washer is not present in the version

with hybrid bearings and steel shaft without

plastic encapsulation.

Attention!

• Do not reuse the plastic washer.

" Remove the outer circlip using pliers “2” and

dispose of it.

Attention!

• Do not reuse the circlip due to the risk of

overstretching.

" Place the extraction tool “1” on the stator

and secure to the stator flange.

L-WAL-007-GB 1546 Index 001 Part.-No.

6/10

L-WAL007 Instruction for disassembly Procedure for disassembly

" Remove the stator “A” from the rotor using the 1

extraction tool “1” by pressing the threaded

spindle onto the front face “Z”.

" Remove the stator “A” from the magnetic field of

the rotor using “B” using the extraction tool.

" Remove the extraction tool from the stator.

Attention!

A

• Never attempt to remove the stator and rotor

manually without an extraction tool. 302a

Z

• There is a strong attraction between the sta- 202

tor “A” and the rotor “B” because of high

magnetic forces – danger of injury! B

304

L-KL-2205

" Remove and dispose of the plastic washer.

Information

• The plastic washer is not present in the version

with hybrid bearings and steel shaft without

plastic encapsulation.

Attention!

• Do not reuse the plastic washer.

" Remove the lower circlip “302a” using pliers “3”

and dispose of it.

Information

• Newer versions have neither plastic washers

nor circlips.

Attention!

• Do not reuse the circlip due to the risk of

overstretching.

L-WAL-007-GB 1546 Index 001 Part.-No.

7/10

L-WAL007 Instruction for disassembly Procedure for disassembly

" Remove the ball bearing on the stator side

using suitable round material.

" Remove the ball bearing on the rotor side using

the extraction sleeve “7”.

If no suitable press is available, the ball bearing

can be pushed off using the extraction tool and a

shaft.

L-WAL-007-GB 1546 Index 001 Part.-No.

8/10

L-WAL007 Instruction for disassembly Disposal / recycling

" Remove the plastic washer from the shaft and

dispose of it.

Information

• Only in version with aluminium die-cast motor.

• For version with steel rotor remove plastic cool-

ing wheel from the ground of the rotor and

dispose of it.

" Remove plastic cooling rings from rotor flange

with an appropirate lifting tool (e.g. screwdriver

“6” and dispose of it.

Information Aluminium die-cast rotor with plastic washer (not shown) on flange

• For motor size G with steel rotor instead loosen

screw M5 with screwdriver “5” TX25 and re-

move cooling ring.

Steel rotor with plastic cooling fan

Attention!

Removed components must not be reused!

6 Disposal / recycling

Disposal must be carried out professionally and in an environmentally friendly way in accordance with

the respective national legal stipulations.

" Separate the materials by type and in an environmentally friendly way.

" If necessary, commission a specialist company with the waste disposal.

L-WAL-007-GB 1546 Index 001 Part.-No.

9/10

L-WAL007 Instruction for disassembly Enclosure

7 Enclosure

7.1 Manufacturer

Our products are manufactured in compliance with valid international standards and regulations.

If you have any questions about how to use our products or if you are planning special applications,

please contact:

ZIEHL-ABEGG SE

Heinz-Ziehl-Straße

D-74653 Künzelsau

Phone 07940/16-0

Fax 07940/16-300

info@ziehl-abegg.de

7.2 Service address

Please refer to the homepage at www.ziehl-abegg.com for a list of our subsidiaries worldwide.

L-WAL-007-GB 1546 Index 001 Part.-No.

10/10

You might also like

- Manual For 1215 Kva Rig AlternatorDocument18 pagesManual For 1215 Kva Rig Alternatorprem080910No ratings yet

- Metal Core Drilling MachineDocument13 pagesMetal Core Drilling MachineamekhzoumiNo ratings yet

- HifiDocument50 pagesHifigolddigger19890% (1)

- Pioneer Single Trip Retreival SystemDocument13 pagesPioneer Single Trip Retreival SystemRight S AlexNo ratings yet

- Taladro Magnetico Rotabest Mini 36-50 Manual OperacionDocument12 pagesTaladro Magnetico Rotabest Mini 36-50 Manual OperacionAtahualpa Bulganin Infante YañezNo ratings yet

- Operating Instructions Zet-Horn AC: Zöllner - KielDocument25 pagesOperating Instructions Zet-Horn AC: Zöllner - Kielbob228340No ratings yet

- Roller Chain Coupling: Features 1. Simple Structure 1. Advantages of HousingDocument5 pagesRoller Chain Coupling: Features 1. Simple Structure 1. Advantages of Housingsyaifularifin33No ratings yet

- Alfra Rotabest Midi 5050 Operation ManualDocument13 pagesAlfra Rotabest Midi 5050 Operation Manualsudofim2006No ratings yet

- ACE3 Maintenance and Service InstructionDocument12 pagesACE3 Maintenance and Service InstructionduhgrandoNo ratings yet

- Eixo Dif Simples Vel ENGDocument62 pagesEixo Dif Simples Vel ENGAhmedNo ratings yet

- Caterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)Document26 pagesCaterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)kfm8seuuduNo ratings yet

- Installation and Operating Instructions for RLK 402 Cone Clamping ElementsDocument5 pagesInstallation and Operating Instructions for RLK 402 Cone Clamping ElementshamishjbadamsonNo ratings yet

- Maytag Triple Lip and Bearing Kit Installation InstructionsDocument8 pagesMaytag Triple Lip and Bearing Kit Installation InstructionsSamurai Appliance Repair ManNo ratings yet

- Workshop MDocument69 pagesWorkshop MmanhNo ratings yet

- Rotary Joint Unit: Supplementary Instruction ManualDocument17 pagesRotary Joint Unit: Supplementary Instruction ManualAntonio Montesinos ChavarríaNo ratings yet

- Engine Valve Lash - Inspect: Testing and AdjustingDocument5 pagesEngine Valve Lash - Inspect: Testing and AdjustingSuharto ZuhriNo ratings yet

- Medición en La ArmaduraDocument5 pagesMedición en La ArmaduraAlvaro arceNo ratings yet

- John Deere PowerTech 10.5L Diesel Base Engine Service Repair Technical Manual (CTM100)Document17 pagesJohn Deere PowerTech 10.5L Diesel Base Engine Service Repair Technical Manual (CTM100)laopaodunNo ratings yet

- ZOOMLION 櫓젬路옰Document376 pagesZOOMLION 櫓젬路옰Jamyansuren Tseveendorj100% (1)

- Bondura Bolt - Assembly ProcedureDocument5 pagesBondura Bolt - Assembly ProceduresamersurfNo ratings yet

- ACFrOgA-8u3Zi5xFimnR2twGIAR XM 1KM eb9M5yAVQlQaPUftir ttiG38JZ683E p-uvv8f8iyrSkHSm4UjBP2DaHTvFIR3JmerfXdpfovmicTsXQSp5hQFOz2sMDocument27 pagesACFrOgA-8u3Zi5xFimnR2twGIAR XM 1KM eb9M5yAVQlQaPUftir ttiG38JZ683E p-uvv8f8iyrSkHSm4UjBP2DaHTvFIR3JmerfXdpfovmicTsXQSp5hQFOz2sMYN Motors Yonnier PintoNo ratings yet

- Caterpillar Cat 330 TRACK-TYPE EXCAVATOR (Prefix 6SK) Service Repair Manual (6SK00001 and Up)Document24 pagesCaterpillar Cat 330 TRACK-TYPE EXCAVATOR (Prefix 6SK) Service Repair Manual (6SK00001 and Up)kfm8seuudu100% (1)

- Connecting Rod Repair GuideDocument32 pagesConnecting Rod Repair GuideJorge Espinoza100% (1)

- John Deere 450CLC Excavator Service Repair Technical Manual (TM1925)Document14 pagesJohn Deere 450CLC Excavator Service Repair Technical Manual (TM1925)laopaodunNo ratings yet

- Front Axle: SectionDocument14 pagesFront Axle: Sectiontomallor101No ratings yet

- Manual Transmission GuideDocument21 pagesManual Transmission GuideKwun Hok ChongNo ratings yet

- Alternator - Remove & InstallDocument3 pagesAlternator - Remove & InstallZawminhtunNo ratings yet

- Cylinder Head B3.9 EnginesDocument82 pagesCylinder Head B3.9 EnginesWaad HarbNo ratings yet

- JC2013 JAW CRUSHER 200 X 130 All Voltages (Rev3)Document15 pagesJC2013 JAW CRUSHER 200 X 130 All Voltages (Rev3)sharedfilepcNo ratings yet

- Inertia Dynamic TypeSL SpecsheetDocument3 pagesInertia Dynamic TypeSL SpecsheetElectromateNo ratings yet

- Maintain Rail Coach Draw GearDocument8 pagesMaintain Rail Coach Draw Gearanunay kumarNo ratings yet

- Caterpillar Cat 303.5 D Mini Excavator (Prefix RHP) Service Repair Manual (RHP00001 and Up)Document23 pagesCaterpillar Cat 303.5 D Mini Excavator (Prefix RHP) Service Repair Manual (RHP00001 and Up)kfmuseddkNo ratings yet

- Alco em 01Document22 pagesAlco em 01Claudio MatiasNo ratings yet

- Drive Technology: Rope Winches and GearboxesDocument20 pagesDrive Technology: Rope Winches and GearboxesAnonymous ODKk6IgUJNNo ratings yet

- Demontare Caseta de DirectieDocument8 pagesDemontare Caseta de DirectieSerban SimiNo ratings yet

- Wadkin BER 2 Spindle Moulder Manual & Parts ListDocument18 pagesWadkin BER 2 Spindle Moulder Manual & Parts Listmkmk15793No ratings yet

- Er 108 1 PDFDocument3 pagesEr 108 1 PDFDIEGO YECID MILLAN MENDOZANo ratings yet

- Er 108 1Document3 pagesEr 108 1DIEGO YECID MILLAN MENDOZANo ratings yet

- Install Piston and ConrodDocument8 pagesInstall Piston and ConrodLUIZ GUSTAVONo ratings yet

- Weir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedureDocument10 pagesWeir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedurePutra JawaNo ratings yet

- C6.6 Cam Shaft InstallDocument5 pagesC6.6 Cam Shaft InstallsenNo ratings yet

- Servodirectii EatonDocument14 pagesServodirectii Eatonwappii100% (1)

- Caterpillar Cat 304C CR Mini Hydraulic Excavator (Prefix FPK) Service Repair Manual (FPK00001 and Up)Document23 pagesCaterpillar Cat 304C CR Mini Hydraulic Excavator (Prefix FPK) Service Repair Manual (FPK00001 and Up)kfmuseddkNo ratings yet

- ML B 200 b200fmm1035Document11 pagesML B 200 b200fmm1035Marco Antonio PrietoNo ratings yet

- Automatic Drawbar ManualDocument24 pagesAutomatic Drawbar Manualjason mossNo ratings yet

- Caterpillar Cat M318C WHEELED Excavator (Prefix H2F) Service Repair Manual (H2F00001 and Up) PDFDocument27 pagesCaterpillar Cat M318C WHEELED Excavator (Prefix H2F) Service Repair Manual (H2F00001 and Up) PDFfkdmmaNo ratings yet

- Flowserve Seal - ISC2 - Install - LTRDocument8 pagesFlowserve Seal - ISC2 - Install - LTRjame11inNo ratings yet

- Grupo Frontal D5GDocument4 pagesGrupo Frontal D5GjulianmatabajoyNo ratings yet

- BPM800 BPM800 Repair - Rev 1Document7 pagesBPM800 BPM800 Repair - Rev 1api-3752216No ratings yet

- Caterpillar Cat 330B L Excavator (Prefix 6DR) Service Repair Manual (6DR00001 and Up)Document27 pagesCaterpillar Cat 330B L Excavator (Prefix 6DR) Service Repair Manual (6DR00001 and Up)kfm8seuuduNo ratings yet

- Manual Yamaha YST-SW012 (Service)Document16 pagesManual Yamaha YST-SW012 (Service)Alex NikitinNo ratings yet

- Engine Timing ValvesDocument44 pagesEngine Timing ValvesSlobodanNo ratings yet

- Armado de Valvula de Salida Del ConvertidorDocument2 pagesArmado de Valvula de Salida Del ConvertidorKerbin Enrique NuñezNo ratings yet

- Important Information: Section 1D - Outboard Motor InstallationDocument13 pagesImportant Information: Section 1D - Outboard Motor InstallationDr. Centelha Mecânica NaúticaNo ratings yet

- Pages From FJ HDJ Hzj-80 Series Chassis-WinchDocument55 pagesPages From FJ HDJ Hzj-80 Series Chassis-WinchcharNo ratings yet

- Caterpillar Cat M322D MH WHEELED EXCAVATOR (Prefix W2T) Service Repair Manual (W2T00001 and Up) PDFDocument20 pagesCaterpillar Cat M322D MH WHEELED EXCAVATOR (Prefix W2T) Service Repair Manual (W2T00001 and Up) PDFfkdmmaNo ratings yet

- Wing Bend FlyerDocument2 pagesWing Bend Flyeralexayala5151No ratings yet

- Connecting Rod Bearings - Install - Connecting Rods in PositionDocument4 pagesConnecting Rod Bearings - Install - Connecting Rods in PositionTatiano BrolloNo ratings yet

- Lc320dxj Sfe1 LGDocument8 pagesLc320dxj Sfe1 LGdreamyson1983No ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Electromagnetic Clutch System Full Seminar Report 4537Document30 pagesElectromagnetic Clutch System Full Seminar Report 4537Dani RiccNo ratings yet

- ECEG 4123 Electrical Machines: Types of Synchronous MachinesDocument17 pagesECEG 4123 Electrical Machines: Types of Synchronous MachinesmebrahtenNo ratings yet

- Emc-38 Manual PDFDocument9 pagesEmc-38 Manual PDFMrutyanjaya JethyNo ratings yet

- Renewable and Sustainable Energy Reviews: Hira Singh Sachdev, Ashok Kumar Akella, Niranjan KumarDocument10 pagesRenewable and Sustainable Energy Reviews: Hira Singh Sachdev, Ashok Kumar Akella, Niranjan KumarUros KaradzicNo ratings yet

- Geared Motors CatalogDocument120 pagesGeared Motors CatalogWawan SetiawanNo ratings yet

- Quasi-Direct Drive Actuation For A Lightweight Hip Exoskeleton With High Backdrivability and High BandwidthDocument9 pagesQuasi-Direct Drive Actuation For A Lightweight Hip Exoskeleton With High Backdrivability and High Bandwidth李磊No ratings yet

- ست خطوات العاكس لقيادة المحرك التعريفي ثلاث مراحلDocument113 pagesست خطوات العاكس لقيادة المحرك التعريفي ثلاث مراحلMOUHSSINE BEN HAMMOUNo ratings yet

- Induction GeneratorDocument12 pagesInduction GeneratorSumaira SaifNo ratings yet

- FILE - 20220221 - 070144 - TBHK & DĐB - Lesson 1Document13 pagesFILE - 20220221 - 070144 - TBHK & DĐB - Lesson 1LONG HUYNH HOANGNo ratings yet

- John Deere 24 Skid Steer Loader Service ManualDocument15 pagesJohn Deere 24 Skid Steer Loader Service ManualiloNo ratings yet

- Alternator Parts BreakdownDocument8 pagesAlternator Parts BreakdownVlad PtashnichenkoNo ratings yet

- Bath County VH Paper HV 2015 2015-05-19Document12 pagesBath County VH Paper HV 2015 2015-05-19Aura RNo ratings yet

- 1 Delta Ia-Asda Asda-A2r CDocument44 pages1 Delta Ia-Asda Asda-A2r CBana YasinNo ratings yet

- Generator Manual-1Document11 pagesGenerator Manual-1Wilson PalacioNo ratings yet

- Part numbers for vehicle componentsDocument242 pagesPart numbers for vehicle componentsMallikarjun S ModiNo ratings yet

- Backhus A30Document2 pagesBackhus A30Leo ManciniNo ratings yet

- Mems Based Wheel ChairDocument68 pagesMems Based Wheel ChairSaikrishna JulakantiNo ratings yet

- Chapter 2 REV1Document42 pagesChapter 2 REV1ahmadmosadeghNo ratings yet

- A Flux Focusing Ferrite Magnetic GearDocument6 pagesA Flux Focusing Ferrite Magnetic GearHuynh Thanh AnhNo ratings yet

- PMSM Vs Induction MotorDocument4 pagesPMSM Vs Induction MotorGarry GeorgeNo ratings yet

- Unit - I Synchronous GeneratorDocument25 pagesUnit - I Synchronous GeneratorVenkatesan SwamyNo ratings yet

- p203 PDFDocument7 pagesp203 PDFMehmood Khan MarwatNo ratings yet

- Utilization of Electrical Energy Question Bank PDFDocument17 pagesUtilization of Electrical Energy Question Bank PDFKranthi Kumar100% (1)

- Ansys MAXWELLDocument38 pagesAnsys MAXWELLluis900000100% (2)

- Mag Apps+Instal v1.5Document19 pagesMag Apps+Instal v1.5electron13No ratings yet

- Ventilador Chiller LaudaDocument12 pagesVentilador Chiller LaudaLuis Miguel C. L.No ratings yet

- Ee8401 Electrical Machines Ii Department of Eee 2021-2022Document20 pagesEe8401 Electrical Machines Ii Department of Eee 2021-2022NagendranNo ratings yet

- Tutorial 2 (Answer)Document9 pagesTutorial 2 (Answer)NAYAB HASSANo ratings yet

- Introduction of VFD and Its Programming, Faults, Troubleshooting and MaintenenceDocument27 pagesIntroduction of VFD and Its Programming, Faults, Troubleshooting and MaintenenceDigvijay singhNo ratings yet

- PI734B-Wdg 13Document6 pagesPI734B-Wdg 13tony suNo ratings yet