Professional Documents

Culture Documents

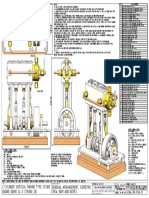

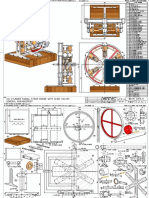

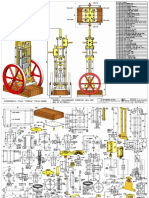

2 Cylinder Vertical Marine Type Steam Engine (Bore 24 X Stroke 28) General Arrangement, Isometric View, Bom and Notes

Uploaded by

Miguel MotaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 Cylinder Vertical Marine Type Steam Engine (Bore 24 X Stroke 28) General Arrangement, Isometric View, Bom and Notes

Uploaded by

Miguel MotaCopyright:

Available Formats

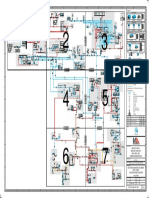

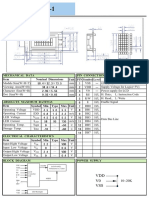

NOTES: QTY.

PART NUMBER

0. ALL DRAWINGS ARE IN METRIC MEASUREMENTS 1 BP9763-01-BASE PLATE

1. ALL ENGINEERING PRACTICES SHALL BE APPLIED WITH REGARDS TO HOLE AND SHAFT TOLERANCES. 2 BP9763-02-CRANKSHAFT BEARING TYPE-1

2. WHERE SCREWS OR BOLTS ARE USED THE CLEARANCE HOLES SHALL BE APPROXIMATELY 5% TO 8% LARGER THAN THE 1 BP9763-03-CRANKSHAFT BEARING TYPE-2

MATCHING TAPPED HOLE. 3 BP9763-04-BEARING OIL POT

3. PREFERABLY ALL TAPPED HOLES AND MATCHING SCREWS AND/OR BOLTS TO BE METRIC FINE (MF) 4 BP9763-05-CYLINDER BLOCK PILLAR

4. MATERIALS SPECIFIED ON THE DRAWINGS ARE INDICATIVE ONLY. THE BUILDER CAN MAKE HIS/HER OWN MATERIAL CHOICE. 1 BP9763-06-CYLINDER BLOCK

5. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM PRESSURE APPLIED TO IT SHALL BE SILVER/HARD SOLDERED. 2 BP9763-07-CYLINDER TOP COVER

6. COMPRESSION SPRINGS ARE DRAWN IN COMPRESSED STATE (CP), UNCOMPRESSED STATE IS APPROX 40% TO 60% LONGER 2 BP9763-08-CYLINDER BOTTOM COVER

2 BP9763-09-VALVE CHAMBER TOP COVER

THEN COMPRESSED STATE. 2 BP9763-10-VALVE CHAMBER BOTTOM COVER

7. WHERE PREFERRED SCREW OR RIVETED CONNECTIONS CAN BE OMITTED AND PARTS CAN BE BONDED TOGETHER BY USING

150 5.91

2 BP9763-11-PISTON ROD GLAND

EITHER HIGH STRENGTH GLUE, EPOXY RESIN, OR SOLDER. 2 BP9763-12-VALVE ROD GLAND

8. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM AND/OR WATER SHOULD BE CONSTRUCTED USING NON-FERROUS OR 1 BP9763-13-CRANKSHAFT END-1

NON CORROSIVE MATERIAL SUCH AS BRASS, BRONZE, GUNMETAL, STAINLESS STEEL, COPPER OR MONEL. 1 BP9763-14-CRANKSHAFT END-2

9. THE ORDER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED AND THE MODEL IS ASSEMBLED IS ENTIRELY LEFT 2 BP9763-15-OUTER CRANK WEB

TO THE BUILDER/MODEL MAKER. 1 BP9763-16-INNER CRANK WEB

10. A COLOUR SCHEME FOR THIS PROJECT IS ENTIRELY LEFT UP TO THE MODEL MAKER. 2 BP9763-17-CRANKPIN

11. THE MANNER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED IS ENTIRELY LEFT UP TO THE BUILDER. 2 BP9763-18-ECCENTRIC SHEAVE

12. USE LOCTITE, ON SCREW OR PRESS FIT CONNECTIONS OR SURFACES, WERE DEEMED NECESSARY TO PREVENT PARTS 2 BP9763-19-PISTON

FROM LOOSENING. 2 BP9763-20-PISTON ROD

13. WASHER SHALL BE USED WHERE DEEMED NECESSARY. 2 BP9763-21-PISTON ROD YOKE

14. N/A 2 BP9763-22-CON-ROD

XX. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE DRAWINGS, DO NOT HESITATE TO CONTACT ME SO THAT THE 2 BP9763-23-CON-ROD BIG END PART-1

ERRORS/OMISSIONS CAN BE RECTIFIED. 2 BP9763-24-CON-ROD BIG END PART-2

STEAM IN 4 BP9763-25-CON-ROD BIG END BEARING

2 BP9763-26-CON-ROD YOKE CONNECTOR

2 BP9763-27-PISTON ROD YOKE PIVOT PIN

2 BP9763-28-PISTON VALVE

2 BP9763-29-PISTON VALVE ROD

2 BP9763-30-PISTON VALVE ROD YOKE

2 BP9763-31-PISTON VALVE ROD YOKE PIVOT PIN

2 BP9763-32-ECCENTRIC STRAP

2 BP9763-33-ECCENTRIC STRAP ROD

4 BP9763-34-ECCENTRIC STRAP LOCATION SCREW

1 BP9763-35-FLYWHEEL

8 BP9763-36-IN-OUTLET PIPE NIPPLE

1 BP9763-37-REVERSER BASE PLATE

1 BP9763-38-REVERSER PORT PLATE

1 BP9763-39-REVERSER TOP PLATE

1 BP9763-40-REVERSER VALVE

STEAM OUT 9 BP9763-41-IN-OUTLET PIPE NUT

1 BP9763-42-REVERSER VALVE OPERATOR HANDLE

2 BP9763-43-IN-OUT LET PIPE

6 BP9763-44-BASE STAND-OFF

1 BP9763-45-BASE

261 10.28

4 BP9763-M3x4 GRUB SREW

16 BP9763-M4x18 HEX BOLT

4 BP9763-M4x22 HEX BOLT

1 BP9763-M5x9 GRUB SREW

16 BP9763-M5x18 HEX BOLT

5 BP9763-M6 DOME NUT

2 BP9763-M6x6 HEX BOLT

2 BP9763-M6x18 HEX BOLT

6 BP9763-M6x40-WOOD SCREW

4 BP9763-M6x52 THREADED ROD

4 BP9763-M8 DOME NUT

OTHER ABBREVIATIONS

DP = DEEP

DAA= DRILL AFTER ASSEMBLY

D&TAA= DRILL AND TAP AFTER

ASSEMBLY

CF = CLOSE FIT (SIZE FOR SIZE)

PF = PRESS FIT

PFAA= PRESS FIT AFTER ASSEMBLY

270 10.63 PCD = PITCH CIRCLE DIAMETER

RM = REAM

MATERIAL ABBREVIATIONS: HEX = HEXACON, 6SIDED

ALU = ALUMINIUM CP = COMPRESSED

BRS = BRASS THE OFF SET ANGLE OF THE ECCENTRIC(S) KNL = KNURLED

BRZ = BRONZE OR GUNMETAL (BRZ/GM) IN RELATION TO THE CRANK AXIS TO BE CSK = COUNTERSINK

CI = CAST IRON EXPERIMENTALLY DETERMINED FOR THE PL = PLACES

CU = COPPER SMOOTH RUNNING IN BOTH DIRECTIONS OF DWL= DOWEL

GRA = GRAPHITE THE ENGINE AND TO THE SATISFACTION OF (T)HESOP=(TAPPED)HOLES EQUALLY

MS = MILD STEEL/BRIGHT MILD STEEL THE BUILDER SPACED ON PCD

S/S = SILVER STEEL OR STAINLESS STEEL (T)HESOC=(TAPPED)HOLES EQUALLY

SPS = SPRING STEEL SPACED ON CIRCUMFERENCE

PEEK= POLYETHER ETHER KETONE SA-xxx = SUB ASSEMBLY-xxx

SYN = SYNTHETIC MATERIAL SUCH AS VETON, NYLON, TEFLON OR RUBBER

IN GENERAL SYNTHETIC MATERIALS SOULD BE ABLE TO WITHSTAND THE HEAT AND PRESSURE(S) APPLIED TO THEM.

nnn/nnn MEANS THAT EITHER MATERIAL CAN BE USED

NOTES: FOUND ORIGINAL DRAWINGS ON INTERNET, GERMAN ORIGIN. REFERENCE "BAUPLAN Nr. 9763 VOM NECKAR-VERLAG, KONSTRUKTION: K.-E. JENCZOK"

TITLE DRAWING CONTENTS PROJECT No 09C-22-00 MODEL SCALE: 1:1

JDWDS

PROJECTION

2 CYLINDER VERTICAL MARINE TYPE STEAM GENERAL ARRANGEMENT, ISOMETRIC JDW DRAUGHTING SERVICES DATE

NOVEMBER 2016

DWG SCALE: NTS @A3 OR AS SHOWN

J.A.M. DE WAAL PAPAKURA NZ

ENGINE (BORE 24 X STROKE 28) VIEW, BOM AND NOTES

Copyright ©

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA 2110.

NEW ZEALAND. PHONE: OO64 09 2988815. MOB: 0211791000

E-MAIL: dewaal@xtra.co.nz. SHEET: 01 OF 03 A3 No: BP-9763-01

You might also like

- BP9763 A3 Sheet 01 PDFDocument1 pageBP9763 A3 Sheet 01 PDFjuan pedro pastor garciaNo ratings yet

- A Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesDocument1 pageA Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesSARGEN YOHAN LOZANO ARIASNo ratings yet

- A Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesDocument1 pageA Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesStojan Pece CmarNo ratings yet

- Jpb2cvse A3 Sheet 01Document1 pageJpb2cvse A3 Sheet 01Juan PastorNo ratings yet

- 09C-40-00-A3-SHEET-01 - Sheet1Document1 page09C-40-00-A3-SHEET-01 - Sheet1Nam HoangNo ratings yet

- 09C-40-00-A3-SHEET-03 - Sheet1Document1 page09C-40-00-A3-SHEET-03 - Sheet1Abdul MannanNo ratings yet

- Msy Parts PricelistDocument5 pagesMsy Parts PricelistBillClintonRepNo ratings yet

- Web ZZ76250 RX-V685 QSG UCRALH EnFrEs A0Document80 pagesWeb ZZ76250 RX-V685 QSG UCRALH EnFrEs A0Jarf PlartNo ratings yet

- Proyeccion de Cubierta: Oficio BARDocument1 pageProyeccion de Cubierta: Oficio BARBruce JimenezNo ratings yet

- Denah Tampak - Detail Pintu JendelaDocument8 pagesDenah Tampak - Detail Pintu Jendelahansen 97No ratings yet

- Lanz A3 Sheet 05 PDFDocument1 pageLanz A3 Sheet 05 PDFsrihariNo ratings yet

- Parts List From MSYDocument5 pagesParts List From MSYkanetrebleNo ratings yet

- Sven Ha-385 SCHDocument2 pagesSven Ha-385 SCHАндрюха КорнNo ratings yet

- (Hoccokhi - VN) Bai Tap Lap Rap Solidworks 2dongco NgangDocument4 pages(Hoccokhi - VN) Bai Tap Lap Rap Solidworks 2dongco NgangChien Dang VanNo ratings yet

- 15112739-D-T01-02 (STS Crane - GH) - SGNDocument1 page15112739-D-T01-02 (STS Crane - GH) - SGNdheeraj SureshNo ratings yet

- Yamaha RX-V685 EnglishDocument124 pagesYamaha RX-V685 EnglishegalNo ratings yet

- Road From Palugaswewa To HabaranaDocument2 pagesRoad From Palugaswewa To HabaranaRenga Ramanujan CNo ratings yet

- Bikeways MapDocument1 pageBikeways MapfdgsNo ratings yet

- 2500 160 VE 7100 22000 - 002 2500 160 VE 7100 22000 - 002 - CompressedDocument1 page2500 160 VE 7100 22000 - 002 2500 160 VE 7100 22000 - 002 - Compressedshafiq3221821No ratings yet

- Cce - MD 4600BDocument5 pagesCce - MD 4600BJose Luiz da SilvaNo ratings yet

- Fa JVC Lt50da960Document2 pagesFa JVC Lt50da960Fabian OrtuzarNo ratings yet

- Plano en AutocadDocument1 pagePlano en AutocadJuan PastorNo ratings yet

- Manual Punto A Punto mp2851Document15 pagesManual Punto A Punto mp2851JorgeMarioOteroVega100% (1)

- This Area Must Be Confirmed With Landscape Package: D.F.01.03 D.F.01.02 D.F.01.05 D.F.01.01Document1 pageThis Area Must Be Confirmed With Landscape Package: D.F.01.03 D.F.01.02 D.F.01.05 D.F.01.01janNo ratings yet

- RUTAS OP2 Rev2-1Document1 pageRUTAS OP2 Rev2-1maryjosyjohnNo ratings yet

- Muncaster 11 A3 Sheet 02Document1 pageMuncaster 11 A3 Sheet 02Juan PastorNo ratings yet

- 6 CylinderDocument5 pages6 CylinderCường TrọngNo ratings yet

- Refer To Building 5 Package: For ConstructionDocument1 pageRefer To Building 5 Package: For ConstructionjanNo ratings yet

- NX Sheet MetalDocument2 pagesNX Sheet MetalSathish KumarNo ratings yet

- Existing Water Scheme Bint Jbeil Water Directorate Key Plan: LegendDocument1 pageExisting Water Scheme Bint Jbeil Water Directorate Key Plan: LegendNassif Abi AbdallahNo ratings yet

- Redmi Note 7 - Final Layout - Bintang BenignoDocument1 pageRedmi Note 7 - Final Layout - Bintang BenignoBeni CahyadiNo ratings yet

- Single Cylinder Oscillating Steam Engine Named "Lucy" General Arrangement and Components A3Document3 pagesSingle Cylinder Oscillating Steam Engine Named "Lucy" General Arrangement and Components A3Jhon Fredy MartinNo ratings yet

- Creacion Complejo Turistico Baños Termales Yaurisque Plano de ConjuntoDocument1 pageCreacion Complejo Turistico Baños Termales Yaurisque Plano de ConjuntoYuri GzlsNo ratings yet

- Section BBDocument1 pageSection BBVaamika yadavNo ratings yet

- Single Cylinder Oscillating Steam EngineDocument1 pageSingle Cylinder Oscillating Steam EngineNiruban Santiagu Fernando100% (1)

- Railway Toilet Detail 3Document1 pageRailway Toilet Detail 3Shreenidhi JoshiNo ratings yet

- Agua 1er Nivel Agua - Replanteo-Tribuna IvDocument1 pageAgua 1er Nivel Agua - Replanteo-Tribuna Ivraul hernan copari coloradiNo ratings yet

- PIU508 PIU509 PIU6011: PRLSOL (1R1) - 5 / 6 / 7,5kVA - 400VDocument1 pagePIU508 PIU509 PIU6011: PRLSOL (1R1) - 5 / 6 / 7,5kVA - 400VFernando Silva0% (1)

- Mapa Geral Com LogoDocument1 pageMapa Geral Com Logofreitasjgabriel6No ratings yet

- Lusu CartillasDocument1 pageLusu CartillasMauroNo ratings yet

- 2 Cyl Vert Steam Engine With Reverser J.p.duval-5Document4 pages2 Cyl Vert Steam Engine With Reverser J.p.duval-5duy2854No ratings yet

- Hisense Rsag7.820.2123 Psu SCHDocument2 pagesHisense Rsag7.820.2123 Psu SCHJuan CarlosNo ratings yet

- A Simple Horizontal Mill Steam Engine With Slide Valve by H.Muncaster. Notes, Parts and AssembliesDocument1 pageA Simple Horizontal Mill Steam Engine With Slide Valve by H.Muncaster. Notes, Parts and AssembliesStojan Pece CmarNo ratings yet

- Inch To MM ChartDocument3 pagesInch To MM Chartthemoon69No ratings yet

- LSPWM (9R1) 30 06 11Document1 pageLSPWM (9R1) 30 06 11Elenilson Fernandes0% (1)

- Wren Minibike PlansDocument1 pageWren Minibike PlansANDRES MARCELO GORDON GARCESNo ratings yet

- General Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)Document5 pagesGeneral Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)adil jabaroNo ratings yet

- LSPWM (10) 31 01 13-5kDocument1 pageLSPWM (10) 31 01 13-5kerik josé de souza corrreaNo ratings yet

- Cilindro Horizontal PequeñoDocument1 pageCilindro Horizontal PequeñoNMM100% (1)

- PMS Series Hand Pumps PDFDocument3 pagesPMS Series Hand Pumps PDFJonathan GiraldoNo ratings yet

- Maquina 34 PDFDocument3 pagesMaquina 34 PDFEstefannyNo ratings yet

- 4 Cylindres Oscillant en Ligne PDFDocument3 pages4 Cylindres Oscillant en Ligne PDFJose Guadalupe AntonioNo ratings yet

- General Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)Document5 pagesGeneral Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)adil jabaroNo ratings yet

- Fisher Controls: Tight Shutoff-Throttling-sleeve Design With TFEDocument14 pagesFisher Controls: Tight Shutoff-Throttling-sleeve Design With TFEfiguev2208No ratings yet

- General Arrangement, Sections Bom, Parts and Assemblies Steam Operated Water Pump/InjectorDocument2 pagesGeneral Arrangement, Sections Bom, Parts and Assemblies Steam Operated Water Pump/InjectorJuan Manuel Arguello EspinosaNo ratings yet

- Single Cylinder Balance BeamDocument6 pagesSingle Cylinder Balance BeamAmar Hairlahovic0% (1)

- Dell 13321-1Document104 pagesDell 13321-1Carlos Alberto Miranda PerezNo ratings yet

- Regulator HF Series (MS-01-156) R0Document4 pagesRegulator HF Series (MS-01-156) R0herysyam1980No ratings yet

- General Arrangement. Complete Steam Plant Including Two Steam Engines (1cyl + 2cyl Vertical)Document12 pagesGeneral Arrangement. Complete Steam Plant Including Two Steam Engines (1cyl + 2cyl Vertical)Trung NguyenNo ratings yet

- 2cwse PDFDocument2 pages2cwse PDFOrlando Rojas PintoNo ratings yet

- CITGO028-03-G-P-0 52-1 PlotPlanCorales I - FALCONDocument1 pageCITGO028-03-G-P-0 52-1 PlotPlanCorales I - FALCONMiguel MotaNo ratings yet

- The “ Shoulderproblem” of Forming, Filling and Closing Machines For PouchesDocument13 pagesThe “ Shoulderproblem” of Forming, Filling and Closing Machines For PouchesMiguel MotaNo ratings yet

- MillionaireMindDeclarations PDFDocument1 pageMillionaireMindDeclarations PDFYves MhannaNo ratings yet

- MillionaireMindDeclarations PDFDocument1 pageMillionaireMindDeclarations PDFYves MhannaNo ratings yet

- A 2 - 02 (2014) PDFDocument3 pagesA 2 - 02 (2014) PDFpiziyuNo ratings yet

- Tabla Escala de Planos PDFDocument1 pageTabla Escala de Planos PDFMiguel MotaNo ratings yet

- SP3D Tutorials For PipingDocument347 pagesSP3D Tutorials For PipingTonyGold2579% (19)

- Ejercicios Solidworks PDFDocument50 pagesEjercicios Solidworks PDFRic Frs80% (5)

- BP9763 A3 Sheet 03Document1 pageBP9763 A3 Sheet 03Miguel MotaNo ratings yet

- Equivalencia en Pernos ASTM ChinosDocument1 pageEquivalencia en Pernos ASTM ChinosMiguel MotaNo ratings yet

- Hex Structural Shoulder Bolts With Hex Nuts, Steel: Maryland MetricsDocument5 pagesHex Structural Shoulder Bolts With Hex Nuts, Steel: Maryland MetricsMiguel MotaNo ratings yet

- Elbowpatterns-Todas Las Tuberias PDFDocument101 pagesElbowpatterns-Todas Las Tuberias PDFMiguel MotaNo ratings yet

- The Rise of Biometric CardsDocument66 pagesThe Rise of Biometric CardstyempuserNo ratings yet

- 03 T HVP PDFDocument6 pages03 T HVP PDFkimikien1No ratings yet

- Question Bank of Computer FundamentalDocument2 pagesQuestion Bank of Computer Fundamentalibilalhussain67% (3)

- I564 E1 01 3g3ax PG Users ManualDocument69 pagesI564 E1 01 3g3ax PG Users ManualF HusaimaNo ratings yet

- V0 VSS VDD: Unit PIN Symbol Level Nominal Dimensions Pin Connections Function Mechanical Data ItemDocument1 pageV0 VSS VDD: Unit PIN Symbol Level Nominal Dimensions Pin Connections Function Mechanical Data ItemBasir Ahmad NooriNo ratings yet

- Non PO AP FD OverviewDocument19 pagesNon PO AP FD OverviewRoohi AjmeraNo ratings yet

- STEP7 TIA Portal V11 HSP en PDFDocument12 pagesSTEP7 TIA Portal V11 HSP en PDFFlávio VieiraNo ratings yet

- Broadband Distribution Passives EnglishDocument12 pagesBroadband Distribution Passives EnglishbvlahovicyuNo ratings yet

- SQRDocument53 pagesSQRvasubandi8100% (1)

- Project 1Document2 pagesProject 1kb8448No ratings yet

- AG-X PlusDocument20 pagesAG-X PlusOscarPriegoNo ratings yet

- ADVANTAGES AND DISADVANTAGES OF 5TH GENRATION sLANGUAGESDocument4 pagesADVANTAGES AND DISADVANTAGES OF 5TH GENRATION sLANGUAGESKaren NguyenNo ratings yet

- Week1 - Chapter1 COMPUTER PROGRAMMINGDocument57 pagesWeek1 - Chapter1 COMPUTER PROGRAMMINGWan SyazwanNo ratings yet

- 1492 pp009 - en PDocument3 pages1492 pp009 - en PAngel MeauryNo ratings yet

- GRADE-10 TLE Electronic Products Assembly and Servicing Week OneDocument15 pagesGRADE-10 TLE Electronic Products Assembly and Servicing Week OneSer Takeshi100% (1)

- Winner 1-3KVA ManualDocument19 pagesWinner 1-3KVA ManualAndré Frota PaivaNo ratings yet

- Assignment 1 - History of ComputerDocument3 pagesAssignment 1 - History of ComputerAnonymous w7r911SD76% (17)

- Corporate Gifts: White Collection Spring / Summer 2020Document35 pagesCorporate Gifts: White Collection Spring / Summer 2020Contacto CloudNo ratings yet

- RMPart USBDocument3 pagesRMPart USBZöhrab ƏmiNo ratings yet

- KK Programmer ReplacementDocument12 pagesKK Programmer ReplacementshaneNo ratings yet

- Acer Aspire V5-551G 1 Quanta ZRP - RevA1ADocument44 pagesAcer Aspire V5-551G 1 Quanta ZRP - RevA1ATom ArcillaNo ratings yet

- Manual Parts Ricoh Aficio MPC2500Document175 pagesManual Parts Ricoh Aficio MPC2500Joseth Hernandez SierraNo ratings yet

- Module 1: Introduction To Operating System: Need For An OSDocument15 pagesModule 1: Introduction To Operating System: Need For An OSDr Ramu KuchipudiNo ratings yet

- Installation Manual US01B.M8 / US04B.M8: Ultrasonic Sensor For Web Guiding SystemsDocument12 pagesInstallation Manual US01B.M8 / US04B.M8: Ultrasonic Sensor For Web Guiding SystemsAsif JeeNo ratings yet

- Introduction To Operating System Chandigarh UniversityDocument49 pagesIntroduction To Operating System Chandigarh UniversityasdasdaNo ratings yet

- Quick Track PositionerDocument138 pagesQuick Track Positionersanjoy panda100% (1)

- 17078EN TLMP SeriesDocument2 pages17078EN TLMP Seriesxuanphuong2710No ratings yet

- EDS Quick RefDocument20 pagesEDS Quick Ref003086No ratings yet

- StreamlineDocument4 pagesStreamlinecloviskrellingNo ratings yet