Professional Documents

Culture Documents

Truck Crane stc250 PDF

Truck Crane stc250 PDF

Uploaded by

rhoewiebOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Truck Crane stc250 PDF

Truck Crane stc250 PDF

Uploaded by

rhoewiebCopyright:

Available Formats

STC250

STC250 TRUCK CRANE

25 TONS LIFTING CAPACITY

Quality Changes the World

STC250 Truck Crane STC250 Truck Crane

2 COMPANY BRIFE INTRODUCTION COMPANY BRIFE INTRODUCTION 3

SANY Automobile Hoisting Machinery is one of the core business unit of Sany Heavy

Industry, mainly engaged in the research and development of high end, mid to large

tonnage crane series, including mobile crane, crawler crane, tower crane and loader crane.

It has two industrial parks in Ningxiang and Huzhou, since entering the market, the products

of Sany Automobile Hoisting Machinery have received worldwide recognition with advanced

technology, lean manufacturing, high reliability and excellent service.

Quality Changes the World Quality Changes the World

STC250 Truck Crane STC250 Truck Crane

4 ICON Selling points 5

SANY TRUCK Crane

content

04 Icon

05 Selling Points

06 Introduction

09 Dimension

10 Technical Parameter

11 Operation Condition

12 Load Chart

14 Wheel Crane Family Map

Excellent and stable chassis performance / Ultra long, super strong and highly sensitive

chassis system load lifting capacity

Double-axle drive is used, providing good trafficability and Four-section boom of high strength steel structure and optimized

comfortableness under complex road condition with reliable U-shaped cross section reduces weight significantly with higher

traveling performance. safety rates. Jib mounting angles are 0°, 15° and 30°, which

Cab Carrier frame Suspension system

Engine has the multimode power output function, which reduces ensures fast and convenient change-over between different

power consumption. operating conditions so as to improving working efficiency of the

machine.

Hydraulic system Outriggers Telescopic boom

Control system Engine Lattice jibs

Telescopic system Transmission system Superlift devices

Luffing system Drive/Steer Luffing lattice jib

Slewing Axles winch mechanism:

Highly efficient, stable, energy-saving Safe, stable, advanced,

and adjustable hydraulic system and intelligent electric control system

Triple gear pump, load feedback and constant power control Self-developed controller SYMC specially for engineering

Counterweight Tyres are applied to provide strong lifting capacity and good micro- machinery is configured. The adoption of CAN-bus full-digital

mobility. Unique steering buffer design is applied to ensure network control technology ensures stable control signal, simple

stable braking operation. harness and high reliability. Timely feedback of data information

can achieve the monitoring of the overall working status in real-

Safety system Brakes system time. The load moment limiter equipped with the comprehensive

intelligent protection system is used with accuracy within 3%

to provide a comprehensive logic and interlock control, thus

ensuring more safe and reliable operation.

Hoist system Electrical system

Quality Changes the World Quality Changes the World

STC250 TruCk Crane STC250 TruCk Crane

6 INTRODUCTION INTRODUCTION 7

Superstructure Superstructure

Cab ■ It is made of safety glass and anti-corrosion steel plate with ergonomic design such as Slewing system ■ 360° rotation can be achieved with Max. slewing speed of 2.0r/min., providing stable and

full-coverage soften interior, panoramic sunroof and adjustable seats etc., and humanized reliable operation of the system. Single-row ball slewing ring is applied for strong bearing

design providing more comfortable and relaxing operation experience. The display of load capacity, good stability, high safety and good micro-mobility.

moment limiter integrates main console and operation display system, which clearly show

the data of all operating superstructure conditions for lifting operation. Hoisting system ■ The winch adopts the electronic control variable plunger motor, enabling convenient

switch-over between low load high speed mode and high load low speed mode, and

Hydraulic system ■ High-quality key hydraulic components such as main oil pump, rotary pump, main valve, ensuring highly efficient operation and stable lifting and lowering of the load.

winch motor and balancing parts etc. are adopted to achieve stable and reliable operation ■ One main hook: 320Kg, one auxiliary hook: 90Kg. Wire rope of main winch: left-handed

of the hydraulic system. Superior operation performance is guaranteed by accurate wire rope 16-35W×7-1960, with length of 175m. Wire rope of auxiliary winch: left-handed

parameter matching. wire rope 16-35W×7-1960, with length of 105m.

■ Main valve has flow compensation, load feedback control function, enabling stable

and convenient control of single action and combined action under different operation Safety system ■ Load moment limiter: Load moment limiter calculation system based on lifting load

conditions mechanical model is established using an analytical mechanics method, with rated lifting

■ Winch adopts the variable motor to ensure high operation efficiency. Max. single line accuracy up to ±3% through on-line non-load calibration, providing full protection to lifting

speeds of main and auxiliary winches is up to 120m/min which ensures the lifting efficiency operation. In case of overload operation, system will automatically issue an alarm to provide

take the lead in industry. safety protection for manipulation.

■ The use of new slewing system ensures more stable starting and control of the slewing ■ Hydraulic system is configured with the balance valve, overflow valve, and two-way

operation and excellent micro-mobility. hydraulic lock etc. components, thus achieving the stable and reliable operation of the

■ Hydraulic oil tank capacity: 480L hydraulic system.

■ Main and auxiliary winches are equipped with over roll-out limiter to prevent over rolling-out

Control system ■ CAN-bus instrument: CAN-bus instrument with a combined intelligent control electrical of wire rope.

system is used for easy reading of the traveling parameters at any time. The engine fault ■ Boom and jib ends are equipped with height limiters respectively to prevent over-hoisting of

warning function is applied, ensuring convenient and fast troubleshooting. wire rope.

■ Load moment limiter: The adoption of high intelligent load moment limiter system can ■ Equipped with length sensor, angle sensor and press sensor to indicate the working

comprehensively protect lifting operation, ensuring accurate, stable and comfort operation. condition of whole crane in real-time, giving an alarm and cutting off the dangerous action

■ With fully security protection system, main and auxiliary winches are equipped with over- automatically.

roll out limiter and height limiters to prevent over-rolling out and over-hoisting of steel rope,

including tip-over and limit angle protection. Counterweight ■ Counterweight is 3800kg, no flexible counterweight.

Luffing system ■ Dynamic luffing system with controllable speed provides more stable luffing operation.

Luffing angle: -2°~80°.

Telescopic system ■ Four-section boom is applied with basic boom length of 10.65m, fully extended boom

length of 33.5m, jib length of 8m and fully extended boom lifting height of 34m respectively.

Max. lifting height is 42m including jib.

■ It is made of fine grain high-strength steel with U-shaped cross section and with telescopic

operation controlled independently by dual-cylinder rope.

Quality Changes the World Quality Changes the World

STC250 TruCk Crane STC250 TruCk Crane

8 INTRODUCTION DIMENSION 9

Chassis

Cab ■ Cab is made of new steel structure self-developed by SANY, featuring excellent shock

absorption and tightness, which is configured with swing-out doors at both sides,

pneumatically suspended driver’s seat and passenger's seat, adjustable steering wheel,

large rearview mirror, comfortable driver’s chair with a headrest, anti-fog fan, air conditioner,

stereo radio and complete control instruments and meters, providing more comfortable, (10650~33500)

safe and humanized operation experience.

Carrier frame ■ Designed and manufactured by SANY, anti-torsion box structure is welded by fine-grain

high-strength steel plate to provide strong load bearing capacity.

1375

3550

Axles ■ Axles 2 and 3 are drive axles and axles 1 is steering axles, axle and wheel differentials are

2597

installed in axles 2 and 3.The use of welding process for axle housing provides stronger

load bearing capacity.

1402

17° 12°

Engine ■ Type: Inline six-cylinder, water cooled, supercharged and inter-cooling diesel engine 400 3247

■ Rated power: 213kW/2100( r/min) 1575 4325 1350 2615

■ Environment-protection: Emission complies with EuroⅢ standard

■ Capacity of fuel tank: 300L

5300

Transmission system ■ Gearbox: Manual / Automatic gearbox is adopted with 9-gear and large speed ratio range 3100 2200

applied, which meets the requirements of low gradeability speed and high traveling speed. Ø400

■ Transmission shaft: With optimized arrangement of the transmission shaft, the transmission

is stable and reliable. For most optimized transmission, plate flange is used with large

transmission torque.

Brakes system ■ Brakes system includes traveling brake and parking brake.

■ All wheels use the air servo brakes and dual-circuit brake system, engine is equipped with

an exhaust brake.

6200

2500

Suspension system ■ All axles adopt the plate spring suspension systems with plate spring passed 100,000

fatigue tests and with optimization of performance parameters of the front and rear plate

springs applied to ensure strength and also to provide comfort ridding.

R1

R12 R1150 1000

Steering system ■ Hydraulic power mechanical steering systems are applied for axles 1 with unloading valve 000 0

R10

installed in the steering gear. 000

Outriggers ■ Four-point supporting of the H-shaped outriggers ensures easy operation and strong

stability, with Max. span up to 5.3m×6.2m.They are made of fine-grain high-strength steel

sheet, movable outriggers are full hydraulic transverse telescopic.

2976.5 2323.5

5300

Tyres ■ 11 (number of tyres) – spec.: 11.00-20 ; diagonal tires are adopted, which features with

large load bearing capacity and durability.

Electrical system ■ With 2*12V maintenance-free batteries, the crane power can be cut off manually via a

mechanical master power switch.

Quality Changes the World Quality Changes the World

STC250 Truck Crane STC250 Truck Crane

10 TECHNICAL PARAMETER OPERATION CONDITION 11

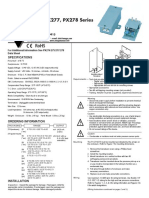

STC250 Working Ranges

Type Item Parameter

Capacity Max. lifting capacity 25t

Overall length 12750mm

Overall width 2500mm

45m

Dimensions Overall height 3550mm

44

Axle-1,2 4325mm 0°

Axle distance 15° 43

Axle-2,3 1350mm 2.8 30° 42

2.8

2.75

Overall weight 30000kg 2.35

41

2.2 2.6

Axle load-1 6500kg 1.7 2.05 1.9

40

Axle load 1.6

39

Weight Axle load-2,3 23500kg 1.5

2.15 1.65 38

Rated power 213kW/ 2100 rpm 1.45

37

Rated torque 1050N.m/ (1200~1400) rpm 1.35 1.8

36

1.45

33.5m

Max.traveling speed 80km/h 35

1.25 1.3

Min.turning radius 10m 34

Turning radius 6.15 5.6 1.2

Min.turning radius of boom head 12m 5.1 0.95 33

4.8

Wheel formula 6×4 32

29.7m

4.38 1.15

4.2 0.85

3.85 31

Traveling Min.ground clearance 220mm 7.5 7.5 7.5 3.7

30

Lifting height (m)

7.4 6.5 3.15

Approach angle 17 ° 6.2 0.8

5.7 2.9 29

Departure angle 12 ° 5.2 2.55

25.9m

4.8 28

2.2

Max.gradeability 38% 4.4

27

9.2 9.2 9.15 3.9 1.97

9.158.9

Fuel consumption per 100km ≤ 37 L 8.3 3.55 1.8 26

7.6

Temperature range – 30 ℃ ~ + 60 ℃ 7.2 3.15 1.6 25

6.5

22.1m

2.85

Min.rated range 3m 5.7 24

5.1 2.58 1.4

23

Tail slewing radius of swingtable 3.37m 11 11 11

11 11 4.51 2.2 1.3

9.5 3.95 22

Boom section 4 8.5 2

7.55 3.55 1.1

21

18.3m

Boom shape U-shaped 20

6.7 3.15 1.8

Main Performance Base boom 962kN·m 15 14.9 5.8

19

14.9 14.5 5.1 2.8 1.6

Data Max.lifting moment Full-extend boom 544kN·m 13.8

13.3 18

11.3 4.55 2.58

Full-extend boom+jib 341kN·m 9.8 17

14.5m

4 1.4

2.21

Base boom 10.65m 18 1818 8.25 16

17 16.5 6.9 3.5

16 15

Boom length Full-extend boom 33.5m 14.5 5.85 2.05

12.2 3.2 14

Full-extend boom+jib 41.5m

10.65m

10 5.16 13

Outrigger span (Longitudinal×Transversal) 5.3 × 6.2m 1.8

25 8.5 2.8 12

25 24.3

Jib offset 0°,15°,30° 4.6

11

21.8 7.5

18.9

Max.single rope lifting speed of main winch (no load) ≧120m/min 17.3 10

15.8 4 2.6 1.65

Max.single rope lifting speed of auxiliary winch (no load) ≧120m/min 6.25

9

Working speed 8

Full extension/retraction time of boom 70 / 50s 12.2

7

Full lifting/descending time of boom 70 / 55s

6

Slewing speed (0~2)r/min 5.5

3.5

9.7 5

Aircondition in up cab Cooling and Heating

Aircondition 4

Aircondition in low cab Cooling and Heating 3

2

1

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28m

Radius (m)

Quality Changes the World Quality Changes the World

STC250 Truck Crane STC250 Truck Crane

12 LOAD CHART LOAD CHART 13

Unit:Kg Unit:Kg

Prerequisites : Prerequisites :

① Boom operating condition(fully extended boom length),min.length is 10.65 and.max.length is 33.5m ① Boom operating condition( fully extended boom length + jib length),max. length is 33.5m+8m

② The span of outrigger is 5.3×6.2m ② The span of outriggers is 5.3×6.2m

③ 360°rotation is applied ③ 360°rotation is applied

④ Counterweight is 3.8T ④ Counterweight is 3.8T

Main boom Main boom+Jib

Working range(m) Working range(m) Main boom angle

10.65 14.5 18.3 22.1 25.9 29.7 33.5 0° 15° 30°

3 25000 18000 3 78° 2800 2350 1700

3.5 25000 18000 15000 3.5 75° 2800 2200 1600

4 24300 18000 14900 11000 9200 4 72° 2750 2050 1500

4.5 21820 17000 14900 11000 9200 4.5 70° 2600 1900 1450

5 18900 16500 14500 11000 9150 7500 5 65° 2150 1650 1350

5.5 17350 16000 13800 11000 9150 7500 5.5 60° 1800 1450 1250

6 15800 14500 13300 11000 8900 7500 6 55° 1300 1200 1150

7 12200 12200 11300 9500 8300 7400 7 50° 950 850 800

8 9700 10000 9800 8500 7600 6500 6150 8

9 8500 8250 7550 7200 6200 5600 9

10 7500 6900 6700 6500 5700 5100 10

11 6250 5850 5800 5700 5200 4800 11

12 5500 5160 5100 5100 4800 4380 12

13 4600 4550 4510 4400 4200 13

14 4000 4000 3950 3900 3850 14

15 3500 3500 3550 3550 3700 15

16 3200 3150 3150 3150 16

17 2800 2800 2850 2900 17

18 2600 2580 2580 2550 18

19 2210 2200 2200 19

20 2050 2000 1970 20

21 1800 1800 1800 21

22 1650 1600 1600 22

23 1400 1400 23

24 1300 24

25 1100 25

Number of lines 8 8 6 4 4 4 3 Number of lines

Telescoping condition(%)

Ⅰ 100% 100% 100% 100% 100% 100% 100% Ⅰ

Ⅱ 0 17% 34% 50% 67% 84% 100% Ⅱ

Ⅲ 0 17% 34% 50% 67% 84% 100% Ⅲ

Ⅳ 0 17% 34% 50% 67% 84% 100% Ⅳ

1. Values listed in the table refer to rated lifting capacity measured at flat and solid gound under the lever state of the crane.

2. Value above heavy line shall be determined by strength of the crane and under this line shall be determined by stability of the crane.

3. Rated load values determined by stability shall comply with ISO 4305.

4. Rated lifting capacity listed in the table included weights of lifting hooks (320kg of main hook and 90kg of auxiliary hook)and hangers.

5. Rated lifting capacity with pulley at boom tip shall not exceed 3500kg.

6. If actual boom length and range are between two values specified in the table, larger value will determine the lifting capacity.

Quality Changes the World Quality Changes the World

STC250 Truck Crane

14 WHEEL CRANE FAMILY MAP

Quality Changes the World

Quality Changes the World

SANY AUTOMOBILE HOISTING MACHINERY

address: SanY Industrial Park, Jinzhou Development Zone, Distributed By:

Changsha, Hunan, China.

Service Hotline: 4006098318

email: crd@sany.com.cn

For more information, please visit: www.sanygroup.com

For our consistent improvement in techonology, specifications may change without notice.

The machines illustrated may show optional equipment which can be supplied at additional cost.

Version: 2015.08

You might also like

- Cmaa 70-2015-30102017121538 PDFDocument100 pagesCmaa 70-2015-30102017121538 PDFAnwar DeenNo ratings yet

- NCK Orion HC80 Spec Book BWDocument28 pagesNCK Orion HC80 Spec Book BWNitin PatelNo ratings yet

- Basic Rigging 106-09 PDFDocument80 pagesBasic Rigging 106-09 PDFAnwar DeenNo ratings yet

- P&ID of CCPDocument74 pagesP&ID of CCPNguyễnTrường80% (10)

- Subject: Page 1 of 57Document57 pagesSubject: Page 1 of 57PHÁT NGUYỄN THẾNo ratings yet

- Gear Pumps Technical InformationDocument48 pagesGear Pumps Technical Informationalecandro_90100% (3)

- Machine Profiles: 16G and 16H Motor GradersDocument6 pagesMachine Profiles: 16G and 16H Motor GradersRulver Quiroz CabanillasNo ratings yet

- Breaker SeriesDocument6 pagesBreaker SeriesDeno Manuel LudzanNo ratings yet

- SoilmecDocument12 pagesSoilmecMohamedAbdelnasserNo ratings yet

- Yen00003 00Document386 pagesYen00003 00Wilson Jh100% (1)

- M250 Sales MaterialDocument23 pagesM250 Sales MaterialRonaldi motterNo ratings yet

- Cat 416DDocument24 pagesCat 416DJulio MeesNo ratings yet

- Crawler Excavator Specifications: Service Weight 57.9 - 63.6 T Engine Output BucketsDocument14 pagesCrawler Excavator Specifications: Service Weight 57.9 - 63.6 T Engine Output Bucketsdamqn filipovNo ratings yet

- ERU Series: Electric Remote ControllerDocument2 pagesERU Series: Electric Remote ControllerUziel CHIMINo ratings yet

- SM PC3000-1Document464 pagesSM PC3000-1Suwandi100% (1)

- C729387 Compactador cb54Document12 pagesC729387 Compactador cb54Robinson Guaneme100% (1)

- HPV 02 VariablePump enDocument36 pagesHPV 02 VariablePump enSorinNo ratings yet

- Manual de Partes de Excavadora 320DDocument812 pagesManual de Partes de Excavadora 320DCristian NeiraNo ratings yet

- 2 PDFDocument9 pages2 PDFRicardo OjedaNo ratings yet

- 329 D PDFDocument24 pages329 D PDFCapacitaciones RutasNo ratings yet

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerSAFE EARTHMOVERSNo ratings yet

- Sany 250Document9 pagesSany 250arifNo ratings yet

- Main Pump - Test - Measurement of Case Drain Oil: Shutdown SISDocument4 pagesMain Pump - Test - Measurement of Case Drain Oil: Shutdown SISR I SantosoNo ratings yet

- SR150C Rotary Drilling Rig Service Manual-Hydraulic System (Upper Carriage)Document40 pagesSR150C Rotary Drilling Rig Service Manual-Hydraulic System (Upper Carriage)Rizal Abi100% (1)

- Manitou 180 ATJ (EURO 3) Hydraulic CircuitDocument4 pagesManitou 180 ATJ (EURO 3) Hydraulic CircuitPHÁT NGUYỄN THẾNo ratings yet

- Bauer BG 36: Rotary Drilling RigDocument24 pagesBauer BG 36: Rotary Drilling Rigputra100% (1)

- Capacitor Discharger ManualDocument30 pagesCapacitor Discharger Manualhandoyo100% (1)

- RentalDocument2 pagesRentalDirectorio FotograficoNo ratings yet

- Boom Cylinder Remove and InstallDocument8 pagesBoom Cylinder Remove and InstallEDSON JONATHAN SALINAS AYALANo ratings yet

- Bosch Rexroth Hydraulic Hybrids - Ra98310 - 2010-08Document8 pagesBosch Rexroth Hydraulic Hybrids - Ra98310 - 2010-08MattH3No ratings yet

- Caterpillar 143h II Spec SheetDocument24 pagesCaterpillar 143h II Spec SheetRobinson Guaneme100% (2)

- (KENR9561-00) Schematic - 793F OHT Air SystemDocument2 pages(KENR9561-00) Schematic - 793F OHT Air SystemFredy Manrique Asto100% (1)

- 345 GC Hydraulic Excavator - Technical Specifications (Electronic Only) (LAXB) AEXQ2380Document13 pages345 GC Hydraulic Excavator - Technical Specifications (Electronic Only) (LAXB) AEXQ2380souleymane aboudramane SOOBANo ratings yet

- Esquema Hidraulico Cat cb22bcDocument9 pagesEsquema Hidraulico Cat cb22bcgalvis1020No ratings yet

- Crawler Crane-Hitachi Sumitomo SCX550E 55t SpecificationsDocument28 pagesCrawler Crane-Hitachi Sumitomo SCX550E 55t SpecificationsAnonymous hRWwL7pZnCNo ratings yet

- Análisis de Miniexcavadora Caterpillar 303C-CRDocument12 pagesAnálisis de Miniexcavadora Caterpillar 303C-CRJuan Emilio Schönherr100% (1)

- Subject: ZX-ALL-240Document14 pagesSubject: ZX-ALL-240Brian CareelNo ratings yet

- SP12C - SP14CJ Service ManualDocument173 pagesSP12C - SP14CJ Service ManualMMM-MMMNo ratings yet

- R920Document24 pagesR920equipment9278No ratings yet

- Testing and Adjusting Hydraulic PressureDocument6 pagesTesting and Adjusting Hydraulic Pressuremink4u100% (2)

- Calibration Manual (RS13-XX)Document19 pagesCalibration Manual (RS13-XX)Amit Tawte100% (1)

- Komatsu D51EXPX-22 PDFDocument20 pagesKomatsu D51EXPX-22 PDFDavid Chusnul Khotim100% (1)

- R210W 9S NamibiaDocument10 pagesR210W 9S NamibiaTran Trong PhuNo ratings yet

- En - 1676 - Hydraulic Systems For Truck TractorsDocument4 pagesEn - 1676 - Hydraulic Systems For Truck TractorsAli ShdiefatNo ratings yet

- Planetary Gp-Transmission Partes 2Document7 pagesPlanetary Gp-Transmission Partes 2Jose PichinteNo ratings yet

- Poclain Hydraulics Selection GuideDocument44 pagesPoclain Hydraulics Selection GuideM S GokulNo ratings yet

- Carga Suspensiones PDFDocument82 pagesCarga Suspensiones PDFmarioNo ratings yet

- SY35 Vs Competition - V2Document4 pagesSY35 Vs Competition - V2Raj Kumar V RNo ratings yet

- Kawasaki Pump - Parallel Pressure ControlDocument2 pagesKawasaki Pump - Parallel Pressure ControlHamza LashinNo ratings yet

- R30CDocument4 pagesR30CEnrique MurgiaNo ratings yet

- Caterpillar Motor GradersDocument32 pagesCaterpillar Motor GradersAshraf m aliNo ratings yet

- Dozers: What Are These ? & What They Does ?Document118 pagesDozers: What Are These ? & What They Does ?harirambo100% (1)

- Motor Gradder 2 PDFDocument54 pagesMotor Gradder 2 PDFJose Cruz Martinez Medina100% (1)

- VP1 Service ParkerDocument16 pagesVP1 Service ParkerAdrian Alonso Bustos GonzalezNo ratings yet

- L150H/L180H/L220H/L250H: Podręcznik OperatoraDocument322 pagesL150H/L180H/L220H/L250H: Podręcznik OperatoraJan KoniecznyNo ratings yet

- Genuine Quality at Special Prices: Our Winter Deals 2019 / 2020 For YouDocument36 pagesGenuine Quality at Special Prices: Our Winter Deals 2019 / 2020 For YouBakat SetiyaNo ratings yet

- AX27 - 50u-5f Service ManualDocument8 pagesAX27 - 50u-5f Service ManualMb0% (1)

- Engine Air Intake: Service When IndicatedDocument14 pagesEngine Air Intake: Service When IndicatedLeandro Sienra100% (1)

- SML10 SystemDocument33 pagesSML10 SystemgilbertoNo ratings yet

- 006 - CAT-6040 - RH170B - Servo SystemDocument28 pages006 - CAT-6040 - RH170B - Servo SystemJorby CuadrosNo ratings yet

- Technical Specifications: Hydraulic ExcavatorDocument10 pagesTechnical Specifications: Hydraulic ExcavatorJonathan KaleNo ratings yet

- Sany 20tonDocument9 pagesSany 20tonKazim Nawaz100% (1)

- Stc550 Truck Crane 55 Tons Lifting Capacity: Quality Changes The WorldDocument9 pagesStc550 Truck Crane 55 Tons Lifting Capacity: Quality Changes The Worldryo asg3No ratings yet

- Offline Filter Pressure Olfp 1 / 3 / 6: Description Technical DetailsDocument4 pagesOffline Filter Pressure Olfp 1 / 3 / 6: Description Technical DetailsAnwar DeenNo ratings yet

- FM-X Technical Data Driver Seated Reach TruckDocument11 pagesFM-X Technical Data Driver Seated Reach TruckAnwar DeenNo ratings yet

- B30 Standards Committee Publication StatusDocument3 pagesB30 Standards Committee Publication StatusAnwar DeenNo ratings yet

- ANSI Requirements For Overhead and Gantry CranesDocument7 pagesANSI Requirements For Overhead and Gantry CranesRizki SadikinNo ratings yet

- JH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistAnwar DeenNo ratings yet

- Cargo Net l3 Ast Le Adma 314Document6 pagesCargo Net l3 Ast Le Adma 314Anwar DeenNo ratings yet

- Cabinets HoserackDocument3 pagesCabinets Hoserackrennes desamparadoNo ratings yet

- Hydra Plus UD 300: Reduced Height Design Car Door OperatorDocument2 pagesHydra Plus UD 300: Reduced Height Design Car Door OperatorDarwin MontezumaNo ratings yet

- SonyDocument64 pagesSonyNelu Fn100% (1)

- Mmcircuit ComDocument4 pagesMmcircuit ComhussainArifNo ratings yet

- NMJT 2 LatestDocument19 pagesNMJT 2 LatestAnonymous pSozzNFcNo ratings yet

- ADDISON Drills Price List MC 45-MergedDocument116 pagesADDISON Drills Price List MC 45-MergedVenkateshan VenuNo ratings yet

- Forrec Single Shaft Shredder Type XK-3000-H: Hammer MillDocument2 pagesForrec Single Shaft Shredder Type XK-3000-H: Hammer MillAmr KamelNo ratings yet

- Lzv2622 Series Manual Trilingual R4-WebDocument72 pagesLzv2622 Series Manual Trilingual R4-WebEdgar DragonNo ratings yet

- 3.4.5 Boot Modes: Chapter 3: Getting It WorkingDocument11 pages3.4.5 Boot Modes: Chapter 3: Getting It Workingcarlosmg4No ratings yet

- Capacitive Tactile SensingDocument4 pagesCapacitive Tactile Sensing장동기No ratings yet

- Control A DC Motor With An ArduinoDocument5 pagesControl A DC Motor With An Arduinolizhi0007No ratings yet

- LG 47lm6400Document156 pagesLG 47lm6400Boniface AsuvaNo ratings yet

- FILE 20220214 005220 02242021 GM200 Installation and Configuration Guide v3.0Document126 pagesFILE 20220214 005220 02242021 GM200 Installation and Configuration Guide v3.0Khánh Phạm QuốcNo ratings yet

- Fl2 Handbook 2007Document294 pagesFl2 Handbook 2007Josh Warrell100% (2)

- Acer Aspire Es1-512 Wistron Ea53-Bm SCH PDFDocument49 pagesAcer Aspire Es1-512 Wistron Ea53-Bm SCH PDFAlexguate AguilarNo ratings yet

- J940305 PDFDocument4 pagesJ940305 PDFratheeshNo ratings yet

- Caracteristicas NEW CONE-1080Document109 pagesCaracteristicas NEW CONE-1080Carlos AdameNo ratings yet

- Monthly Report of Captive Generating SetsDocument2 pagesMonthly Report of Captive Generating Setsjai parkashNo ratings yet

- A321 VrconfigDocument15 pagesA321 VrconfigMax HayesNo ratings yet

- CVMEnglish ManualDocument50 pagesCVMEnglish ManualJorge DominguezNo ratings yet

- Vaillant VRC 400 Manual PDFDocument48 pagesVaillant VRC 400 Manual PDFJosé MacedoNo ratings yet

- PX274 ManualDocument4 pagesPX274 ManualEnrique EsquivelNo ratings yet

- Choice of Heads, Standard B&W, VC or Colour: Kaiser EnlargersDocument12 pagesChoice of Heads, Standard B&W, VC or Colour: Kaiser EnlargersLucas FurlanNo ratings yet

- Masina Spalat Gorenje 352677Document24 pagesMasina Spalat Gorenje 352677Nina NiculescuNo ratings yet

- Excavator Instructors NotesDocument31 pagesExcavator Instructors Notescandracute33% (3)

- Bs 240 IsDocument188 pagesBs 240 IsboltgingerkoppyNo ratings yet

- Oceanic Delta 4Document14 pagesOceanic Delta 4afs121196No ratings yet

- HHW 65 T5 (Soundproof C10) ENDocument9 pagesHHW 65 T5 (Soundproof C10) ENJavier Menendez CoronasNo ratings yet

- Mosfet: Metal Oxide Silicon Field Effect Transistor Is Abbreviated As MOSFET. It Is Merely A UnipolarDocument6 pagesMosfet: Metal Oxide Silicon Field Effect Transistor Is Abbreviated As MOSFET. It Is Merely A UnipolarJade JoseNo ratings yet