Professional Documents

Culture Documents

Hardness conversion and metric screw thread excerpts

Uploaded by

Natthawut CheencharoenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hardness conversion and metric screw thread excerpts

Uploaded by

Natthawut CheencharoenCopyright:

Available Formats

[Technical Data] [Technical Data]

Hardness Conversion Table (SAEJ417)†Revised in 1983 Metric Coarse Screw Threads Excerpts from JIS B0205(2001)

Approximate Conversion of Rockwell C Hardness Values for Steel(1)

8

H

Brinell Hardness (HB) Rockwell Hardness(3) Rockwell Superficial Hardness (Hs) Tensile Strength

(HRC) (HV) 10mm Ball , Load 3000kgf Diamond Cone Indenter (Approximated Value) Rockwell

2

H

Shore Hardness

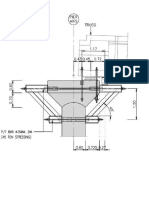

Female Thread

Rockwell (HRA) (HRB) (HRD) C-Scale

H1

C-Scale Vickers Standard Tungsten A Scale, B Scale, D Scale, 15-N 30-N 45-N Mpa Hardness

H

Hardness Hardness Sphere Carbide Load 60kgf, Load100kgf, Load 100kgf, Scale Load Scale Load Scale Load (kgf/mm2) (3) 30° 30°

(2)

d or D

Sphere Diamond Cone Diameter1.6mm Diamond Cone

15kgf 30kgf 45kgf

2

60 °

H

Indenter (1/16in)Sphere Indenter H =0.866025P D =d

4

H

68 940 − − 85.6 − 76.9 93.2 84.4 75.4 97 − 68 Male Thread

d2 or D2

67 900 − − 85.0 − 76.1 92.9 83.6 74.2 95 − 67

H1=0.541266P D2=d2

d1 or D1

66 865 − − 84.5 − 75.4 92.5 82.8 73.3 92 − 66 P D1=d1

65 832 − (739) 83.9 − 74.5 92.2 81.9 72.0 91 − 65

d2=d−0.649519P

90

64 800 − (722) 83.4 − 73.8 91.8 81.1 71.0 88 − 64 Axial Line of Thread

°

d1=d−1.082532P

63 772 − (705) 82.8 − 73.0 91.4 80.1 69 9 87 − 63

62 746 − (688) 82.3 − 72.2 91.1 79.3 68.8 85 − 62

61 720 − (670) 81.8 − 71.5 90.7 78.4 67.7 83 − 61

60 697 − (654) 81.2 − 70.7 90.2 77.5 66.6 81 − 60

59 674 − (634) 80.7 − 69.9 89.8 76.6 65.5 80 − 59

Unit:mm

58 653 − 615 80.1 − 69.2 89.3 75.7 64.3 78 − 58

Female Thread

57 633 − 595 79.6 − 68.5 88.9 74.8 63.2 76 − 57 Nominal of Thread(1)†

56 613 − 577 79.0 − 67.7 88.3 73.9 62.0 75 − 56 Height of Minor Dia. D Effective Dia. D2 Inner Dia. D1

55 595 − 560 78.5 − 66.9 87.9 73.0 60.9 74 2075(212) 55

Pitch P Engagement H1 Male Thread

54 577 − 543 78.0 − 66.1 87.4 72.0 59.8 72 2015(205) 54 Column 1 Column 2 Column 3

Outer Dia. d Effective Dia. d2 Inner Dia. d1

53 560 − 525 77.4 − 65.4 86.9 71.2 58.5 71 1950(199) 53 M 1 0.25 0.135 1.000 0.838 0.729

52 544 (500) 512 76.8 − 64.6 86.4 70.2 57.4 69 1880(192) 52

51 528 (487) 496 76.3 − 63.8 85.9 69.4 56.1 68 1820(186) 51

M 1.1 0.25 0.135 1.100 0.938 0.829

50 513 (475) 481 75.9 − 63.1 85.5 68.5 55.0 67 1760(179) 50 M 1.2 0.25 0.135 1.200 1.038 0.929

49 498 (464) 469 75.2 − 62.1 85.0 67.6 53.8 66 1695(173) 49 M 1.4 0.3 0.162 1.400 1.205 1.075

48 484 451 455 74.7 − 61.4 84.5 66.7 52.5 64 1635(167) 48 M 1.6 0.35 0.189 1.600 1.373 1.221

47 471 442 443 74.1 − 60.8 83.9 65.8 51.4 63 1580(161) 47 M 1.8 0.35 0.189 1.800 1.573 1.421

46 458 432 432 73.6 − 60.0 83.5 64.8 50.3 62 1530(156) 46

45 446 421 421 73.1 − 59.2 83.0 64.0 49.0 60 1480(151) 45

M 2 0.4 0.217 2.000 1.740 1.567

44 434 409 409 72.5 − 58.5 82.5 63.1 47.8 58 1435(146) 44 M 2.2 0.45 0.244 2.200 1.908 1.713

M 2.5 0.45 0.244 2.500 2.208 2.013

43 423 400 400 72.0 − 57.7 82.0 62.2 46.7 57 1385(141) 43

42 412 390 390 71.5 − 56.9 81.5 61.3 45.5 56 1340(136) 42 M 3 0.5 0.271 3.000 2.675 2.459

41 402 381 381 70.9 − 56.2 80.9 60.4 44.3 55 1295(132) 41 M 3.5 0.6 0.325 3.500 3.110 2.850

40 392 371 371 70.4 − 55.4 80.4 59.5 43.1 54 1250(127) 40

39 382 362 362 69.9 − 54.6 79.9 58.6 41.9 52 1215(124) 39

M 4 0.7 0.379 4.000 3.545 3.242

M 4.5 0.75 0.406 4.500 4.013 3.688

38 372 353 353 69.4 − 53.8 79.4 57.7 40.8 51 1180(120) 38 M 5 0.8 0.433 5.000 4.480 4.134

37 363 344 344 68.9 − 53.1 78.8 56.8 39.6 50 1160(118) 37

36 354 336 336 68.4 (109.0) 52.3 78.3 55.9 38.4 49 1115(114) 36 M 6 1 0.541 6.000 5.350 4.917

35 345 327 327 67.9 (108.5) 51.5 77.7 55.0 37.2 48 1080(110) 35 M7 1 0.541 7.000 6.350 5.917

34 336 319 319 67.4 (108.0) 50.8 77.2 54.2 36.1 47 1055(108) 34

M 8 1.25 0.677 8.000 7.188 6.647

33 327 311 311 66.8 (107.5) 50.0 76.6 53.3 34.9 46 1025(105) 33 M9 1.25 0.677 9.000 8.188 7.647

32 318 301 301 66.3 (107.0) 49.2 76.1 52.1 33.7 44 1000(102) 32 M10 1.5 0.812 10.000 9.026 8.376

31 310 294 294 65.8 (106.0) 48.4 75.6 51.3 32.7 43 980(100) 31

30 302 286 286 65.3 (105.5) 47.7 75.0 50.4 31.3 42 950 (97) 30 M11 1.5 0.812 11.000 10.026 9.376

29 294 279 279 64.7 (104.5) 47.0 74.5 49.5 30.1 41 930 (95) 29 M12 1.75 0.947 12.000 10.863 10.106

28 286 271 271 64.3 (104.0) 46.1 73.9 48.6 28.9 41 910 (93) 28

M14 2 1.083 14.000 12.701 11.835

27 279 264 264 63.8 (103.0) 45.2 73.3 47.7 27.8 40 880 (90) 27 M16 2 1.083 16.000 14.701 13.835

26 272 258 258 63.3 (102.5) 44.6 72.8 46.8 26.7 38 860 (88) 26 M18 2.5 1.353 18.000 16.376 15.294

25 266 253 253 62.8 (101.5) 43.8 72.2 45.9 25.5 38 840 (86) 25

24 260 247 247 62.4 (101.0) 43.1 71.6 45.0 24.3 37 825 (84) 24 M20 2.5 1.353 20.000 18.376 17.294

M22 2.5 1.353 22.000 20.376 19.294

23 254 243 243 62.0 100.0 42.1 71.0 44.0 23.1 36 805 (82) 23

22 248 237 237 61.5 99.0 41.6 70.5 43.2 22.0 35 785 (80) 22

M24 3 1.624 24.000 22.051 20.752

21 243 231 231 61.0 98.5 40.9 69.9 42.3 20.7 35 770 (79) 21 M27 3 1.624 27.000 25.051 23.752

20 238 226 226 60.5 97.8 40.1 69.4 41.5 19.6 34 760 (77) 20 M30 3.5 1.894 30.000 27.727 26.211

(18) 230 219 219 − 96.7 − − − − 33 730 (75) (18)

M33 3.5 1.894 33.000 30.727 29.211

(16) 222 212 212 − 95.5 − − − − 32 705 (72) (16) M36 4 2.165 36.000 33.402 31.670

(14) 213 203 203 − 93.9 − − − − 31 675 (69) (14)

(12) 204 194 194 − 92.3 − − − − 29 650 (66) (12)

M39 4 2.165 39.000 36.402 34.670

(10) 196 187 187 − 90.7 − − − − 28 620 (63) (10) M42 4.5 2.436 42.000 39.077 37.129

(8) 188 179 179 − 89.5 − − − − 27 600 (61) (8) M45 4.5 2.436 45.000 42.077 40.129

(6) 180 171 171 − 87.1 − − − − 26 580 (59) (6) M48 5 2.706 48.000 44.752 42.587

(4) 173 165 165 − 85.5 − − − − 25 550 (56) (4) M52 5 2.706 52.000 48.752 46.587

(2) 166 158 158 − 83.5 − − − − 24 530 (54) (2)

(0) 160 152 152 − 81.7 − − − − 24 515 (53) (0)

M56 5.5 2.977 56.000 52.428 50.046

Note (1)

Blue figures:Based on ASTM E 140, Table 1(Jointly coordinated by SAE, ASM and ASTM.) M60 5.5 2.977 60.000 56.428 54.046

(2)

The units and figures shown in brackets are the results of conversion from psi figures by reference to JIS Z 8413 and Z 8438 conversion tables. M64 6 3.248 64.000 60.103 57.505

Moreover, 1MPa=1N/mm2 M68 6 3.248 68.000 64.103 61.505

(3)

The figures in brackets are in ranges not frequently used. They are given as referential data. †Priority should be given to Column 1. If required, select items in Column 2 and 3, in that order.

2841 2842

You might also like

- Basic of Forging: Types, Methods, and ProcessesDocument53 pagesBasic of Forging: Types, Methods, and ProcessesKomal TagraNo ratings yet

- Performance Slurry PumpDocument154 pagesPerformance Slurry PumpJhonny AlvarezNo ratings yet

- Heat Treatment-1 PDFDocument104 pagesHeat Treatment-1 PDFSagnik ChakrabortyNo ratings yet

- NutsDocument49 pagesNutsIshant JaiswalNo ratings yet

- ISO 9001 Rochi Engineers profileDocument26 pagesISO 9001 Rochi Engineers profileGautamNo ratings yet

- Us 12e pr1265 PDFDocument1 pageUs 12e pr1265 PDFAzis AbdNo ratings yet

- HighTens EN25Document2 pagesHighTens EN25Annamali Thiayagarajan0% (1)

- Helical Compressing Spring Calculation PDFDocument4 pagesHelical Compressing Spring Calculation PDFViktor KovtunNo ratings yet

- Mvi Vertical ShaftDocument4 pagesMvi Vertical ShaftMarcel BaqueNo ratings yet

- Wear ProtectionDocument6 pagesWear ProtectionRafael CortezNo ratings yet

- General Kinematics - UncoalerDocument38 pagesGeneral Kinematics - UncoalerJogesh NarulaNo ratings yet

- Evaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForDocument13 pagesEvaluating The Microstructure of Graphite in Iron Castings: Standard Test Method Forraulpalma93No ratings yet

- Is 6051 1970Document15 pagesIs 6051 1970harshal161987100% (1)

- Technical Data (Thai) 3Document1 pageTechnical Data (Thai) 3NatKThNo ratings yet

- Wecall CatalogDocument20 pagesWecall Catalogpdoherty100% (2)

- DIN 7168 General tolerances for linear and angular dimensionsDocument1 pageDIN 7168 General tolerances for linear and angular dimensionsAnwarNo ratings yet

- Spring Wire: Patented Cold-Drawn Steel Wire For Mechanical SpringDocument10 pagesSpring Wire: Patented Cold-Drawn Steel Wire For Mechanical SpringGage Floyd BitayoNo ratings yet

- EU Emission Standards PDFDocument5 pagesEU Emission Standards PDFStephanie StewartNo ratings yet

- Torsion Springs CALCULATIONDocument14 pagesTorsion Springs CALCULATIONnarshihNo ratings yet

- Foundery Shop (Ch-6)Document121 pagesFoundery Shop (Ch-6)Shubham VermaNo ratings yet

- Equivalência Materiais - OTIMO PDFDocument40 pagesEquivalência Materiais - OTIMO PDFTúlio Barata FrançaNo ratings yet

- E1102m PDFDocument283 pagesE1102m PDFBhawani Singh RajawatNo ratings yet

- Prevailing Torque Locknut Technical SpecificationsDocument3 pagesPrevailing Torque Locknut Technical SpecificationsLiu YangtzeNo ratings yet

- Radial Drilling Machine Specs & DetailsDocument1 pageRadial Drilling Machine Specs & DetailsVarun PatelNo ratings yet

- Spring Design 101: Ace Wire Spring & Form Co., IncDocument15 pagesSpring Design 101: Ace Wire Spring & Form Co., IncmshameliNo ratings yet

- Arw314124523secunda RioDocument1 pageArw314124523secunda Rioalonsooo_No ratings yet

- Machinary For Crushing & GrindingDocument75 pagesMachinary For Crushing & GrindingAsad Imran MunawwarNo ratings yet

- Chapter 6. Tolerance Stack Up AnalysisDocument31 pagesChapter 6. Tolerance Stack Up AnalysisNguyên Bành QuốcNo ratings yet

- E-ABRASIC P 12 To P 220: For Coated Abrasives ProductsDocument2 pagesE-ABRASIC P 12 To P 220: For Coated Abrasives ProductsBas100% (1)

- Cone Ranger: Mobile Cone Crushing UnitsDocument2 pagesCone Ranger: Mobile Cone Crushing UnitsYousef AlipourNo ratings yet

- Mechanical OPerationDocument10 pagesMechanical OPerationAnshika RajputNo ratings yet

- Critical Analysis of Zwietering Correlation For Solids Suspension in Stirred TanksDocument10 pagesCritical Analysis of Zwietering Correlation For Solids Suspension in Stirred TanksVerónica ArévaloNo ratings yet

- Analysis of Spiral Power SpringDocument4 pagesAnalysis of Spiral Power SpringMuhd IlhamNo ratings yet

- Determining Clearance and Interference Fits for CouplingsDocument4 pagesDetermining Clearance and Interference Fits for Couplingsvilaschinke123No ratings yet

- Vertical and Horizontal Screw ConveyorsDocument4 pagesVertical and Horizontal Screw ConveyorsLLNo ratings yet

- 14C28N Draft Data SheetDocument3 pages14C28N Draft Data SheetWarren NelNo ratings yet

- 02 Training Program Gear 2013Document56 pages02 Training Program Gear 2013amrit002No ratings yet

- Engineering SectionDocument176 pagesEngineering Sectionlhgrahl100% (1)

- Natural RubberDocument7 pagesNatural RubberFrancis AdrianNo ratings yet

- Alloy Steel Castings Table 1Document16 pagesAlloy Steel Castings Table 1takumi_zNo ratings yet

- SDG PLUMMER BLOCK HOUSINGS FOR SPHERICAL ROLLER BEARINGSDocument26 pagesSDG PLUMMER BLOCK HOUSINGS FOR SPHERICAL ROLLER BEARINGSSandip GhoshNo ratings yet

- Design of Main GirderDocument58 pagesDesign of Main GirderovikbasuNo ratings yet

- Ball Screw CalculatorDocument60 pagesBall Screw Calculatorمنير بوزيدNo ratings yet

- Key Way SpecifyDocument1 pageKey Way SpecifyMichaelNo ratings yet

- Grades of Steel ChartDocument3 pagesGrades of Steel ChartKimNo ratings yet

- Spiral Wound GasketsDocument7 pagesSpiral Wound GasketsPrem NautiyalNo ratings yet

- Welding TermsDocument9 pagesWelding Termssanjibkrjana100% (1)

- Agitators, Tanks & ThickenersDocument29 pagesAgitators, Tanks & ThickenersAhmed Khalid RasheedNo ratings yet

- Drilling ExamplesDocument7 pagesDrilling ExamplesAdept Titu EkiNo ratings yet

- Outotec - Seismic Design of Elevated Slurry Storage Tanks For As NZS 1170 (Rosart)Document8 pagesOutotec - Seismic Design of Elevated Slurry Storage Tanks For As NZS 1170 (Rosart)Serguei DobrinNo ratings yet

- SKF Locknut Shaft Details InchDocument6 pagesSKF Locknut Shaft Details InchKOMATSU SHOVELNo ratings yet

- Precise Finite-Element Model For Pulleys Based On The Hamiltonian Form of ElasticityDocument13 pagesPrecise Finite-Element Model For Pulleys Based On The Hamiltonian Form of ElasticityShamik ChowdhuryNo ratings yet

- Appendix f2-III Calculation SheetsDocument46 pagesAppendix f2-III Calculation SheetsTobi BerrospiNo ratings yet

- SAIL BSBK Visit Docx-15.06. R-1rtfDocument7 pagesSAIL BSBK Visit Docx-15.06. R-1rtfsssadangi100% (1)

- ROPS FOPS Test Certificate ST1030Document1 pageROPS FOPS Test Certificate ST1030Ventasde VehiculosNo ratings yet

- Hardening and Hardness Tests Conversion Table of Hardness: Materials Technical DataDocument1 pageHardening and Hardness Tests Conversion Table of Hardness: Materials Technical DataalexmontellNo ratings yet

- Bang Chuyen Doi Don VI Do Do CungDocument1 pageBang Chuyen Doi Don VI Do Do CungThuy DttqNo ratings yet

- Strength of Bolts, Screw Plugs and Dowel Pins Calculation of Cubic VolumeDocument1 pageStrength of Bolts, Screw Plugs and Dowel Pins Calculation of Cubic VolumeUdhasu NayakNo ratings yet

- Hexagon Socket Set Screws, Flat Type Hexagon BoltsDocument1 pageHexagon Socket Set Screws, Flat Type Hexagon BoltsVarun VaruNo ratings yet

- Roughness Conversion TableDocument1 pageRoughness Conversion Tabledreamingscientist3393No ratings yet

- LECTURE 3 - Shear StressesDocument13 pagesLECTURE 3 - Shear StressesAbe SaulnierNo ratings yet

- Spring CalculationsDocument1 pageSpring CalculationswarhamniNo ratings yet

- Structural Steel Fabrication SpecificationDocument40 pagesStructural Steel Fabrication SpecificationNatthawut Cheencharoen80% (5)

- Revised Load and Resistance Factors For The AASHTO LRFD - Andrzej S. Nowak PDFDocument13 pagesRevised Load and Resistance Factors For The AASHTO LRFD - Andrzej S. Nowak PDFNatthawut CheencharoenNo ratings yet

- Production RatesDocument17 pagesProduction Ratesyonatan1351No ratings yet

- Epoxy JointDocument2 pagesEpoxy JointNatthawut CheencharoenNo ratings yet

- Limits and Fits Pr1171 - 1172Document1 pageLimits and Fits Pr1171 - 1172Teguh Nugraha KusnanNo ratings yet

- CFLHD Production RatesDocument7 pagesCFLHD Production RatesabhiazadNo ratings yet

- HZS60 Concrete Mixing StationDocument6 pagesHZS60 Concrete Mixing StationNatthawut CheencharoenNo ratings yet

- Production RatesDocument17 pagesProduction Ratesyonatan1351No ratings yet

- 7718Document1 page7718Natthawut CheencharoenNo ratings yet

- Genset 79-102-125 kVADocument2 pagesGenset 79-102-125 kVANatthawut CheencharoenNo ratings yet

- CTT Elastomeric BearingsDocument20 pagesCTT Elastomeric Bearingsjajaytt100% (1)

- TG 1200MDocument12 pagesTG 1200MNatthawut CheencharoenNo ratings yet

- Dextra Prestressing Bar Rev 11 Oct 2016Document14 pagesDextra Prestressing Bar Rev 11 Oct 2016Natthawut CheencharoenNo ratings yet

- Chord OCT16Document5 pagesChord OCT16Natthawut CheencharoenNo ratings yet

- Nikon D800 PDFDocument14 pagesNikon D800 PDFmamarraoulNo ratings yet

- BIM Management - BIM@SGDocument2 pagesBIM Management - BIM@SGNatthawut CheencharoenNo ratings yet

- 15.12.16, 11:13 Cubus Front Support Frame: Scale 1:49.3 StructureDocument5 pages15.12.16, 11:13 Cubus Front Support Frame: Scale 1:49.3 StructureNatthawut CheencharoenNo ratings yet

- The Power of Prestressing J. StraskyDocument19 pagesThe Power of Prestressing J. StraskyNatthawut CheencharoenNo ratings yet

- Repair of Unbonded Single Strand Tendons - July 2005Document5 pagesRepair of Unbonded Single Strand Tendons - July 2005Natthawut CheencharoenNo ratings yet

- Rules of Thumb For Steel StructuresDocument5 pagesRules of Thumb For Steel StructuresLincs lincoln100% (1)

- Hardness TestingDocument32 pagesHardness TestingShivashankrappa BalawatNo ratings yet

- I Materials Grades R en PDFDocument47 pagesI Materials Grades R en PDFprocess processNo ratings yet

- Hardness Conversion ChartDocument6 pagesHardness Conversion ChartIjabiNo ratings yet

- Astm E10 18Document12 pagesAstm E10 18Şəbnəm SeyidovaNo ratings yet

- Micro/Vickers Hardness (HV) Test ResultsDocument3 pagesMicro/Vickers Hardness (HV) Test ResultsMohamed NasrNo ratings yet

- Lesson 12 - Hardness RockwellDocument6 pagesLesson 12 - Hardness Rockwell4gen_5No ratings yet

- Vickers Hardness Test ExplainedDocument5 pagesVickers Hardness Test ExplaineddiscotopNo ratings yet

- Astm E92 Vickers Hardness of Matallic MaterialsDocument10 pagesAstm E92 Vickers Hardness of Matallic Materialshackz3003No ratings yet

- D-Hardness Test (2019-2020)Document19 pagesD-Hardness Test (2019-2020)Vipul MetaNo ratings yet

- Vickers Hardness Lab SheetDocument10 pagesVickers Hardness Lab SheetazimNo ratings yet

- Hardness Conversion ChartDocument13 pagesHardness Conversion ChartCristian Alejandro Huerta HernandezNo ratings yet

- Assignment 1 (Hardness Test)Document14 pagesAssignment 1 (Hardness Test)Azri LunduNo ratings yet

- Hardness Testing of Metallic MaterialsDocument4 pagesHardness Testing of Metallic MaterialsAshan Marambe100% (1)

- Standard Hardness Conversion Tables For Metals: Superficialhardness, Knoophardness ScleroscopehardnessDocument20 pagesStandard Hardness Conversion Tables For Metals: Superficialhardness, Knoophardness ScleroscopehardnessIgnacio Hiram M Roque100% (1)

- Hardness TestDocument15 pagesHardness TestAnand KvNo ratings yet

- Microindentation Hardness Operating InstructionsDocument7 pagesMicroindentation Hardness Operating InstructionsnetzaalvaradoNo ratings yet

- Vickers Test PresentationDocument21 pagesVickers Test PresentationnailamushNo ratings yet

- E 140Document23 pagesE 140Luna Hernandez Ricardo100% (1)

- Hardness Testing Methods ExplainedDocument9 pagesHardness Testing Methods ExplainedMohan S kumarNo ratings yet

- Uji KekerasanDocument55 pagesUji KekerasanShiezkhaede ShirakawaNo ratings yet

- Indian Institute of Technology, Guwahati: Laboratory SheetDocument6 pagesIndian Institute of Technology, Guwahati: Laboratory SheetKamini GoyalNo ratings yet

- Portable BHN Astm-E110!14!2023Document3 pagesPortable BHN Astm-E110!14!2023Arthanari VaidyanathanNo ratings yet

- Module 8 Hardness TestingDocument33 pagesModule 8 Hardness TestingAnonymous 4APvkrc6No ratings yet

- STEEL HARDNESS CONVERSION TABLE REFERENCE GUIDEDocument2 pagesSTEEL HARDNESS CONVERSION TABLE REFERENCE GUIDEJannes PandianganNo ratings yet

- Hardness Test: NO: 3 Supervised By: Dr. OsmanDocument9 pagesHardness Test: NO: 3 Supervised By: Dr. Osmanwrya hussainNo ratings yet

- Hardness Conversion TableDocument3 pagesHardness Conversion TableRavindra KirangeNo ratings yet

- Calculation of Electrode ConsumptionDocument4 pagesCalculation of Electrode ConsumptionhgolestaniNo ratings yet

- Wall Chart For Hardness Testing PDFDocument1 pageWall Chart For Hardness Testing PDFabhiNo ratings yet

- Bulent Aydemir Baris Cal Serdar Salman: The Advantages of New Generation Hardness Measurement MethodsDocument8 pagesBulent Aydemir Baris Cal Serdar Salman: The Advantages of New Generation Hardness Measurement MethodsRahmat HidayatNo ratings yet

- Rockwell Hardness: Mirza Bilal SaleemDocument23 pagesRockwell Hardness: Mirza Bilal Saleemtanzil10No ratings yet