Professional Documents

Culture Documents

GC Column Installation Quick Reference PDF

GC Column Installation Quick Reference PDF

Uploaded by

mardonioandradeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GC Column Installation Quick Reference PDF

GC Column Installation Quick Reference PDF

Uploaded by

mardonioandradeCopyright:

Available Formats

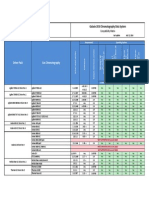

Agilent GC Support - Quick Reference Guide

GC Column Installation Quick Reference Guide - Inlets

Inlet Diagram Procedure

Place a septum over the column, then the

column nut and ferrule. Trim the end of the

column with a column cutter.

Split/Splitless Pull the column back so that 4-6 mm of column is

extending past the end of the ferrule.

Thread the column nut and column into the inlet

and tighten slightly past where the column grabs

– retighten after heating.

Place a septum over the column, then the

column nut and ferrule. Trim the end of the

column with a column cutter.

Purged Packed Pull the column back so that 1-2 mm of column is

extending past the end of the ferrule.

Thread the column nut and column into the inlet

and tighten slightly past where the column grabs

– retighten after heating.

NOTE: Make sure the column adapter nut on

the inlet base is fully threaded on and

spinning freely – Collar Up!

Multimode

Tighten with two wrenches - ¼” and 5/16”

To prevent damage the inlet threads.

Cool Insert the column all the way into the inlet until

On Column you feel the spring tension – do not withdraw.

The column cut is critical.

Tighten with two wrenches - ¼” and 5/16”

to avoid damaging the inlet.

There should be 17mm of column above the

graphpak ferrule – the graphpak ferrule should

PTV be installed with the graphite end towards the

inlet base. The column nut is slotted. Use a 5

mm wrench to tighten the fitting.

There is a longer column nut for the VI so that

you don’t have to remove the inlet block.

Volatiles Part Number - G3504-20504

Interface

01 June 2010 Page 1 of 2

Agilent GC Support - Quick Reference Guide

GC Column Installation Quick Reference Guide - Detectors

Detector Diagram Procedure

Place a septum over the column, then the

column nut and ferrule. Trim the end of the

column with a column cutter.

FID/NPD Thread the column nut and column into the

detector base. Insert the column all the way

into the detector jet until it stops, then

withdraw 1-2 mm before tightening the nut.

The dimensions shown of 48 and 68 mm

are provided for very narrow columns

(<100um) which may go all the way through

the jet.

Place a 1/8” Swagelok nut and the Back

and Front ferrules over the column. (Be

TCD – sure to select the front ferrule size to match

Using the the column) Trim the end of the column with

standard a column cutter.

Low

Thread the column nut and column into the

Leakage detector base. Insert the column all the way

Ferrules into the detector jet until it stops, then

withdraw 1-2 mm before tightening the nut.

Re-tighten after heating.

Install the column adapter to the 1/8”

Swagelok TCD base using a

TCD – graphite/vespel ferrule.

Original

Design Thread the column nut and column into the

adapter. Insert the column all the way into

Column

the detector jet until it stops, then withdraw

Adapter 1-2 mm before tightening the nut.

Be sure that the Makeup gas adapter is

installed with the 19 mm dimension shown.

Thread the column nut with column into the

uECD make-up gas adapter. Insert the column all

Final Makeup the way into the mixing liner until it stops,

Adapter then withdraw 1-2 mm - Use 2 wrenches to

Installation tighten the nut.Re-tighten after heating.

Dimensions: The 70 mm dimension shown is provided

for very narrow columns (<100um) which

may go all the way through the mixing liner.

Install the column into the Column

Measuring Tool Provided. Trim the column

such that 1 mm extends from the end of the

FPD tool. Tighten the column nut and mark the

position of the column at the back of the

nut. Install into the detector base.

01 June 2010 Page 2 of 2

You might also like

- Elegun - Those That Orisa Climb Their HeadsDocument4 pagesElegun - Those That Orisa Climb Their HeadsHazel100% (1)

- Hydride Vapor Generator: For Shimadzu Atomic Absorption SpectrophotometerDocument23 pagesHydride Vapor Generator: For Shimadzu Atomic Absorption SpectrophotometerKhalid Zghear100% (2)

- Improving The Performance of The EB104 Amplifier With A Transmission Line TransformerDocument20 pagesImproving The Performance of The EB104 Amplifier With A Transmission Line Transformerpino100% (1)

- Prominence Pumps PDFDocument2 pagesProminence Pumps PDFsandNo ratings yet

- The Impact of PH On HPLC Method Development: Separations at Low PH - Retention and SelectivityDocument6 pagesThe Impact of PH On HPLC Method Development: Separations at Low PH - Retention and SelectivityHikmah AmelianiNo ratings yet

- Ey Commerce and Consumer Internet SectorDocument71 pagesEy Commerce and Consumer Internet SectorAnish ShahNo ratings yet

- Boogie Woogie and How To Play It Book Two David Carr Glover 1958Document26 pagesBoogie Woogie and How To Play It Book Two David Carr Glover 1958Ilya OstapenkoNo ratings yet

- Ultra-High Sensitivity in Triple Quadrupole LCMS TechnologyDocument42 pagesUltra-High Sensitivity in Triple Quadrupole LCMS TechnologyngobaochanNo ratings yet

- Gas ChromatographyDocument97 pagesGas ChromatographysalduwikatNo ratings yet

- 91494711Document97 pages91494711vzimak2355No ratings yet

- USP Chapter 788 Particulate Matter in InjectionDocument4 pagesUSP Chapter 788 Particulate Matter in InjectionQC MahakamNo ratings yet

- Freak The Mighty Tic Tac ToeDocument2 pagesFreak The Mighty Tic Tac Toelagarcia8002No ratings yet

- Lab Testing Report - REACHDocument4 pagesLab Testing Report - REACHajayNo ratings yet

- COA of Chondroitin SulfateDocument1 pageCOA of Chondroitin SulfatePan EmmaNo ratings yet

- Industrial RO Water SystemDocument3 pagesIndustrial RO Water SystemAhm N NstNo ratings yet

- Troubleshoot GC MSMSDocument45 pagesTroubleshoot GC MSMSSilmiNo ratings yet

- Industrial RO System DubaiDocument34 pagesIndustrial RO System DubaiaquaproNo ratings yet

- CN 1.4 Striking and Fielding GamesDocument3 pagesCN 1.4 Striking and Fielding GamesShaun LouiseNo ratings yet

- Commercial Craft Thruster Systems 2014 enDocument100 pagesCommercial Craft Thruster Systems 2014 enMefNo ratings yet

- The Membrane Selector Guide. MilliporeDocument1 pageThe Membrane Selector Guide. MilliporeClaudiaNo ratings yet

- Astm D 2269Document3 pagesAstm D 2269Faisal RahmadNo ratings yet

- HPLC P-Series With UV DetectorDocument28 pagesHPLC P-Series With UV DetectorUrva VasavadaNo ratings yet

- DTD - Homebrew EquipmentDocument34 pagesDTD - Homebrew EquipmentEdwiz0% (1)

- Fluorospectrometer RF-20A:20Axs Prominence User ManualDocument352 pagesFluorospectrometer RF-20A:20Axs Prominence User ManualChristos Georgiou100% (1)

- Manual Detector FluorescenciaDocument198 pagesManual Detector FluorescenciaEdgar Nina Velasquez100% (1)

- C Elementar Vario MACRO Cube PDFDocument16 pagesC Elementar Vario MACRO Cube PDFWaleed El-azab100% (1)

- 10988, Waters 2690/2695 Performance Maintenance KitDocument1 page10988, Waters 2690/2695 Performance Maintenance KitSteve HarrisNo ratings yet

- ADA5000 - K45603 - K45604 - K45703-TS - K45704-TS Manual REV BDocument26 pagesADA5000 - K45603 - K45604 - K45703-TS - K45704-TS Manual REV Bmoh_ichwanuddin100% (1)

- QMM-2011 - GC-2010Pro SMDocument79 pagesQMM-2011 - GC-2010Pro SMAtongo George AtiahNo ratings yet

- AA 1800C User's Manual 1Document39 pagesAA 1800C User's Manual 1Kidus YohannesNo ratings yet

- 02-2021 - Quant Advanced 2Document71 pages02-2021 - Quant Advanced 2Mahardhika Harry NugrahaNo ratings yet

- SOP ASTM D1946-90 (Rev. 1.7)Document16 pagesSOP ASTM D1946-90 (Rev. 1.7)Joseph MuirNo ratings yet

- Kjeltec 2100 Datasheet 2 - GBDocument7 pagesKjeltec 2100 Datasheet 2 - GBAMC AnalisisNo ratings yet

- Gas Chromatography Protocol - 2Document6 pagesGas Chromatography Protocol - 2pmdNo ratings yet

- CE Certificate OptiFlash - Pensky MartensDocument1 pageCE Certificate OptiFlash - Pensky MartenskevinNo ratings yet

- Oilpac eDocument85 pagesOilpac eAri CleciusNo ratings yet

- EcoSEC Quick Reference Manual Rev.A080218Document39 pagesEcoSEC Quick Reference Manual Rev.A080218PrianurraufikachmadNo ratings yet

- NIR - Multivariate Calibration - 3rd Edition 2014Document12 pagesNIR - Multivariate Calibration - 3rd Edition 2014Ingeniero Alfonzo Díaz GuzmánNo ratings yet

- Gas Chromatography Driver Pack: Galaxie 2010 Chromatography Data SystemDocument3 pagesGas Chromatography Driver Pack: Galaxie 2010 Chromatography Data SystemmardonioandradeNo ratings yet

- BKC 80Document2 pagesBKC 80jawaidchemicalsNo ratings yet

- C-R8A Operation Guide CR8ADocument224 pagesC-R8A Operation Guide CR8AAlvaro Atenco50% (2)

- Aas PQ Protocol For ZincsulphateDocument7 pagesAas PQ Protocol For Zincsulphateshaik janiNo ratings yet

- Magnesium Stearate: Magnesii StearasDocument3 pagesMagnesium Stearate: Magnesii StearaswilNo ratings yet

- DGU-403 DGU-405: Instruction ManualDocument30 pagesDGU-403 DGU-405: Instruction ManualCrystal LinNo ratings yet

- Promo HNZ Sigma Aldrich Labware GuideDocument12 pagesPromo HNZ Sigma Aldrich Labware GuideMargaretaSianneNo ratings yet

- D4861Document16 pagesD4861Fredi Cari CarreraNo ratings yet

- HDT and VSPDocument1 pageHDT and VSPscribdkth100% (1)

- Water System Reagents 072014Document3 pagesWater System Reagents 072014Mamang EstepeNo ratings yet

- Fertilizer Confirmatory Method ListDocument1 pageFertilizer Confirmatory Method ListĐăng LưuNo ratings yet

- Gas Chromatograph Based On-line/At-line Analysis For Sulfur Content of Gaseous FuelsDocument6 pagesGas Chromatograph Based On-line/At-line Analysis For Sulfur Content of Gaseous FuelsDIAZCORDOBA100% (1)

- Guide To Set Up RheometerDocument7 pagesGuide To Set Up RheometerMattia RosaNo ratings yet

- Rheodyne 2-Way SwitchDocument34 pagesRheodyne 2-Way SwitchOliver Müller100% (1)

- B 373 - 00 - QJM3MWDocument5 pagesB 373 - 00 - QJM3MWmalika_00No ratings yet

- Manual Optrode MetrohmDocument23 pagesManual Optrode MetrohmNacho RodríguezNo ratings yet

- Catalogo de Consumibles HTADocument13 pagesCatalogo de Consumibles HTAAlexander Nieto VelaNo ratings yet

- D-Glucuronic Acid and D-Galacturonic Acid, UV MethodDocument4 pagesD-Glucuronic Acid and D-Galacturonic Acid, UV MethodWenliuli W-sNo ratings yet

- Sparkle FilterklDocument5 pagesSparkle FilterklArvind ChaudharyNo ratings yet

- Li 6090 - TDS - Eoc PiplDocument2 pagesLi 6090 - TDS - Eoc Piplsantosh mhetreNo ratings yet

- DiacereinDocument3 pagesDiacereinMulayam Singh Yadav0% (2)

- Digital Inclinometer - 2022-15-FM1Document1 pageDigital Inclinometer - 2022-15-FM1Chethan Nagaraju KumbarNo ratings yet

- Agilent 1100 LC-MSD Replacement Parts PDFDocument37 pagesAgilent 1100 LC-MSD Replacement Parts PDFCraig McelroyNo ratings yet

- HP 5890 Parts BreakdownsDocument129 pagesHP 5890 Parts BreakdownszeppelinboyNo ratings yet

- Flash Point Stanhope-SetaDocument6 pagesFlash Point Stanhope-SetarabeaNo ratings yet

- TDS - Synocure 561X60Document2 pagesTDS - Synocure 561X60BERKAT RAJA SEMESTANo ratings yet

- MAN0011430 Pierce BCA Protein Asy UGDocument8 pagesMAN0011430 Pierce BCA Protein Asy UGIvie João GabrielNo ratings yet

- GC Column Installation Quick Reference GuideDocument2 pagesGC Column Installation Quick Reference GuideMohamed IbrahimNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Acm12 Ei06Document2 pagesAcm12 Ei06Anonymous OFfJVrQY6No ratings yet

- Samantha DetailsDocument2 pagesSamantha DetailskarthikrameshNo ratings yet

- 08.12.2021 Enrolment Final Present ListDocument16 pages08.12.2021 Enrolment Final Present ListMala deviNo ratings yet

- Manual - Laserworld CS-400GDocument10 pagesManual - Laserworld CS-400GAhmedić-Kovačević KrigeNo ratings yet

- Learning Disciplines: Abilities & LoresDocument2 pagesLearning Disciplines: Abilities & LoresJoshua JenningsNo ratings yet

- Bohinj Park ECO Hotel - Hotel Bohinj Park BrochureDocument28 pagesBohinj Park ECO Hotel - Hotel Bohinj Park BrochurebohinjparkhotelNo ratings yet

- Book: Sarah'S Key Author: Tatiana de RosnayDocument5 pagesBook: Sarah'S Key Author: Tatiana de Rosnayapi-305288552No ratings yet

- EBBRDocument132 pagesEBBRSaarthak BhattNo ratings yet

- Case Study JabongDocument10 pagesCase Study JabongTEJVEER SINGHNo ratings yet

- Gold Pre-First Unit 4 Test: Name - ClassDocument2 pagesGold Pre-First Unit 4 Test: Name - ClassMaría Marta OttavianoNo ratings yet

- HanLNG ExamDocument6 pagesHanLNG ExamTeacherNo ratings yet

- Reading Comprehension 1Document2 pagesReading Comprehension 1vanina szekelyNo ratings yet

- Sidewinder PartsDocument4 pagesSidewinder PartsKhalidNo ratings yet

- Soal Pas 1 Kls X 2021Document4 pagesSoal Pas 1 Kls X 2021riska andrianiNo ratings yet

- Pride and Extreme Prejudice v1.1 (Text Only)Document3 pagesPride and Extreme Prejudice v1.1 (Text Only)Timóteo ThoberNo ratings yet

- APPLICATION MtopDocument3 pagesAPPLICATION MtopAnn Manalocon100% (1)

- DPP Technique Manny LibrodoDocument8 pagesDPP Technique Manny Librodoapi-240618646No ratings yet

- Destination BrandingDocument31 pagesDestination Brandingrosermary100% (1)

- Khalid Ali Shah Highlights and MemoriesDocument3 pagesKhalid Ali Shah Highlights and Memoriesgdrive.r859abNo ratings yet

- Chapter 4 ReviewerDocument20 pagesChapter 4 ReviewerJoe-an GarrovilloNo ratings yet

- Your English Pal - Grammar - 2.1 - GerundsDocument4 pagesYour English Pal - Grammar - 2.1 - GerundsMonica Liliana Melo SierraNo ratings yet

- Woofer Is The Term Commonly Used For A: LoudspeakerDocument4 pagesWoofer Is The Term Commonly Used For A: LoudspeakerRey Maurice DonesaNo ratings yet

- An Email To A Friend About The First Week After Starting Work in A New City - S Past N Prepositions of Place N TimeDocument2 pagesAn Email To A Friend About The First Week After Starting Work in A New City - S Past N Prepositions of Place N TimeRoshan RajuNo ratings yet