Professional Documents

Culture Documents

Flexible coupling pin design and shaft key selection

Uploaded by

Manivannan0 ratings0% found this document useful (0 votes)

39 views3 pagesDME unit test

Original Title

Internal Test-II Dme. Section b Docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDME unit test

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views3 pagesFlexible coupling pin design and shaft key selection

Uploaded by

ManivannanDME unit test

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

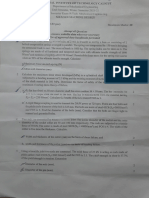

Reg.

No : B) i) A flexible coupling is used to transmit 15 kW power at 100

rpm. There are six pins and their pitch circle diameter is 200 mm. The

effective length of bush, the gap between two flanges and the length of

the pin in contact with right hand flange are 35, 5 and 23 mm

respectively. The permissible shear and bending stresses in the pin are

IAT-II 35 and 152 N/mm2 respectively. Calculate Pin diameter by shear

ME 6503-DESIGN OF MACHINE ELEMENTS consideration, bending consideration.

Year/Sem/sec: III/V/B Time: 3.00P.M-4.30P.M ii)A shaft made of AISI 1030 cold drawn steel (σu=520MPa and

Date: 24 .08.2018 Max Marks: 50 σy=440MPa) transmits 50KW at 900 rpm through in a gear, selce an

appropriate square key for the gear.

PART-A

(5 x 2 = 10 Marks) 8. A) Design a muff coupling to connect two steel shafts

ANSWER ALL QUESTIONS

1. What is the main use of woodruff keys?

transmitting 25 KW power at 360 rpm. the shaft and key are

2. Under what circumferences flexible couplings are used? made of plain carbon steel 30 c8 (Syt =Syc =400 N/mm2). The

3. Differentiate between keys and splines. sleeve is made of grey CI FG200 (Sut= 200N/mm2). The factor

4. Define surge in springs. of safety for the shafts and key is 4. For the sleeve , the factor

5. When a helical compression spring is cut into two halves, what is the stiffness of of safety is 6 based on ultimate strength.

the resulting half spring? (OR)

PART-B (4*10 =40) B) Design a Clamp or compression coupling for a shaft to transmit

ANSWER ALL QUESTIONS 30KW at 100 rpm. The allowable shear stress for the shaft and key is

6. A) It is required to design a rigid type of flange coupling to connect two shafts. 40 MPa and the number of bolts connecting the two halves are 4. The

The input shaft transmits 37.5 kW power at 180 rpm to the output shaft through the permissible tensile stress for the bolts material is 70 MPa. The

coupling. The service factor for the application is 1.5, i.e. the design torque is 1.5 coefficient of friction between the muff and the shaft surface may be

times of rated torque. Select suitable materials for various parts of the coupling, taken as 0.3.

design the coupling and specify the dimensions of its components. (OR)

9. A) A helical compression spring made of oil tempered

B) Design a protective type of cast iron flange coupling for a steel shaft carbon steel is subjected to a load which varies from 400N to

transmitting 15kW at 200 rpm and having an allowable shear stress of 40 1000 N. the spring index is 6 and design factor safety is 1.25.

N/rnm2. The working stress in the bolt should not exceed 30 N/mm 2. Assume if the yield stress in shear is 770MPa and endurance stress in

that the same material is used for shaft and key that the crushing stress is twice shear is 350 MPa, find size of the spring wire, diameter of

the value of its shear stress. The maximum torque is 25% greater than the full spring, number of turns of spring and free length of the

load torque. The shear stress for cast iron is 14 N/mm 2. spring. The compression of the spring at the maximum load is

30mm.take G=80KN/mm2.

(OR)

7. A) Design a bushed-pin type of flexible coupling to connect a pump shaft to a

B) A close coiled helical compression spring has plain ends and is to fit

motor shaft transmitting 30 kW at 900 rpm. The overall torque is 15% more than

over a 25 mm dia rod. When a compressive force of 100N is applied to

mean torque. The material allowable properties are as follows : σ (in crushing for

the spring it compresses by 50mm. if the spring has preferred wire dia

shaft and key material) = 80 MPa τ (in shear for shaft and key material) = 40 MPa

of 4 mm, and spring material has a maximum allowable shear stress of

τ (in shear for cast iron) = 15 MPa. Bearing pressure for rubber bush = 0.8 MPa 180MN/m2 and G= 81GPa.calculate i) D ii) the diametrical clearance

Material of the pin as same as that of shaft and key. Draw the sketch of the

between the spring and the rod. Iii) the number of coils in the

coupling. (OR)

spring.iv)the solid length of spring.

7. Determine the diameter of a circular rod made of ductile

material with a endurance limit is 265 MPa and a tensile

yield strength of 350 MPa. The member is subjected to a

varying axial load from - 300 kN to 700 kN and has a

stress concentration factor is 1.8 .

7. A cylindrical shaft made of steel of yield strength 700 MPa is

subjected to static loads consisting of bending moment 10 kN-m

and a torsional moment 30 kN-m. Determine the diameter of the

shaft using two different theories of failure, and assuming a

factor of safety of 2. Take E = 210GPa and poisson's ratio = 0.25.

8. Find the diameter of a shaft to transmit twisting moments

Reg.No varying from 900 N-m to1800 N-m. The ultimate tensile

strength for the material is 650 MPa and yield stress is 480

MPa. Assume the stress concentration factor = 1.2, surface

finish factor = 0.5 and size factor = 0.85.

1. allowable tensile stress in the plate 90Mpa; compressive stress

140MPa; and shear stress in the rivet 56MPa?

IAT-1

ME 6503-DESIGN OF MACHINE ELEMENTS

Year/Sem/sec: III/V/A Time: 3.00P.M-4.30P.M

Date: 28.08.2017 Max Marks: 50

PART-A

(5 x 2 = 10 Marks)

ANSWER ALL QUESTIONS

1. What do you mean by optimum design? NOV2007

2. Define limits and fits.

3. What is preferred number?

4. Differentiate between curved beam and straight beam

5. What are the methods to reduce stress concentration?

PART-B (4*10 =40)

ANSWER ALL QUESTIONS

6. An unknown weight falls through 10 mm on a collar rigidly attached to the

lower end of a vertical bar 3 m long and 600 mm2 in section. If the maximum

instantaneous extension is known to be 2 mm, what is the corresponding stress

and the value of unknown weight? Take E = 200 kN/mm2

1.2 in and it has four straight

arms of elliptical cross-section,

in which the

Reg.N major axis is twice the minor axis.

Determine the dimensions of the

o:

arm if the

allowable

bending stress is

GE6757-TOTAL QUALITY MANAGEMENT

15 MPa.

Year/Sem/sec: IV/VII/B Time: 9.30AM-11.00AM

Date: 05.07.2017 Max Marks: 50

PART-A

(5 x 2 = 10 Marks)

ANSWER ALL QUESTIONS

1. Define quality.

2. What are the elements of TQM?

3. List out any four barriers to TQM implementation.

4. What are the four absolutes of quality defined by Crosby? A Cast iron pulley transmits 10 kW at 400 rpm. The diameter of the pulley is1.2 in and it has four

straight arms of elliptical cross-section, in which the major axis is twice the minor axis. Determine the

5. Define quality policy statement. dimensions of the arm if the allowable bending stress is15 MPa.

PART-B (4*10 =40)

ANSWER ALL QUESTIONS

6. Describe the various dimensions of quality with respect to the

following: Quality in products and quality in services.

7. Elaborate the fourteen steps involved in Crosby’s total quality

approach.

8. Describe juran’s principles of quality management.

9. Explain Deming’s fourteen point philosophy quality

improvement.

A Cast iron pulley transmits 10 kW at 400 rpm. The diameter of the pulley is

You might also like

- Cisco Ccna Presentation SlideDocument623 pagesCisco Ccna Presentation SlideKomal Ahmad100% (1)

- Assignment 1Document4 pagesAssignment 1sonawanepmsNo ratings yet

- Geometric Cabinet Insets, Cards and ActivitiesDocument3 pagesGeometric Cabinet Insets, Cards and Activitiessonia sanchez espada100% (1)

- The Selection and Design of Mill LinersDocument11 pagesThe Selection and Design of Mill Linersluis martinezNo ratings yet

- Reg - No:: Ii) Design A Rectangular Key For The Following Application: A ShaftDocument3 pagesReg - No:: Ii) Design A Rectangular Key For The Following Application: A ShaftManivannanNo ratings yet

- 3-1 DMM1 (Nov 2009 Regular)Document9 pages3-1 DMM1 (Nov 2009 Regular)micmechNo ratings yet

- Machine Members Design AssignmentDocument13 pagesMachine Members Design AssignmentHafiz Mahar28No ratings yet

- Register Number NIT Mechanical Design Machine Elements ExamDocument2 pagesRegister Number NIT Mechanical Design Machine Elements ExamdharaniventhanNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHerat HirparaNo ratings yet

- PART-B QUESTIONS STEADY STRESSES AND VARIABLE STRESSESDocument12 pagesPART-B QUESTIONS STEADY STRESSES AND VARIABLE STRESSESMadhu MithaNo ratings yet

- Code: 13A03505: (Mechanical Engineering)Document2 pagesCode: 13A03505: (Mechanical Engineering)MrHEMAMAHEHNo ratings yet

- Design of machine elements exam questions and solutionsDocument3 pagesDesign of machine elements exam questions and solutionsvikaskumar1986No ratings yet

- No of Pages Course Code:: Fig.1 Fig 2Document4 pagesNo of Pages Course Code:: Fig.1 Fig 2CRAZY PIANO PLAYERNo ratings yet

- TUTORIAL 3 Design of Shaft Key and CouplingDocument2 pagesTUTORIAL 3 Design of Shaft Key and Couplingrip111176100% (1)

- Tutorial Sheet-II MEC3110/317 (Machine Design II)Document4 pagesTutorial Sheet-II MEC3110/317 (Machine Design II)Prateeksha ShakyaNo ratings yet

- Dme Model 2Document6 pagesDme Model 2YashwanthI-StyleKuttiNo ratings yet

- QB Unit-1,2Document5 pagesQB Unit-1,2Agranshu BhardwajNo ratings yet

- ME 331 - DESIGN OF MACHINE ELEMENTS EXAMDocument5 pagesME 331 - DESIGN OF MACHINE ELEMENTS EXAMarumugam_rNo ratings yet

- DME - Assignment - IDocument3 pagesDME - Assignment - ISathis KumarNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNo ratings yet

- MD ConventionalDocument8 pagesMD ConventionalBipin KumarNo ratings yet

- Me8593 Iq R17Document4 pagesMe8593 Iq R17Vaideesh LJNo ratings yet

- Me1302 Dme 2Document4 pagesMe1302 Dme 2sumikannu100% (1)

- DMM-1 MID-2 Assignment QuestionsDocument3 pagesDMM-1 MID-2 Assignment Questionsuppada AnilNo ratings yet

- QuestionsDocument11 pagesQuestionsSundara MoorthyNo ratings yet

- DME Chapter Three: or (Summer 15)Document7 pagesDME Chapter Three: or (Summer 15)honeyfunnyNo ratings yet

- Btech Auto 5 Sem Design of Machine Components Pau5i101 2020Document2 pagesBtech Auto 5 Sem Design of Machine Components Pau5i101 2020Pagal KutaNo ratings yet

- Cat 2 Ear 306Document4 pagesCat 2 Ear 306Mercy MerryNo ratings yet

- Machine Design End Sem 2022Document1 pageMachine Design End Sem 2022vivek geddamNo ratings yet

- GTU BE Semester IV Machine Design & Industrial Drafting ExamDocument3 pagesGTU BE Semester IV Machine Design & Industrial Drafting ExamhukNo ratings yet

- Dme Lab Sheets Ii Iii IvDocument4 pagesDme Lab Sheets Ii Iii IvA58Vikas UbovejaNo ratings yet

- Me 2303 Imp QnsDocument3 pagesMe 2303 Imp QnsAJAY63No ratings yet

- Mech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsDocument5 pagesMech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsARIGARAN SNo ratings yet

- Internal Test 1Document3 pagesInternal Test 1Sathish KumarNo ratings yet

- No of Pages: 4 Course Code: 12M502: Fig.1 Fig 2Document4 pagesNo of Pages: 4 Course Code: 12M502: Fig.1 Fig 2CRAZY PIANO PLAYERNo ratings yet

- dmm1 PDFDocument9 pagesdmm1 PDFmohan_rapaka6095No ratings yet

- Macine Element I Worksheet for Final ExamDocument4 pagesMacine Element I Worksheet for Final Examdagimawgchew777No ratings yet

- Design of Machine Elements 2 Jan 2018 (2010 Scheme)Document2 pagesDesign of Machine Elements 2 Jan 2018 (2010 Scheme)KishoreNo ratings yet

- Me 6503 Design of Machine Elements QBDocument3 pagesMe 6503 Design of Machine Elements QBDeepak SNo ratings yet

- DME Assignment 1Document2 pagesDME Assignment 1sumikannuNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.lavanya babuNo ratings yet

- Question Bank - DMEDocument6 pagesQuestion Bank - DMEBdhdhshNo ratings yet

- R09 B.Tech III Year I Semester Machine Elements ExamDocument1 pageR09 B.Tech III Year I Semester Machine Elements Examprasaad08No ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- Rr310305 Design of Machine Members IDocument8 pagesRr310305 Design of Machine Members ISrinivasa Rao GNo ratings yet

- MDDocument5 pagesMDYogesh DanekarNo ratings yet

- PART-A (10 X 2 20 Marks)Document4 pagesPART-A (10 X 2 20 Marks)Arun R UNo ratings yet

- Dme 2Document6 pagesDme 2NITHISH KUMAR M SNo ratings yet

- DME - Numerical Question Bank - GTUSTUDIESDocument7 pagesDME - Numerical Question Bank - GTUSTUDIESKevin RanpariaNo ratings yet

- Dme Question BankDocument4 pagesDme Question BankRavi Patil100% (1)

- PMD ModelDocument8 pagesPMD ModelDamodara SatyaDeva MadhukarNo ratings yet

- 13 ME AssignmentDocument2 pages13 ME AssignmentMuhammad Sharif JamaliNo ratings yet

- QB Unit-3,4,5Document7 pagesQB Unit-3,4,5Agranshu BhardwajNo ratings yet

- R7310305-Design of Machine Members-I2Document4 pagesR7310305-Design of Machine Members-I2slv_prasaad100% (1)

- DESIGN OF MACHINE MEMBERS - I Nov 2007 Question PaperDocument8 pagesDESIGN OF MACHINE MEMBERS - I Nov 2007 Question PaperelimelekNo ratings yet

- QP Pe Series 2Document2 pagesQP Pe Series 2AADARS M SNo ratings yet

- Dme I Mock Test Question BankDocument5 pagesDme I Mock Test Question BankRushikesh SwamiNo ratings yet

- NR-310305-Design of Machine ElementsDocument9 pagesNR-310305-Design of Machine ElementsSrinivasa Rao GNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- One Day National Seminar On "Current Trends in Pharmaceutical Sciences" and "World Pharmacists Day Celebrations" Date: 25 September, 2017Document15 pagesOne Day National Seminar On "Current Trends in Pharmaceutical Sciences" and "World Pharmacists Day Celebrations" Date: 25 September, 2017ManivannanNo ratings yet

- Anna University: Chennai - 600025Document1 pageAnna University: Chennai - 600025ManivannanNo ratings yet

- Welcome SpeechDocument3 pagesWelcome SpeechJenny DumalagNo ratings yet

- Sales Commission Schedule PDFDocument1 pageSales Commission Schedule PDFManivannanNo ratings yet

- Allotted List Round4Document768 pagesAllotted List Round4ManivannanNo ratings yet

- Format for Dept Newsletter on EventsDocument1 pageFormat for Dept Newsletter on EventsManivannanNo ratings yet

- Flexible coupling pin design and shaft key selectionDocument3 pagesFlexible coupling pin design and shaft key selectionManivannanNo ratings yet

- 4th Round Revised ScheduleDocument1 page4th Round Revised ScheduleBanupriya-No ratings yet

- MECH Dept Industrial Visit Newsletter FormatDocument1 pageMECH Dept Industrial Visit Newsletter FormatManivannanNo ratings yet

- Analytical Study On Self Closing Flood Barrier Using Ansys IJERTCONV3IS16005Document4 pagesAnalytical Study On Self Closing Flood Barrier Using Ansys IJERTCONV3IS16005ManivannanNo ratings yet

- Format for Dept Newsletter on EventsDocument1 pageFormat for Dept Newsletter on EventsManivannanNo ratings yet

- B.E. Mech PDFDocument113 pagesB.E. Mech PDFarulmuruguNo ratings yet

- Icmlci 2019 FlyerDocument2 pagesIcmlci 2019 FlyerManivannanNo ratings yet

- GAS & Smoke Leakage Detection and Automatic Valve Control SystemDocument3 pagesGAS & Smoke Leakage Detection and Automatic Valve Control SystemManivannanNo ratings yet

- Part 1Document576 pagesPart 1ManivannanNo ratings yet

- QB 114534Document19 pagesQB 114534ManivannanNo ratings yet

- AVS Engineering College Question Bank on Shaft and Coupling DesignDocument2 pagesAVS Engineering College Question Bank on Shaft and Coupling DesignManivannanNo ratings yet

- DME 3rdDocument5 pagesDME 3rdManivannanNo ratings yet

- U114534 PDFDocument4 pagesU114534 PDFManivannanNo ratings yet

- Leaf Springs - Design, Calculation and Testing Requirements: January 2014Document11 pagesLeaf Springs - Design, Calculation and Testing Requirements: January 2014ManivannanNo ratings yet

- DME4THDocument17 pagesDME4THManivannanNo ratings yet

- QB 114533Document22 pagesQB 114533ManivannanNo ratings yet

- Pg. No.144Document4 pagesPg. No.144ManivannanNo ratings yet

- Student success tips and tricksDocument4 pagesStudent success tips and tricksManivannanNo ratings yet

- QB 114532Document33 pagesQB 114532ManivannanNo ratings yet

- Machine Design Question BankDocument4 pagesMachine Design Question BankManivannanNo ratings yet

- QB 114532Document33 pagesQB 114532ManivannanNo ratings yet

- Oro551-Renewable Energy Sources Part B & Part C Questions - Unit WiseDocument2 pagesOro551-Renewable Energy Sources Part B & Part C Questions - Unit WiseManivannanNo ratings yet

- Robert Smith: Lead Principal Software EngineerDocument2 pagesRobert Smith: Lead Principal Software EngineerHardik PatelNo ratings yet

- An Overview of The Ansi Z359 Fall Protection Code: FEBRUARY 16, 2018Document24 pagesAn Overview of The Ansi Z359 Fall Protection Code: FEBRUARY 16, 2018isabel Cristina Agresott TorresNo ratings yet

- Week 5 Lecture Pigeonhole Principle 1Document58 pagesWeek 5 Lecture Pigeonhole Principle 1CODING with ASAD.No ratings yet

- Shs Genmath Module 8 Core Revised DuenasDocument42 pagesShs Genmath Module 8 Core Revised DuenasAPRIL JOY ARREOLANo ratings yet

- A Demonstration Lesson Plan Solutions and ColloidsDocument9 pagesA Demonstration Lesson Plan Solutions and ColloidsJenny Lynn dela Rosa100% (1)

- Bolt Circle CalculatorDocument21 pagesBolt Circle CalculatorMarcos PeralesNo ratings yet

- Seal Pot: Seal Fluid Supply TankDocument4 pagesSeal Pot: Seal Fluid Supply Tankmadhu gawadeNo ratings yet

- Application Notes UC3710TDocument16 pagesApplication Notes UC3710TSHAHID_71No ratings yet

- ERP Practice Exam4 7115Document40 pagesERP Practice Exam4 7115Sakthivel Balakrishnan100% (1)

- Full Mock-3 Olevel-Paper-4 Final SourceDocument10 pagesFull Mock-3 Olevel-Paper-4 Final SourceDewan Olin ChotepadaeNo ratings yet

- MOS-Construction of 132kv OHTL From Ad Darb To Looping PointDocument27 pagesMOS-Construction of 132kv OHTL From Ad Darb To Looping PointEngr Muhammad Azam ThaheemNo ratings yet

- EE5220 Project TRV CBRatings ReportDocument22 pagesEE5220 Project TRV CBRatings ReportsasikalasivakumarNo ratings yet

- Circuit Cellar 354 2020-01Document84 pagesCircuit Cellar 354 2020-01romanNo ratings yet

- 1993 Engines Eurovan - 2.5L 5-CylinderDocument20 pages1993 Engines Eurovan - 2.5L 5-Cylinderfrancesco pavanNo ratings yet

- Final 1019w06 PDFDocument11 pagesFinal 1019w06 PDFamir moghaddamNo ratings yet

- IN Sneddon - The Distribution of Stress in The Neighborhood of A Crack in An Elastic Solid - For Shape Factor QDocument32 pagesIN Sneddon - The Distribution of Stress in The Neighborhood of A Crack in An Elastic Solid - For Shape Factor QShaun Raphael LeeNo ratings yet

- SPE-18166-Correlaciones y RegistrosDocument14 pagesSPE-18166-Correlaciones y RegistrosSofiaNo ratings yet

- Sentence Correction Practice Questions 01Document5 pagesSentence Correction Practice Questions 01Dhiman NathNo ratings yet

- Bloch OscillationsDocument16 pagesBloch OscillationsrkluftingerNo ratings yet

- Lathe Machine OperationDocument68 pagesLathe Machine OperationKarthick N100% (8)

- Manual Aid 2Document136 pagesManual Aid 2Luis Chinchilla CruzNo ratings yet

- R&D Update - Design Rules For Forming Aluminum Stampings-Part 1 - The FabricatorDocument5 pagesR&D Update - Design Rules For Forming Aluminum Stampings-Part 1 - The FabricatorSIMONENo ratings yet

- Effect of Upstream Dam Geometry On Peak Discharge During Overtopping Breach in Noncohesive Homogeneous Embankment Dams Implications For Tailings DamsDocument22 pagesEffect of Upstream Dam Geometry On Peak Discharge During Overtopping Breach in Noncohesive Homogeneous Embankment Dams Implications For Tailings DamsHelvecioNo ratings yet

- Herramientas ProskitDocument4 pagesHerramientas ProskitCleyton Archbold BarkerNo ratings yet

- Duns Scotus - Duns Scotus On Time and Existence. The Questions On Aristotle's 'De Interpretatione'Document401 pagesDuns Scotus - Duns Scotus On Time and Existence. The Questions On Aristotle's 'De Interpretatione'Luiz Henrique Lopes100% (1)

- Chapter-14 Final Aerobic-DigestionDocument18 pagesChapter-14 Final Aerobic-DigestionIrvin joseNo ratings yet

- C Language Basic Programs Which Used For BigginnersDocument112 pagesC Language Basic Programs Which Used For BigginnersRavikumar VendiNo ratings yet