0% found this document useful (0 votes)

104 views6 pagesInternal Combustion Engine Overview

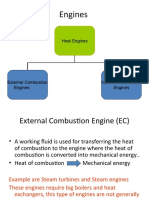

1. The document discusses internal combustion (IC) engines, which are engines that combust fuel within the engine itself. It focuses on describing the 4-stroke operating principle for both spark ignition and compression ignition engines.

2. In a 4-stroke spark ignition engine, the cycle consists of intake, compression, power, and exhaust strokes, with the spark plug igniting the fuel/air mixture at or just before top dead center during the power stroke.

3. In a 4-stroke compression ignition (diesel) engine, air is compressed to a higher pressure than a gasoline engine, and fuel is directly injected into the hot compressed air, causing self-ignition.

Uploaded by

Gebremariam alemuCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

104 views6 pagesInternal Combustion Engine Overview

1. The document discusses internal combustion (IC) engines, which are engines that combust fuel within the engine itself. It focuses on describing the 4-stroke operating principle for both spark ignition and compression ignition engines.

2. In a 4-stroke spark ignition engine, the cycle consists of intake, compression, power, and exhaust strokes, with the spark plug igniting the fuel/air mixture at or just before top dead center during the power stroke.

3. In a 4-stroke compression ignition (diesel) engine, air is compressed to a higher pressure than a gasoline engine, and fuel is directly injected into the hot compressed air, causing self-ignition.

Uploaded by

Gebremariam alemuCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd