Professional Documents

Culture Documents

(Type The Document Title) : Title - California Bearing Ratio

Uploaded by

Debasish Dev BarmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Type The Document Title) : Title - California Bearing Ratio

Uploaded by

Debasish Dev BarmaCopyright:

Available Formats

[Type the document title]

TITLE –CALIFORNIA BEARING RATIO

AIM OF THE EXPERIMENT: To determine the ratio of force per unit area required to

penetrate into a soil mass with a circular plunger of 50mm diameter at the rate of 1.25mm /

min

THEORY:

The California bearing ratio test is penetration test meant for the evaluation of subgrade

strength of roads and pavements. The results obtained by these tests are used with the

empirical curves to determine the thickness of pavement and its component layers. This is the

most widely used method for the design of flexible pavement.

Originally California bearing ratio test was developed in 1929 by California division

of highway for evaluating the stability of soil sub grade and others flexible pavements design.

The abbreviation of California bearing ratio is (C.B.R). C.B.R may be defined as the ratio of

the test load required to force a cylindrical plunger of 19.355 cm² cross sectional area into a

soil mass at the rate of 1.25 mm/min to the load required for the corresponding penetration of

the plunger into a standard sample.

CBR = TEST LOAD/ STANDARD LOAD

Penetration of plunger (mm) Standard load (kg)

2.5 1370

5.0 2055

7.5 2630

10.0 3180

12.5 3600

The California bearing ratio test essentially is an arbitrary strength test and thus cannot be

used to evaluate the soil properties as angle of internal friction, cohesion or shearing

resistance etc. The C.B.R. test results are used in the empirical method of flexible pavement

design.

APPARATUS:-

1. Moulds with internal diameter and effective height of 150 mm.175 mm with base

plate, stay rod and wing nut.

2. Collar, Spacer Disc.

3. Metal rammer having weight of 2.6Kg.

4. Expansion measuring apparatus with the adjustable stem, perforated plates, tripod

5. Penetration plunge (50 mm dia × 100 mm height).

6. Dial gauge two numbers (least count of 0.01mm).

Assam Kaziranga University Page 1

[Type the document title]

7. Loading machine having a capacity of at least 5000kg and equipped with a

movable head or base that travels at a uniform rate of 1.25mm / minfor use in

forcing the penetration plunger in to the specimen.

8. Spacer disc (148 mm dia ×47.7 mm height).

9. Surcharge weight (2.5 kg).

10. Slotted weight (2.5 kg).

11. IS sieves 20mm.

12. Miscellaneous apparatus such as mixing bowl, straight edge, scales, drying oven,

filter paper, dishes and calibrated measuring jar.

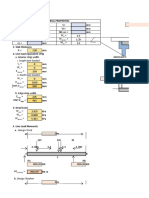

DIAGRAM :

Assam Kaziranga University Page 2

[Type the document title]

PROCEDURE:-

1. For assembling the mould, first place the spacer disc with threaded hole side at the

bottom of the base plate.

2. Place a filter paper at the spacer disc.

3. Apply some lubricant inside the surface area of the cylindrical mould.

4. Place the mould over the spacer disc on the detachable base plate, also fix the annular

collar and fit the screw.

5. Take about 5 kg of oven dried soil sample passing 20 mm IS sieve.

6. Add water to the optimum moisture content of the soil.

7. Compact the soil in three layers in the mould with 56 numbers of blows in each layer

with 2.5 kg rammer.

8. After compacting the last layer or the top layer, remove the annular collar and trim

the top surface.

Assam Kaziranga University Page 3

[Type the document title]

9. Now remove the cylindrical mould from the base plate and make it upside down.

10. Remove the filter paper.

11. Take the weight of the mould plus soil sample.

12. Remove the spacer disc.

13. Clean the base plate and put another fresh filter paper at the bottom and place the

mould to the base such that the compacted surface comes to the bottom.

14. Tighten the screw.

15. Place an annular weight of mass 2.6 kg and add another slotted weight over annular

weight.

16. Place the assembly to the pedestal of the loading unit.

17. Set the proving ring and the dial gauge in position.

18. Place the needle in the position for both dial gauge and proving ring dial gauge and

set the initial to zero.

19. Start the machine to penetrate at the rate of 1.25mm/ min.

20. Observe the load proving ring reading corresponding to the given penetration.

NOTE-

If 2.5 mm reading is greater than 5 mm reading, then the value of 2.5 mm is taken.

If 2.5 mm reading is lesser than 5 mm reading, then repeat the test.

Again after repeating the test if 2.5 mm reading is lesser than 5 mm reading then takes

the 5 mm reading.

Assam Kaziranga University Page 4

[Type the document title]

REFERENCE TABLE:-

PENETRATION UNIT LOAD ( Kg/cm2) TOTAL LOAD (Kgf)

IN (mm)

2.5 70 1370

5 105 2055

REFERENCE TABLE:-

SOAKED C.B.R 2 3 4 5 7 10 75 20 50 100

VALUE %

k-VALUE 2.1 2.8 3.5 4.2 4.8 5.5 6.2 6.9 14.0 22.2

Kg/cm2/cm

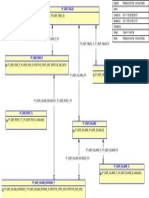

REFERENCE DIAGRAM -

Assam Kaziranga University Page 5

[Type the document title]

OBSERVATION TABLE:-

PENETRATION PROVING RING READING

IN (mm)

READING LOAD (Kgf)

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

6

6.5

7

7.5

8

8.5

9

9.5

10

10.5

11

11.5

12

12.5

CALCULATION:-

REPORT-

1. Report the CBR value to the nearest second decimal.

2. Take the average of three test specimens as the CBR value of the test.

3. Generally, the CBR value at 2.50mm penetration will be greater than that at 5.00mm

penetration and in such case take the value at 2.50mm as the CBR value.

4. If the CBR value corresponding to a penetration of 5.00mm exceeds that of

2.50mm,repeat the test.

5. If the identical results follow, take the value corresponding to 5.00mm as the CBR value.

Assam Kaziranga University Page 6

[Type the document title]

RESULT:-

1. C.B.R VALUE =

2. K- VALUE =

SIGNIFICANCE-

It gives the subgrade strength

The CBR value can be used for design of flexible pavement through the CBR method.

If the plate load test is not available, the CBR method can be used to find the k value

of soil.

Assam Kaziranga University Page 7

You might also like

- Mild Steel Welded Wire MeshDocument2 pagesMild Steel Welded Wire Meshmanoj983@gmail.comNo ratings yet

- Greater Yangon Water Supply Improvement Project (Phase II) Final Report Feb 2017Document198 pagesGreater Yangon Water Supply Improvement Project (Phase II) Final Report Feb 2017lwin_oo2435No ratings yet

- Feature wall foundation design calculationsDocument3 pagesFeature wall foundation design calculationsmsiddiq1No ratings yet

- LRFD SteelDocument280 pagesLRFD SteelKhalid YousafNo ratings yet

- Remove Password From A Protected Excel Worksheet - The Most Authoritative Technology BlogDocument8 pagesRemove Password From A Protected Excel Worksheet - The Most Authoritative Technology Bloglaiping_lumNo ratings yet

- Typical Cohesion and Internal Friction ValuesDocument11 pagesTypical Cohesion and Internal Friction ValuesFahim MarwatNo ratings yet

- Rebound Hammer PresentationDocument18 pagesRebound Hammer PresentationMohmed RiazNo ratings yet

- How To Calculate Bearing Capacity of Soil From Plate Load TestDocument5 pagesHow To Calculate Bearing Capacity of Soil From Plate Load TestDEBOPRASAD BISWASNo ratings yet

- Tank Design Calculation NoteDocument37 pagesTank Design Calculation NoteEbraheemGamalNo ratings yet

- Bearing Capacity For Non-Geotechnical Engineers PDFDocument21 pagesBearing Capacity For Non-Geotechnical Engineers PDFMohamedNo ratings yet

- D1653Document5 pagesD1653manox007No ratings yet

- Aci Beam LedgeDocument4 pagesAci Beam LedgeLove SemsemNo ratings yet

- Structural Design Sample Exams-95-96-97-98Document73 pagesStructural Design Sample Exams-95-96-97-98Arnel FreoNo ratings yet

- Membrane Vs Shell in EtabsDocument1 pageMembrane Vs Shell in Etabstaz_taz3100% (1)

- Report Schmidt HammerDocument3 pagesReport Schmidt HammerIhsan FakhryNo ratings yet

- Working Stress Design MethodDocument4 pagesWorking Stress Design MethodUopEmptyNo ratings yet

- Mark VieDocument4 pagesMark VieWalid Bahi100% (1)

- Service Life DesignDocument16 pagesService Life Designapi-3766593No ratings yet

- QC Tests For Road Works by Bhavanna Rao DVDocument24 pagesQC Tests For Road Works by Bhavanna Rao DVmilind_0786No ratings yet

- GANTRY GIRDER ANALYSISDocument66 pagesGANTRY GIRDER ANALYSISsureshNo ratings yet

- F - Deludge SystemDocument11 pagesF - Deludge Systemkelvin_totNo ratings yet

- Bridge Design Using SAPDocument77 pagesBridge Design Using SAPSukhwinder Singh Gill100% (2)

- Good Construction Practice Book CBRI 2017Document36 pagesGood Construction Practice Book CBRI 2017Muhammed NaseefNo ratings yet

- Semiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007Document1 pageSemiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007civixxNo ratings yet

- TMR Surveying Standards Part 2 - Geomatic Survey Types: ManualDocument135 pagesTMR Surveying Standards Part 2 - Geomatic Survey Types: Manual18400681menaNo ratings yet

- Sheet Pile Calculation REF Calculations OutputDocument7 pagesSheet Pile Calculation REF Calculations OutputAgboola OluwasolaNo ratings yet

- NCEL Technical Note N-1627 OfficialDocument50 pagesNCEL Technical Note N-1627 OfficialTim LeeNo ratings yet

- Etabs 2016 16.2Document10 pagesEtabs 2016 16.2innermanifestoNo ratings yet

- Minimizing Sand Content in ConcreteDocument2 pagesMinimizing Sand Content in ConcreteInternational Journal of Research in Engineering and TechnologyNo ratings yet

- SQL Cheat Sheet For Data Scientists by Tomi Mester 2019 PDFDocument12 pagesSQL Cheat Sheet For Data Scientists by Tomi Mester 2019 PDFVishal Shah100% (1)

- 2.5 Exercise: 12×18 M 3 M 4×6 M 2.5 M M 220 T M 44 T M 180 T M 44 T M 20 T M 4 T 0.12gDocument2 pages2.5 Exercise: 12×18 M 3 M 4×6 M 2.5 M M 220 T M 44 T M 180 T M 44 T M 20 T M 4 T 0.12gAhmedSakrNo ratings yet

- Manual de Servicio Jac 5 InglésDocument375 pagesManual de Servicio Jac 5 InglésJT Pe100% (1)

- SP - 052 Bridge Inspection Manual PDFDocument65 pagesSP - 052 Bridge Inspection Manual PDFRam Balak RoyNo ratings yet

- BoxDocument8 pagesBoxJack Danielz LubisNo ratings yet

- Top Down MethodDocument13 pagesTop Down MethodNurulNo ratings yet

- Rebound Hammer Test Results for Wharf BeamsDocument6 pagesRebound Hammer Test Results for Wharf BeamsShielou GuanzonNo ratings yet

- Ms7820 ManualDocument64 pagesMs7820 ManualJesus Velazquez AriasNo ratings yet

- Gen Math11 - Q1 - Mod1 - Functions - v2Document28 pagesGen Math11 - Q1 - Mod1 - Functions - v2Anonymous 6gthRen100% (1)

- Soil Subgrade - Module 1Document32 pagesSoil Subgrade - Module 1viren chandanshiveNo ratings yet

- Fire Protection Systems Engineering GuideDocument18 pagesFire Protection Systems Engineering GuideAli MehrpourNo ratings yet

- Answer Ndeb Released Questions 2013 AfkDocument1 pageAnswer Ndeb Released Questions 2013 AfkKareem Shawa33% (6)

- Aggregates FMDocument5 pagesAggregates FMabualamalNo ratings yet

- Chapter 3 Bearing Capacity PDFDocument11 pagesChapter 3 Bearing Capacity PDFIan SeguritanNo ratings yet

- Simplified Design Charts (Using Linear Relationship - Short Range For Thickness & Reinforcement)Document23 pagesSimplified Design Charts (Using Linear Relationship - Short Range For Thickness & Reinforcement)Asif Mostafa AnikNo ratings yet

- Shell Elements Plane Elements Asolid ElementsDocument1 pageShell Elements Plane Elements Asolid Elementsasghar7No ratings yet

- Calculation of Earth Retaining Structure: To CesDocument31 pagesCalculation of Earth Retaining Structure: To CesMongkol JirawacharadetNo ratings yet

- SAP2000 Range Add Combo for pattern loadingDocument8 pagesSAP2000 Range Add Combo for pattern loadingcurvedbrainNo ratings yet

- Transit Center - Structural Design Calculations1Document26 pagesTransit Center - Structural Design Calculations1yan naingNo ratings yet

- Shear-Transfer Strength of Reinforced ConcreteDocument11 pagesShear-Transfer Strength of Reinforced ConcretePremasiri KarunarathnaNo ratings yet

- Rebound Hammer DirectionsDocument3 pagesRebound Hammer DirectionsEric Cruz Atienza100% (1)

- As Inspected by Mr. N.Dhamarajan Senior Pavement SpecialistDocument14 pagesAs Inspected by Mr. N.Dhamarajan Senior Pavement SpecialistBIJAY KRISHNA DASNo ratings yet

- Slab Bridge DesignDocument1 pageSlab Bridge DesignMars VillalunaNo ratings yet

- LevelingDocument80 pagesLevelingAizat Sera SuwandiNo ratings yet

- Tips For Developing Models and SAP2000 and ETABSDocument30 pagesTips For Developing Models and SAP2000 and ETABSSami Syed100% (3)

- Design Concrete Bridge (Quiz 1)Document11 pagesDesign Concrete Bridge (Quiz 1)Jamaica MarambaNo ratings yet

- NDT of Concrete: By: Bhaskar JoshiDocument32 pagesNDT of Concrete: By: Bhaskar JoshiBhaskar JoshiNo ratings yet

- Stiffness Modification Factor in Sap2000Document1 pageStiffness Modification Factor in Sap2000husrem2001No ratings yet

- MEngC Presentation (U San Kyu)Document56 pagesMEngC Presentation (U San Kyu)Anonymous 5XPWdQcu100% (1)

- Tips For Developing Models and SAP2000 and ETABSDocument30 pagesTips For Developing Models and SAP2000 and ETABSHector RuizNo ratings yet

- California Bearing Ratio Test (IS: 2720-1979 (Part XVI) ) ObjectiveDocument11 pagesCalifornia Bearing Ratio Test (IS: 2720-1979 (Part XVI) ) ObjectiveDevansh TiwariNo ratings yet

- California Bearing Ratio Test (CBR Test) (IS: 2720 PART-16) : Test Load Standar D LoadDocument8 pagesCalifornia Bearing Ratio Test (CBR Test) (IS: 2720 PART-16) : Test Load Standar D LoadBad BadNo ratings yet

- California Bearing Ratio Test: 1. ObjectiveDocument3 pagesCalifornia Bearing Ratio Test: 1. ObjectiveVickyNo ratings yet

- California Bearing Ratio Test: 1. ObjectiveDocument3 pagesCalifornia Bearing Ratio Test: 1. ObjectivesiddharthNo ratings yet

- California Bearing Ratio Test: 1. ObjectiveDocument3 pagesCalifornia Bearing Ratio Test: 1. ObjectivePanchadcharam PushparubanNo ratings yet

- CBR ProcedureDocument5 pagesCBR ProcedureRohitNo ratings yet

- Civil - Highway Lab Manual - 2018Document17 pagesCivil - Highway Lab Manual - 2018Altamash NadimallaNo ratings yet

- Geotechnical Engineering Lab: Anup KumarDocument7 pagesGeotechnical Engineering Lab: Anup Kumar008 Anup KumarNo ratings yet

- CBR Test ProcedureDocument12 pagesCBR Test ProcedureQaim ShahNo ratings yet

- Food Groups Intake in Relation To Stunting Among Exceptional ChildrenDocument8 pagesFood Groups Intake in Relation To Stunting Among Exceptional ChildrenAriqah GinaNo ratings yet

- Royal College Grade 08 Geography First Term Paper English MediumDocument7 pagesRoyal College Grade 08 Geography First Term Paper English MediumNimali Dias67% (3)

- NanomagnetismDocument32 pagesNanomagnetismMohammad RameezNo ratings yet

- K-Gamma and K-Beta FunctionDocument5 pagesK-Gamma and K-Beta FunctionketashiNo ratings yet

- Immunofluorescence Tests: Direct and IndirectDocument489 pagesImmunofluorescence Tests: Direct and IndirectmeskiNo ratings yet

- Benefits of Using FlowchartsDocument14 pagesBenefits of Using FlowchartsDave FlautaNo ratings yet

- End Sem - Solution & Marking SchemeDocument41 pagesEnd Sem - Solution & Marking SchemeHaryanvi ChhoraNo ratings yet

- Relativistic Electrodynamics NotesDocument13 pagesRelativistic Electrodynamics NotesPritika SabharwalNo ratings yet

- HeatDocument31 pagesHeatnicky1213a100% (1)

- Android: Uni-Stroke Touch Gesture Recognition Using $1 Gesture ReconigizerDocument13 pagesAndroid: Uni-Stroke Touch Gesture Recognition Using $1 Gesture Reconigizerpi194043No ratings yet

- GCE O Level Practice PaperDocument12 pagesGCE O Level Practice Paperjina910% (1)

- Three Dimensional Geometry - JEE Main 2023 January Chapter Wise Questions by MathonGoDocument43 pagesThree Dimensional Geometry - JEE Main 2023 January Chapter Wise Questions by MathonGoVansh ParasharNo ratings yet

- Periodic table elements in Chinese charactersDocument3 pagesPeriodic table elements in Chinese charactersTheodore HaralabisNo ratings yet

- Chap2 SlidesDocument127 pagesChap2 SlidesDhara RajputNo ratings yet

- Samsung CAC Duct S Brochure 20140729 0Document16 pagesSamsung CAC Duct S Brochure 20140729 0Callany AnycallNo ratings yet

- Applied Stochastic ProcessDocument132 pagesApplied Stochastic ProcessMygodNo ratings yet

- JBMO ShortLists-2001Document2 pagesJBMO ShortLists-2001OklaNo ratings yet

- A Novel IGBT Gate Driver To Eliminate The Dead-Time Effect: Bin Zhang, Alex Q. Huang, Bin ChenDocument5 pagesA Novel IGBT Gate Driver To Eliminate The Dead-Time Effect: Bin Zhang, Alex Q. Huang, Bin Chenmutharasu29No ratings yet

- National Talent Search Examination Path to SuccessDocument25 pagesNational Talent Search Examination Path to SuccessSudhanshuNo ratings yet

- Inf311 01 42016022Document12 pagesInf311 01 42016022Hazem QaedNo ratings yet

- Suzanne Saroff - Year 9 Exam AnnaDocument1 pageSuzanne Saroff - Year 9 Exam Annaapi-569107627No ratings yet

- Relational-HcmTop - HcmUserTablesDocument1 pageRelational-HcmTop - HcmUserTablesKhalil De la CruzNo ratings yet