Professional Documents

Culture Documents

Coolant Pumps: Tough Engisol PVT LTD

Uploaded by

Shila DixitOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coolant Pumps: Tough Engisol PVT LTD

Uploaded by

Shila DixitCopyright:

Available Formats

TOUGH ENGISOL PVT LTD

1ST First floor , Bhairavnath post office building,

Maninagar,Ahmedabad-380028 India

Tele Fax : + 91-079-25431453,8140179903.

E-mail :- coolantpumps@gmail.com , toughengisol@yahoo.com.

COOLANT PUMPS

“PHULSONS ” range of immiscible pumps has been designed especially for filtering

systems in the machine tool industry. The low-pressure pumps are available in

different flow variants and come with a choice of bottom suction or suction from the

top of the volute.

The compact coolant pumps efficiently transport liquid containing chips, fibers and

abrasive particles on to the filtering unit. Semi open impellers allow the passing of

chips up to 10 mm, making the pumps ideal for removing liquid from any machining

process- from boring and milling to grinding.

High – Quality materials :- Carefully chosen materials ensure trouble free

operation and long life the top of the pump is made of cast iron, while the impeller is

available in composite Bronze/aluminum/engineering plastic etc are used in pumps

with flow up to 1000 l/min. in the bigger pumps with higher flow the impellers are

made of bronze to ensure perfect Resistance to e.g metal chips. As the pumped liquid

will always contain oil there no risk of Corrosion.

Easy Installation:- Easy installation is another of the benefits of the pumps. The

tank –mounting flange dimensions’ have been carefully designed to ensure that even

replacement of compacting products can be carried out without any inconvenience no

special tools are required to the Installation of the coolant pumps just as the entire range

is easily serviced and cleaned.

Full – line supplier :- In addition to the range for filtering systems, we offers a wide

range of pumps for the cooling and cleaning of tools inside the machine. this allows our

customers the benefit of convenient and time –saving one stop shopping.

WIDE RANGE OF APPLICATION

Turning Grinding Granite

Boring Filtration Fountains

Drilling Circulation Washing

Milling Prininting Heat treatment

Cutting Conveyor Oil Transfer

Sawing Cooling

FEATURES:-

Available in very wide range.

High of Design.

Availability in any type of material like CI, SS-316,SS-304,Bronze , Alloy-20 Etc.

Balanced Shaft & Rotor with excellent grade stamping & wire so highly efficient

motor

Totally Noiseless Operation.

Available in any length and for any Liquid.

Extruded powder coated motor body (up to 1 hp)

No shaft seal (100% Maintenance free .)

Semi Open Impellers (Ensure free passage of solids and chips)

Large stock, Earliest Delivery.

TYPE OF COOLANT PUMPS :

Standard Coolant pumps.

Coolant pumps with DC motor.

Coolant pumps with flame proof motor.

Coolant pumps with “C E” and “UL” Mark Motor

Custom built coolant pumps for different lengths.

Very high discharged pump.

Very high head pump / High pressure pump.

Pumps in special material like stainless steel, bronze, PP, alloy – 20 etc.

Multistage Coolant pumps.

Coolant pump without stem.

Coolant pump for oil (gear type).

Submersible Coolant pumps.

COOLANT PUMPS RANGE :

Max discharge up to 1000 LPM.

Max pressure up to 21 bar.

Max length up to 1500 mm.

Max HP up to 20 HP .

Max outlet size up to 4” .

Max temp up to 240º C .

Max Size of chips up to 15 mm.

Material or construction – CI / SS Alloy 20 / PP /bronze etc.

SINGLE STAGE COOLANT PUMPS (SP SERIES)

PERFORMANCE CHART OF “SP” SERIES

Head in meters VS LPM

MODEL OUTLET SIZE KW/HP

2 4 6 8 10 12 14

SP 25 12 mm 0.08 KW/ 0.1 HP 25 10 0 0 0 0 0

SP 40 20 mm 0.12 KW / 0.15 HP 40 25 0 0 0 0 0

SP 63 20 mm 0.18 KW/ 0.25 HP 63 40 0 0 0 0 0

SP 80 20 mm 0.18 KW/ 0.25HP 80 60 30 0 0 0 0

SP100 25 mm 0.25 KW/ 0.34HP 100 80 65 0 0 0 0

SP160 25 mm 0.37KW/ 0.5 HP 160 140 120 75 15 0 0

SP250 40 mm 0.55KW/ 0.75 HP 250 245 200 130 80 0 0

You might also like

- 6 T 30Document4 pages6 T 30Marco Aurelio AntunesNo ratings yet

- INSTALLATION TESTING COMMISSIONINGDocument26 pagesINSTALLATION TESTING COMMISSIONINGAamer100% (2)

- 06 SCT Extended PDFDocument40 pages06 SCT Extended PDFSlobodan Antic100% (2)

- Vertical Sump PumpDocument6 pagesVertical Sump Pumpsahildhingra100% (1)

- Liquid ControlsDocument20 pagesLiquid ControlsDeny SafariNo ratings yet

- Grundfos Axial Flow Pumps BrochureDocument7 pagesGrundfos Axial Flow Pumps Brochurefg_111307359No ratings yet

- Submersible PumpDocument3 pagesSubmersible Pumpeddy brachoNo ratings yet

- PN Update 8 June 2021Document125 pagesPN Update 8 June 2021Andrian Putranto EdogawaNo ratings yet

- BR MiningDocument12 pagesBR MiningSteven TremolNo ratings yet

- GE GAP 2.5.2 - 2001 Oil and Chemical Plant Layout and Spacing (High Quality)Document13 pagesGE GAP 2.5.2 - 2001 Oil and Chemical Plant Layout and Spacing (High Quality)vne01100% (4)

- KSB Centrifugal PumpsDocument12 pagesKSB Centrifugal Pumpswoodywheel100% (1)

- LSP LowSpeedHighPressurePumps E00522Document7 pagesLSP LowSpeedHighPressurePumps E00522Sigit PramonoNo ratings yet

- Steam Sterilizer Service ManualDocument20 pagesSteam Sterilizer Service ManualSaleh Hamadany57% (7)

- Catalogo de Bombas GrundfosDocument7 pagesCatalogo de Bombas Grundfosgabriel_grlNo ratings yet

- Fire FightingDocument14 pagesFire FightingMostafa AwadNo ratings yet

- STD 145Document124 pagesSTD 145Aditya Sharma100% (4)

- Grundfos Submersible Pumps Data BookDocument100 pagesGrundfos Submersible Pumps Data BookonspsnonsNo ratings yet

- Modern HydronicsDocument32 pagesModern HydronicsRico SanchezNo ratings yet

- Bomba Hidraulica Sauer Sustran Serie 90Document88 pagesBomba Hidraulica Sauer Sustran Serie 90mantenedor01100% (1)

- Axially Splitcase Pumps - HS & HST SeriesDocument12 pagesAxially Splitcase Pumps - HS & HST SeriesSuhas Natu100% (1)

- Paper Fan PumpsDocument8 pagesPaper Fan PumpsnazeerNo ratings yet

- Manufacturing Range En-2012Document32 pagesManufacturing Range En-2012mmihai_popa200650% (2)

- 1.6 Back Pull Out - Bpo PumpsDocument3 pages1.6 Back Pull Out - Bpo PumpsharishupretiNo ratings yet

- Sintech Pumps For Sugar Processing PlantDocument18 pagesSintech Pumps For Sugar Processing Plantsahildhingra100% (2)

- Complete Range of Sintech Make PumpsDocument8 pagesComplete Range of Sintech Make PumpssahildhingraNo ratings yet

- Bombas de Cavidad ProgresivaDocument8 pagesBombas de Cavidad ProgresivaJohanna RojasNo ratings yet

- Mini and Solid submersible pumps for tough dewatering jobsDocument4 pagesMini and Solid submersible pumps for tough dewatering jobssilviupumbaNo ratings yet

- Centrifugal Pump Model SMP SeriesDocument2 pagesCentrifugal Pump Model SMP SeriesNour Nour El IslamNo ratings yet

- Vertical Multistage Pumps Series 4700: Solution OutlineDocument8 pagesVertical Multistage Pumps Series 4700: Solution OutlineProyecyma CANo ratings yet

- NM CataloguesDocument6 pagesNM CataloguessuinpeNo ratings yet

- Vircap Profile NewDocument12 pagesVircap Profile Newtgohiakri2006No ratings yet

- A 02 1064Document4 pagesA 02 1064Marliton SalinasNo ratings yet

- طلمبات أفقية أحادية المرحلةDocument12 pagesطلمبات أفقية أحادية المرحلةRheoserve Industrial SolutionsNo ratings yet

- Tensile Specimen Punches ZS 400 650 1200 1500 2000 CN PDFDocument3 pagesTensile Specimen Punches ZS 400 650 1200 1500 2000 CN PDFOguz GirdapNo ratings yet

- Emp Dry ProcessDocument6 pagesEmp Dry ProcessragandaNo ratings yet

- SS Pumps - Ce SeriesDocument3 pagesSS Pumps - Ce Seriesshashank ovhalNo ratings yet

- Compact Cold Water Pressure Washer for Commercial UseDocument15 pagesCompact Cold Water Pressure Washer for Commercial UseNaren VmdNo ratings yet

- Position Qty. Description SP 30-16: Further Product DetailsDocument9 pagesPosition Qty. Description SP 30-16: Further Product DetailsJulio César Elías RiveraNo ratings yet

- MENGIN cutter pump performance and specificationsDocument8 pagesMENGIN cutter pump performance and specificationsawhk2006100% (1)

- TC Fls Sihi MSL MSM enDocument24 pagesTC Fls Sihi MSL MSM enAndresNo ratings yet

- Carmex Catalogue WebDocument203 pagesCarmex Catalogue WebPaisaje SilenciosoNo ratings yet

- Hot Rolled Coils (8311868)Document2 pagesHot Rolled Coils (8311868)rashid isaarNo ratings yet

- Kirloskar SP 3HH Leaflet (A)Document2 pagesKirloskar SP 3HH Leaflet (A)Imran_firdousiNo ratings yet

- Eaton Vickers Cylinders Hydro TransDocument592 pagesEaton Vickers Cylinders Hydro TransCentral HydraulicsNo ratings yet

- Pump STDRDocument7 pagesPump STDRsopian320No ratings yet

- 1.3 Sanitary Pumps CfsDocument4 pages1.3 Sanitary Pumps CfsJitendra KadamNo ratings yet

- DSP High PDFDocument41 pagesDSP High PDFsahidudin100% (2)

- Bellin - Inglese Eccentric Screw PumpDocument8 pagesBellin - Inglese Eccentric Screw PumpHoangNguyen167No ratings yet

- Data Técnica KRS2-80Document5 pagesData Técnica KRS2-80CésarUgarteArgomedoNo ratings yet

- DEPA DiaphragmDocument4 pagesDEPA DiaphragmmorizoneNo ratings yet

- PumpDocument14 pagesPumpdhineshpNo ratings yet

- Kumar Pumps BroucherDocument18 pagesKumar Pumps BroucherSrikanth Kesanakurthi50% (2)

- Topgear: Internal Gear PumpsDocument8 pagesTopgear: Internal Gear PumpsCrisan Radu-HoreaNo ratings yet

- 5.02.e.adcamat PPO14 Pressure Operated Pump DN25-50Document4 pages5.02.e.adcamat PPO14 Pressure Operated Pump DN25-50Matias MancillaNo ratings yet

- Gem Chiller Catalogue Proof - 27 4 13Document4 pagesGem Chiller Catalogue Proof - 27 4 13abianshbaralNo ratings yet

- Taco Expansion TankDocument16 pagesTaco Expansion Tanksas999333No ratings yet

- Mackwell Catalouge FinalDocument16 pagesMackwell Catalouge FinalexportNo ratings yet

- 15 Metal Seated Butterfly ValvesDocument8 pages15 Metal Seated Butterfly ValvesrajfmcNo ratings yet

- Goulds LP3400 Series Low Pulse Fan Pumps: Lenntech LenntechDocument8 pagesGoulds LP3400 Series Low Pulse Fan Pumps: Lenntech LenntechSergio Roa PerezNo ratings yet

- 300-9 4Document16 pages300-9 4avabhyankar9393No ratings yet

- Scanpump PN25 BK NKDocument2 pagesScanpump PN25 BK NKRafael SouzaNo ratings yet

- FAQ - Pump Tech DetailsDocument4 pagesFAQ - Pump Tech DetailsRaghavendra SarafNo ratings yet

- Inbound1489398261588462301 PDFDocument16 pagesInbound1489398261588462301 PDFAbdellaoui nadaNo ratings yet

- INDAG Rotary Piston Pump for Gentle Conveyance and DosingDocument4 pagesINDAG Rotary Piston Pump for Gentle Conveyance and DosingSergioNo ratings yet

- Elettropompe Sommerse Inox Multistadio Per Pozzi 4": ApplicazioniDocument1 pageElettropompe Sommerse Inox Multistadio Per Pozzi 4": ApplicazioniMilos KovacevicNo ratings yet

- Hyd E-02-7750 VfinDocument4 pagesHyd E-02-7750 VfinNoe Fraire AlcaláNo ratings yet

- طلمبات أفقية متعددة المراحلDocument16 pagesطلمبات أفقية متعددة المراحلRheoserve Industrial Solutions0% (1)

- 1.38 Motorised Barrel PumpDocument3 pages1.38 Motorised Barrel PumpShila DixitNo ratings yet

- Cost and Returns of Banana CultivationDocument43 pagesCost and Returns of Banana CultivationShila DixitNo ratings yet

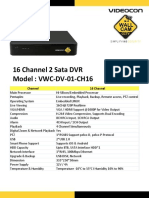

- 16CH 2SATA DVR H.264 1080PDocument1 page16CH 2SATA DVR H.264 1080PShila DixitNo ratings yet

- 16CH 2SATA DVR H.264 1080PDocument1 page16CH 2SATA DVR H.264 1080PShila DixitNo ratings yet

- 16 Channel 2 Sata DVR with HDMI and PTZ ControlDocument1 page16 Channel 2 Sata DVR with HDMI and PTZ ControlShila DixitNo ratings yet

- XMSNJD Dkizis Sjjabz ???mind PDFDocument35 pagesXMSNJD Dkizis Sjjabz ???mind PDFShila DixitNo ratings yet

- 1.65 Dabang High Pressure Washing PumpDocument1 page1.65 Dabang High Pressure Washing PumpShila DixitNo ratings yet

- 3mp 16 Channel 2 Sata DVR Owc-dv01-Ch16m3s2h8-1Document1 page3mp 16 Channel 2 Sata DVR Owc-dv01-Ch16m3s2h8-1Shila DixitNo ratings yet

- Ds-7200Hghi-E2 Series Turbo HD DVR: Features and FunctionsDocument3 pagesDs-7200Hghi-E2 Series Turbo HD DVR: Features and FunctionsShila DixitNo ratings yet

- Avds 1790Document17 pagesAvds 1790alexNo ratings yet

- Liquid Ring Vacuum Pump Guide for Maximized EfficiencyDocument12 pagesLiquid Ring Vacuum Pump Guide for Maximized EfficiencyTrần Phước TrungNo ratings yet

- WT30X Trash Pump ManualDocument64 pagesWT30X Trash Pump ManualgomooneyNo ratings yet

- Document Modification and Revision: N Position Discription RemarksDocument76 pagesDocument Modification and Revision: N Position Discription RemarksQuyet PhungNo ratings yet

- Lh514 Specification Sheet EnglishDocument16 pagesLh514 Specification Sheet EnglishEnzo VanderlindenNo ratings yet

- VFD For Centrifugal PumpsDocument11 pagesVFD For Centrifugal PumpsChem.EnggNo ratings yet

- 5760-111 RevlDocument100 pages5760-111 RevlSantos RodriguezcervantesNo ratings yet

- Plunger Pump Service Manual: Installation and Start-Up InformationDocument6 pagesPlunger Pump Service Manual: Installation and Start-Up InformationDark CenobiteNo ratings yet

- Prevent Pipe Collapse and Bursting with HWE Air Cushion ValveDocument1 pagePrevent Pipe Collapse and Bursting with HWE Air Cushion ValveniranpaiNo ratings yet

- Air Arms s510 Xs Fac Iss2Document22 pagesAir Arms s510 Xs Fac Iss2trestiros100No ratings yet

- 3535 HDocument4 pages3535 HomaryehudeNo ratings yet

- Manual MoynoDocument34 pagesManual Moynocarlangas77No ratings yet

- DESMI Centrifugal Pump: Modular HDocument17 pagesDESMI Centrifugal Pump: Modular HИгорьNo ratings yet

- Instruction Manual: HM 150 Basic Hydraulics BenchDocument13 pagesInstruction Manual: HM 150 Basic Hydraulics Benchs_nimalanNo ratings yet

- Introduction To Wind Energy E.H. Lysen CWD 82-1 May 1983 OCRDocument309 pagesIntroduction To Wind Energy E.H. Lysen CWD 82-1 May 1983 OCRfrank100% (1)

- Analisa Water Hammer Pada Pipa Condensate PLTUDocument6 pagesAnalisa Water Hammer Pada Pipa Condensate PLTUamrullah100% (1)

- LRV 1 - 300 I 9010050 enDocument92 pagesLRV 1 - 300 I 9010050 enCzeszcza23No ratings yet

- Turbomachinery Assignments Me 603 Me 6BDocument6 pagesTurbomachinery Assignments Me 603 Me 6Bd v rama krishnaNo ratings yet

- S RodDocument8 pagesS RodtwofortheNo ratings yet

- Dr. Ram ManoharLohia Institute of Medical Sciences STP ETP System DetailsDocument2 pagesDr. Ram ManoharLohia Institute of Medical Sciences STP ETP System DetailsVishal shuklaNo ratings yet