0% found this document useful (0 votes)

568 views31 pagesTypes and Design of Machinery Keys

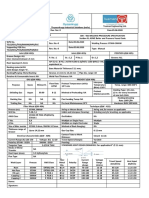

Keys are used to connect a shaft to a hub to transmit torque and prevent relative motion. Common key types include parallel, tapered, and Woodruff keys. Keys are designed to have sufficient shear strength and prevent bearing failure under the loads from the shaft. The example shows how to design keys for a given shaft based on torque values, including calculating shear and bearing stresses, stress concentrations, and verifying sufficient safety factors. The key design is iterated as needed to better match the shaft safety factors.

Uploaded by

danish gujjarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

568 views31 pagesTypes and Design of Machinery Keys

Keys are used to connect a shaft to a hub to transmit torque and prevent relative motion. Common key types include parallel, tapered, and Woodruff keys. Keys are designed to have sufficient shear strength and prevent bearing failure under the loads from the shaft. The example shows how to design keys for a given shaft based on torque values, including calculating shear and bearing stresses, stress concentrations, and verifying sufficient safety factors. The key design is iterated as needed to better match the shaft safety factors.

Uploaded by

danish gujjarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd