Professional Documents

Culture Documents

Ficha Tecnica Mod 2-5002

Uploaded by

Nestor Augusto Duran SanchezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ficha Tecnica Mod 2-5002

Uploaded by

Nestor Augusto Duran SanchezCopyright:

Available Formats

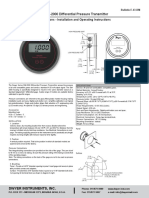

010_Layout 2 8/14/13 1:38 PM Page 10

Series ®

Minihelic II Differential Pressure Gages

PRESSURE

2-5000

Combining High Accuracy, Compactness, Dependability, and Low Cost RoHS

LOW PRESSURE PORT

Ø7/16 [11.11] HOLE IN

PANEL FOR

Differential Pressure Gages

SURFACE MOUNT

Ø2-19/32 (2) Ø5/32 HOLES

[65.62] IN PANEL FOR

Ø2-29/32 1 SURFACE MOUNT

[73.81] [25.40]

9/32 HIGH PRESSURE PORT

[6.96] Ø7/16 [11.11] HOLE IN

1-17/32 2-21/64 PANEL FOR

[38.79] [59.18] SURFACE MOUNT

SURFACE MOUNT

2-3/8 HOLES

[60.38]

Combining clean design, small size, and low cost with enough accuracy for SPECIFICATIONS

all, but the most demanding applications our Minihelic® II gage offers the latest Service: Air and compatible gases.

in design features for a dial type differential pressure gage. It is our most Wetted Materials: Consult factory.

compact gage, but is easy to read and can safely operate at total pressures up to Housing: Glass filled nylon; acrylic lens.

30 psig. The Minihelic® II is designed for panel mounting in a single 2-5/8˝ Accuracy: ±5% of FS at 70°F (21.1°C).

diameter hole. Standard pressure connections are barbed fittings for 3/16˝ ID Pressure Limits: 30 psig (2.067 bar) continuous to either pressure

tubing; optional 1/8˝ male NPT connections are also available. Over-pressure connection.

protection is built into the Minihelic II® gage by means of a blow-out membrane Temperature Limits: 20 to 120°F (-6.67 to 48.9°C).

molded in conjunction with the diaphragm. Accidental over-ranging up to the Size: 2-1/16˝ (52.39 mm) diameter dial face.

rated total pressure will not damage the gage. With removable lens and rear Mounting Orientation: Diaphragm in vertical position. Consult factory

housing, the gage may be easily serviced at minimum cost. for other position orientations.

With the housing molded from mineral and glass filled nylon and the lens Process Connections: Barbed, for 3/16˝ ID tubing (standard); 1/8˝

molded from acrylic, the gage will withstand rough use and exposure as well male NPT (optional).

as high total pressure. The 5% accuracy and low cost of the Minihelic® II gage Weight: 6 oz (170.1 g).

make it well-suited for a wide variety of OEM and user applications. OEM Agency Approvals: RoHS.

applications include cabinet air purging, medical respiratory therapy

equipment, air samplers, laminar flow hoods, and electronic air cooling

systems. As an air filter gage, the Minihelic® II gage finds many end use

applications on large stationary engines, compressors, ventilators, and air

handling units. The Minihelic® II gage is suitable for many of the same

applications as the Magnehelic® gage where the greater accuracy, sensitivity, CAUTION: For use only with air or compatible gases.

and higher and lower differential pressure ranges of the Magnehelic® gage are

not required.

PRESSURE CONNECTIONS

A. The standard Minihelic® II gage is supplied with

two barbed pressure taps molded into the rear

housing of the gage. These connections allow easy,

fast connection to the gage using 3/16˝ ID rubber or

plastic tubing.

B. For applications in systems having higher total

operating pressures, optional male 1/8˝ NPT pressure

connections can be supplied.

Note: The oblong over-pressure vent hole on the back of the

gage at the right of the connections. This vent is sealed by a

membrane molded in conjunction with the diaphragm and

A B will blow out at approximately 75 psi.

10 DWYER INSTRUMENTS, INC. | www.dwyer-inst.com

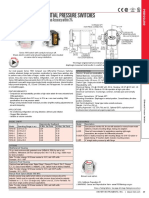

011_Layout 2 7/12/13 11:24 AM Page 11

Simplicity of Design Ensures Reliable Operation

PRESSURE

Housing is molded from strong mineral and glass Range spring calibration clamp fixes live length

filled nylon. of spring for proper gage calibration and is factory

set and sealed.

Pointer stops of molded rubber prevent pointer

over-travel without damage. Silicone rubber diaphragm allows accurate

response to a broad range of temperatures and at

Differential Pressure Gages

Full view lens is removable and molded of acrylic. extremely low pressure. Incorporates blow out area

for overpressure protection.

Aluminum scale litho-printed black on white,

enhances readability. Diaphragm support plates of lightweight

aluminum on each side of the diaphragm minimize

Red tipped aluminum pointer, rigidly mounted to position or attitude sensitivity and help define

helix is easy to see. pressure area.

Wishbone assembly provides mounting for helix, Flat leaf range spring reacts to pressure on the

helix bearings, and pointer shaft. diaphragm. Live length is adjustable for calibration.

Small amplitude of motion minimizes inaccuracies

Jewel bearings provide virtually friction-free helix and assures long life.

motion.

Low pressure tap connects to rear chamber.

Helix is free to rotate in jewel bearings. It aligns

with magnetic field of magnet to transmit pressure Coil spring link provides a resilient connection

indications to pointer. between the diaphragm and the range spring.

Zero adjustment screw, located behind the Ceramic magnet mounted on a molded bracket at

removable lens, eliminates tampering. the end of the range spring rotates the helix without

direct mechanical linkage.

High pressure tap connects with the front

SURFACE MOUNTING chamber through passageway in the plastic case

and a sealing ring molded into the edge of the

diaphragm.

Range, Range,

Inches of Range, MM of

Model Water Model PSI Model Water

2-5000-0 0-0.5 2-5205 0-5 2-5000-25MM 0-25

2-5001 0-1.0 2-5000-50MM 0-50

2-5002 0-2.0 2-5000-100MM 0-100

2-5003 0-3.0 Range,

2-5005 0-5.0 Model Pascals

Optional surface mounting with back mounting plate allows for quick 2-5010 0-10 2-5000-125PA 0-125

installation to any surface. Process connections are barbed and point 2-5020 0-20 2-5000-250PA 0-250

downwards. Add -BB for bottom barbed surface mount option. 2-5040 0-40 2-5000-500PA 0-500

2-5060 0-60 Range,

PANEL MOUNTING 2-5100 0-100 Model kPa

2-5000-1KPA 0-1

2-5000-3KPA 0-3

OPTIONS

For optional 1/8˝ male NPT connections, add suffix -NPT to model numbers listed above.

Example: 2-5001-NPT.

For optional bottom barbed surface mount, add suffix -BB to model numbers listed above.

Example: 2-5001-BB.

For NIST traceable calibration certificate, add suffix -NIST to model numbers. Example: 2-5001-

NIST.

For factory calibration certificate, add suffix -FC to model numbers. Example: 2-5001-FC.

ACCESSORIES

A-302F-A, 303 SS Static Pressure Tip with mounting flange. For 3/16˝ ID rubber or plastic

Mounting hardware is supplied with the Minihelic® II gage for panel tubing. 4˝ insertion depth. Includes mounting screws

mounting through a single hole, 2-5/8˝ (67 mm) in diameter. Panel A-434, Portable Kit

thickness up to 1/2˝ (13 mm) can be accommodated with the A-489, 4˝ Straight Static Pressure Tip with Flange

hardware supplied. If necessary, surface mounting of the gage can A-497, Surface Mtg. Brkt

be accomplished by means of two 4-40 screws into the tapped A-609, Air Filter Kit

mounting bracket stud holes in the rear of the gage. Surface A-480, Plastic Static Pressure Tip

mounting requires clearance holes in the panel for the two pressure

taps. See page 567 for process tubing options.

CONTACT US | U.S. 219/879-8000 | U.K. (+44) (0)1494-461707 | A.U. (+61) (0) 2 4272 2055 | China +852-23181007 11

You might also like

- Series 2-5000 Minihelic II Differential Pressure Gage: Bulletin A-36-ADocument2 pagesSeries 2-5000 Minihelic II Differential Pressure Gage: Bulletin A-36-ATrie IrsadNo ratings yet

- Differential Pressure Transmitter: Same Size As Standard Magnehelic Differential Pressure GageDocument1 pageDifferential Pressure Transmitter: Same Size As Standard Magnehelic Differential Pressure GageJose Antonio Yupa MedinaNo ratings yet

- Sensor de Presion Serie DM-2000Document1 pageSensor de Presion Serie DM-2000Giancarlo Reategui GuerraNo ratings yet

- DM 2000 IxxxxxxDocument1 pageDM 2000 IxxxxxxJose MeraNo ratings yet

- Dwyer-1910-1-Product OverviewDocument1 pageDwyer-1910-1-Product OverviewRusty AllenNo ratings yet

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJorge Renato Chirinos QuiñonezNo ratings yet

- MAGNEHELICDocument2 pagesMAGNEHELICCésar Arturo TorresNo ratings yet

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJuan Carlos Chara VelazcoNo ratings yet

- Product Spec.: Wall-Smart Model: FamilyDocument1 pageProduct Spec.: Wall-Smart Model: FamilyMichael Ben-DorNo ratings yet

- Dweyer Pressure SwitchDocument1 pageDweyer Pressure SwitchMuhamad PriyatnaNo ratings yet

- Glacier Bay Faucet Specifications - HD67726WDocument1 pageGlacier Bay Faucet Specifications - HD67726WKilty ONealNo ratings yet

- Transmisor Presion Diferencial dm-2007-lcdDocument2 pagesTransmisor Presion Diferencial dm-2007-lcdhanshr87No ratings yet

- 1031 Goodworth Drive, Apex, NC 27539, USA ISO 9001 Registered CompanyDocument3 pages1031 Goodworth Drive, Apex, NC 27539, USA ISO 9001 Registered CompanyNachio RodriguezNo ratings yet

- R514A CVHE Centravac Centrifugal Chiller Dimension DrawingsDocument13 pagesR514A CVHE Centravac Centrifugal Chiller Dimension DrawingsBegundalz PotterNo ratings yet

- Span Locksl20Document2 pagesSpan Locksl20Cathy PrikhodkoNo ratings yet

- Spec - EN - 0614000 - STUDIO - Undermount (35C8)Document2 pagesSpec - EN - 0614000 - STUDIO - Undermount (35C8)chris.sousaNo ratings yet

- Manage Water Pressure with JET PRVsDocument4 pagesManage Water Pressure with JET PRVsneiljonesNo ratings yet

- Compact Low Differential Pressure Switches: Set Points From 0.07 To 20 in W.C. Repetitive Accuracy Within 3%Document1 pageCompact Low Differential Pressure Switches: Set Points From 0.07 To 20 in W.C. Repetitive Accuracy Within 3%ANGEL FLORESNo ratings yet

- Fuseclips For A480r5r-1 and A480t2eDocument2 pagesFuseclips For A480r5r-1 and A480t2eM. Taufik HidayatNo ratings yet

- 1 Sample PDFDocument7 pages1 Sample PDFRachel FloresNo ratings yet

- Series 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsDocument4 pagesSeries 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsAlberto Angel Mora ZavalaNo ratings yet

- Dwyer AT2000 EX PROOF BrochureDocument1 pageDwyer AT2000 EX PROOF BrochurePT VeritasNo ratings yet

- P - 616KD Manual TransmiterDocument2 pagesP - 616KD Manual TransmiterFR PERANo ratings yet

- Tyco Mlaznica TY BDocument8 pagesTyco Mlaznica TY BMilos StojanovicNo ratings yet

- Type R122H First-Stage RegulatorDocument2 pagesType R122H First-Stage RegulatorJVMNo ratings yet

- Magnehelic-Gage Series 2000Document2 pagesMagnehelic-Gage Series 2000Jonathan GanNo ratings yet

- Purafil Side Access BulletinDocument5 pagesPurafil Side Access BulletinPablo TorresNo ratings yet

- Carrier - CC 6400 - Manual de InstalaçaoDocument4 pagesCarrier - CC 6400 - Manual de InstalaçaoAdelson nojosa da silva SilvaNo ratings yet

- Explosion-Proof Differential Pressure SwitchDocument1 pageExplosion-Proof Differential Pressure SwitchTadau EnergyNo ratings yet

- Double-Lock Dl20: Is L El Whi CH IsDocument2 pagesDouble-Lock Dl20: Is L El Whi CH IsHalim KhanNo ratings yet

- Series 1630 Differential Pressure Switch: Specifications - Installation and Operating InstructionsDocument2 pagesSeries 1630 Differential Pressure Switch: Specifications - Installation and Operating InstructionseeeNo ratings yet

- Wet/Wet Differential Pressure Transmitter: Series 629CDocument2 pagesWet/Wet Differential Pressure Transmitter: Series 629CElmer Ramón Murillo MejiaNo ratings yet

- AB 036090 001 Joints For Cement Lined Pipe PDFDocument1 pageAB 036090 001 Joints For Cement Lined Pipe PDFfdfazfzNo ratings yet

- DMC Dimensiones 22001Document1 pageDMC Dimensiones 22001JhonNo ratings yet

- DS 616KDRev.2Document2 pagesDS 616KDRev.2Carlos TorresNo ratings yet

- Service SinkDocument4 pagesService SinkAnita CabassaNo ratings yet

- Dwyer DM 2000Document2 pagesDwyer DM 2000Jos Albo FerNo ratings yet

- B-2012_tdDocument1 pageB-2012_tdshivap341995No ratings yet

- Ps 001222Document16 pagesPs 001222Lassané KINDONo ratings yet

- MacDougall production drawing set requirementsDocument1 pageMacDougall production drawing set requirementsAnonymous WXJTn0No ratings yet

- 97120-3DDocument3 pages97120-3Dpnoc.kblduenasNo ratings yet

- Double Lock DL15Document2 pagesDouble Lock DL15Cathy PrikhodkoNo ratings yet

- Diaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive ApplicationsDocument1 pageDiaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive Applicationsluat1983No ratings yet

- Flanged Ball Bearing CatalogDocument1 pageFlanged Ball Bearing CatalogFreddy Enrique Torres OrtizNo ratings yet

- VISTIPORT-E220 Product Information PDFDocument5 pagesVISTIPORT-E220 Product Information PDFGoto SamNo ratings yet

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Document4 pagesMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Johan VBNo ratings yet

- DWYER_1630-PRESOSTATO SWITCHDocument2 pagesDWYER_1630-PRESOSTATO SWITCHomorales.cyvsaNo ratings yet

- Series TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageDocument8 pagesSeries TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageLucila BordenaveNo ratings yet

- CouplingsDocument110 pagesCouplingsMORTEMNo ratings yet

- Series 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating Instructionsindra_onevisionNo ratings yet

- Instrument Cluster 2010 CobaltDocument1 pageInstrument Cluster 2010 CobaltjariarmaturesincNo ratings yet

- Uni-Directional and Bi-Directional Ranges: PX2300 SeriesDocument1 pageUni-Directional and Bi-Directional Ranges: PX2300 SeriesASIM RIAZNo ratings yet

- Series 616Kd - : Differential Pressure Transmitter 0.25, 1 or 2% AccuracyDocument2 pagesSeries 616Kd - : Differential Pressure Transmitter 0.25, 1 or 2% AccuracyOperacao RDBrasilandiaNo ratings yet

- Entrance Door 4Document1 pageEntrance Door 4AYSON N. DELA CRUZNo ratings yet

- Product Drawing: Power Entry 13 1/2" WIDE X 7" HIGHDocument1 pageProduct Drawing: Power Entry 13 1/2" WIDE X 7" HIGHsamersibaniNo ratings yet

- RXD-V333/V333S/V535/V535-GR/V535S/ V535S-H/V636/V737/V737S: Service ManualDocument43 pagesRXD-V333/V333S/V535/V535-GR/V535S/ V535S-H/V636/V737/V737S: Service ManualKasun Chamara PrathapasinghaNo ratings yet

- Series TY-FRB - 2.8, 4.2, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard CoverageDocument14 pagesSeries TY-FRB - 2.8, 4.2, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard Coveragemy.work.ksabNo ratings yet

- Dwyer 2300 250pa Pressure Gauge DatasheetDocument2 pagesDwyer 2300 250pa Pressure Gauge DatasheetGorch Marroko100% (1)

- Connector Industry: A Profile of the European Connector Industry - Market Prospects to 1999From EverandConnector Industry: A Profile of the European Connector Industry - Market Prospects to 1999No ratings yet

- Name: Mikhaela Genevieve G. Eduarte Age: 17 Year: 1 Year Program: Communication ArtsDocument10 pagesName: Mikhaela Genevieve G. Eduarte Age: 17 Year: 1 Year Program: Communication ArtsDana UyNo ratings yet

- Lecture 13 Yield CriterionDocument10 pagesLecture 13 Yield CriterionManoj MallickNo ratings yet

- Fabrication and Properties of Carbon Fiber PDFDocument35 pagesFabrication and Properties of Carbon Fiber PDFSalih ÜnalNo ratings yet

- Guide Ergoline d325 d330 English PDFDocument99 pagesGuide Ergoline d325 d330 English PDFFilipe RibeiroNo ratings yet

- PFM-42-0 Document ReviewDocument9 pagesPFM-42-0 Document ReviewSIVAKUMAR NATARAJANNo ratings yet

- Anatomy of A Boiler FailureDocument14 pagesAnatomy of A Boiler FailureIlker CetinNo ratings yet

- 01 - Different Types of Metal Joining ProcessesDocument44 pages01 - Different Types of Metal Joining ProcessesMetwally NaserNo ratings yet

- Practical 1: AIM:-Write All The Queries For Data DefinitionDocument15 pagesPractical 1: AIM:-Write All The Queries For Data DefinitionPoojaNo ratings yet

- Document From Mirha FatimaDocument16 pagesDocument From Mirha Fatimaafrah afriNo ratings yet

- PRICE E1203257Mrev4-20-EST-JON EPPM MARAFIQ STG 5&6 FPS OPTION 2Document13 pagesPRICE E1203257Mrev4-20-EST-JON EPPM MARAFIQ STG 5&6 FPS OPTION 2AliZenatiNo ratings yet

- ADDIE Model: Analysis PhaseDocument2 pagesADDIE Model: Analysis PhaseNimSha NimzzNo ratings yet

- Course Outline CEN 323 - Fall - 10Document4 pagesCourse Outline CEN 323 - Fall - 10Touhid AhamedNo ratings yet

- How Many Watt Solar Panel To Charge Deep Cycle Battery - EditedDocument5 pagesHow Many Watt Solar Panel To Charge Deep Cycle Battery - EditedalexNo ratings yet

- Assembler Syntax: Lui $at, 4096 Addu $at, $at, $a1 LW $a0, 8 ($at)Document35 pagesAssembler Syntax: Lui $at, 4096 Addu $at, $at, $a1 LW $a0, 8 ($at)GonzaloDominguezNo ratings yet

- Panasonic KX Ft906hg B 908hg BDocument188 pagesPanasonic KX Ft906hg B 908hg BafraniobatistaNo ratings yet

- Catalogos de Distribuidores Aquatrol PDFDocument24 pagesCatalogos de Distribuidores Aquatrol PDFcanizales70No ratings yet

- Comparative Study of Bioethanol and Commercial EthanolDocument21 pagesComparative Study of Bioethanol and Commercial Ethanolanna sophia isabelaNo ratings yet

- SOP For RheometerDocument4 pagesSOP For RheometerKeshab Pradhan100% (1)

- Simpson Rule PDFDocument29 pagesSimpson Rule PDFBrajesh Narayan100% (1)

- Alfa Romeo GiuliaDocument5 pagesAlfa Romeo GiuliakapetuszoNo ratings yet

- Replace fan kit for hp Model 211A Square Wave GeneratorDocument1 pageReplace fan kit for hp Model 211A Square Wave GeneratorxibmNo ratings yet

- USITT Lighting Design GraphicsDocument9 pagesUSITT Lighting Design Graphicstu papi sedNo ratings yet

- Suva Exemplu Metoda-E BriciDocument35 pagesSuva Exemplu Metoda-E BricisilvercristiNo ratings yet

- 18a.security GSM & CDMADocument18 pages18a.security GSM & CDMAwcdma123No ratings yet

- Technical Data for Jotun BlockfillerDocument3 pagesTechnical Data for Jotun BlockfillerrajeshNo ratings yet

- Ziegler-Mfm-3480 Manual-E1R0Document78 pagesZiegler-Mfm-3480 Manual-E1R0Naveed Syed MohammadNo ratings yet

- M N DasturDocument2 pagesM N DasturAnonymous 5lZJ470No ratings yet

- LM 723Document22 pagesLM 723Zoran DjukicNo ratings yet