Professional Documents

Culture Documents

NOTES FOR PLUM CONCRETE RETAINING WALL DESIGN

Uploaded by

Mani KantaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NOTES FOR PLUM CONCRETE RETAINING WALL DESIGN

Uploaded by

Mani KantaCopyright:

Available Formats

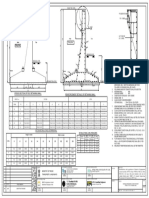

NOTES FOR PLUM CONCRETE RETAINING WALL:

1. PLUM CONCRETE SHALL CONSIST OF CONCRETE CLASS B 170 Kg/cm² (2500Psi)

CONTAINING LARGE EMBEDDED STONES HAVING NO STONE DIMENSION LESS

THAN 200mm. FOR HIGH SEISMIC ZONES

2. NO TWO STONES SHALL BE CLOSER THAN 150mm TO EACH OTHER.

3. ONLY STEEL PLATES FORM WORK SHOULD BE USED AND IT SHOULD NOT BE 400

DAMAGED OR MISPLACED WHILE PLACING/DUMPING OF STONES.

4. PLUM CONCRETE WILL CONSTITUTE ONLY 33% STONES OF TOTAL VOLUME AND PARAPET WALL CONCRETE

CONCRETE CLASS B WILL NOT BE LESS THAN 67%. CLASS "B" (2500psi)

600

5. THE COMMON PRACTICE OBSERVED IN SUCH CONSTRUCTIONS IS THAT STONES 160 600 ROAD

USED ARE MORE THAN 33% AND CONCRETE USED IS LESS THAN 67%, WHICH IS

INCORRECT PRACTICE AND NEEDS TO BE MONITORED AT THE SITE.

6. ANOTHER INCORRECT PRACTICE OBSERVED IS THAT A LAYER OF STONES IS O.F. E.F.

PLACED AND THEN A LAYER OF MORTAR IS SPREAD OVER THE STONE LAYERS.

PLUM CONCRETE

1000

THE CORRECT PRACTICE IS TO FIRST PLACE A CONCRETE LAYER OF 150mm AND

THEN PLACES A FEW STONES 150mm APART. (CONCRETE 67% +

7. EACH STONE SHOULD BE COVERED BY 150mm CLASS B CONCRETE ALL AROUND 300 150 760 150 STONES 33%)

2000

AND THE SPACES IN BETWEEN THE LAR GER STONES SHOULD NOT BE FILLED

WITH SMALLER STONE CHIPPING EXCEPT CONCRETE.

50mm PVC DRAIN FILTER MATERIAL

8. IT IS ALSO TO BE ENSURED THAT WATER CURING IS CARRIED OUT FOR AT LEAST

10 DAYS.

PIPE @ 2m C/C(HORIZ & 200X200X200

9. WHERE EVER POSSIBLE, THE RETAINING WALL SHOULD BE PLACED AWAY FROM VERTICALLY BOTH WAYS) DETAIL 'X' 2600

1300

THE CARRIAGEWAY WITH AN EMBANKMENT SLOPE OF 2:1. IT WILL HELP IN

REDUCTION IN THE HEIGHT / TOTAL COST OF THE WALL.

10. IN CASE THE EMBANKMENT SLOPE IS STEEP AS 1.5:1, THEN SLOPE PROTECTION IS N.S.L./ BED LEVEL

MANDATORY.

11. IN CASE THE SLOPE OF EMBANKMENT IS EVEN STEEPER THAN 1.5:1, THEN FULL

100 1360 100

600

HEIGHT WALL WILL BE CONSTRUCTED..

300

12. POOR WORKMANSHIP AND LACK OF SUPERVISION IS ALSO A CAUSE OF POOR

CONSTRUCTION AND ULTIMATELY FAILURE. HENCE, PROPER SUPERVISION MUST

100

ALSO BE INSURED.

13. LEAN CONCRETE IS 100 Kg/cm² (1400 Psi) .

300mm CONCRETE 100mm LEAN (1400 psi)

BEARING CAPACITY OF THE SITE: CLASS "B" (2500 psi) 1560

1. IF THE BEARING CAPACITY AT SITE IS LESS THAN THE REQUIRED THEN PROVIDE (0.6H)

ONE OR TWO LAYERS OF 150 mm AGGREGATE BASE MATERIAL COMPACTED TO

95% AASHTO DENSITY UNDER THE WALL FOUNDATION.

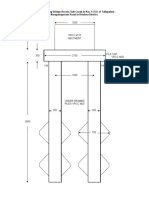

2. FOR VERY POOR SOIL CONDITIONS PROVIDE 150 mm MICRO PILES AT 1500 C/C 2.6 METER HEIGHT PLUM CONCRETE RETAINING WALL

BOTH WAYS TO IMPROVE BEARING CAPACITY,UPTO A DEPTH OF FIRM SOIL.

3. THE COST OF IMPROVEMENT OF FOUNDATION BASE WILL BE ADDED IN THE TOTAL

COST.

BACK FILL:

BY USING SURVEY EQUIPMENT FIND OUT CROSS SECTIONAL AREA OF BACK FILL

AND THEN CALCULATE VOLUME OF BACK FILL.

LEGENDS:

COSTING:

1. THE GIVEN QUANTITY IS FOR ONE METER LENGTH OF WALL. THE TOTAL QUANTITY

O.F. = OUTER FACE

WILL BE = ACTUAL LENGTH OF WALL(m) X QUANTITY PER UNIT LENGTH. E.F. = EARTH FACE

2. IN ADDITION,WHERE EVER REQUIRED THE QUANTITY OF COMMON BACK FILL AS N.S.L. = NATURAL SOIL LEVEL

WELL AS FOR PROTECTION WORKS MAY BE ADDED.

DESIGNED BY: DR. CM IQBAL DWG. DWG. NO.

CECON (Civil Engineers & Consultants) PLUM CONCRETE RETAINING WALL 2.6 METER HEIGHT PLUM CONCRETE RETAINING WALL 01

Email: cecon.cmi@gmail.com

PLUM CONCRETE WALL

QUANTITY PER METER LENGTH

Total Height = 2.6 m

Height above NSL = 2m

Height below NSL = 0.6 m

CODE DESCRIPTION UNIT NO LENGTH BREADTH HEIGHT QUANTITY

Structural Excavation in

107cii CM 1.2

medium rock Material

Foundation Base 1 1 1.76 0.7 1.23

401f Lean Concrete CM 1 1 1.76 0.1 0.2

401h Plum Concrete 2.3

Wall Body 2 CM 1 1 0.68 1 0.7

Wall Body 1 CM 1 1 1.21 1.3 1.6

401b Concrete Class B CM 0.8

Base CM 1 1 1.56 0.3 0.5

Parrapet CM 1 1.25 0.4 0.6 0.3

107e Common Backfill CM 3.8

Behind Retaining wall CM 1 1 2 1.9 3.8

107d Granular backfill CM 1.4

Behind Retaining wall CM 1 1 2 0.7 1.4

Filter Layer of Granual

509h CM 0.01

Material

CM 1 0.2 0.2 0.2 0.008

NSI PVC Drain Pipe RM 1.8

RM 1 1.8 Dia 50mm 1.8

DESIGNED BY: DR. CM IQBAL QUANTITY PER METER

CECON: (Civil Engineers & Consultants) PLUM CONCRETE RETAINING WALL LENGTH FOR 2.6m HEIGHT 02

E-mail: cecon.cmi@gmail.com RETAINING WALL

METHODOLOGY FOR PLUM CONCRETE RETAINING WALL

(Rubble or Cyclopean concrete)

1. Specifications (Plum, Rubble or Cyclopean Concrete) :-

· Rubble or cyclopean concrete shall consist of Class B concrete containing large

embedded stones.

· The total volume of the stone shall not be greater than one third (33%) of the total volume

of the portion of the work in which it is placed.

· Each stone shall be surrounded by at least fifteen centimeter (150 mm) of concrete and no

stone shall be closer than thirty centimeter (300 mm) to any top surface or any closer than

fifteen centimeter (150 mm) to any coping.

2. Methodology:-

· Plum concrete will constitute only 33% stones of total volume and concrete Class B will not

be less than 67%. This means that the volume of stones is only one-third and two-third in

concrete.

· Plum concrete shall consist of concrete Class B 170 kg/cm² (2500psi) containing large

embedded stones that one man can handle it.

· Class B concrete slump should not be more than 150mm.

· No two stones shall be closer than 150mm to each other either sideways or bottom to top

layer.

· Only steel plates or plywood form work should be used and it should not be damaged or

misplaced while placing of stones.

· Each stone should be covered by 150mm Class B concrete all around and the spaces in

between the larger stones should not be filled with smaller stone chippings except

concrete.

· It is also to be ensured that water curing is carried out for at least 14 days.

3. Correct / Incorrect Practices:-

· The common practice observed in such constructions is that stones used are more than

33% and concrete used is less than 67%, which is incorrect practice and needs to be

monitored at the site. Such substandard works should be rejected/ devalued proportionally.

· Another incorrect practice observed is that a layer of closely placed stones is made and

then a layer of mortar is spread over the stone layers. The correct practice is to first place

a concrete layer of 150mm and then place the stones 150mm apart on the concrete layer.

DESIGNED BY: DR. CM IQBAL DWG. DWG. NO.

CECON (Civil Engineers & Consultants) PLUM CONCRETE RETAINING WALL METHODOLOGY FOR PLUM CONCRETE RETAINING WALL 03

Email: cecon.cmi@gmail.com

METHODOLOGY FOR PLUM CONCRETE RETAINING WALL

(Rubble or Cyclopean concrete)

CORRECT PRACTICES INCORRECT PRACTICES

150 150

150 150 150

150 150 150

CONCRETE CONCRETE

150 CLASS "B" CLASS "B"

150

STONE 150mm

APART STONE CLOSER

150 THAN 150mm

PLAN VIEW PLAN VIEW

ALL STONES ARE PLACED 150 mm APART STONES ARE PLACED CLOSER THAN 150mm.

150 150

150 150

150 150

CONCRETE CONCRETE

CLASS "B" CLASS "B"

150

STONE 150mm

APART STONE CLOSER

150 THAN 150mm

ELEVATION ELEVATION

ALL STONES ARE PLACED 150mm APART. THE CONCRETE THE CONCRETE LAYER BETWEEN THE STONES LAYER IS

LAYER BETWEEN THE STONES LAYER IS 150 mm. LESS THAN 150 mm.

Advantages: Disadvantages:

· It is according to specifications for Plum, · It is not according to specifications for Plum,

Rubble or Cyclopean Concrete. Rubble or Cyclopean Concrete.

· Concrete quantity 67% with respect to stones · Concrete quantity less than 67% and stones

33% is achieved. used are more than 33% is achieved.

· The work needs to be devalued accordingly.

DESIGNED BY: DR. CM IQBAL DWG. DWG. NO.

CECON (Civil Engineers & Consultants) PLUM CONCRETE RETAINING WALL METHODOLOGY FOR PLUM CONCRETE RETAINING WALL 04

Email: cecon.cmi@gmail.com

You might also like

- Gabion Wall Typical Design Sheet-Front-19-8-2008Document8 pagesGabion Wall Typical Design Sheet-Front-19-8-2008jfejfe100% (1)

- Analysis of PCC/Random Rubble Stone Masonry TOE Wall StabilityDocument3 pagesAnalysis of PCC/Random Rubble Stone Masonry TOE Wall StabilityKamlesh Parihar100% (1)

- Pile vs Well Foundation ComparisonDocument16 pagesPile vs Well Foundation Comparisongvgbabu100% (4)

- Staging System (Cribs)Document5 pagesStaging System (Cribs)Surya Gowtham100% (4)

- Calculation For Bearing Capacity As Per IS: 6403: (Soils With Cohesion and Shearing Resistance)Document1 pageCalculation For Bearing Capacity As Per IS: 6403: (Soils With Cohesion and Shearing Resistance)radhikas49100% (2)

- Gabion Wall Design SheetDocument3 pagesGabion Wall Design SheetTej Bdr. paliNo ratings yet

- ContractDocument3 pagesContractIsak BerkovitzNo ratings yet

- Design of Plum Concrete Breast Wall Design Note No: SAI/TKD-219016/PKG-5/DN/STR/BW-04Document9 pagesDesign of Plum Concrete Breast Wall Design Note No: SAI/TKD-219016/PKG-5/DN/STR/BW-04Rishikesh Majumdar100% (2)

- Trimix Flooring AnalysisDocument6 pagesTrimix Flooring AnalysisShashank Hegde75% (8)

- Friction Coefficient For Concrete Cast On SoilDocument2 pagesFriction Coefficient For Concrete Cast On SoilBogdanB100% (2)

- B.6.23 - STD SPECS - For Plum Concrete & Plum MasonaryDocument3 pagesB.6.23 - STD SPECS - For Plum Concrete & Plum MasonaryBijay Krishna Das100% (3)

- Cutting length calculationDocument2 pagesCutting length calculationsibendu0% (2)

- Design of Gap SlabDocument15 pagesDesign of Gap Slabvivek100% (1)

- Pipe Culvert 1000MMDocument8 pagesPipe Culvert 1000MMgtarun22gupta86% (7)

- Concrete Bridge Code 2014 - 6Document124 pagesConcrete Bridge Code 2014 - 6Anonymous YHcvra8Xw693% (15)

- Concrete Bridge Code 2014 - 6Document124 pagesConcrete Bridge Code 2014 - 6Anonymous YHcvra8Xw693% (15)

- Managerial Eco and Accounting FinalDocument16 pagesManagerial Eco and Accounting FinalMichael Paul GabrielNo ratings yet

- Morth 3100 Reinforce EarthDocument5 pagesMorth 3100 Reinforce EarthRamesh67% (3)

- RE Wall - RDSO PDFDocument65 pagesRE Wall - RDSO PDFgaurave50% (4)

- Staging Design For Bridge SlabDocument10 pagesStaging Design For Bridge SlabRajarathinam RajamanickamNo ratings yet

- Mistake in Bitumen Content Assessment in OGPC and SC in APDocument14 pagesMistake in Bitumen Content Assessment in OGPC and SC in APPrakasam VemavarapuNo ratings yet

- Measures To Prevent Damages in Black Cotton Soil AreasDocument6 pagesMeasures To Prevent Damages in Black Cotton Soil AreasSabyasachi Naik (Zico)100% (1)

- I R C - S P 13 - 2004 With PlatesDocument152 pagesI R C - S P 13 - 2004 With PlatesMuthusamy ArumugamNo ratings yet

- RCC Retaining Wall-01Document1 pageRCC Retaining Wall-01HegdeVenugopalNo ratings yet

- RE Wall ConstructionDocument80 pagesRE Wall ConstructionV Venkata Narayana88% (8)

- IS1904 2021 Smp1lqeyrbvvhc4m2mxflc00zwsd20230309113713Document20 pagesIS1904 2021 Smp1lqeyrbvvhc4m2mxflc00zwsd20230309113713Naveen kumar JakkulaNo ratings yet

- Is 12720 2004 PDFDocument14 pagesIs 12720 2004 PDFBishowkumar Shrestha100% (1)

- 1786 2012 New Ammendments PDFDocument23 pages1786 2012 New Ammendments PDFS RamakrishnaNo ratings yet

- Re-Wall MethodologyDocument9 pagesRe-Wall Methodologytitus100% (3)

- IS-2911 (Part 1 Sec 2) - 2010 (Ref 2015)Document26 pagesIS-2911 (Part 1 Sec 2) - 2010 (Ref 2015)Guessss..........!!!!!100% (1)

- Toe Wall Design Final PDFDocument2 pagesToe Wall Design Final PDFDADADADGGG50% (2)

- Analysis of tremie technique in well bottom plug concretingDocument16 pagesAnalysis of tremie technique in well bottom plug concretingtangkokhong67% (3)

- VDF-Flooring (Floor-M20 Grade) 75 mm thkDocument3 pagesVDF-Flooring (Floor-M20 Grade) 75 mm thkDeepa Junnarkar DegwekarNo ratings yet

- Reinforced Concrete Bunkers and Silos DesignDocument20 pagesReinforced Concrete Bunkers and Silos DesignFiraol TayeNo ratings yet

- Providing Bailey Bridge Across Salt Creak in Krishna DistrictDocument9 pagesProviding Bailey Bridge Across Salt Creak in Krishna DistrictKiran AEE BvrmNo ratings yet

- Guidelines for Conventional, Thin, and Ultra-Thin WhitetoppingDocument31 pagesGuidelines for Conventional, Thin, and Ultra-Thin WhitetoppingSri Ramya100% (1)

- Bow String Girder Launching ProgramDocument1 pageBow String Girder Launching ProgramrohitNo ratings yet

- Is SP 16 1980 PDFDocument255 pagesIs SP 16 1980 PDFShaik Abdul RaheemNo ratings yet

- Staging DesignDocument8 pagesStaging DesignAbhinandan Jasrotia0% (1)

- 15 - High Mast Light Pole Foundation DesignDocument20 pages15 - High Mast Light Pole Foundation DesignHamOdy SadeqNo ratings yet

- Pile DesignDocument17 pagesPile DesignMuhammad HasanNo ratings yet

- Reinforced - C - Vol - I PART - I - and - IIDocument12 pagesReinforced - C - Vol - I PART - I - and - IIAKSNo ratings yet

- Binding Wire Consumption As Per Is CodeDocument1 pageBinding Wire Consumption As Per Is CodeSyed ZamanNo ratings yet

- IS 6403 1981 2002 Ed 2.1 PDFDocument18 pagesIS 6403 1981 2002 Ed 2.1 PDFjinesh shah100% (2)

- Selection of Retaining Walls in Hill Areas - Indian StandardsDocument14 pagesSelection of Retaining Walls in Hill Areas - Indian Standardsnimm1962100% (1)

- Is 2911-PART-1-Sec2-1979 Bored Cast in Situ Pile Foundations 1997Document44 pagesIs 2911-PART-1-Sec2-1979 Bored Cast in Situ Pile Foundations 1997selva_65195058% (12)

- PWD Standard DataDocument295 pagesPWD Standard Datadeh tnrsp2tup92% (13)

- Rate Analysis For Concrete PavementDocument1 pageRate Analysis For Concrete PavementSuraj Shenoy Nagar100% (1)

- Marth 1800 PrestressingDocument17 pagesMarth 1800 PrestressingRamesh100% (4)

- Uplift Rock AnchorsDocument7 pagesUplift Rock AnchorsSantoshNo ratings yet

- Boundary Wall Design Calculations With PileDocument32 pagesBoundary Wall Design Calculations With PileWahid wrbel100% (1)

- Is - 14687-1999 Falsework For Concrete StructuresDocument27 pagesIs - 14687-1999 Falsework For Concrete StructuresJarrod HarrellNo ratings yet

- Rate Analysis Crash BarrierDocument1 pageRate Analysis Crash Barrierrupali vijNo ratings yet

- (PDF) IRC-58 2015 Excel SheetDocument3 pages(PDF) IRC-58 2015 Excel SheetMadhavpokale0% (1)

- Type Design For KM HM StonesDocument1 pageType Design For KM HM StonesYedla Neelakanteshwar100% (3)

- Box Culvert Design ParametersDocument18 pagesBox Culvert Design ParametersPrafulla MallaNo ratings yet

- CC Road Design PalasaDocument18 pagesCC Road Design PalasaManikantaNo ratings yet

- Elevator Installation Requirements for Main Power Supply and Shaft SpecificationsDocument1 pageElevator Installation Requirements for Main Power Supply and Shaft SpecificationsleekodakNo ratings yet

- ShopDrawings - Part 1Document51 pagesShopDrawings - Part 1YapNo ratings yet

- ShopDrawings - Part 1Document51 pagesShopDrawings - Part 1YapNo ratings yet

- Stone Masonry WallDocument1 pageStone Masonry WallHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Cemex Solid K4 - Raw Meal SiloDocument3 pagesCemex Solid K4 - Raw Meal Silojoselito navarroNo ratings yet

- Sediment Fence 2Document1 pageSediment Fence 2Wing MacNo ratings yet

- Structural Notes 1Document1 pageStructural Notes 1missiklein3No ratings yet

- IndexDocument1 pageIndexMani KantaNo ratings yet

- PaDocument2 pagesPaMani KantaNo ratings yet

- PaDocument2 pagesPaMani KantaNo ratings yet

- Section III QR 16717 01Document1 pageSection III QR 16717 01Mani KantaNo ratings yet

- Chainage Location Span FRL GL Height of Pier / ABTDocument1 pageChainage Location Span FRL GL Height of Pier / ABTMani KantaNo ratings yet

- Notification For Police JobsDocument22 pagesNotification For Police JobsMani KantaNo ratings yet

- 83e 14Document1 page83e 14Mani KantaNo ratings yet

- Full Year Syllabus PDFDocument140 pagesFull Year Syllabus PDFMani KantaNo ratings yet

- CE2402 Estimation and Quantity Surveying PDFDocument107 pagesCE2402 Estimation and Quantity Surveying PDFMuthu Praveen SarwanNo ratings yet

- Полнотекстовый Поиск В Postgresql За МиллисекундыDocument54 pagesПолнотекстовый Поиск В Postgresql За МиллисекундыSzERGNo ratings yet

- Gypsum Mineral DataDocument4 pagesGypsum Mineral Datamalaya tripathy0% (1)

- Precision Agriculture Using LoraDocument22 pagesPrecision Agriculture Using Loravrashikesh patilNo ratings yet

- Resolve Error in FI Document Parking WorkflowDocument4 pagesResolve Error in FI Document Parking WorkflowManohar G ShankarNo ratings yet

- Skylab 4 PAO Mission Commentary 16 of 32Document188 pagesSkylab 4 PAO Mission Commentary 16 of 32Bob Andrepont100% (1)

- Company ProfileDocument3 pagesCompany ProfileSubi SubishaNo ratings yet

- Calimlim Vs RamirezDocument3 pagesCalimlim Vs RamirezMoon BeamsNo ratings yet

- ResumeDocument2 pagesResumeCameron Bracken100% (3)

- 5-Cyanophthalide ProjDocument7 pages5-Cyanophthalide ProjdrkrishnasarmapathyNo ratings yet

- Qingdao ACT Auto Brake Disc Drum For Volkswagen Ford ToyotaDocument9 pagesQingdao ACT Auto Brake Disc Drum For Volkswagen Ford ToyotaQingdao act brake discNo ratings yet

- De La Salle University College of Business Course Checklist: Basirec SystandDocument2 pagesDe La Salle University College of Business Course Checklist: Basirec SystandncllpdllNo ratings yet

- D-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) Fuel Filter and LinesDocument3 pagesD-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) Fuel Filter and LinesMANUALES100% (1)

- Metro BrochureDocument27 pagesMetro BrochureKhaled Saif Al-hakimiNo ratings yet

- 1 s2.0 S0021979718302352 MainDocument6 pages1 s2.0 S0021979718302352 MainShuvam PawarNo ratings yet

- Bair Hugger 775 Operator ManualDocument23 pagesBair Hugger 775 Operator Manualpiotr.lompartNo ratings yet

- All Hands Naval Bulletin - Jan 1945Document84 pagesAll Hands Naval Bulletin - Jan 1945CAP History LibraryNo ratings yet

- The Concept of Mutuum Legal Provisions and CasesDocument129 pagesThe Concept of Mutuum Legal Provisions and CasesGerard TinampayNo ratings yet

- GLSL Specification 1.40.08.fullDocument111 pagesGLSL Specification 1.40.08.fullmushakkNo ratings yet

- Varrsana Details FinalDocument5 pagesVarrsana Details FinalAmarjeet RoyNo ratings yet

- Order in Respect of Application Filed by Munjal M Jaykrishna Family Trust Under Regulation 11 of Takeover Regulations, 2011 For Acquisition of Shares in AksharChem (India) LimitedDocument10 pagesOrder in Respect of Application Filed by Munjal M Jaykrishna Family Trust Under Regulation 11 of Takeover Regulations, 2011 For Acquisition of Shares in AksharChem (India) LimitedShyam SunderNo ratings yet

- Insurance As A Investment Tool at Icici Bank Project Report Mba FinanceDocument73 pagesInsurance As A Investment Tool at Icici Bank Project Report Mba FinanceBabasab Patil (Karrisatte)No ratings yet

- CV of Reaz EHS EngineerDocument3 pagesCV of Reaz EHS EngineerReaz UddinNo ratings yet

- EmployersDocument4 pagesEmployersksNo ratings yet

- DXR Series Refrigerated Air Dryers: Operator'S Instruction ManualDocument48 pagesDXR Series Refrigerated Air Dryers: Operator'S Instruction ManualDavid BarrientosNo ratings yet

- 545-950 ThermaGuard 2021Document2 pages545-950 ThermaGuard 2021AbelNo ratings yet

- sbec cs executiveDocument34 pagessbec cs executiveEISHAN PATELNo ratings yet

- Professional GoalsDocument2 pagesProfessional Goalsapi-530115287No ratings yet

- ToshibaDocument38 pagesToshibadvishal77No ratings yet

- TLB ResumeDocument1 pageTLB Resumeapi-486218138No ratings yet