Professional Documents

Culture Documents

Super Safety Valve

Uploaded by

Paul Ticona SOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Super Safety Valve

Uploaded by

Paul Ticona SCopyright:

Available Formats

LEVEL 1 CAPABILITY

DOWNHOLE | Level 2 Capability (if applicable)

TEST TOOLS

Super Safety™ Valve

MASTER VALVE USED FOR TESTING OPERATIONS

FROM JACKUP OR LAND RIGS

OVERVIEW downhole to a separate injection sub or

to actuate a subsurface safety valve. The

The Super Safety™ valve is installed in the

valve is held open by maintaining hydraulic

test string so that a blowout preventer ram

pressure on the control line.

can be closed on the ramlock sub located in

the upper section of the valve. The annulus The valve is designed to close by spring

is then protected by the BOP rams, and the force but incorporates a nitrogen dome

test string is protected by the Super Safety charge chamber to provide increased

Valve. closing force and to lessen the time

required for closing. This feature gives

The Super Safety valve is capable of

the valve the ability to cut wireline and

cutting wireline and 1.5-inch coiled tubing.

coiled tubing without adding balance line

If equipped with a cutter ball, it is capable

pressure.

of cutting coiled tubing with a 2-inch

outside diameter (OD) and 0.125-inch wall »» Normally closed/fail-safe

thickness, using a nitrogen dome charge or »» Maintains pump-through capabilities

by applying balance line pressure. at all times

»» Nitrogen dome charge for fast response

FEATURES AND BENEFITS »» Capable of cutting 1.5-inch coiled tubing,

The Super Safety valve is controlled by two or, if equipped with a cutter ball, coiled

hydraulic lines: a control line (open) and a tubing with 2-inch OD and 0.125-inch

balance line (close). It also contains a third wall thickness

line for chemical injection. The port for »» Small 8-inch OD fits inside 9-5/8-inch

injecting chemicals is at the ball valve body casing

or can be used to pump chemicals farther

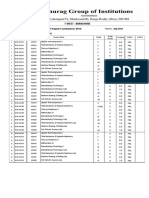

Outer Diameter Inner Diameter Valve Length Total Length End Differential Pressure 1 Tensile Load

2 Service

in. (cm) in. (cm) in. (cm) in. (cm) Connections psi (bar) lb (kg) Temperature ˚F (˚C)

Top Connection:

8.0 3.0 50.00 79.6 5 3/4 4-Stub Acme Box 15,000 400,000 32 to 325

(20.32) (7.62) (127.0) (202.2) (1034) (181,440) (0 to 163)

Bottom Connection:

5 4-Acme Box

Notes:

1 Differential pressure is the difference in pressure between the casing annulus and the tool ID.

2 The values of tensile, burst, and collapse strength are calculated with new tool conditions: Lamé formulas with von Mises’ Distortion Energy Theory for

burst and collapse strength, as well as stress, are calculations for tensile strength

»» Meets requirements of NACE MR0175 (> 175°F/79°C)

»» These ratings are guidelines only. Refer to the equipment data book for individual specifications.

For more information, contact your local Halliburton representative

or visit us on the web at www.halliburton.com

HAL42294

Sales of Halliburton products and services will be in accord solely with the terms and conditions

contained in the contract between Halliburton and the customer that is applicable to the sale.

H012332 9/16 © 2016 Halliburton. All Rights Reserved.

You might also like

- UoTT Petroleum Engineering Coiled Tubing CourseDocument10 pagesUoTT Petroleum Engineering Coiled Tubing CourseTrini_thug100% (1)

- Agitator Handbook 2005Document22 pagesAgitator Handbook 2005casda73No ratings yet

- Well WorkoverDocument17 pagesWell WorkoverHasnain TariqNo ratings yet

- Perforation SeminarDocument24 pagesPerforation SeminarSuleiman BaruniNo ratings yet

- Process & Instrumentation Diagram (P&ID)Document66 pagesProcess & Instrumentation Diagram (P&ID)Syed HameedNo ratings yet

- EXP Well Testing Commisioning A4 24p ProofDocument24 pagesEXP Well Testing Commisioning A4 24p ProofMohan RajaNo ratings yet

- Chapter 6 The Well Control System (Temporarily)Document61 pagesChapter 6 The Well Control System (Temporarily)Tu Dang TrongNo ratings yet

- Downhole ProblemsDocument15 pagesDownhole Problemsnasr yassinNo ratings yet

- 3701 - Safety Relief ValveDocument10 pages3701 - Safety Relief ValveSIVA50% (2)

- Sewerage System NotesDocument34 pagesSewerage System NotesArshdeep Ashu100% (2)

- Special Services Presentation - 18 June 2018 Rev 1Document23 pagesSpecial Services Presentation - 18 June 2018 Rev 1Juan CamachoNo ratings yet

- 4 Workover and Potential HazardsDocument24 pages4 Workover and Potential HazardsaliNo ratings yet

- Well Testing EquipmentDocument26 pagesWell Testing Equipmentlaribi mohammedNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- Predict combustion gas emissivities with simple equationsDocument4 pagesPredict combustion gas emissivities with simple equationsFranny CasasolaNo ratings yet

- Workover Planning: Ask For Skillup Drilling & Workover CoursesDocument44 pagesWorkover Planning: Ask For Skillup Drilling & Workover Coursessaer oklaNo ratings yet

- Lube and Bleed Operation KLS-1 Rig Less Feb 2017Document19 pagesLube and Bleed Operation KLS-1 Rig Less Feb 2017Ali Boubenia100% (1)

- Detail Specification of Rig Sagar Gaurav: Ongc Videsh Ltd. Out Line Drilling Unit SpecificationDocument25 pagesDetail Specification of Rig Sagar Gaurav: Ongc Videsh Ltd. Out Line Drilling Unit SpecificationMohitNo ratings yet

- Itcoloy and Milling Tools: Instruction Manual 5100Document12 pagesItcoloy and Milling Tools: Instruction Manual 5100Foros IscNo ratings yet

- Tubing StringDocument32 pagesTubing StringKAORU AmaneNo ratings yet

- Understanding Sour Service Performance of Coiled Tubing After H2S ExposureDocument12 pagesUnderstanding Sour Service Performance of Coiled Tubing After H2S ExposureMubeenNo ratings yet

- Control Valve Question and Answer - 2Document13 pagesControl Valve Question and Answer - 2TATA STEELNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Introduction To DrillingDocument25 pagesIntroduction To Drillingrobin2806100% (1)

- Part 1 Introduction New PDFDocument12 pagesPart 1 Introduction New PDFRanim HishamNo ratings yet

- Parker VOAC F11-F12 Technical DocumentDocument44 pagesParker VOAC F11-F12 Technical DocumentPablo Soto100% (1)

- Packer Testing Program Design and Management: August 2013Document7 pagesPacker Testing Program Design and Management: August 2013wily784No ratings yet

- Helical Buckling of Coiled Tubing in Directional Oil Wellbores 2009Document1 pageHelical Buckling of Coiled Tubing in Directional Oil Wellbores 2009SIMULIACorpNo ratings yet

- Ring Type Joint Gaskets Styles: R, RX, BXDocument2 pagesRing Type Joint Gaskets Styles: R, RX, BXiswantmachooNo ratings yet

- Retrievble Packer System - BakerDocument60 pagesRetrievble Packer System - BakerLAGRAA Med Bechikh KheiraNo ratings yet

- Well CompletionDocument26 pagesWell Completioneliud apindiNo ratings yet

- 2.1 PackersDocument13 pages2.1 PackersVeviet pomataNo ratings yet

- WARMAN WBV Series Brochure Low Res GLOBALDocument8 pagesWARMAN WBV Series Brochure Low Res GLOBALJOKO WIKARNANo ratings yet

- Blowout Preventer - Wikipedia PDFDocument70 pagesBlowout Preventer - Wikipedia PDFEndhy Wisnu Novindra100% (1)

- Interim Project Report on Packer DesignDocument26 pagesInterim Project Report on Packer DesignPiyush NamdeoNo ratings yet

- Basic Symbals P&ID PDFDocument736 pagesBasic Symbals P&ID PDFPavar Raviteja100% (1)

- An Over View of Annulus Pressure For New Wellhead TechnicianDocument8 pagesAn Over View of Annulus Pressure For New Wellhead TechnicianShahid PakistaniNo ratings yet

- Well Control Checklist for Safe Drilling OperationsDocument14 pagesWell Control Checklist for Safe Drilling OperationsAdam InesNo ratings yet

- Coiled Tubing Pressure Control CapabilitiesDocument8 pagesCoiled Tubing Pressure Control CapabilitiesGuido100% (1)

- IWCF Well Intervention Pressure Control Level 3 and 4 Cross Reference FormDocument82 pagesIWCF Well Intervention Pressure Control Level 3 and 4 Cross Reference FormairlinemembershipNo ratings yet

- Water Gas Shift ReactorDocument44 pagesWater Gas Shift ReactorNitish Kumar KushwahaNo ratings yet

- Well Killing ProceduresDocument28 pagesWell Killing ProceduresYeho ShuaNo ratings yet

- HeuristicsDocument16 pagesHeuristicsGöksu KutluNo ratings yet

- Buoyancy Forces in CT ApplicationsDocument3 pagesBuoyancy Forces in CT ApplicationsQazi WaqasNo ratings yet

- Tubing String Testing (TST) Valve: Provides Tubing Testing Capability With Automatic Fill of The WorkstringDocument2 pagesTubing String Testing (TST) Valve: Provides Tubing Testing Capability With Automatic Fill of The Workstringadi nugroho100% (1)

- Coiled TubingDocument31 pagesCoiled TubingMostafa KorttamNo ratings yet

- Production Logging Tools 2014Document2 pagesProduction Logging Tools 2014Alicia Izquierdo HernandezNo ratings yet

- STD 174Document38 pagesSTD 174Subhadip Sadhukhan100% (1)

- Side Pocket MandrelDocument3 pagesSide Pocket MandrelSyameer109No ratings yet

- Sprint CTU ContigencyPlanDocument32 pagesSprint CTU ContigencyPlanJawad Khan100% (1)

- DS-1 4th Ed - Volume 3 - Addendum 2Document7 pagesDS-1 4th Ed - Volume 3 - Addendum 2MARVELNo ratings yet

- 03 Tuned CementsDocument8 pages03 Tuned Cementshamora33100% (1)

- DST Slip Joint PDFDocument8 pagesDST Slip Joint PDFcrni rokoNo ratings yet

- Seal Assemblies (Locator, Anchor, Latch)Document2 pagesSeal Assemblies (Locator, Anchor, Latch)Yougchu LuanNo ratings yet

- 37 Coiled TubingDocument45 pages37 Coiled TubingBrahim LetaiefNo ratings yet

- Cement Retainer 103387896 PDFDocument1 pageCement Retainer 103387896 PDFhitesh kumarNo ratings yet

- Collet Catcher SubDocument1 pageCollet Catcher SubjasonNo ratings yet

- Pressure Control GroupDocument4 pagesPressure Control GroupAbdelhamid HaramiNo ratings yet

- Cge578 Chapter 5 Well CPLDocument52 pagesCge578 Chapter 5 Well CPLNurfatini Che100% (2)

- PPE I PR 005Document11 pagesPPE I PR 005MahanderOadNo ratings yet

- Well-Head SelectionDocument13 pagesWell-Head Selectionmghareeb100% (1)

- Maxfire Electronic Firing Systems: Conveyance and Triggering OptionsDocument7 pagesMaxfire Electronic Firing Systems: Conveyance and Triggering OptionsGabriel GonzalezNo ratings yet

- Powerstroke Drilling Jar: Instruction Manual 4250Document24 pagesPowerstroke Drilling Jar: Instruction Manual 4250Foros IscNo ratings yet

- Packer HPHT Downhole Completion Equipment Bsee May 2015 Hilts PDFDocument16 pagesPacker HPHT Downhole Completion Equipment Bsee May 2015 Hilts PDFfredyNo ratings yet

- Super Pack: Making The Packoff Super!Document2 pagesSuper Pack: Making The Packoff Super!Jeff NehmeNo ratings yet

- Offshore and Onshore Well Pressure Control Systems Design ManualDocument5 pagesOffshore and Onshore Well Pressure Control Systems Design Manualvignesh100% (1)

- Part 2 Well DesignDocument12 pagesPart 2 Well DesignAbdelaziz Mohamed Abdelmoaty ArafaNo ratings yet

- PETE 411 Plugback Cementing LessonDocument42 pagesPETE 411 Plugback Cementing LessonAdhi NugrohoNo ratings yet

- 9.5in OntrakDocument2 pages9.5in OntrakPaul Ticona SNo ratings yet

- Super Safety ValveDocument1 pageSuper Safety ValvePaul Ticona SNo ratings yet

- Equation For Estimating Mud Minimum Rate For Cuttings Transport in An Inclined-UntilDocument15 pagesEquation For Estimating Mud Minimum Rate For Cuttings Transport in An Inclined-UntilSergio Pablo RodríguezNo ratings yet

- Tutorial PetromodDocument15 pagesTutorial PetromodPaul Ticona SNo ratings yet

- Tutorial PetromodDocument15 pagesTutorial PetromodPaul Ticona SNo ratings yet

- Comparison of k ε and RNG k ε Turbulent Models for Estimation of Velocity Profiles along the Hydraulic Jump on Corrugated BeDocument6 pagesComparison of k ε and RNG k ε Turbulent Models for Estimation of Velocity Profiles along the Hydraulic Jump on Corrugated BeAhsan LatifNo ratings yet

- Shell Tellus S2 M 100 Technical Data SheetDocument3 pagesShell Tellus S2 M 100 Technical Data SheetMuhtiar DarjaNo ratings yet

- 02 - Radial Flow and Radius of InvestigationDocument16 pages02 - Radial Flow and Radius of InvestigationrogerNo ratings yet

- CounterweightDocument25 pagesCounterweightLami BojaNo ratings yet

- SPE-15103-PA - Prediction of Slug Length in Horizontal Large-Diameter PipesDocument6 pagesSPE-15103-PA - Prediction of Slug Length in Horizontal Large-Diameter PipesMubarik AliNo ratings yet

- One Pipe Steam DesignDocument44 pagesOne Pipe Steam Designreyes hernandezNo ratings yet

- Reciprocating PumpDocument43 pagesReciprocating PumpSudeesh SudevanNo ratings yet

- Lecture #12: Distillation Column Design-ContinueDocument7 pagesLecture #12: Distillation Column Design-ContinueAbdul MoeedNo ratings yet

- VAG Non-Return Valves: The Optimum Valve For Each MediumDocument4 pagesVAG Non-Return Valves: The Optimum Valve For Each MediumAhmedRamadanNo ratings yet

- 2020-Dec CHD-413 93Document1 page2020-Dec CHD-413 93Sahil ChoudharyNo ratings yet

- Ba 86LDocument2 pagesBa 86LAQUILES CARRERA100% (1)

- Sim2Cool A Two-Phase Cooling System Simulator and Design ToolDocument10 pagesSim2Cool A Two-Phase Cooling System Simulator and Design ToolZahid MaqboolNo ratings yet

- CTV Compressor Component WeightsDocument1 pageCTV Compressor Component WeightsTrane De Colombia SANo ratings yet

- Centrate TreatmentDocument11 pagesCentrate TreatmentAnonymous U9hjjuSwBkNo ratings yet

- Pressure ReliefDocument124 pagesPressure ReliefFrancis5801No ratings yet

- Shell and Tube Type Heat Exchanger Explained - saVReeDocument7 pagesShell and Tube Type Heat Exchanger Explained - saVReenuvvnak nachaNo ratings yet

- Hydraulics 2 exam questionsDocument4 pagesHydraulics 2 exam questionsLeoChok100% (1)

- T Sheet - Branchwise: Course/Sem: II B.TECH II SEMESTER Regular Examinations (R18) Held In: July 2021Document50 pagesT Sheet - Branchwise: Course/Sem: II B.TECH II SEMESTER Regular Examinations (R18) Held In: July 2021LE 335 P NAVEENNo ratings yet

- Fluid MechanicsDocument62 pagesFluid Mechanicss.yosores.janchristineNo ratings yet

- Gas Lift Pittman - para Revisar PDFDocument8 pagesGas Lift Pittman - para Revisar PDFedi agurto carrascoNo ratings yet