Professional Documents

Culture Documents

5S - Sorting

Uploaded by

PLASTIC LAB CBD0 ratings0% found this document useful (0 votes)

7 views3 pages5S - Sorting

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document5S - Sorting

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views3 pages5S - Sorting

Uploaded by

PLASTIC LAB CBD5S - Sorting

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

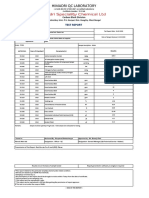

Plastic Lab: 5S Implementation

Date: _________________

Location: ______________ Category: Sorting

Area/ Item/ Picture Picture Remarks

Location S. No Check List Equipments Sorting Out taken taken

before? after?

Room A Excessive reagents;

unnecessary kits;

1 Table defective kits retained in

area; extra parts;

specimens piling up

Unused instruments in

the lab?

Equipment

Transport equipment

stored in work cell?

Unnecessary tables,

cabinets, files, shelves

Tools etc. present?

Unnecessary tools?

Everything in its place?

Extra gloves stored in

Supplies work area? Withdrawal

of extra gloves?

Extra/duplicate forms,

office supplies clutter

area; absence/obsolete

Documents

standard work sheets;

obsolete procedure

manuals

Parts and reagent

containers labeled?

Containers

Cabinets, files, shelves,

etc. labeled?

Storage locations

marked? Safety

Stabilize/ equipment accessible

Set in and identified? Outsider

Locations

Order can understand workflow

“Arranging and process visually?

needed Items can be located

items so immediately?

that they Designated and clearly

Aisles,

are easy to marked?

Floors

use and Clear of obstructions?

labeling Properly stored?

them so Quality standards visible

that they New and clear?

are easy to Specimens, Designated location for

find and SIP, each item visually

put away.” Completed defined?

Specimens Designated locations for

untested, tested, and

completed specimens?

Equipment, Clearly marked and

tools, accessible?

supplies Easy to locate/replace

Plastic Lab: 5S Implementation

for anyone?

Supplies maintained and

controlled?

Min/max levels marked

and visible?

Designated posting

areas?

Visible to operators?

Documents,

Visible to anyone

standards,

auditing the work cell?

charts,

Continual evaluation of

instructions

methods and process to

implement

improvements?

Equipment clean and

orderly?

Equipment

Cleaning performed

regularly and recorded?

Specimens put away in

timely fashion?

Specimens

Spills properly

addressed?

Shine Supplies maintained and

“Clean properly labeled?

Supplies

work areas Supplies kept separate

improve from specimens?

employee Counter tops clean and

morale and orderly? Spill kits

keep available?

Work areas

unneeded Disinfectant bottles

materials filled? Paper towels

out of the available?

workcell.” All tools clean and

properly stored?

Tools Tools cleaned on a

regular basis? Cleaning

recorded?

Documents are clean

and serum-free?

Documents

Cleaning records are

well maintained?

(Continued)

Date: _________________

Location: ______________ Good: 3

Needs Improvement: 2

Not Good: 1

Category Check Item Evaluation Criteria Evaluation

Materials are stored and handled according to standard

Materials

procedures?

Standardize

“Everybody Equipment is maintained and operated according to standard

Equipment

performs all procedures?

operations the The right tool is used at the right time?

same way every Tools

Tools are properly stored?

time.”

Supplies Supplies used properly and as intended?

Plastic Lab: 5S Implementation

Documentation of standard procedures is visible in the work cell.

Documents Results are promptly reported.

New methods are continually proposed and tested.

Clean and unobstructed?

Workspace

Everything in its place?

Sustain

“All workers in All personnel have read and understand standard work?

Laboratorians

the cell Personnel are actively pursuing process improvements?

understand Specimen All specimens are handled in a safe manner?

where things Handling Specimens are properly and promptly stored when complete?

go, what to do,

and when to do Documents, Operators understand and utilize the documents posted in the work

it.” standards, cell. Scheduled maintenance is performed and documented. Work

charts, improvement processes have been implemented. Results are

instructions promptly reported.

Proposed By: ______________ Verified By: ______________

Date: ______________ Date: ______________

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Child Support Agency - CSA Ccjs No Lawful JurisdictionDocument6 pagesChild Support Agency - CSA Ccjs No Lawful JurisdictionChild Support Agency.85% (13)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cape 2003 Answers For Module 1 Structured Questions by Edlin Rochford Author of The Textbook Communication Studies: Preparing Students For CAPEDocument7 pagesCape 2003 Answers For Module 1 Structured Questions by Edlin Rochford Author of The Textbook Communication Studies: Preparing Students For CAPEedlinrochford853367% (6)

- Coca-Cola Bottlers v. Ilocos Professional (G.R. No. 193798. September 9, 2015.)Document1 pageCoca-Cola Bottlers v. Ilocos Professional (G.R. No. 193798. September 9, 2015.)Emmanuel Alejandro YrreverreIiiNo ratings yet

- Liability of Intermediaries Under Information Technology ActDocument5 pagesLiability of Intermediaries Under Information Technology ActArnab ChatterjeeNo ratings yet

- Listening Skills IeltsDocument4 pagesListening Skills IeltsReynalda DessyriantiNo ratings yet

- Legal Ethics 2nd Exam CompilationDocument11 pagesLegal Ethics 2nd Exam CompilationTin CaddauanNo ratings yet

- Cdi 1 - Slide 86 - 110Document24 pagesCdi 1 - Slide 86 - 110Cristine AvancenaNo ratings yet

- Special Sample OF 14-2020Document1 pageSpecial Sample OF 14-2020PLASTIC LAB CBDNo ratings yet

- ASTM D1510 - I2 No PDFDocument8 pagesASTM D1510 - I2 No PDFPLASTIC LAB CBDNo ratings yet

- RCT - 1963CB Dispersion On Mechanical Properties of RubberDocument2 pagesRCT - 1963CB Dispersion On Mechanical Properties of RubberPLASTIC LAB CBDNo ratings yet

- Effect of New Generation Blacks On Rubber VulcanizatesDocument12 pagesEffect of New Generation Blacks On Rubber VulcanizatesPLASTIC LAB CBDNo ratings yet

- MRG - D R.sirDocument30 pagesMRG - D R.sirPLASTIC LAB CBDNo ratings yet

- Brochure High Performance Carbon Blacks For Automotive Weather Stripping Asia RegionDocument12 pagesBrochure High Performance Carbon Blacks For Automotive Weather Stripping Asia RegionPLASTIC LAB CBDNo ratings yet

- Certain Types of Carbon Black Used in TiresDocument2 pagesCertain Types of Carbon Black Used in TiresPLASTIC LAB CBDNo ratings yet

- Spheron 6000ADocument2 pagesSpheron 6000APLASTIC LAB CBDNo ratings yet

- SpheronDocument1 pageSpheronPLASTIC LAB CBDNo ratings yet

- FTIR SpectrosDocument11 pagesFTIR SpectrosPLASTIC LAB CBDNo ratings yet

- Fundamentals of Carbon BlackDocument6 pagesFundamentals of Carbon BlackPLASTIC LAB CBDNo ratings yet

- Insights On DispersionDocument3 pagesInsights On DispersionPLASTIC LAB CBDNo ratings yet

- Rubbercon PresentationDocument35 pagesRubbercon PresentationPLASTIC LAB CBDNo ratings yet

- Application of Industrial Black 24112017Document65 pagesApplication of Industrial Black 24112017PLASTIC LAB CBDNo ratings yet

- Nur Ainaa Amirah Binti Shahrulnizam - phm213010Document16 pagesNur Ainaa Amirah Binti Shahrulnizam - phm213010ainaa amirahNo ratings yet

- Internal Assessment: Design Project - Design Technology - 2019-2021Document8 pagesInternal Assessment: Design Project - Design Technology - 2019-2021Kenny HsuNo ratings yet

- Family StressDocument36 pagesFamily StressGuadalupe PérezNo ratings yet

- Northville VI Elementary School SPG Gawad SiklabDocument26 pagesNorthville VI Elementary School SPG Gawad SiklabSillano Eina MAeNo ratings yet

- Impact Factor and Citation Metrics: What Do They Really Mean?Document38 pagesImpact Factor and Citation Metrics: What Do They Really Mean?Islam HasanNo ratings yet

- Capacity and Level of ServiceDocument5 pagesCapacity and Level of ServiceArstuNo ratings yet

- Guard Group, PakistanDocument7 pagesGuard Group, PakistanMubeen JafriNo ratings yet

- 3BSE030430-510 en 800xa For Advant Master 5.1 Graphic Library PDFDocument566 pages3BSE030430-510 en 800xa For Advant Master 5.1 Graphic Library PDFJohn Sundar RajNo ratings yet

- ROCKETSAN 2018-05 No 5Document32 pagesROCKETSAN 2018-05 No 5F16VIPERNo ratings yet

- Technicalities and Scoring of Running and Splinting: Athleti CSDocument50 pagesTechnicalities and Scoring of Running and Splinting: Athleti CSRhea Mae Fernando OberesNo ratings yet

- Diploma in Tourism ManagementDocument8 pagesDiploma in Tourism ManagementAIDA HUSNA AWALLUDIN (AS)No ratings yet

- The Artist-Teacher: Models of Experiential Learning: G. James DaichendtDocument19 pagesThe Artist-Teacher: Models of Experiential Learning: G. James DaichendtMauricio Ríos100% (1)

- It EssayDocument2 pagesIt EssayMC DOMINIC QUIANZONNo ratings yet

- Courses - Mit SDMDocument4 pagesCourses - Mit SDMRahul SahaiNo ratings yet

- State Common Entrance Test CellDocument1,373 pagesState Common Entrance Test CellPRANAV HATWARNo ratings yet

- Chapter 1 - ExercisesDocument3 pagesChapter 1 - ExercisesBatool AliNo ratings yet

- Into The 21st CenturyDocument11 pagesInto The 21st CenturyJhaga PotpotNo ratings yet

- Question 2Document4 pagesQuestion 2Soumya SharmaNo ratings yet

- What Is QualityDocument3 pagesWhat Is Qualitysubhash kumar1958100% (2)

- Camarines Norte State College: Ret. Judge Antonio C. Entienza CampusDocument4 pagesCamarines Norte State College: Ret. Judge Antonio C. Entienza CampusAlyn Cabañal AlmazarNo ratings yet

- Potential: 100% Online MBA Programs 2020 - 2021Document22 pagesPotential: 100% Online MBA Programs 2020 - 2021Sydney Bwalya ChiyungiNo ratings yet

- Organization Change & Development: Nature of Planned ChangeDocument29 pagesOrganization Change & Development: Nature of Planned ChangeKh Aqeel FarooqiNo ratings yet

- TTD Beyond Teaching Training - HLT MagDocument5 pagesTTD Beyond Teaching Training - HLT MagSteve DarnNo ratings yet