Professional Documents

Culture Documents

017-W004-2667 - ITP - Statnamic Test Rev C0 PDF

017-W004-2667 - ITP - Statnamic Test Rev C0 PDF

Uploaded by

Mohammad Hadoumi SaldanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

017-W004-2667 - ITP - Statnamic Test Rev C0 PDF

017-W004-2667 - ITP - Statnamic Test Rev C0 PDF

Uploaded by

Mohammad Hadoumi SaldanCopyright:

Available Formats

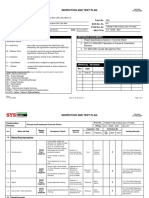

Form No.

INSPECTION AND TEST PLAN 017-F023-2667

Procurement and Construction of New LNG Jetty (Berth 4)

Project Name:

at Bintulu Port, Sarawak Project No.: 2667

Owner / Owner’s Rep.: Petronas LNG 9 Sdn Bhd / Konsultant SHC Sdn Bhd MLNG Doc. No.: N/A

Contractor: SYS – MCD Joint Venture PLNG9 Doc. No.: TRAIN9-P18B-SYMCD-QAC-ITP-0006

Construction Process: Statnamic Load Test Date: 24 June 2015 SMJV ITP No: 017 - W004 - 2667

LEGEND REFERENCE DOCUMENTS

1. Project Specifications Section 3 “Pile Installations”

Verification Activity

2. CEP 017-V004-2667 Statnamic Load Test

H – Hold Point - work shall not proceed past the Hold Point until

released by the organisation imposing the Hold Point. 3. 017-M003-2667 Quality Management Plan

W – Witness Point - an inspection point that may be witnessed by the

organisation imposing the Witness Point.

X – Inspection - formal inspection activity to be undertaken and

recorded.

S – Surveillance - an activity that is subject to ongoing monitoring.

R – Review - review of text reports/records or other evidence of APPROVAL / REVISION

compliance. Prepared Approved

Rev Date Details

Responsible Inspectorate (RI) (may be modified to meet site specific requirements) By By

MCD – McConnell Dowell C0 15/06/24 Issued for Approval ROC BMC

PM – Project Manager

CM – Construction Manager

DEM – Design / Engineering Manager

PE – Project Engineer

SE – Site Engineer

SUR - Surveyor

SQN – Subcontractor Quality Nominee

PQMR – Project Quality Management Representative

CLIENT– Owner / Owner’s Representative

017-F023-2667 Rev0 24 June 2015 Page 1 of 4

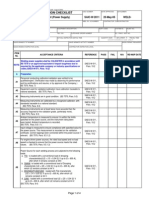

Form No.

INSPECTION AND TEST PLAN 017-F023-2667

Construction Proj. No.: TRAIN9-P18B-SYMCD-QAC-ITP-0006

Statnamic Load Test

Process: ITP No.: 017 – W004 - 2667 Rev C0

Inspection / Test Verification By

Respon- Applicable

Item Basic Job Step Acceptance Criteria Standard Sub- Verifying Records

sibility Method Frequency SMJV Client

Con

1.0 Site Testing Personnel

As

Section 3 – Pile 017-F009-2667Vendor

1.1 Testing Operator Agency Lab. Tech. Approved Testing Agency Approval determined R R

Installation S3.8.5 Approval Request

by Owner

2.0 Statnamic Testing of Test Piles

Identified by the owner

Pile

All the necessary cables is selected

Preparation of pile for statnamic Method Statement 017-F002-2667 Request for

2.1 in place and secured Inspect for X X

testing ASTM D1143 Inspection Notice

statnamic

As per approved method testing

statement

Gravel structure base frame

Pile

position is in place and

selected

Setting up the gravel structure levelled Method Statement 017-F002-2667 Request for

2.2 Inspect for X X

base frame ASTM D1143 Inspection Notice

statnamic

Laser window is clearly

testing

visible from side window

017-F023-2667 Rev0 24 June 2015 Page 2 of 4

Form No.

INSPECTION AND TEST PLAN 017-F023-2667

Construction Proj. No.: TRAIN9-P18B-SYMCD-QAC-ITP-0006

Statnamic Load Test

Process: ITP No.: 017 – W004 - 2667 Rev C0

Inspection / Test Verification By

Respon- Applicable

Item Basic Job Step Acceptance Criteria Standard Sub- Verifying Records

sibility Method Frequency SMJV Client

Con

Fuel charge is properly

installed

Cylinder is clean, greased

and seal

Reaction masses is properly

placed onto the cylinder

Gravel structure bolts is Pile

secured, level selected

Final check prior to proceed to Method Statement 017-F002-2667 Request for

2.3 PE Inspect for X X

statnamic test ASTM D1143 Inspection Notice

Aggregates is level and statnamic

even testing

Data acquisition cable

connected and secured

Check input data, trigger

level is check, laser position

is ok, load cell reading is ok,

earth wire is connected

Tested to 200% of pile

design compression load as

PE / Third Section 3 – Pile As 017-F002-2667 Request for

follows:

2.4 Statnamic test Party Lab. Installation S3.8.2; Test determined X R Inspection Notice , Test

- 1100mm Dia. - 5000 KN

Tech. ASTM D1143 by Owner Report

- 800mm Dia. - 2500 KN

- 600mm Dia. - 1500 KN

017-F023-2667 Rev0 24 June 2015 Page 3 of 4

Form No.

INSPECTION AND TEST PLAN 017-F023-2667

Construction Proj. No.: TRAIN9-P18B-SYMCD-QAC-ITP-0006

Statnamic Load Test

Process: ITP No.: 017 – W004 - 2667 Rev C0

Inspection / Test Verification By

Respon- Applicable

Item Basic Job Step Acceptance Criteria Standard Sub- Verifying Records

sibility Method Frequency SMJV Client

Con

3.0 Quality Records

Statnamic tested pile driving Complete, properly signed Section 3 – Pile Statnamic

3.1 PE/ PQMR Visual R R Pile driving record forms

records are submitted off and submitted Installation S3.4.3 tested pile

Valid Calibration Certificate Calibration Prior to

3.2 Gauges Calibration PE Visual R R Calibration Certificate

is available Procedure proceed

Drawings showing actual

positions, inclination and

eccentricity at pile cut off

level

Off Center Deviation

Horizontal: ± 100mm all

Section 3 – Pile Statnamic As built drawing duly

3.3 Tested Pile As built drawings PE direction Visual R

Installation S3.7.4 tested pile endorsed by Surveyor

Verticality Tolerances ≤1:50

Rake Tolerances ≤ 1:25

Pile Head Elevation : Equal

or above Cut of Level

017-F023-2667 Rev0 24 June 2015 Page 4 of 4

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2c201 - 164e - B.PDF Sgi To PCDocument72 pages2c201 - 164e - B.PDF Sgi To PCkatabalwa eric100% (2)

- Sae Arp 5483-8 2002 (En) PDFDocument9 pagesSae Arp 5483-8 2002 (En) PDFWilliam LooNo ratings yet

- Mud Pump - High Pressure Lines PDFDocument7 pagesMud Pump - High Pressure Lines PDFKaleem UllahNo ratings yet

- MOS Roof Truss InstallationDocument19 pagesMOS Roof Truss InstallationMohammad Hadoumi Saldan100% (9)

- ITPDocument11 pagesITPMohammad Hadoumi Saldan100% (1)

- Rock ExcavationDocument9 pagesRock ExcavationMohammad Hadoumi SaldanNo ratings yet

- A2. PLS 140106 A G MST 001 - Architectural Method Statement - REV 0.2Document60 pagesA2. PLS 140106 A G MST 001 - Architectural Method Statement - REV 0.2Mohammad Hadoumi SaldanNo ratings yet

- QAQC FormDocument26 pagesQAQC FormMohammad Hadoumi Saldan100% (1)

- QAQC Form - ArchitechtureDocument42 pagesQAQC Form - ArchitechtureMohammad Hadoumi SaldanNo ratings yet

- Inspection ChecklistDocument1 pageInspection ChecklistMohammad Hadoumi Saldan100% (1)

- ITP Piling WorksDocument4 pagesITP Piling WorksMohammad Hadoumi Saldan100% (2)

- PLS150129-SBY-A-MST-AW-0001 V0.2 Door Window Louvres Installation Works PDFDocument16 pagesPLS150129-SBY-A-MST-AW-0001 V0.2 Door Window Louvres Installation Works PDFMohammad Hadoumi SaldanNo ratings yet

- PLS150129-SBY-A-MST-AW-0001 V0.2 Door Window Louvres Installation Works PDFDocument16 pagesPLS150129-SBY-A-MST-AW-0001 V0.2 Door Window Louvres Installation Works PDFMohammad Hadoumi SaldanNo ratings yet

- MOS - Electrical ServicesDocument17 pagesMOS - Electrical ServicesMohammad Hadoumi SaldanNo ratings yet

- MOS - Fire FightingDocument23 pagesMOS - Fire FightingMohammad Hadoumi SaldanNo ratings yet

- Notification LetterDocument2 pagesNotification LetterMohammad Hadoumi SaldanNo ratings yet

- 017-W009-2667 - ITP - Precast & Prestressed Concrete - Revc0 PDFDocument9 pages017-W009-2667 - ITP - Precast & Prestressed Concrete - Revc0 PDFMohammad Hadoumi Saldan100% (1)

- MOS - PlumbingDocument19 pagesMOS - PlumbingMohammad Hadoumi SaldanNo ratings yet

- MOS DrainageDocument16 pagesMOS DrainageMohammad Hadoumi Saldan100% (1)

- THERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE Baths Cal926 PDFDocument7 pagesTHERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE Baths Cal926 PDFGustavo SánchezNo ratings yet

- Electrofusion Jointing of Pe Pipe and Fittings For Pressure ApplicationsDocument31 pagesElectrofusion Jointing of Pe Pipe and Fittings For Pressure ApplicationsMohammed sabatinNo ratings yet

- Manual Cobas C311 PDFDocument356 pagesManual Cobas C311 PDFmuhammad iqbal77% (22)

- Saic W 2011rev 0Document4 pagesSaic W 2011rev 0fariboy123No ratings yet

- QAQC Monthly ReportDocument52 pagesQAQC Monthly ReportMohammad Hadoumi Saldan80% (5)

- RIB and Bond Interp PDFDocument24 pagesRIB and Bond Interp PDFroybert arcia100% (1)

- 017-W005-2667 - ITP - PDA Test Rev C0Document3 pages017-W005-2667 - ITP - PDA Test Rev C0Mohammad Hadoumi SaldanNo ratings yet

- Piling Work Mock-Up ReportDocument5 pagesPiling Work Mock-Up ReportMohammad Hadoumi SaldanNo ratings yet

- Nonconformity Report TemplateDocument2 pagesNonconformity Report TemplateMohammad Hadoumi Saldan100% (1)

- MOS Leakage TestDocument2 pagesMOS Leakage TestMohammad Hadoumi Saldan100% (1)

- TCTDocument1 pageTCTMohammad Hadoumi SaldanNo ratings yet

- Materials Delivery RegisterDocument2 pagesMaterials Delivery RegisterMohammad Hadoumi SaldanNo ratings yet

- EMAR 01 Rev01 FINALDocument12 pagesEMAR 01 Rev01 FINALEduardNo ratings yet

- ASTM Pump Test MethodDocument3 pagesASTM Pump Test MethodAlberto GranadosNo ratings yet

- Thermo Tank - ManualDocument42 pagesThermo Tank - ManualGustavo Salguero MoralesNo ratings yet

- Service Manual Asc 1000Document81 pagesService Manual Asc 1000Alejandro DelgadoNo ratings yet

- Pet-Cal-Std-034 Cr511e - Cirrus Acoustic CalibratorDocument13 pagesPet-Cal-Std-034 Cr511e - Cirrus Acoustic CalibratorCALIBRATION TRACKINGNo ratings yet

- Prosedur Testing Ball Valve KVCDocument4 pagesProsedur Testing Ball Valve KVCAl Hamra Ayashofiya100% (1)

- Raymarine Evolution Autopilot p70 p70r ManualDocument4 pagesRaymarine Evolution Autopilot p70 p70r ManualHudson Marine ElectronicsNo ratings yet

- HI98100 Checker Plus InstMan 1p0 0615Document2 pagesHI98100 Checker Plus InstMan 1p0 0615Phuc DVNo ratings yet

- Distek 6100Document2 pagesDistek 6100SutarnoNo ratings yet

- Marine Tank Level GaugeDocument4 pagesMarine Tank Level GaugeAmenNo ratings yet

- NMKL Procedure No. 8, 4. Ed. (2008) : OntentsDocument33 pagesNMKL Procedure No. 8, 4. Ed. (2008) : OntentsTrầnXuânSơnNo ratings yet

- Lab Report Experiment 10 CHM3100Document8 pagesLab Report Experiment 10 CHM3100Nurin BatrisyiaNo ratings yet

- D 2791 - 93 R01 - Rdi3oteDocument10 pagesD 2791 - 93 R01 - Rdi3oteGyna SHNo ratings yet

- DTI-1000 STS-050, - 100,-102: Digital Temperature Indicator and STS Reference SensorsDocument10 pagesDTI-1000 STS-050, - 100,-102: Digital Temperature Indicator and STS Reference Sensorssara kubikaNo ratings yet

- Pin Brinell Hardness Tester Spec SheetDocument2 pagesPin Brinell Hardness Tester Spec SheetMelissa MurrayNo ratings yet

- Frequency CounterDocument12 pagesFrequency CounterArun Muthu Chelvan100% (1)

- I.C.T Online Jet Dispensing MachineDocument4 pagesI.C.T Online Jet Dispensing MachineLouis ChewNo ratings yet

- TESA REFLEX Panel Product Presentation V1 ENDocument24 pagesTESA REFLEX Panel Product Presentation V1 ENJilluNo ratings yet

- Iso 4267-2Document38 pagesIso 4267-2Haytham DiaaNo ratings yet

- Academic Calibration Procedure: Higher Education Standards Framework (Threshold Standards)Document9 pagesAcademic Calibration Procedure: Higher Education Standards Framework (Threshold Standards)Rt SaragihNo ratings yet

- Verilum® 5.2: Video Display Calibration and Conformance TrackingDocument19 pagesVerilum® 5.2: Video Display Calibration and Conformance TrackingleagagaNo ratings yet

- Strain-Controlled Fatigue Testing: Standard Test Method ForDocument16 pagesStrain-Controlled Fatigue Testing: Standard Test Method ForNilton SantillanNo ratings yet