Professional Documents

Culture Documents

TDS VDSL

Uploaded by

Abdel Baziir Ekong0 ratings0% found this document useful (0 votes)

47 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views1 pageTDS VDSL

Uploaded by

Abdel Baziir EkongCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

VOLTEX® DSL

BENTONITE GEOTEXTILE WATERPROOFING SYSTEM

VOLTEX DSL DESCRIPTION

Voltex DSL is a sodium bentonite-based waterproofing barrier with a HDPE laminate for improved

performance.The bentonite is contained between two geotextile carriers, which are needle punched to prevent

movement of the bentonite during construction and handling. This type of package also prevents the product

from being damaged by moisture.

TECHNICAL DATA SHEET

PROPERTIES TEST METHOD FREQUENCY TYPICAL VALUE

BENTONITE PROPERTIES

Bentonite Swell Index1 ASTM D 5890 1/100,000 lb (1/50,000kg) ≥ 24 ml/2 g

1

Bentonite Fluid Loss ASTM D 5891 1/100,000 lb (1/50,000kg) ≤ 18 ml

FINISHED GCL PROPERTIES

Bentonite Mass2 per unit ASTM D 5993 1/30,000 ft2 (1/3,000m2) ≥ 2400 g/sq. m

3 2 2

Peel Strength ASTM D 6496 1/30,000 ft (1/3,000m ) ≥ 6.1 N/cm

3 2 2

Grab Tensile Strength ASTM D 6768 1/30,000 ft (1/3,000m ) ≥ 70 N/cm

4

Permeability (D = 100 mm) ASTM D 5084 Weekly ≤ 5.0 x 10-10 cm/sec

Index Flux4 ASTM D 5084 Weekly ≤ 1.0 x 10-9 m3/m2/sec

GEOTEXTILE PROPERTIES

Non-Woven Geotextile Mass ASTM D 5261 1/200,000 ft2 (1/20,000m2) ≥ 200 g/sq. m

2 2

Woven Geotextile Mass ASTM D 5261 1/200,000 ft (1/20,000m ) ≥ 110 g /sq. m

ROLL DIMENSIONS

Width × Length5 Typical Every Roll 40m × 5 m

Area per Roll Typical Every Roll 200 m2

Package Weight Typical Every Roll 750 kg

Package Typical Every Roll PE film

Notes:

1. Bentonite property tests performed at CETCO’s bentonite processing facility before shipment to CETCO’s GCL production facilities.

2. Bentonite mass/ unit area reported at 0% percent moisture content.

3. All tensile testing is performed in the machine direction using ASTM D 6768 with results as minimum average roll values unless otherwise indicated. All peel strength testing is

performed using ASTM D 6496. Upon request, tensile and peel results can be reported per modified ASTM D 4632 using 4 inch grips.

4. Index flux and permeability testing with desired distilled/ deionized water at 80psi (551 kPa) cell pressure, 77 psi (531 kPa) headwater pressure and 75 psi

(517 kPa) tail water pressure. Flux and permeability values above should not be used for equivalency calculations unless the pressures and gradients used

represent field conditions.

5. Roll width and lengths have a tolerance of ±1%.

This information is provided for reference purposes only and is not intended as a warranty or guarantee. CETCO assumes no liability in connection with the use of

this information. Please check with CETCO for current, standard minimum quality assurance procedures and specifications.

WWW.CETCO.COM

You might also like

- Technical Data Sheet Eurobent Nt-35 (Zakładka)Document1 pageTechnical Data Sheet Eurobent Nt-35 (Zakładka)Dannyamil AriasNo ratings yet

- Bentomat STDocument1 pageBentomat STDanilo Rojas MartinezNo ratings yet

- Specifications For Geotextiles in India: by R. P. Indoria 19 November 2010Document42 pagesSpecifications For Geotextiles in India: by R. P. Indoria 19 November 2010Sandeep MeruguNo ratings yet

- Hdpe LinerDocument15 pagesHdpe LinerDaniel MartinezNo ratings yet

- HD Smooth Geomembrane Technical Data SheetDocument1 pageHD Smooth Geomembrane Technical Data SheetAndreas Erdian WijayaNo ratings yet

- Non Woven, Needle Punched, Staple FiberDocument2 pagesNon Woven, Needle Punched, Staple FiberAnonymous MAQrYFQDzVNo ratings yet

- Flexamat Spec SheetDocument5 pagesFlexamat Spec SheetJamesNo ratings yet

- Ficha Tecnica Polietileno Chemium Hdpe 2285 (7000f)Document1 pageFicha Tecnica Polietileno Chemium Hdpe 2285 (7000f)Carlos SiuNo ratings yet

- Fibre-Reinforced Geosynthetic Clay Liner (GBR-C) Bentofix® NSP 4000Document1 pageFibre-Reinforced Geosynthetic Clay Liner (GBR-C) Bentofix® NSP 4000Luis Alberto GutiérrezNo ratings yet

- Sikalastic®-632: Product Data SheetDocument5 pagesSikalastic®-632: Product Data SheetShanaei MiskinNo ratings yet

- 0.8mm THK Pennar Metal Deck PropertiesDocument4 pages0.8mm THK Pennar Metal Deck PropertiesSathwik kattaNo ratings yet

- Benfelt 48 140820182 Extended Version 09 2022Document2 pagesBenfelt 48 140820182 Extended Version 09 2022MarijaRRRRNo ratings yet

- DR.FIXIT FASTFLEX HIGH-QUALITY FLEXIBLE WATERPROOFINGDocument5 pagesDR.FIXIT FASTFLEX HIGH-QUALITY FLEXIBLE WATERPROOFINGSwapnil JadhavNo ratings yet

- TDS of Energy C3N-6004B120-BL 13sDocument1 pageTDS of Energy C3N-6004B120-BL 13sCesar PereiraNo ratings yet

- Geomembrane Technical DataDocument1 pageGeomembrane Technical DataYusufAliMuktiNo ratings yet

- Lldpe - LL7410D PDSDocument1 pageLldpe - LL7410D PDSchinchotarngNo ratings yet

- HDPE Smooth Geomembrane Technical Data SheetDocument1 pageHDPE Smooth Geomembrane Technical Data SheetAgun GunawanNo ratings yet

- FGI PVC Geomembrane Specification: Effective January 1, 2017Document3 pagesFGI PVC Geomembrane Specification: Effective January 1, 2017Paul Alex Quiroz BarrionuevoNo ratings yet

- TDS of Libra-5004B120-BL 13sDocument1 pageTDS of Libra-5004B120-BL 13selojaesquivelNo ratings yet

- General PropertiesDocument2 pagesGeneral PropertiesIsrael ExporterNo ratings yet

- Polyethylene GeomembranesDocument18 pagesPolyethylene GeomembranesPalo DushiiNo ratings yet

- Sikawrap 300 cDocument5 pagesSikawrap 300 cAkram ShakirNo ratings yet

- 23882Document1 page23882skiu paket 31No ratings yet

- 3m VHB Tape 5958frDocument9 pages3m VHB Tape 5958frDonald A HuntNo ratings yet

- High Density Film Grade Excellent StrengthDocument1 pageHigh Density Film Grade Excellent StrengthRPM28XINo ratings yet

- Sikawrap®-300 C: Product Data SheetDocument4 pagesSikawrap®-300 C: Product Data SheetHenri DormoyNo ratings yet

- TDS of Stemgrass-5004B120-BL 13sDocument1 pageTDS of Stemgrass-5004B120-BL 13selojaesquivelNo ratings yet

- FT - Chelsea PX2Document1 pageFT - Chelsea PX2Cesar PereiraNo ratings yet

- F7000Document1 pageF7000mohamad mostafaviNo ratings yet

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDocument1 pageCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiNo ratings yet

- GRI-GM30 Specification Coated Tape Polymeric BarriersDocument28 pagesGRI-GM30 Specification Coated Tape Polymeric BarriersГригорий ЛевашовNo ratings yet

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetAgustina De Winne100% (1)

- Ficha Técnica Stemgrass 50mm - Chile PastosDocument1 pageFicha Técnica Stemgrass 50mm - Chile PastosCarlosAlfonsoVasconcelloPeñaNo ratings yet

- BinanizincspecsDocument6 pagesBinanizincspecsJimmy ThomasNo ratings yet

- Self-Adhesive Waterproofing MembranesDocument2 pagesSelf-Adhesive Waterproofing Membraneskhiem44No ratings yet

- Sikawrap - 300 CDocument4 pagesSikawrap - 300 CAlexis KarampasNo ratings yet

- For - Geocells Made From HDPE Strips: GTI-GS15 SpecificationDocument33 pagesFor - Geocells Made From HDPE Strips: GTI-GS15 SpecificationГригорий ЛевашовNo ratings yet

- LFTD PanelDocument39 pagesLFTD PanelErnane RitaNo ratings yet

- PP PP9074MED DatasheetDocument1 pagePP PP9074MED DatasheetDiogo SouzaNo ratings yet

- CARBON FIBER PLATE SPECIFICATIONSDocument2 pagesCARBON FIBER PLATE SPECIFICATIONSPutinNo ratings yet

- PVC SpecDocument2 pagesPVC SpecMuhammad Noor FizuanNo ratings yet

- High Density Polyethylene HDPE Properties ApplicationsDocument1 pageHigh Density Polyethylene HDPE Properties ApplicationsEleannys GarciasNo ratings yet

- LT DiffusersDocument8 pagesLT DiffusersJam OdonelNo ratings yet

- B03 EMIX Putty Product SheetDocument3 pagesB03 EMIX Putty Product SheetAnthony Al LakissNo ratings yet

- Mdpe Dx800: Application / Use CaseDocument1 pageMdpe Dx800: Application / Use CaseJaime222No ratings yet

- MAX 50 Soccer Turf SpecificationDocument1 pageMAX 50 Soccer Turf SpecificationFernando Daga JanampaNo ratings yet

- Trelleborg ATP Ballast Mat BrochureDocument8 pagesTrelleborg ATP Ballast Mat BrochureÜmit KukulaNo ratings yet

- Specifications: FSK JacketingDocument1 pageSpecifications: FSK JacketingMazwan Che MansorNo ratings yet

- Sikasil 728 SLDocument5 pagesSikasil 728 SLJesusFloresRodriguezNo ratings yet

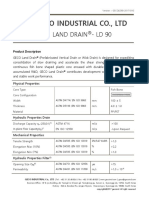

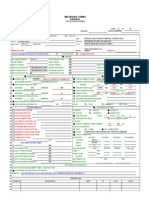

- Geco Industrial Co., LTD: Land Drain - LD 90Document2 pagesGeco Industrial Co., LTD: Land Drain - LD 90Gisella Mariel RubilarNo ratings yet

- SEASHIELD HDPE OUTERCOVER MATERIAL SPECIFICATIONSDocument1 pageSEASHIELD HDPE OUTERCOVER MATERIAL SPECIFICATIONSJorge QuintanaNo ratings yet

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 pagesIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraNo ratings yet

- Sikawrap - 230 CDocument4 pagesSikawrap - 230 CNyein ZawNo ratings yet

- Miratech GT500: Technical Data SheetDocument3 pagesMiratech GT500: Technical Data SheetNicolás CanoNo ratings yet

- MacMat Technical Data SheetDocument1 pageMacMat Technical Data SheetinfoNo ratings yet

- Daftar Spesifikasi Teknis Pembangunan Gedung Kantor BPN BojonegoroDocument6 pagesDaftar Spesifikasi Teknis Pembangunan Gedung Kantor BPN BojonegoroIrwin DarmansyahNo ratings yet

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingFrom EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingNo ratings yet

- PETE 411: Well DrillingDocument38 pagesPETE 411: Well DrillingNes ThanutNo ratings yet

- Introduction To E100Document30 pagesIntroduction To E100Ehsan SalehiNo ratings yet

- 8 U8 LD LangsumDocument227 pages8 U8 LD LangsumJose Manuel Romero ZamoraNo ratings yet

- IPhO 2010 Theo Problem 2Document4 pagesIPhO 2010 Theo Problem 2Cretu NicolaeNo ratings yet

- FSSA Guide to Estimating Pressure Relief Vent AreaDocument1 pageFSSA Guide to Estimating Pressure Relief Vent AreaLaura Galarza100% (1)

- Biopharm 32887Document3 pagesBiopharm 32887Martin ŠimurdaNo ratings yet

- Tubing Conveyed Gauge Carriers Datasheet PDFDocument3 pagesTubing Conveyed Gauge Carriers Datasheet PDFDenier RubianoNo ratings yet

- Vacuum Leaf FilterDocument2 pagesVacuum Leaf FilterGangadharan NagappanNo ratings yet

- Mist Drilling: Soal-Soal PetroleagueDocument9 pagesMist Drilling: Soal-Soal PetroleagueHeri YantoNo ratings yet

- Plate Freezer Performance.Document4 pagesPlate Freezer Performance.Behnam AshouriNo ratings yet

- Distillation Trays That Operate Beyond The Limits of Gravity by Using Centrifugal SeparationDocument6 pagesDistillation Trays That Operate Beyond The Limits of Gravity by Using Centrifugal SeparationdonyaNo ratings yet

- Fluid MechanicsDocument16 pagesFluid MechanicsRaju SinghNo ratings yet

- Solutions DPP 1Document3 pagesSolutions DPP 1Tech. VideciousNo ratings yet

- ENV CBC TG (2022) 25.enDocument23 pagesENV CBC TG (2022) 25.enFlahautNo ratings yet

- Reservoir ExamnDocument9 pagesReservoir ExamnBelén KlixNo ratings yet

- HPK03Document4 pagesHPK03Tan CkNo ratings yet

- Problems FluidsDocument7 pagesProblems FluidsSameer SamaraNo ratings yet

- Gas Well Deliverability Fetkovich PDFDocument33 pagesGas Well Deliverability Fetkovich PDFBarbara_LFCNo ratings yet

- Natural Gas Properties CourseDocument319 pagesNatural Gas Properties CourseJason FerrerNo ratings yet

- DATA SHEET MULTIPHASE PUMP REV0 BornermanDocument5 pagesDATA SHEET MULTIPHASE PUMP REV0 BornermanJessika López100% (1)

- Controlling liquid pipeline surgesDocument6 pagesControlling liquid pipeline surgesalyshahNo ratings yet

- Liquid Recirculation System-2Document7 pagesLiquid Recirculation System-2Behnam AshouriNo ratings yet

- PPPPPPPPDocument102 pagesPPPPPPPPTGX DevilNo ratings yet

- Api 2540Document8 pagesApi 2540biondimi100% (1)

- Beggs and Brill MethodDocument26 pagesBeggs and Brill MethodHassanKMNo ratings yet

- Filtration of Solid and Liquid Aerosol Mixtures: Pressure Drop Evolution and Influence of Solid/liquid RatioDocument3 pagesFiltration of Solid and Liquid Aerosol Mixtures: Pressure Drop Evolution and Influence of Solid/liquid RatiosafiraginaNo ratings yet

- Week 5 Module 17Document23 pagesWeek 5 Module 17Lotheia RosenblumNo ratings yet

- Meivalvole SerieCD ENG 20150212Document4 pagesMeivalvole SerieCD ENG 20150212Marine CaptainNo ratings yet

- Thermo1 Chapter 04Document110 pagesThermo1 Chapter 04Yasser Hijji80% (15)

- Bernoulli PrincipleDocument8 pagesBernoulli PrinciplePrasillaPrisiNo ratings yet