Professional Documents

Culture Documents

Sizing Air Receiver Tank

Uploaded by

Dennis DanielOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sizing Air Receiver Tank

Uploaded by

Dennis DanielCopyright:

Available Formats

SIZING AIR RECEIVER TANK

An air receiver is essential to every compressed air system to act as a buffer and a storage

medium between the compressor and the consumption system. There are in principal two

different air receivers in a compressed air system:

• PRIMARY receiver - located near the compressor, after the after-cooler but before

filtration and drying equipment

• SECONDARY receivers - located close to points of larger intermittent air

consumption

The maximum capacity of the compressor in a well designed systems always exceed

the maximum mean air consumption of the system (maximum mean air consumption is

the mean air consumption over some reasonable time).

Since the maximum capacity of an air compressor also always exceed the minimum air

consumption in the system - the compressor must modulate its capacity during normal work,

often by using primitive strategies as on/off modulating or more advanced strategies as

frequency drives and inverters. Primitive modulating strategies cause more pressure

variations in compressed air systems than more advanced strategies.

In addition, the air consumption vary due to the process supported. In shorter periods the

demand for compressed air may even exceed the maximum capacity of the compressor. In

fact, it is common in well designed systems not to design the compressor for the maximum

peek loads.

Air receivers in compressed air systems serves the important purposes of

• equalizing the pressure variation from the start/stop and modulating sequence of

the compressor

• storage of air volume equalizing the variation in consumption and demand from the

system

In addition the receiver serve the purpose of

• collecting condensate and water in the air after the compressor

Sizing the Air Receiver

The air receiver must in general be sized according

• the variation in the consumption demand

• the compressor size and the modulation strategy

In general it is possible to calculate the maximum consumption in the system by

summarizing the demand of each consumer. The summarized consumption must be

multiplied with a

• usage factor ranging 0.1 - 1

depending on the system. In practice it is common that the manufacturer use standardized

receivers for specific compressor models based on their know-how.

For calculating the receiver, note that it is necessary with a pressure band for the receiver

to be effective. If the consumption process requires 100 psig (6.9 bar) and the compressor is

set to 100 psig, there is no storage and no buffer. Any increased demand will make a

pressure drop below 100 psig until the compressor responds by increasing the air volume

compressed.

If the compressors operates at 110 psig the difference between 110 psig and 100

psig accounts for the air stored in the receiver. If the demand increases, the pressure can

drop 10 psig before the minimum requirement is met. Pressure and flow controllers can be

used after the receiver for stabilizing downstream pressure to 100 psig and flattening

demand peaks. Note that in a compressed air system the pipe work also makes the purpose

of a buffered volume.

There is no generally accepted method of sizing air receivers but a commonly used formula

is based on the mass balance

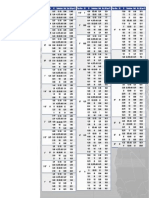

C pa t = V (p1 - p2) (1)

that can be transformed to

t = V (p1 - p2) / C pa (1b)

where

V = volume of the receiver tank (cu ft)

t = time for the receiver to go from upper to lower pressure limits (min)

C = free air needed (scfm)

pa= atmosphere pressure (14.7 psia)

p1 = maximum tank pressure (psia)

p2 = minimum tank pressure (psia)

Example - Sizing an Air Receiver

For an air compressor system with mean air consumption 1000 cfm, maximum tank

pressure 110 psi, minimum tank pressure 100 psi and 5 sec time for the receiver to go from

upper to lower pressure - the volume of the receiver tank can be calculated by

modifying (1) to

V = t C pa / (p1 - p2)

= (5 sec) (1/60 min/sec) (1000 cfm) (14.7 psi) / ((110 psi) - (100 psi))

= 122 ft3

It is also common to size receivers

• to 1 gallon for each ACFM (Actual Cubic Feet per Minute), or

• 4 gallons per compressor hp (horse power)

You might also like

- Sizing The Air ReceiverDocument5 pagesSizing The Air Receiveranon_151761797No ratings yet

- Calculating Receivers in Compressed Air SystemsDocument4 pagesCalculating Receivers in Compressed Air Systemsdharwin100% (1)

- PositiveDisplacementBlowerCalculations Brochuremay2017Document4 pagesPositiveDisplacementBlowerCalculations Brochuremay2017hardik033No ratings yet

- Pneumatic Conveying Spreadsheet-ContentDocument27 pagesPneumatic Conveying Spreadsheet-Contentaladdin4dNo ratings yet

- Dry Vacuum Pump Cobra Busch enDocument2 pagesDry Vacuum Pump Cobra Busch enJessica ChandlerNo ratings yet

- Air Requirements: 2004 by Marcel Dekker, Inc. All Rights ReservedDocument36 pagesAir Requirements: 2004 by Marcel Dekker, Inc. All Rights ReservedGustavo Hernandez100% (1)

- Fans & Blowers - 1Document8 pagesFans & Blowers - 1Santosh BaladhyeNo ratings yet

- PomeDocument17 pagesPomeAnirudh KaushikNo ratings yet

- Gas-Solid Flows: 2004 by Marcel Dekker, Inc. All Rights ReservedDocument36 pagesGas-Solid Flows: 2004 by Marcel Dekker, Inc. All Rights ReservedGustavo Hernandez100% (1)

- Centrifugal Compressor Power-US Field UnitsDocument4 pagesCentrifugal Compressor Power-US Field UnitssurawutwijarnNo ratings yet

- T.E. Mechanical (A-4) MONIL DOSHI-0815054 KIRAN PATIL - 1125027 JIGAR SHAH - 0815045Document19 pagesT.E. Mechanical (A-4) MONIL DOSHI-0815054 KIRAN PATIL - 1125027 JIGAR SHAH - 0815045wahyuNo ratings yet

- 9 Transport of Particles by FluidsDocument8 pages9 Transport of Particles by FluidsArun AppaduraiNo ratings yet

- Learn Instrument SymbolsDocument15 pagesLearn Instrument SymbolsMelody Lolup100% (1)

- Assessment of CompresorsDocument14 pagesAssessment of CompresorsranveerNo ratings yet

- C Module-5 Reciprocating Air Compressors. Reciprocating Compressors - Construction - WorkingDocument48 pagesC Module-5 Reciprocating Air Compressors. Reciprocating Compressors - Construction - WorkingJasraj Gill100% (1)

- KMBD BP(国外罗茨泵ROOTS)Document2 pagesKMBD BP(国外罗茨泵ROOTS)tutuli1990No ratings yet

- Misc Equipment ItemsDocument18 pagesMisc Equipment Itemshk168No ratings yet

- WET AIR TO DRY AIR Types of Dryers.......................................Document8 pagesWET AIR TO DRY AIR Types of Dryers.......................................HARKULVINDER SINGHNo ratings yet

- Recommended Steam Piping Velocities 2Document1 pageRecommended Steam Piping Velocities 2Hassan AbdulAzim FadilNo ratings yet

- Transportasi Fluida (Compressible Fluid-Fan Blower)Document36 pagesTransportasi Fluida (Compressible Fluid-Fan Blower)Evia Salma ZauridaNo ratings yet

- Stepless Variable Capacity ControlDocument7 pagesStepless Variable Capacity Controlswapneel_kulkarniNo ratings yet

- Compressor Selection Criteria: PAGE 1 of 21Document21 pagesCompressor Selection Criteria: PAGE 1 of 21Sabar KumarNo ratings yet

- Compressed Air Energy Efficiency PDFDocument95 pagesCompressed Air Energy Efficiency PDFYASSERHENDY80100% (2)

- Process Equipment Design-1Document15 pagesProcess Equipment Design-1Nikunj Thummar100% (1)

- The Affinity Laws of Centrifugal PumpsDocument8 pagesThe Affinity Laws of Centrifugal PumpsArunkumar SubramanianNo ratings yet

- Compressed Air Velocity CalculatorDocument1 pageCompressed Air Velocity CalculatorLucky Karunia Setyawan PratamaNo ratings yet

- Blowers and Vacuum BoostersDocument6 pagesBlowers and Vacuum BoostersMara RusyadiNo ratings yet

- Kinney Piston Vacuum Pump BrochureDocument18 pagesKinney Piston Vacuum Pump BrochureVivek BelaNo ratings yet

- A Quick Look at Pneumatic Convey Systems Basics-NOL-TECDocument3 pagesA Quick Look at Pneumatic Convey Systems Basics-NOL-TECStacy WilsonNo ratings yet

- Static Pressure Calculation SheetDocument24 pagesStatic Pressure Calculation Sheetsam7sNo ratings yet

- Air Receivers Tech TipDocument3 pagesAir Receivers Tech TipOthman Mat YamanNo ratings yet

- PressorsDocument8 pagesPressorsManoj MisraNo ratings yet

- Twin Screw Vs Centrifugal & Reciprocating ArticleDocument12 pagesTwin Screw Vs Centrifugal & Reciprocating ArticlecaratorresmNo ratings yet

- Pressure Drop in PipelineDocument13 pagesPressure Drop in PipelineNilambar BarihaNo ratings yet

- Assignment Pump and Its PartsDocument19 pagesAssignment Pump and Its PartsSabyasachi PradhanNo ratings yet

- At AssignmentDocument3 pagesAt AssignmentYogesh PatilNo ratings yet

- Compressed Air Distribution SystemsDocument33 pagesCompressed Air Distribution SystemsSamik MukherjeeNo ratings yet

- Brown & Root, Inc.: Centrifugal Compressor Data Sheet (Api 617-6Th) U.S. Customary UnitsDocument12 pagesBrown & Root, Inc.: Centrifugal Compressor Data Sheet (Api 617-6Th) U.S. Customary UnitsPebriyantoNo ratings yet

- Compressor GATE Mechanical EngineerDocument45 pagesCompressor GATE Mechanical Engineersap2279100% (1)

- Lab Manual Cycle 1Document66 pagesLab Manual Cycle 1Kaustubh SatheNo ratings yet

- IA Compressor & SystemDocument51 pagesIA Compressor & SystemKazi Irfan100% (1)

- Net Positive Suction HeadDocument7 pagesNet Positive Suction HeadNenad MutavdzicNo ratings yet

- API 610 - Why BEP Should Be Between Normal Point and Rated PointDocument7 pagesAPI 610 - Why BEP Should Be Between Normal Point and Rated PointMuhammad ImranNo ratings yet

- Condensate PumpsDocument1 pageCondensate Pumpstricky11No ratings yet

- Positive Displacement CompressorsDocument46 pagesPositive Displacement CompressorsMahendra PuguhNo ratings yet

- Reciprocating air compressor guideDocument25 pagesReciprocating air compressor guideRichardt LootsNo ratings yet

- BlowersDocument58 pagesBlowersmahmad61100% (1)

- Centrifugal Compressor NotesDocument23 pagesCentrifugal Compressor NotesSubhash Padmanabhan100% (1)

- Contraction Expansion Pressure Drop CalculatorDocument3 pagesContraction Expansion Pressure Drop CalculatorBubai111No ratings yet

- Pneumatic Conveyor: I. Introduction of Pneumatics and Its ApplicationsDocument11 pagesPneumatic Conveyor: I. Introduction of Pneumatics and Its ApplicationsAbas S. AcmadNo ratings yet

- Air Receivers Volume CalculationDocument123 pagesAir Receivers Volume CalculationsdgthdtrtretNo ratings yet

- 6206 Guide For Selection Installation andDocument32 pages6206 Guide For Selection Installation andakbavra80% (5)

- CH 7. Pneumatic and HydroulicDocument20 pagesCH 7. Pneumatic and HydroulicAbenezer Tasew100% (1)

- Process Design of Compressed Air SystemsDocument19 pagesProcess Design of Compressed Air Systemsавдей александр0% (1)

- Pump DesignDocument10 pagesPump DesignashokrangasamyNo ratings yet

- Gas Compression: A Primer on Rotary CompressorsDocument5 pagesGas Compression: A Primer on Rotary CompressorsLe Anh DangNo ratings yet

- Tanques Pulmon A. ComprimidoDocument4 pagesTanques Pulmon A. ComprimidoYobany López DiazNo ratings yet

- Sizing of Air ReceiverDocument6 pagesSizing of Air Receiverraghu_mn100% (1)

- Centrifugal Air Compressor Basics: Key Concepts, Choke, Surge, CapacityDocument7 pagesCentrifugal Air Compressor Basics: Key Concepts, Choke, Surge, CapacityCésarNo ratings yet

- Why Do You Need An Air Receiver?Document21 pagesWhy Do You Need An Air Receiver?Himanshi SharmaNo ratings yet

- TCD 2 9Document2 pagesTCD 2 9Dennis DanielNo ratings yet

- WEIR SPM TWS600S Pump-ManualDocument41 pagesWEIR SPM TWS600S Pump-ManualDennis Daniel50% (2)

- Battery Sizing CalculationDocument3 pagesBattery Sizing CalculationDennis DanielNo ratings yet

- Paket Internet Haji UmrohDocument4 pagesPaket Internet Haji UmrohAnton SusiloNo ratings yet

- Paket Internet Haji UmrohDocument4 pagesPaket Internet Haji UmrohAnton SusiloNo ratings yet

- Servo Valves TechnicalDocument24 pagesServo Valves Technicalobvert100% (2)

- Day 1 Part 1 - AVR ConceptDocument56 pagesDay 1 Part 1 - AVR ConceptDennis DanielNo ratings yet

- Day 1 Part 2 - AVR ConceptDocument27 pagesDay 1 Part 2 - AVR ConceptDennis DanielNo ratings yet

- Droop Speed My StudiesDocument1 pageDroop Speed My StudiesDennis DanielNo ratings yet

- Day 1 Part 2 - AVR ConceptDocument27 pagesDay 1 Part 2 - AVR ConceptDennis DanielNo ratings yet

- ExpDocument8 pagesExpDennis DanielNo ratings yet

- Im Decs200Document184 pagesIm Decs200Dennis DanielNo ratings yet

- 16 Reason To Change To Static ExciterDocument2 pages16 Reason To Change To Static ExciterDennis DanielNo ratings yet

- ABB UnitrolDocument12 pagesABB UnitrolRogério Ferro Do NascimentoNo ratings yet

- Generator Protection GersDocument186 pagesGenerator Protection GersRaviteja NowduruNo ratings yet

- Waukesha WPS EngomaticsDocument2 pagesWaukesha WPS EngomaticsDennis DanielNo ratings yet

- Redapt Hazardous Area GuideDocument11 pagesRedapt Hazardous Area GuidekarthipetroNo ratings yet

- Generator Fire Supression SystemDocument18 pagesGenerator Fire Supression SystemDennis DanielNo ratings yet

- Voltage Regulation GeneratorsDocument29 pagesVoltage Regulation Generatorsprabhakaran_hdecNo ratings yet

- Waukesha 7101 SpecDocument4 pagesWaukesha 7101 SpecDennis Daniel100% (1)

- Relay Symbols and Fuction NumDocument14 pagesRelay Symbols and Fuction NumPrasanna DharmapriyaNo ratings yet

- Control & Protection Solutions: Control Systems & Products For Process, Engines, Compressors and PumpsDocument105 pagesControl & Protection Solutions: Control Systems & Products For Process, Engines, Compressors and PumpsDennis Daniel100% (1)

- Chapter 13 Section 4 WebsiteDocument9 pagesChapter 13 Section 4 Websiteapi-260037870No ratings yet

- Desco SP7000 Drill Rig Powerful Water Well and Geothermal DrillingDocument4 pagesDesco SP7000 Drill Rig Powerful Water Well and Geothermal DrillingGogot Pantja ParijogoNo ratings yet

- Pipe DiameterDocument1 pagePipe DiameterLeonardo AmpueroNo ratings yet

- Science 8 Unit 4 Mechanical Systems Final Review BookletDocument45 pagesScience 8 Unit 4 Mechanical Systems Final Review BookletKostas KarageorgiouNo ratings yet

- Comprehensive HVAC System Design and Maintenance TrainingDocument8 pagesComprehensive HVAC System Design and Maintenance TrainingSuresh Velu100% (1)

- Product Information on Servo-Hydraulic Load FramesDocument3 pagesProduct Information on Servo-Hydraulic Load FramesAnilNo ratings yet

- Service and Maintenance of Engine TAD1355GEDocument90 pagesService and Maintenance of Engine TAD1355GEЕвгений АрабаджиNo ratings yet

- 1995 Sarawak Water Supply RegulationDocument69 pages1995 Sarawak Water Supply RegulationCheng Siaw HueiNo ratings yet

- Operator'S ManualDocument52 pagesOperator'S ManualAlbertoNo ratings yet

- Packed Column Calculation Results: Packing Details System DetailsDocument1 pagePacked Column Calculation Results: Packing Details System Detailsdinakaranpatel100% (1)

- U of A ANSYS Tutorials - Effect of Self WeightDocument5 pagesU of A ANSYS Tutorials - Effect of Self WeightJean David ChanNo ratings yet

- 3300 Proximity Transducer System: DescriptionDocument18 pages3300 Proximity Transducer System: DescriptionSuvek KumarNo ratings yet

- Nfpa 22 IndexDocument5 pagesNfpa 22 Indexsaladin1977No ratings yet

- Internal External Gear PumpsDocument15 pagesInternal External Gear PumpsAndreDericiNo ratings yet

- Dme 2Document20 pagesDme 2Yogesh DanekarNo ratings yet

- SK Codes of Practice GasesDocument50 pagesSK Codes of Practice GaseseimrehNo ratings yet

- Ground improvement methods classification and principlesDocument89 pagesGround improvement methods classification and principlesMaria TabaresNo ratings yet

- Handbook of Physics - Arihant Aiimsneetshortnotes1Document464 pagesHandbook of Physics - Arihant Aiimsneetshortnotes1VinayNo ratings yet

- X20B3522P07F: Flange Forged Carbon Steel ASME - CL600 WNRF SA 105-N SCH80 8" NPSDocument1 pageX20B3522P07F: Flange Forged Carbon Steel ASME - CL600 WNRF SA 105-N SCH80 8" NPSSathish KumarNo ratings yet

- Investigation of Vibration Isolation Performance of Trench Type Wave BarriersDocument111 pagesInvestigation of Vibration Isolation Performance of Trench Type Wave Barriersonur.toygarNo ratings yet

- Introduction To Computational Fluid DynamicsDocument51 pagesIntroduction To Computational Fluid DynamicsJuma Alaydi100% (1)

- OHB Manual PDFDocument68 pagesOHB Manual PDFLuis Angel Huaratazo HuallpaNo ratings yet

- HVAC ReportDocument5 pagesHVAC ReportrazahNo ratings yet

- Cooling Hyundai ScoupeDocument19 pagesCooling Hyundai ScoupeCanelo BalbinNo ratings yet

- P108Document1 pageP108teban09No ratings yet

- DC LabDocument8 pagesDC LabJohn Cedrik RetardoNo ratings yet

- PCC Small Engine Repair CourseDocument2 pagesPCC Small Engine Repair CourseMyriam ValanNo ratings yet

- AMK DT ServomotorsDocument30 pagesAMK DT ServomotorsPaolo GiorgianniNo ratings yet

- Stop Log Mu - Din - 19569 - 4-bs - 7775 - en - r5Document12 pagesStop Log Mu - Din - 19569 - 4-bs - 7775 - en - r5Arif HakimNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsFrom EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!From EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No ratings yet

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Industrial Waste Treatment HandbookFrom EverandIndustrial Waste Treatment HandbookRating: 5 out of 5 stars5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Grid-Scale Energy Storage Systems and ApplicationsFrom EverandGrid-Scale Energy Storage Systems and ApplicationsFu-Bao WuNo ratings yet

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyFrom EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyRating: 5 out of 5 stars5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Power Quality in Power Systems and Electrical MachinesFrom EverandPower Quality in Power Systems and Electrical MachinesRating: 4.5 out of 5 stars4.5/5 (11)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Biogas Production: Pretreatment Methods in Anaerobic DigestionFrom EverandBiogas Production: Pretreatment Methods in Anaerobic DigestionNo ratings yet