Professional Documents

Culture Documents

Carding Machine Pak Endang

Carding Machine Pak Endang

Uploaded by

Ranu JanuarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carding Machine Pak Endang

Carding Machine Pak Endang

Uploaded by

Ranu JanuarCopyright:

Available Formats

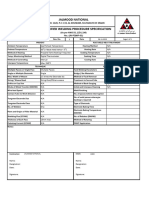

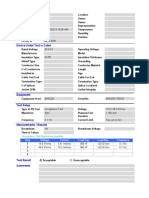

Project Name CAP 2 Doc No.

LATER

Equipment Tag No. LATER Rev 0A

Qty LATER Dated 20-Dec-19

Location Purwakarta Prep. By RJ

General Electric Motor

Number required Later unit Manufacturer ABB / SIEMENS

Equipment Tag Number Later Type TEFC

Parallel operation required No Rated Motor Power By Vendor kW

Machinery Type Carding Machine Frame Size By Vendor

Guaranteed maximum sound level, dB @ 1 m 85 Motor Efficiency Class As min. IE 2

Location Indoor Insulation Class F

Elevation Above Sea Level 86 m Temp. Rise B

Relative Humidity 50 % Degree Of Protection IP 55

Inlet Air Temperature °C 38 C Full Load Speed By Vendor rpm

Tropicalization Required Electrical Supply 380 V / 3 Phase / 50 Hz

Delivered Material FIBER?? Thermal Protection PTC

Operating Condition Space Heater Yes

Cooling System

Type and design of card Flexible card clothing Cooling Water Temp. In 30 C

Rotation speed of the cylinder By Supplier Cooling Water Temp. Out 35 C

Production rate BY FPU Ton/h Cooling Water Flow Rate By Vendor m3/h

Material throughput BY FPU

Raw material type Woven

Fiber characteristics BY FPU Certification & Documentation

Overall quality requirements BY FPU

Card Type Flexible card clothing

Auto Levelling Type Long term auto leveling

Measuring Devices in Carding Active Pneumatic

Carding Angle

Stripping o

Cylinder o

Doffer o

Methods of stripping Vacuum stripper

Grinding

Grinding Methode

Grinding Interval Per Ton

Card Wire Specification

Height of Wire mm

Angle of Wire o

Thickness of Wire mm

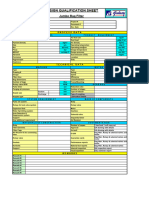

Declaration of Conformity for Machinery Directive

ISO 13849-1:2015 Preview Safety of machinery

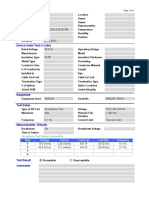

Accessories AHRI 550/590 certified

Soft Starter Required All transmiter to be 4-20 mA

Auotomatic Anti Surge, Hot Gas By

Compressor

Pass, IGV

Pressurize external oil pump with oil

Lubrication System

heater and thermostatically control

Oil Filter Dual Type

Vibration Transmitter For Motor Bearing

Tempearture Transmitter For Motor Bearing

Vibration Transmitter For Compressor Bearing

Temperature Transmitter For Compressor Bearing

Dual PSV Required

Control System Piping Connection

Common PLC Siemens S7 at control room Required Flange ANSI B16.5

Enclosure Material SS 304 L

Remote chiller start and stop Required

Remote leaving chiller liquid temperature adjust Required

Remote current limit set point adjust Required

Remote ready to start contacts Required

Remote Safety shutdown contacts Required

Remote Cycling shutdown contacts Required

Remote Run contacts Required

Dedicated Micro Processor Required

You might also like

- HFT500 Service Manual Rev2.0 20171208Document48 pagesHFT500 Service Manual Rev2.0 20171208alex obregon100% (3)

- Operating and Maintenance Instructions BC 462-472 BR PDFDocument130 pagesOperating and Maintenance Instructions BC 462-472 BR PDFVương Xuân Nghiêm100% (1)

- Damper Datasheet FormDocument1 pageDamper Datasheet FormharishcsharmaNo ratings yet

- Volvo EW180 Wheeled Excavator Service ManualDocument1,034 pagesVolvo EW180 Wheeled Excavator Service ManualPIKO MOB100% (2)

- Carrier Bus Air Conditioning Unit Model GR 45 GR 60 Operation Service Manual Pub T295Document56 pagesCarrier Bus Air Conditioning Unit Model GR 45 GR 60 Operation Service Manual Pub T295Sharyn TurnerNo ratings yet

- Air Cooler Data SheetDocument3 pagesAir Cooler Data Sheetarisandiyusuf0% (1)

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- Electrical System Design For High Rise BuildingDocument12 pagesElectrical System Design For High Rise Buildingbookbok100% (5)

- Piper Seneca II Service Manual - SM 761-590Document675 pagesPiper Seneca II Service Manual - SM 761-590Alejandro100% (1)

- Technical Data Sheet For UEA-01,02 CentrífugoDocument13 pagesTechnical Data Sheet For UEA-01,02 Centrífugocarmen hernandezNo ratings yet

- Pacu 02-Py100fa - 1,645 CFMDocument2 pagesPacu 02-Py100fa - 1,645 CFMAnonymous qOBFvINo ratings yet

- Start-Up AHU Test FormsDocument1 pageStart-Up AHU Test FormsLâm trầnNo ratings yet

- As-Nzs 1554.1-2014 PQR & WPSDocument2 pagesAs-Nzs 1554.1-2014 PQR & WPSBobby Currie100% (1)

- Data Sheet of Cummins 500kva by IntranusaDocument9 pagesData Sheet of Cummins 500kva by IntranusaDeni DendenNo ratings yet

- Doc. No.: Ibce-6373-C00-Ele-Dat-000-0012Document6 pagesDoc. No.: Ibce-6373-C00-Ele-Dat-000-0012rahul rNo ratings yet

- WPS New 2Document1 pageWPS New 2Erica SandersNo ratings yet

- Procedure Qualification Record: Run Sequence Joint DetailsDocument2 pagesProcedure Qualification Record: Run Sequence Joint DetailsBobby CurrieNo ratings yet

- 17.-XT31502TS-4 Customer Information PacketDocument10 pages17.-XT31502TS-4 Customer Information PacketmaricruolivarNo ratings yet

- WLD PDFDocument1 pageWLD PDFYogesh TheCyaNo ratings yet

- ECP4314T 4 InfoPacketDocument8 pagesECP4314T 4 InfoPacketmaricruolivarNo ratings yet

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- 10.-ECP84410T-4 Customer Information PacketDocument11 pages10.-ECP84410T-4 Customer Information PacketmaricruolivarNo ratings yet

- CH Aly080dDocument2 pagesCH Aly080dEngineer HassanNo ratings yet

- HVA Report IS1-C.B-R2: Acceptance Test Finished SuccessfullyDocument1 pageHVA Report IS1-C.B-R2: Acceptance Test Finished SuccessfullyAhmed RabaaNo ratings yet

- NPT Sop Pde 006 f02 DQ AgitatorDocument2 pagesNPT Sop Pde 006 f02 DQ AgitatorMohamed SelimNo ratings yet

- Mcfe1-2402148 DWGDocument9 pagesMcfe1-2402148 DWGghazi4uNo ratings yet

- HVA Report IS2-IS1: Acceptance Test Finished SuccessfullyDocument1 pageHVA Report IS2-IS1: Acceptance Test Finished SuccessfullyAhmed RabaaNo ratings yet

- 4161 - Frontier Series II F230+4x4 - Legal - MECH - 1016Document4 pages4161 - Frontier Series II F230+4x4 - Legal - MECH - 1016Erwin HidayatNo ratings yet

- 15.-XT31252TS Customer Information PacketDocument10 pages15.-XT31252TS Customer Information PacketmaricruolivarNo ratings yet

- ECP4400T 4 InfoPacketDocument9 pagesECP4400T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- FC03 - Technical Data SheetDocument2 pagesFC03 - Technical Data SheetALAN QUISPE VELASQUEZNo ratings yet

- Vertical Pump QueryDocument17 pagesVertical Pump QueryNurye NigusNo ratings yet

- CHILLER MAGNÉTICO VFD Water Cooled 500 TR - Technical Data SheetDocument3 pagesCHILLER MAGNÉTICO VFD Water Cooled 500 TR - Technical Data SheetKarina SolisNo ratings yet

- K 100 XL Sileo: Technical ParametersDocument9 pagesK 100 XL Sileo: Technical Parameterskadir tanzaniaNo ratings yet

- EL-QT-CTB-S - 20180420B-ESTRUAGUA LATAM-SOPLADORES TURBO-Floculación-Ficha Tecnica Jul1018Document2 pagesEL-QT-CTB-S - 20180420B-ESTRUAGUA LATAM-SOPLADORES TURBO-Floculación-Ficha Tecnica Jul1018mafevalle4201No ratings yet

- Questionnaire For Selection of Flame Monitors (1/2) : Plant DetailsDocument2 pagesQuestionnaire For Selection of Flame Monitors (1/2) : Plant DetailsIbadurrahman IbadNo ratings yet

- ECPM4406T 4 InfoPacketDocument11 pagesECPM4406T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- K 160 M Sileo: Centrifugal Circular Duct Fan 125WDocument9 pagesK 160 M Sileo: Centrifugal Circular Duct Fan 125WOscar Barres MoreiraNo ratings yet

- HVA Report IS16-IS17-B1: 33.0kV Accept. C. XLPE (T) Finished SuccessfullyDocument1 pageHVA Report IS16-IS17-B1: 33.0kV Accept. C. XLPE (T) Finished SuccessfullyAhmed RabaaNo ratings yet

- HVA Report IS1-C.B-B1: Acceptance Test Finished SuccessfullyDocument1 pageHVA Report IS1-C.B-B1: Acceptance Test Finished SuccessfullyAhmed RabaaNo ratings yet

- Packaged UnitDocument1 pagePackaged UnitnasermohdNo ratings yet

- Goods Goods Details Specification: Sample of Materials To Be Inclueded in 2008 Procuement PlanDocument2 pagesGoods Goods Details Specification: Sample of Materials To Be Inclueded in 2008 Procuement PlanዘቃልአብሞላNo ratings yet

- ECPM4316T 4 InfoPacketDocument10 pagesECPM4316T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- A MC Msi 1 CP PM Ds 001 Ace r02Document38 pagesA MC Msi 1 CP PM Ds 001 Ace r02vijender07No ratings yet

- ECPM4407T 4 InfoPacketDocument11 pagesECPM4407T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- Deviation Detail of Key EquipmentsDocument58 pagesDeviation Detail of Key EquipmentschetanmaleNo ratings yet

- ECP4407T 4 InfoPacketDocument10 pagesECP4407T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- CPF1 - PAUT-2023-636-20" CO Header From V-21740 To Oil-Oil HE (E-21810 ABC) Inlet (Abnormal Points)Document14 pagesCPF1 - PAUT-2023-636-20" CO Header From V-21740 To Oil-Oil HE (E-21810 ABC) Inlet (Abnormal Points)Vignesh PanchabakesanNo ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document2 pagesPreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- 1PH8137-1DF02-0BA1 Datasheet en PDFDocument1 page1PH8137-1DF02-0BA1 Datasheet en PDFpincopallinoNo ratings yet

- HVA Report IS7-C.B-B1: Acceptance Test Finished SuccessfullyDocument1 pageHVA Report IS7-C.B-B1: Acceptance Test Finished SuccessfullyAhmed RabaaNo ratings yet

- Method Statemetn FormDocument11 pagesMethod Statemetn FormEswar ReddyNo ratings yet

- Calculo Puesta A Tierra Cacpe Pastaza EtapDocument3 pagesCalculo Puesta A Tierra Cacpe Pastaza EtapRICHARD ARMANDO ELIZALDE PINNo ratings yet

- AHU - With Recovery Fan Startup ChecklistDocument2 pagesAHU - With Recovery Fan Startup Checklisttekken123joNo ratings yet

- ECP4404T Customer Information BALDORDocument9 pagesECP4404T Customer Information BALDOREduleofNo ratings yet

- 5.-ECP4404T-4 Customer Information PacketDocument10 pages5.-ECP4404T-4 Customer Information PacketmaricruolivarNo ratings yet

- 4161 Frontier Series II F230 Legal MECH 1016Document4 pages4161 Frontier Series II F230 Legal MECH 1016Nick NugrohoNo ratings yet

- QC E7018 CJP B-L1a OverheadDocument1 pageQC E7018 CJP B-L1a Overheadwmajordan13No ratings yet

- Welding Procedure Specification (WPS) Yes Prequalified or Procedure Qualification Records (PQR) YesDocument2 pagesWelding Procedure Specification (WPS) Yes Prequalified or Procedure Qualification Records (PQR) YesRuben Purca0% (1)

- Service Manual: Split Type Wall Mounted Air ConditionerDocument44 pagesService Manual: Split Type Wall Mounted Air ConditionerBane RadovicNo ratings yet

- Systemair Prio 250E2 Circular Duct FanDocument6 pagesSystemair Prio 250E2 Circular Duct FanYvanNo ratings yet

- Quinco Steel Inc.: Welding Procedure Specification (WPS)Document1 pageQuinco Steel Inc.: Welding Procedure Specification (WPS)wmajordan13No ratings yet

- 3g HW Acceptance Bts 030747-KapauDocument36 pages3g HW Acceptance Bts 030747-KapauOsivy100% (1)

- 5 Kme 6 U 5 JwsnyabteDocument1 page5 Kme 6 U 5 JwsnyabteMohamed SelimNo ratings yet

- RRP AGRO TR Test Report 33 - 11 PDFDocument9 pagesRRP AGRO TR Test Report 33 - 11 PDFJRC TestingNo ratings yet

- Deliverable List - Attachment 1: No Doc No. Deliverable List Issue For Quantity Unit Paper Size Remarks ApprovalDocument4 pagesDeliverable List - Attachment 1: No Doc No. Deliverable List Issue For Quantity Unit Paper Size Remarks ApprovalRanu Januar100% (1)

- Service Water TankDocument58 pagesService Water TankRanu Januar100% (1)

- CCL - Basic Engineering Service R1Document1 pageCCL - Basic Engineering Service R1Ranu Januar100% (1)

- Vendor InformationDocument1 pageVendor InformationRanu JanuarNo ratings yet

- 7 - Psy - Chart - XLS Cooling CoilDocument28 pages7 - Psy - Chart - XLS Cooling CoilRanu JanuarNo ratings yet

- New Carding MachineDocument2 pagesNew Carding MachineRanu JanuarNo ratings yet

- 5 MEP Fire Protection RevDocument64 pages5 MEP Fire Protection RevRanu JanuarNo ratings yet

- Title: Detail Assessment of Exisiting Tank: Sheet No. Purchaser Rev. No. Doc. No. DateDocument2 pagesTitle: Detail Assessment of Exisiting Tank: Sheet No. Purchaser Rev. No. Doc. No. DateRanu JanuarNo ratings yet

- Cooling Coil SizingDocument4 pagesCooling Coil SizingRanu JanuarNo ratings yet

- PoetryDocument13 pagesPoetryRanu JanuarNo ratings yet

- Hoist Troley Catalogue PDFDocument47 pagesHoist Troley Catalogue PDFRanu JanuarNo ratings yet

- Support LCOE PDFDocument1 pageSupport LCOE PDFRanu JanuarNo ratings yet

- BASIC & PRIMUS C90 V 3.4 enDocument68 pagesBASIC & PRIMUS C90 V 3.4 enGogoseanu PaulNo ratings yet

- Hybrid System IntroductionDocument35 pagesHybrid System IntroductionAbo MohammedNo ratings yet

- WSHP SVX014G en - 11192021Document84 pagesWSHP SVX014G en - 11192021gregoriomartinezNo ratings yet

- PRICE LIST Comprehensive - List Price 2020 - EURODocument1 pagePRICE LIST Comprehensive - List Price 2020 - EUROSuriyachai NiamsornNo ratings yet

- Airflow Control in HVAC SystemDocument36 pagesAirflow Control in HVAC SystemChienNo ratings yet

- 2004-01-0784-An Innovative Method of Heating Windshield Washer Fluid For Improved Windshield Cleaning EfficiencyDocument11 pages2004-01-0784-An Innovative Method of Heating Windshield Washer Fluid For Improved Windshield Cleaning EfficiencyJicheng PiaoNo ratings yet

- Pump Station BOQDocument43 pagesPump Station BOQMustafa Abdullah100% (1)

- Nibe F2040-12 VVM S320 - 1Document5 pagesNibe F2040-12 VVM S320 - 1sciucNo ratings yet

- HS-2141BLe 1811Document67 pagesHS-2141BLe 1811Walid BouchananeNo ratings yet

- Tecsurge Service: Catalogues and Specifications For Pdms/E3D Specification and CataloguesDocument3 pagesTecsurge Service: Catalogues and Specifications For Pdms/E3D Specification and CataloguesVishnu RavindranNo ratings yet

- Thermally Active Surfaces in Architecture - (Intro)Document20 pagesThermally Active Surfaces in Architecture - (Intro)kun lyuNo ratings yet

- Air FiltersDocument4 pagesAir Filtershussam_98No ratings yet

- Calculating Sizing For Electric Baseboard HeatersDocument10 pagesCalculating Sizing For Electric Baseboard HeatersRoddy PfeifferNo ratings yet

- Training ISO 50008Document48 pagesTraining ISO 50008Ricardo AndresNo ratings yet

- Media CommercialDocument28 pagesMedia CommercialLekule, Ibrahim HamisNo ratings yet

- Cooke Ductwork ManualDocument37 pagesCooke Ductwork Manualquantum 46bNo ratings yet

- Compressor Embraco Capillary Selection GuideDocument4 pagesCompressor Embraco Capillary Selection GuiderayrefrigNo ratings yet

- Energy Audit of 107Document17 pagesEnergy Audit of 107Mark Angelo UyNo ratings yet

- TM Daikin 50Hz SingaporeDocument86 pagesTM Daikin 50Hz SingaporeericyuenNo ratings yet

- Product Configuration SJB01752Document2 pagesProduct Configuration SJB01752irsan pratama putraNo ratings yet

- vss157 Chowdhury 2015 oDocument18 pagesvss157 Chowdhury 2015 oIvan PasterNo ratings yet

- Doaa Abbas Abd-Elshafy Mansour: Personal DataDocument7 pagesDoaa Abbas Abd-Elshafy Mansour: Personal DataGolden HomeNo ratings yet

- Daikin VRV Inverter K Plus 2001Document412 pagesDaikin VRV Inverter K Plus 2001vendas.ilimitadasNo ratings yet

- Comps of Steam Power PLDocument2 pagesComps of Steam Power PLrohit choudharyNo ratings yet