Professional Documents

Culture Documents

Dpa 4 e

Dpa 4 e

Uploaded by

Nicolae Visan0 ratings0% found this document useful (0 votes)

5 views2 pagesOriginal Title

DPA_4_E

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesDpa 4 e

Dpa 4 e

Uploaded by

Nicolae VisanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

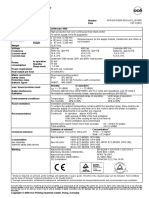

Distillation Process Analyzer DPA-4

Distillation Process Analyzer DPA-4

EXPLOSION PROTECTION Operation approx. 1 Nm³/h

Pressure at inlet 2 to 7 bar (29 to 101.5 psi)

Marking ATEX: II 2 G IIC T4 Gb Quality humidity class 2 or better acc. to ISO 8573.1

NEC 500: Class I, Div. 2, Groups B, C and D

NEC 505: Class I, Zone 1, AEx d e ib px IIB or

Coolant

IIB+H2

TR CU Certification available Consumption max. 60 l/h

Temperature -10 to 55°C (14 to 131°F)

TECHNICAL DATA Pressure at inlet 2 to 7 bar (29 to 101.5 psi)

Quality filtered 50 µm

Technology batch distillation

Method SAM compliant with:

ASTM D86, DIN EN ISO 3405, IP 123 Signal outputs and inputs

Correlates with: Analog outputs temperature at specific distillation batch

ASTM D4814 (calculation of TV/L) Digital outputs Alarm, Ready / Valid

ASTM D4737 (Calculated Cetane Index) Digital inputs Stream Selection, Validation Request, Reset

RAM correlates with:

ASTM D86, DIN EN ISO 3405, IP 123

Electrical data of signal

Measuring range 20 to 420°C (68 to 788°F) outputs and inputs

output of any temperature/distillate

amount via Modbus Analog outputs max. 8 (4 to 20 mA; 1000 Ω)

active isolated on request

Repeatability ≤ DIN EN /ASTM

e.g. gasoline typ. T@ 50% rec. 1°C Analog inputs 4 to 20 mA; 160 Ω

Reproducibility ≤ DIN EN/ASTM Digital outputs 24 VDC; max. 0.5 A

Measuring cycle typical time for gasoline/diesel in SAM (in min) Digital inputs high: 15 to 28 VDC

IBP: approx. 24/29 low: 0 to 4 VDC

50 % recovered: approx. 36/41 Auxiliary power

FBP: approx. 45/50 supply output 24 VDC; max. 0.8 A

cycle time will be reduced by approx. 40 %

in RAM Control unit

Product streams up to 3 x sample, 1 validation sample each Central control unit Industrial PC

(additional hardware required) Operating system Windows Embedded Standard 7®

Electrical data Control software PACS

Nominal voltage 230 VAC ± 10 %, 1 phase; 50 Hz;

other ratings on request

User interfaces

Maximum power

consumption approx. 600 W Display TFT display with touch function

1024 x 768 pixel

Protection class IP 54 (NEMA 13)

Keyboard virtual keyboard, controlled via

Ambient conditions TFT display with touch function

Ambient temperature operation 5 to 40°C (41 to 104°F)

storage 0 to 60°C (32 to 140°F)

Connections

Ambient humidity operation 5 to 80 % relative humidity,

Tube fittings Swagelok® 6 mm/12 mm/18 mm

non-corrosive

other fittings on request

storage 5 to 85 % relative humidity,

non-corrosive Vent/Drain open to atmosphere

backpressure on request

Sample

Quality filtered 50 µm, bubble-free Weight and dimensions

(≤ 37 cSt at inlet temperature) Weight approx. 250 kg

Consumption approx. 10 to 40 l/h Dimensions (W x H x D) approx. 1140 x 1900 x 710 mm

(≥ 10 cSt: max. 15 l/h) Space requirements right: 150 mm / left: 100 mm

Pressure at inlet 1.5 to 2 bar (21.8 to 29 psi)

Temperature at inlet depends on application, max. 55°C (131°F) Optional interfaces

Analog outputs on request

Utilities Analog inputs density

Instrument air MODBUS interface MODBUS/RTU via RS485 or RS422

Consumption or FOC is, MODBUS/TCP via FOC is

Purge 8 Nm³/h while purging (~12 min) Remote access via Ethernet (VDSL or FOC is)

Important notice DPA-4 is subject to continuous product improvement, specifications are preliminary and may be subject to change without notice.

If your technical data do not comply with existing data, please contact us for technical clarification.

BARTEC BENKE GmbH Borsigstrasse 10 Tel: +49 40 72703-0 pat@bartec-benke.de

Germany D-21465 Reinbek Fax : +49 40 72703-228 www.bartec-benke.de

You might also like

- TP 6813Document68 pagesTP 6813Roberto Sanchez Zapata100% (1)

- Secret Codes Sony Xperia Diagnostic Codes FirmwareDocument4 pagesSecret Codes Sony Xperia Diagnostic Codes Firmwarecorneliu.modilcaNo ratings yet

- Design of Charge Pump PLLDocument5 pagesDesign of Charge Pump PLLSwati KashtNo ratings yet

- Electromagnetic Flowmeter: Main FeaturesDocument2 pagesElectromagnetic Flowmeter: Main FeaturesDaniel B. BalmoriNo ratings yet

- FM Receiver in GNU RadioDocument6 pagesFM Receiver in GNU RadioRakesh S KNo ratings yet

- Safety Cosh PDFDocument8 pagesSafety Cosh PDFJohn RamboNo ratings yet

- Kion C11 / Kion C22: Evacuation & Refrigerant Charging Equipment For Flammable GasesDocument6 pagesKion C11 / Kion C22: Evacuation & Refrigerant Charging Equipment For Flammable GasesSylvain AguedaNo ratings yet

- TC544 TC244 TC344 PDFDocument3 pagesTC544 TC244 TC344 PDFGaurav AgrawalNo ratings yet

- Freeze/Cloud Point Process Analyzer FRP-4/CPA-4: Credible Solutions For The Oil and Gas IndustryDocument2 pagesFreeze/Cloud Point Process Analyzer FRP-4/CPA-4: Credible Solutions For The Oil and Gas IndustryNicolae VisanNo ratings yet

- BENKE RVP-4 - Datasheet Triple ExpansionDocument1 pageBENKE RVP-4 - Datasheet Triple ExpansionSadok KsirNo ratings yet

- Rapid Distillation Process Analyzer - Rapidist-4 AnalyzerDocument1 pageRapid Distillation Process Analyzer - Rapidist-4 AnalyzerNicolae VisanNo ratings yet

- ASL SA DSH013 Issue 1 EX 500Document2 pagesASL SA DSH013 Issue 1 EX 500Nwabuze IwunzeNo ratings yet

- APD72-D Automatic Dehydrator, 0.58 SCFM, 230V AC 50/60 HZDocument2 pagesAPD72-D Automatic Dehydrator, 0.58 SCFM, 230V AC 50/60 HZTrina Ritchell AquinoNo ratings yet

- Techincal Specifications With DetailsDocument11 pagesTechincal Specifications With Detailsruturaj v delekarNo ratings yet

- APD72-D Automatic Dehydrator, 0.58 SCFM, 230V AC 50/60 HZDocument3 pagesAPD72-D Automatic Dehydrator, 0.58 SCFM, 230V AC 50/60 HZDaniel Hernando Buitrago NietoNo ratings yet

- DE550016 BA 3 Select 01Document4 pagesDE550016 BA 3 Select 01seve1No ratings yet

- Flow Meter Tech Specs F113AIDocument4 pagesFlow Meter Tech Specs F113AIhalcaldeNo ratings yet

- VariostatDocument2 pagesVariostatletphuongNo ratings yet

- Destilador AtmosfericoDocument4 pagesDestilador AtmosfericoWilliams MedinaNo ratings yet

- General Specifications: Panel Mounted Converter For PH and Redox (ORP) Model PH150Document4 pagesGeneral Specifications: Panel Mounted Converter For PH and Redox (ORP) Model PH150HolicsNo ratings yet

- Moglix Remarks Model: 409 With 2 Relay Alarm + 4-20 MADC RX O/pDocument3 pagesMoglix Remarks Model: 409 With 2 Relay Alarm + 4-20 MADC RX O/pyashNo ratings yet

- Ops en Psds 002 Eu Js1000Document1 pageOps en Psds 002 Eu Js1000mana1345No ratings yet

- Model 51i Total Hydrocarbon Analyzer: Flame Ionization For The Detection of Total HydrocarbonDocument2 pagesModel 51i Total Hydrocarbon Analyzer: Flame Ionization For The Detection of Total HydrocarbonAnjang YudistriNo ratings yet

- LAB4Document4 pagesLAB4Esteban Esguevillas GarcíaNo ratings yet

- Product Data Sheet Flow Computer 7955 Flow Computer Specifications Ras en 133418Document4 pagesProduct Data Sheet Flow Computer 7955 Flow Computer Specifications Ras en 133418VictorNo ratings yet

- Ex 100 1000 DatasheetDocument2 pagesEx 100 1000 DatasheetChico SantanaNo ratings yet

- Banque de SangDocument2 pagesBanque de SangAhmed MehaliNo ratings yet

- Signet 2551 Magmeter Flow Sensor: FeaturesDocument6 pagesSignet 2551 Magmeter Flow Sensor: FeaturesLuis Breña DiazNo ratings yet

- InteliGen 200 Datasheet r8Document4 pagesInteliGen 200 Datasheet r8Arrammah AlkamelNo ratings yet

- InteliGen 200 Datasheet r8Document4 pagesInteliGen 200 Datasheet r8JOSE URREANo ratings yet

- InteliGen 200 Datasheet r8Document4 pagesInteliGen 200 Datasheet r8nguyenbinh20No ratings yet

- En7958 7 10 17 - CS1000Document4 pagesEn7958 7 10 17 - CS1000hangmann169No ratings yet

- InteliGen 200 Datasheet r8Document4 pagesInteliGen 200 Datasheet r8Ramanathpura Venkannachar KiranNo ratings yet

- Technical Data Sheet: InstrumentsDocument4 pagesTechnical Data Sheet: InstrumentsXANPHOXYL KIBETNo ratings yet

- Zelio Control Reg48pun1rhuDocument4 pagesZelio Control Reg48pun1rhuAlexis Algüerno ContrerasNo ratings yet

- Zelio Control Relays - REG48PUN1JHUDocument4 pagesZelio Control Relays - REG48PUN1JHUJorge Aguero CuevaNo ratings yet

- Masibus 5002U-P - R1F - 0616 - Digital Process ControllerDocument2 pagesMasibus 5002U-P - R1F - 0616 - Digital Process ControllerabhimanyuNo ratings yet

- Head-Mount Temperature Transmitter: Abb Measurement & Analytics - Data SheetDocument20 pagesHead-Mount Temperature Transmitter: Abb Measurement & Analytics - Data SheetAlfonso BlancoNo ratings yet

- PSSU DATASHEET - Hw-PSSU-v9Document4 pagesPSSU DATASHEET - Hw-PSSU-v9workdata2223No ratings yet

- Masibus 409-4IN R0F 0716 Large Display IndicatorDocument2 pagesMasibus 409-4IN R0F 0716 Large Display IndicatorAvinNo ratings yet

- PROBHeDocument7 pagesPROBHeFernando BatistaNo ratings yet

- Lab4 50Document4 pagesLab4 50Marn DNo ratings yet

- F5001 Magnetic Meter DatasheetDocument1 pageF5001 Magnetic Meter DatasheetHendra darmantoNo ratings yet

- GF Signet Mag Flow Meter Insertion TypeDocument6 pagesGF Signet Mag Flow Meter Insertion TypeImran Ahmed KhanNo ratings yet

- NguyenManhTuong 186006014 BaoCaoCuoiKyDocument8 pagesNguyenManhTuong 186006014 BaoCaoCuoiKyManh Tuong NguyenNo ratings yet

- Horiba Apha-370: THC-Immission MonitorDocument2 pagesHoriba Apha-370: THC-Immission MonitorWhite MirageNo ratings yet

- GF 9900 DatasheetDocument8 pagesGF 9900 DatasheetKa KowkNo ratings yet

- LG Flatron M228WDP-BZ PDFDocument52 pagesLG Flatron M228WDP-BZ PDFboroda2410No ratings yet

- WF by 1020-BLTDocument4 pagesWF by 1020-BLTducdti99No ratings yet

- Color Monitor: Service ManualDocument52 pagesColor Monitor: Service ManualAnonymous nC9gpUWPNo ratings yet

- Technical Specifications Epc LiteDocument1 pageTechnical Specifications Epc LiteTio SatriaNo ratings yet

- TS2000 DSDocument2 pagesTS2000 DSfernan0504No ratings yet

- General Specifications: Model PH450G PH and Redox (ORP) AnalyzerDocument8 pagesGeneral Specifications: Model PH450G PH and Redox (ORP) AnalyzerHolicsNo ratings yet

- Intelinano Amf 5 Datasheet 2024-05-24Document4 pagesIntelinano Amf 5 Datasheet 2024-05-24gonzalo cruz garciaNo ratings yet

- TF428WNM/U: Communicating Fan Coil ThermostatDocument8 pagesTF428WNM/U: Communicating Fan Coil ThermostatQuyết Nguyễn MạnhNo ratings yet

- Flow Brochure2014Document6 pagesFlow Brochure2014PRECITECNo ratings yet

- KV-N60AR DatasheetDocument4 pagesKV-N60AR Datasheetasrulnizam matnorNo ratings yet

- PXU PID Controller: Temperature/Process ControllersDocument3 pagesPXU PID Controller: Temperature/Process ControllersGaryNo ratings yet

- Domino Uss: Portable Water in Oil and Dewpoint AnalyzerDocument2 pagesDomino Uss: Portable Water in Oil and Dewpoint AnalyzerR.SivachandranNo ratings yet

- PROBHe MDocument7 pagesPROBHe MFernando BatistaNo ratings yet

- 8710 enDocument7 pages8710 enYou nesNo ratings yet

- 2080sc-If4u Micro830 and Micro850 Series PLCsDocument2 pages2080sc-If4u Micro830 and Micro850 Series PLCsrajavinugmailcomNo ratings yet

- TP-624D H2S Mos PDS PDFDocument2 pagesTP-624D H2S Mos PDS PDFkaleeswaranNo ratings yet

- Sharky 775Document8 pagesSharky 775Phuc HuynhNo ratings yet

- RE1 - Transmission Lines 2021Document27 pagesRE1 - Transmission Lines 2021Dinaj AttanayakaNo ratings yet

- Asynchronous CounterDocument5 pagesAsynchronous CounterJose GarciaNo ratings yet

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Document3 pagesQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNo ratings yet

- Communications and Navigation SystemDocument12 pagesCommunications and Navigation SystemEvan TubaleNo ratings yet

- User's Manual: PQP-A EnergotesterDocument77 pagesUser's Manual: PQP-A EnergotesterDariush RumiNo ratings yet

- IPC 7351table3 15january2005Document4 pagesIPC 7351table3 15january2005fantum1No ratings yet

- Dig 31900 Om002 HDocument85 pagesDig 31900 Om002 HGeraldoadriNo ratings yet

- Sony pvm-2530Document6 pagesSony pvm-2530Alberto GordilloNo ratings yet

- John Errington's Tutorial On Power Supply Design: Simplified Diagram For High Voltage SupplyDocument2 pagesJohn Errington's Tutorial On Power Supply Design: Simplified Diagram For High Voltage SupplyDai NgoNo ratings yet

- Keywords Earthing Designs Substation Earthing Resistance Grid Potential Rise Mesh Voltage Step Voltage and Matlab Figures - CompressDocument6 pagesKeywords Earthing Designs Substation Earthing Resistance Grid Potential Rise Mesh Voltage Step Voltage and Matlab Figures - CompressDebasish RahaNo ratings yet

- Class Notes 09.22.08Document2 pagesClass Notes 09.22.08Mike Nguyen100% (2)

- 807700-2 GRS 500 Operations ManualDocument40 pages807700-2 GRS 500 Operations ManualRobson AquinoNo ratings yet

- IAC 77 Type RelayDocument36 pagesIAC 77 Type RelayJoe JohnsonNo ratings yet

- TDA1220B: Am-Fm Quality RadioDocument19 pagesTDA1220B: Am-Fm Quality Radiobugy costyNo ratings yet

- Doorbell Circuit Using Transistors and IC-555Document22 pagesDoorbell Circuit Using Transistors and IC-555ivodioaurelioNo ratings yet

- Phys 272 Final Exam PracticeDocument16 pagesPhys 272 Final Exam Practiceheehee2010No ratings yet

- PID ControllerDocument5 pagesPID ControllerIcarus CanNo ratings yet

- Cotlight 6GFM100XDocument1 pageCotlight 6GFM100XthoyeuruaNo ratings yet

- Digital Electronics Lecture - VI Cannonical and Standard Forms RevistedDocument35 pagesDigital Electronics Lecture - VI Cannonical and Standard Forms RevistedParag ParandkarNo ratings yet

- Daewoo Dtq-21a35r Dtq-21a24n - Chasis Cx-A21fb-Cy8895cDocument24 pagesDaewoo Dtq-21a35r Dtq-21a24n - Chasis Cx-A21fb-Cy8895cEdgar Garcia50% (2)

- Samsung AnalysisDocument20 pagesSamsung AnalysisSunnyNo ratings yet

- Power Semiconductor Drives Course FileDocument163 pagesPower Semiconductor Drives Course FileRuler NanuNo ratings yet

- Saudi Aramco Test Report: DC Cable Holiday Testing 3-Jul-18 CP-SATR-X-3201Document3 pagesSaudi Aramco Test Report: DC Cable Holiday Testing 3-Jul-18 CP-SATR-X-3201karthi51289No ratings yet

- BTech R03 EEE Syllabus BookDocument60 pagesBTech R03 EEE Syllabus BookVenKat50% (2)

- Unit 4 L8 Minimization of Boolean Functionskarnaugh MapDocument17 pagesUnit 4 L8 Minimization of Boolean Functionskarnaugh MapNiteesh KumarNo ratings yet