Professional Documents

Culture Documents

Linear Programming Cases

Linear Programming Cases

Uploaded by

Gaurav KishoreOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Linear Programming Cases

Linear Programming Cases

Uploaded by

Gaurav KishoreCopyright:

Available Formats

Linear Programming

Petroleum Blending

We have two types of crudes that can be blended to form premium

and regular type of petrol. This can be done by two processes.

The output depends on the number of times each process is run.

The requirements and outputs for each of the two processes for

each run are given below:

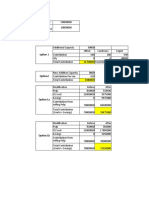

Requirement/Run Output/Run

Process

Crude A Crude B Premium Regular

I 1 3 5 2

II 4 2 3 8

Availability 1000 1500

Minimum Demand 800 700

Profit/Unit 3000 2500

What should we do?

Production Process

A company produces three products X, Y and Z, which sell in

market at price Rs 100/-, 105/- and 115/- per unit respectively.

Total demand for these products in market is known to be at

least 300, 200 and 400 units respectively.

These products require four different raw-materials. Raw

material quantity required per unit of finish product is given

in the table below:

X Y Z

A 1 2 1

B 1 1 2

C 3 2 2

D 15 12 20

These four raw materials cost Rs 12/-, 15/-, 6/- and 0.50/- per

unit. Company can arrange maximum of 1200, 1500, 2400 and 20000

units of raw materials respectively for production purpose.

Company has fixed administrative cost of Rs. 20000/- and it

requires to spend Rs 5/- per unit as distribution cost to sell

one unit in the market.

What should we do?

Sugar Production

We own a sugar processing company that operates two plants at

Nagpur and Pune. Sugarcane is procured from different regions

in the surrounding areas and the maximum availability in each

region is as follows:

R1: 250 tonnes at Rs.4000/- ton

R2: 360 tonnes at Rs.4500/- ton

R3: 450 tonnes at Rs.3500/- ton

Shipping costs in Rs per tonne are

Nagpur Pune

R1 300 400

R2 250 450

R3 500 720

Plant capacities and labour costs are:

Nagpur Pune

Labour cost (Rs/ton) 50 45

Capacity(tons) 450 600

The sugar produced is sold at a price of Rs. 50/kg. There is

ample demand to sell all the sugar produced.

What should we do?

Note: 1 Ton = 1000 kg

Warehousing and Distribution Planning

We own MHCS, a handloom cooperative society in Maharashtra is

responsible for marketing, distribution and sales of handlooms

cooperatives in the state. MHCS collects from cooperatives all

over the state and sells them in the neighbouring states. It has

recently opened warehouses to handle the consolidation and

distribution of merchandise. The warehouses are located in

Nagpur, Pune, Nashik, Kolhapur and Latur.

The merchandise is routed through these warehouses to various

states. The merchandise is transferred in Pallets. The monthly

availability of merchandise at the warehouses (in number of

Pallets) is as given below:

Warehouse Nagpur Pune Nashik Kolhapur Latur

Availability 200 230 120 200 250

The monthly demand (Pallets) in the neighbouring states is as

follows:

State Gujarat Madhya Chhattisgarh Telangana Karnataka Goa

Pradesh

Demand 180 170 130 250 220 50

The cost of transporting one pallet from a given warehouse to

other state is given in the table below (In Rupees Thousands).

Gujarat Madhya Chhattisgarh Telangana Karnataka Goa

Pradesh

Nagpur 850 350 280 500 1100 1100

Pune 660 800 1000 560 840 450

Nashik 520 610 940 670 1060 660

Kolhapur 910 1020 1140 540 610 220

Latur 900 880 800 300 840 530

What should we do?

In the above problem the warehouses are not setup and we need

to setup those too. Each warehouse can handle 400 Pallets. The

cost of setting up a warehouse at each of the location is

given below (In Rupees Crores):

Warehouse Nagpur Pune Nashik Kolhapur Latur

Cost 1.25 1.2 0.8 1 0.9

What should we do?

Call Centre Scheduling

We are consulting for a call centre based out of Kahinaipur. It

specialises in insurance. The company has to schedule the

employees as per the demand. The company knows how many personnel

are required for a given call volume. The call volume keeps

fluctuating throughout the day and the company for ease of

operations evaluates it in four-hour intervals. The call centre

runs 24X7 and the demand on a typical day is as given below.

Time (24hr) Minimum Employees

required

0200 – 0600 20

0600 – 1000 50

1000 – 1400 80

1400 – 1800 100

1800 – 2200 40

2200 – 0200 30

The employees would come and join at the start of any slot, but

would continue for 8 hours (2 slots). We have to assist the call

centre in manpower planning and scheduling.

What should we do?

You might also like

- 30-Day Meal PlanDocument94 pages30-Day Meal PlanAlina Vlad100% (1)

- Sea Buckthorn PosterDocument1 pageSea Buckthorn PosterAlexandru D. GateaNo ratings yet

- 01 1 Mini Farm ProposalDocument6 pages01 1 Mini Farm Proposalapi-388330593No ratings yet

- Restaurant Report Card: March 16, 2023Document6 pagesRestaurant Report Card: March 16, 2023KBTXNo ratings yet

- Feasibility Study of Coconut Husk and Corn Husk As Alternative PaperDocument30 pagesFeasibility Study of Coconut Husk and Corn Husk As Alternative PaperCatherine Joy Seminio60% (10)

- Grade 3 Mtap ReviewerDocument26 pagesGrade 3 Mtap ReviewerEclud97% (37)

- Kalihari Port ProjectDocument1 pageKalihari Port ProjectRohanMohapatra0% (2)

- Process Fundamentals Practice Questions: NstructionsDocument19 pagesProcess Fundamentals Practice Questions: NstructionsDheeraj SinghNo ratings yet

- Indian Ethos & Business EthicsDocument13 pagesIndian Ethos & Business Ethicsshubh'zz JadhavNo ratings yet

- Pricing Strategy Report - Group 5 - Maruti BalenoDocument19 pagesPricing Strategy Report - Group 5 - Maruti BalenodwnpiyushNo ratings yet

- Vayutel Case StudyDocument10 pagesVayutel Case StudyRenault RoorkeeNo ratings yet

- Activity Based Costing Test QuestionsDocument5 pagesActivity Based Costing Test QuestionsMehul GuptaNo ratings yet

- Individual Hand in Case PDFDocument7 pagesIndividual Hand in Case PDFPallavi JNo ratings yet

- Final Acc-Numerical 1Document10 pagesFinal Acc-Numerical 1Rajshree BhardwajNo ratings yet

- OTISLINE PresentationDocument5 pagesOTISLINE PresentationAseem SharmaNo ratings yet

- Unit V-Project Network Analysis - CPMPERT - PPT PDFDocument34 pagesUnit V-Project Network Analysis - CPMPERT - PPT PDFSharmila ShettyNo ratings yet

- CVPDocument3 pagesCVPRajShekarReddyNo ratings yet

- InductionDocument2 pagesInductionNeeta NainaniNo ratings yet

- Cash Budget - QuesDocument3 pagesCash Budget - QuesSaima EliteNo ratings yet

- Case Background: - Mrs. Santha - Owner Small Assembly Shop - Production Line ADocument12 pagesCase Background: - Mrs. Santha - Owner Small Assembly Shop - Production Line AAbhishek KumarNo ratings yet

- Starbucks Case StudyDocument27 pagesStarbucks Case StudyPardeep KapilNo ratings yet

- Porter Five Force ModelDocument5 pagesPorter Five Force ModelAbhishekNo ratings yet

- Nominal Data: Amount in USDDocument5 pagesNominal Data: Amount in USDShivam GuptaNo ratings yet

- Insteel Wire Products Abm at Andrews Year of ABC AnalysisDocument15 pagesInsteel Wire Products Abm at Andrews Year of ABC AnalysisASHUTOSH SHARMANo ratings yet

- OB AssignmentDocument6 pagesOB Assignmentkevin johnsNo ratings yet

- Data Analysis For ManagersDocument8 pagesData Analysis For ManagersMedha SinghNo ratings yet

- DAFMDocument13 pagesDAFMMedha SinghNo ratings yet

- A Zero Wage Increase Again - Situational AnalysisDocument1 pageA Zero Wage Increase Again - Situational AnalysisRahul Kashyap100% (1)

- What Do Think Was This BankDocument20 pagesWhat Do Think Was This BankZeena HodaNo ratings yet

- BRM0012 - Consumer's Perception On Inverters in IndiaDocument3 pagesBRM0012 - Consumer's Perception On Inverters in Indiavarun kumar Verma0% (2)

- Product Relaunch BisleriDocument21 pagesProduct Relaunch BisleriNishi Jain100% (1)

- Managers: We Are Katti With You: A Narrative About Union - Management Conflict at Precision Parts Limited'Document8 pagesManagers: We Are Katti With You: A Narrative About Union - Management Conflict at Precision Parts Limited'AISHWARYA SONINo ratings yet

- Bajaj Lockout Case StudyDocument4 pagesBajaj Lockout Case StudyJayesh RuchandaniNo ratings yet

- Otisline Case AnalysisDocument2 pagesOtisline Case AnalysisSuhas AvgNo ratings yet

- Mannarkkad CaseDocument10 pagesMannarkkad CaseSatyam Uttam0% (1)

- ISM Case Analysis (Cisco Systems) : Group 13 Section - ADocument6 pagesISM Case Analysis (Cisco Systems) : Group 13 Section - AManish Kumar BansalNo ratings yet

- Comp-Xm® Inquirer0Document21 pagesComp-Xm® Inquirer0Jasleen Kaur (Ms)No ratings yet

- Satyam: The Satyam Saga By:Kiran KarnikDocument20 pagesSatyam: The Satyam Saga By:Kiran KarnikRavi SinghNo ratings yet

- Cost Sheet For The Month of January: TotalDocument9 pagesCost Sheet For The Month of January: TotalgauravpalgarimapalNo ratings yet

- Working: Lunch Dinner Sales Units 7800 20280 Sales Price 12 25 93600 507000Document8 pagesWorking: Lunch Dinner Sales Units 7800 20280 Sales Price 12 25 93600 507000kudkhanNo ratings yet

- Q1: A Company Engaged in Producing Tinned Food Has 300 Trained Employee On The Rolls Each of WhonDocument24 pagesQ1: A Company Engaged in Producing Tinned Food Has 300 Trained Employee On The Rolls Each of WhonsjthankiNo ratings yet

- Resource Cell For Juvenile Justice PresentationDocument9 pagesResource Cell For Juvenile Justice PresentationNENCY PATELNo ratings yet

- Report On Data VisualizationDocument6 pagesReport On Data VisualizationSwaraj HachadadNo ratings yet

- Blended Training Program - Batch Commenced On: Assignment - Day 3Document4 pagesBlended Training Program - Batch Commenced On: Assignment - Day 3Shubham BhawsarNo ratings yet

- Mansa Building CaseDocument5 pagesMansa Building CaseshreeshNo ratings yet

- RSPL Limited - R - 16102020Document8 pagesRSPL Limited - R - 16102020DarshanNo ratings yet

- Itsa Excel SheetDocument7 pagesItsa Excel SheetraheelehsanNo ratings yet

- Strike On MRFDocument5 pagesStrike On MRFMegha YmtNo ratings yet

- Animal HealthDocument3 pagesAnimal Healthkritigupta.may1999No ratings yet

- Chemalite Inc - Assignment - AccountingDocument2 pagesChemalite Inc - Assignment - Accountingthi_aar100% (1)

- Session IIDocument1 pageSession IIbharathNo ratings yet

- "Tata Motors: Can The Turnaround Plan Improve Performance?" NameDocument16 pages"Tata Motors: Can The Turnaround Plan Improve Performance?" NameMehdi BelabyadNo ratings yet

- Kim FullerDocument3 pagesKim FullerVinay GoyalNo ratings yet

- Assignment Iii Mansa Building Case Study: Submitted by Group IVDocument14 pagesAssignment Iii Mansa Building Case Study: Submitted by Group IVHeena TejwaniNo ratings yet

- GodrejDocument26 pagesGodrejDeepinder Kaur GrewalNo ratings yet

- Calendar Demand ProblemDocument43 pagesCalendar Demand Problemrahul.iamNo ratings yet

- Northboro Machine Tools CorporationDocument9 pagesNorthboro Machine Tools Corporationsheersha kkNo ratings yet

- Merton Trucks Case Note: I I M A IIMA/QM-xxxDocument8 pagesMerton Trucks Case Note: I I M A IIMA/QM-xxxAyush GuptaNo ratings yet

- Risk Management With A Duration Gap ApproachDocument44 pagesRisk Management With A Duration Gap ApproachDicto RockyNo ratings yet

- ME15 - Unit 3Document59 pagesME15 - Unit 3Bharathi RajuNo ratings yet

- Cap Bud - HeroDocument13 pagesCap Bud - HeroMohmmedKhayyumNo ratings yet

- Decision Sheet - MdbsDocument3 pagesDecision Sheet - MdbsGayatri BommisettyNo ratings yet

- Nandini Milk-FinalDocument19 pagesNandini Milk-Finalopalq100% (1)

- Linear Programming CasesDocument5 pagesLinear Programming CasesarpitNo ratings yet

- Logistics and Supply Chain ManagementDocument3 pagesLogistics and Supply Chain ManagementSatchidananda TripathyNo ratings yet

- 1 Formulation - AssignmentDocument4 pages1 Formulation - AssignmentNamanNo ratings yet

- Consumer's Journey To PurchaseDocument1 pageConsumer's Journey To PurchaseRohanMohapatraNo ratings yet

- FMCG Industry: Porter AnalysisDocument4 pagesFMCG Industry: Porter AnalysisRohanMohapatraNo ratings yet

- Iot Competitor AnalysisDocument6 pagesIot Competitor AnalysisRohanMohapatraNo ratings yet

- Internet of Things (IOT) : Market ResearchDocument12 pagesInternet of Things (IOT) : Market ResearchRohanMohapatraNo ratings yet

- GFNGDocument2 pagesGFNGRohanMohapatraNo ratings yet

- Topic: Consumer Journey To Purchase of Smartwatch Devices Problem StatementDocument2 pagesTopic: Consumer Journey To Purchase of Smartwatch Devices Problem StatementRohanMohapatraNo ratings yet

- What Will You Do?Document1 pageWhat Will You Do?RohanMohapatraNo ratings yet

- Internet of Things - IotDocument12 pagesInternet of Things - IotRohanMohapatraNo ratings yet

- Grgyjarketing Analysis Toolygjofitability AnalysisDocument2 pagesGrgyjarketing Analysis Toolygjofitability AnalysisRohanMohapatraNo ratings yet

- Setting Goals and Managing The Sales Force's PerformanceDocument2 pagesSetting Goals and Managing The Sales Force's PerformanceRohanMohapatraNo ratings yet

- GrovgDocument2 pagesGrovgRohanMohapatraNo ratings yet

- GrogyjgyjDocument2 pagesGrogyjgyjRohanMohapatraNo ratings yet

- Summary of Personal Selling: Preparation and ProcessDocument2 pagesSummary of Personal Selling: Preparation and ProcessRohanMohapatraNo ratings yet

- FsfsDocument2 pagesFsfsRohanMohapatraNo ratings yet

- A Salesperson Is A Salesperson To Be Effective, He Should Have Multiple Sales TraitsDocument2 pagesA Salesperson Is A Salesperson To Be Effective, He Should Have Multiple Sales TraitsRohanMohapatraNo ratings yet

- Setting Goal & Managing Sales Force's PerformanceDocument2 pagesSetting Goal & Managing Sales Force's PerformanceRohanMohapatraNo ratings yet

- Expense Quotas Are The Costs That Are Needed by The Sales Representatives To Convert A SaleDocument2 pagesExpense Quotas Are The Costs That Are Needed by The Sales Representatives To Convert A SaleRohanMohapatraNo ratings yet

- Worldwide Equipment (China) LTD: A Salesforce DilemmaDocument4 pagesWorldwide Equipment (China) LTD: A Salesforce DilemmaRohanMohapatraNo ratings yet

- Process: Sales Knowledge and Sales Related Marketing PoliciesDocument2 pagesProcess: Sales Knowledge and Sales Related Marketing PoliciesRohanMohapatraNo ratings yet

- Siebel Systems: Anatomy of A SaleDocument7 pagesSiebel Systems: Anatomy of A SaleRohanMohapatraNo ratings yet

- SADMAN Assignment Group 10 - Section B Reading Summary The New Science of Sales Force ProductivityDocument2 pagesSADMAN Assignment Group 10 - Section B Reading Summary The New Science of Sales Force ProductivityRohanMohapatraNo ratings yet

- Private & InstitutionalDocument6 pagesPrivate & InstitutionalRohanMohapatraNo ratings yet

- Sadman:: Stepsmart Fitness Case AnalysisDocument5 pagesSadman:: Stepsmart Fitness Case AnalysisRohanMohapatraNo ratings yet

- Raymond (J.K. Helene Curtis LTD.) : Manufact Uring Unit Carry Forward Agency Distribut Ors RetailersDocument2 pagesRaymond (J.K. Helene Curtis LTD.) : Manufact Uring Unit Carry Forward Agency Distribut Ors RetailersRohanMohapatraNo ratings yet

- Company Customer Context Competit ORDocument5 pagesCompany Customer Context Competit ORRohanMohapatraNo ratings yet

- Fcfe Model: Year 2020P 2021 F 2022 F Date 7/24/2020 3/31/2021 3/31/2022 TIME in Years 0.69 1.69Document3 pagesFcfe Model: Year 2020P 2021 F 2022 F Date 7/24/2020 3/31/2021 3/31/2022 TIME in Years 0.69 1.69RohanMohapatraNo ratings yet

- Step SMDZFDZDocument2 pagesStep SMDZFDZRohanMohapatraNo ratings yet

- Limited, Which Is A Joint Venture Between The Tata Group and Tamil Nadu IndustrialDocument2 pagesLimited, Which Is A Joint Venture Between The Tata Group and Tamil Nadu IndustrialRohanMohapatraNo ratings yet

- Income Statement: Particulars Revenue Gross ProfitDocument6 pagesIncome Statement: Particulars Revenue Gross ProfitRohanMohapatraNo ratings yet

- ABC MsDocument17 pagesABC MsdrewbieskieeNo ratings yet

- TurkeyDocument17 pagesTurkeyMawa TataruNo ratings yet

- Moving From HACCP To HARPC - The Practical Steps To ComplianceDocument33 pagesMoving From HACCP To HARPC - The Practical Steps To ComplianceElvira100% (1)

- Sop Chemical PrepDocument2 pagesSop Chemical PrepArief Rachman RamadaniNo ratings yet

- Historical Background of Science and Technology in TheDocument20 pagesHistorical Background of Science and Technology in ThePrimo GeorgeNo ratings yet

- Countable Uncountable NounsDocument32 pagesCountable Uncountable NounsSimona AlexandraNo ratings yet

- Baking GuidelinesDocument28 pagesBaking GuidelinesHonorina MorondozNo ratings yet

- Blood Type DietDocument6 pagesBlood Type DietMarialoretoAGNo ratings yet

- Garbarino Food ForestDocument5 pagesGarbarino Food ForestSeth FoxNo ratings yet

- Berchemia DiscolorDocument5 pagesBerchemia DiscolorvitazzoNo ratings yet

- Differentiating Beef From BuffenDocument15 pagesDifferentiating Beef From BuffenM I KhanNo ratings yet

- KNUST FQM 579 - 20823471 - PG9573121Review Strategies To Mitigate Postworking Edward Christian Brown AppiahDocument20 pagesKNUST FQM 579 - 20823471 - PG9573121Review Strategies To Mitigate Postworking Edward Christian Brown Appiahedward AppiahNo ratings yet

- Soal Kls 7 Semester 1Document7 pagesSoal Kls 7 Semester 1rahmiNo ratings yet

- Naik Krishana R Mtech PDFDocument102 pagesNaik Krishana R Mtech PDFRohit Kumar Sahoo100% (1)

- Manual - Hamilton Beach 68330R 4 QuartDocument32 pagesManual - Hamilton Beach 68330R 4 QuartRyanNo ratings yet

- Agricultural Practice in Greek PrehistoryDocument10 pagesAgricultural Practice in Greek PrehistoryKoKetNo ratings yet

- Weinsier DocsDocument3 pagesWeinsier DocsDavid DworkNo ratings yet

- FDA 2019 P 1911 0003 - ContentDocument8 pagesFDA 2019 P 1911 0003 - ContentBegüm GüzelNo ratings yet

- Ent530 Business Plan AssignmentDocument30 pagesEnt530 Business Plan AssignmentyasszirNo ratings yet

- Typed by The GauravDocument9 pagesTyped by The GauravLokesh manglaNo ratings yet

- Morgan Home Appliances Malaysia - Smart Living V33 (S)Document16 pagesMorgan Home Appliances Malaysia - Smart Living V33 (S)Iskandar ZulqarnainNo ratings yet

- 57 PH TPN - Adm Parenteral Nut & LipidDocument7 pages57 PH TPN - Adm Parenteral Nut & LipidChornelis KristianNo ratings yet

- Grain Journal - 01 JAN-FEB 2013Document296 pagesGrain Journal - 01 JAN-FEB 2013jumanleeNo ratings yet

- 150k Dart Tournament ChachaDocument5 pages150k Dart Tournament ChachaMa. Consolacion TambaoanNo ratings yet