Professional Documents

Culture Documents

Design and Impact Analysis of a Frameless Volvo Bus Chassis

Uploaded by

harshaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Impact Analysis of a Frameless Volvo Bus Chassis

Uploaded by

harshaCopyright:

Available Formats

International Journal of Research p-ISSN: 2348-6848

e-ISSN: 2348-795X

Available at https://edupediapublications.org/journals

Volume 04 Issue 07

June 2017

Design and Impact Analysis on a Frameless Chassis

Construction of Volvo Bus for Different Speeds

Boidapu Jaswanth karthik1 Mr. K.Ravindra2

1M.tech, student, mechanical enginnering viswanadha institute of technology and management. Visakpatnam

2Assistant professor,mechanical enginnering, viswanadha institute of technology and management. Visakpatnam

Abstract: In this project we are reducing the impact by modifying the existing design. Data is collected from the

Body construction work shop in Hyderabad. Presently steel is used for chassis construction. The aim of the project

is to analyze the frameless chassis with presently used material steel and replacing with composite materials like

Carbon Epoxy, E- Glass epoxy. Impact analysis is conducted on chassis for different speeds by varying the

materials. We are conducting above analysis for the existing design and for the modified design. Best of the result

we will consider for the chassis design. Also we are going to reduce weight of the chassis by using composite

materials replacing with steel Software used for modeling CREO and for analysis COSMOS.

Key words: CREO parametric software, solid works, composite materials, speeds.

I. INTRODUCTION CHASSIS FRAME: Chassis is a French term and was

initially used to denote the frame parts or Basic Structure

The chassis forms the main structure of the modern of the vehicle. It is the back bone of the vehicle. A

automobile. A large number of designs in pressed-steel vehicle without body is called Chassis. The components

frame form a skeleton on which the engine, wheels, axle of the vehicle like Power plant, Transmission System,

assemblies, transmission, steering mechanism, brakes, Axles, Wheels and Tyres, Suspension, Controlling

and suspension members are mounted. During the Systems like Braking, Steering etc., and also electrical

manufacturing process the body is flexibly bolted to the system parts are mounted on the Chassis frame. It is the

chassis. main mounting for all the components including the

body. So it is also called as Carrying Unit.

This combination of the body and frame performs a

variety of functions. It absorbs the reactions from the LAYOUT OF CHASSIS AND ITS MAIN

movements of the engine and axle, receives the reaction COMPONENTS: The following main components of

forces of the wheels in acceleration and braking, absorbs the Chassis are

aerodynamic wind forces and road shocks through the

suspension, and absorbs the major energy of impact in 1. Frame: it is made up of long two members called side

the event of an accident. members riveted together with the help of number of

cross members.

There has been a gradual shift in modern small car

designs. There has been a trend toward combining the 2. Engine or Power plant: It provides the source of

chassis frame and the body into a single structural power

element. In this grouping, the steel body shell is

reinforced with braces that make it rigid enough to resist 3. Clutch: It connects and disconnects the power from

the forces that are applied to it. To achieve better noise- the engine fly wheel to the transmission system.

isolation characteristics, separate frames are used for

4. Gear Box

other cars. The presence of heavier-gauge steel

components in modern separate frame designs also tends 5. U Joint

to limit intrusion in accidents.INTRODUCTION OF

Available online: https://edupediapublications.org/journals/index.php/IJR/ P a g e | 1238

International Journal of Research p-ISSN: 2348-6848

e-ISSN: 2348-795X

Available at https://edupediapublications.org/journals

Volume 04 Issue 07

June 2017

6. Propeller Shaft TYPES OF AUTOMOBILE CHASSIS

7. Differential Motorcycle Chassis:

FUNCTIONS OF THE CHASSIS FRAME: An important type of automotive chassis, motorcycle

chassis comprise of different auto parts and components

1. To carry load of the passengers or goods carried in the like auto frame, wheels, two wheeler brakes and

body. suspension. Its basically the frame for motorbikes that

holds these components together. A motorbike chassis

2. To support the load of the body, engine, gear box etc., can be manufactured from different materials. But the

commonly used materials are steel, aluminum, or

3. To withstand the forces caused due to the sudden magnesium.

braking or acceleration

Car Chassis:

4. To withstand the stresses caused due to the bad road

condition. The main structure of a car is known as chassis. Car

chassis functions as a support for the different car parts.

5. To withstand centrifugal force while cornering Automotive parts like engine, suspension & steering

mechanism, braking system, auto wheels, axle

TYPES OF CHASSIS FRAMES:

assemblies and transmission are mounted on the car

There are three types of frames chassis.

1. Conventional frame Bus Chassis:

2. Integral frame Bus chassis is the design and quality of bus chassis

depends on the capacity of bus. It can be tailor made

3. Semi-integral frame according to the needs and can be availed with features

like transverse mounted engine, air suspension as well as

BUS STRUCTURE anti-roll bars. A well manufactured bus chassis offers

various benefits like high torque from low revs, superior

Only in the first years of bus body design, a flexible brake performance and more. Bus chassis designed for

truck chassis was used together with non- structural body urban routes differs from the one manufactured for

elements of wood and canvas resulting in the true chassis suburban routes.

design as a contrary to the integral body design. Today,

even if a channel beam chassis is used together with II. LITERATURE REVIEW

properly designed floor cross members, side wall and

roof structure, a fully' integral structure is achieved. Material Optimization and Analysis on a frameless

chassis construction of Volvo bus

Advantages of a channel beam bus chassis are simplicity

of design, fully equipped drive able vehicle, heavy duty Automotive chassis is a skeletal frame on which various

suspension and sturdy load introduction members. The mechanical parts like engine, tires, axle assemblies,

bus body as a whole is a light weight, stiff structure, brakes, steering etc. are bolted. The chassis is considered

however significant distortion of the overall stiffness to be the most significant component of an automobile. It

occurs at the doors and other large openings Shear is the most crucial element that gives strength and

deformation at the doors is up to 10 times greater than stability to the vehicle under different conditions. Bus

for comparable sidewall sections. Most of the bus bodies chassis is the design and quality of bus chassis depends

on the European continent are fully welded tubular steel on the capacity of bus. It can be tailor made according to

structures having similar stiffness properties. However, the needs and can be availed with features like transverse

there are differences in the local design of welded joints mounted engine, air suspension as well as anti-roll bars.

with respect to dimensions, shape and application of A well manufactured bus chassis offers various benefits

additional stiffeners. Therefore different fatigue life like high torque from low revs, superior brake

performance is achieved. performance and more. Bus chassis designed for urban

routes differs from the one manufactured for suburban

Available online: https://edupediapublications.org/journals/index.php/IJR/ P a g e | 1239

International Journal of Research p-ISSN: 2348-6848

e-ISSN: 2348-795X

Available at https://edupediapublications.org/journals

Volume 04 Issue 07

June 2017

routes. For bus frameless chassis construction is used. In CAD may be used to design curves and figures in two-

this frame less chassis type all the components is dimensional (2D) space; or curves, surfaces, and solids

attached to the body. All the functions of the frame in three-dimensional (3D) space.

carried out by the body itself. Due to elimination of long

frame it is cheaper and due to less weight most CAD is an important industrial art extensively used in

economical also. Only Disadvantage is repairing is many applications, including automotive, shipbuilding,

difficult. This type of frames will affect more in collision and aerospace industries, industrial and architectural

of vehicle. In this project we are reducing the impact by design, prosthetics, and many more. CAD is also widely

changing the existing design materials. Data is collected used to produce computer animation for special

from the Body construction work shape in Vijayawada. effects in movies, advertising and technical manuals,

Presently steel is used for chassis construction. The aim often called DCC digital content creation. The modern

of the project is to analyze the frameless chassis with ubiquity and power of computers means that even

presently used material steel and replacing with perfume bottles and shampoo dispensers are designed

composite materials like Carbon Epoxy, E- Glass epoxy. using techniques unheard of by engineers of the 1960s.

Impact analysis is conducted on chassis for different Because of its enormous economic importance, CAD has

speeds by varying the materials. We are conducting been a major driving force for research in computational

above analysis for the existing design and for the geometry, computer graphics (both hardware and

modified design. Best of the result we will consider for software), and discrete differential geometry.

the chassis design. Also we are going to reduce weight

of the chassis by using composite materials replacing

INTRODUCTION TO CREO

with steel.

III. INTRODUCTION TO CAD PTC CREO, formerly known as Pro/ENGINEER, is 3D

modeling software used in mechanical engineering,

Computer-aided design (CAD) is the use of computer design, manufacturing, and in CAD drafting service

systems (or workstations) to aid in the creation, firms. It was one of the first 3D CAD modeling

modification, analysis, or optimization of a design. CAD applications that used a rule-based parametric system.

software is used to increase the productivity of the Using parameters, dimensions and features to capture the

designer, improve the quality of design, improve behavior of the product, it can optimize the development

communications through documentation, and to create a product as well as the design itself.

database for manufacturing. CAD output is often in the

form of electronic files for print, machining, or other The name was changed in 2010 from Pro/ENGINEER

manufacturing operations. The Wildfire to CREO. It was announced by the company

term CADD (for Computer Aided Design and Drafting) who developed it, Parametric Technology Company

is also used. (PTC), during the launch of its suite of design products

that includes applications such as assembly modeling,

Its use in designing electronic systems is known 2D orthographic views for technical drawing, finite

as electronic design automation, or EDA. In mechanical element analysis and more.

design it is known as mechanical design

automation (MDA) or computer-aided Introduction to solidworks : Solidworks is a 3d

drafting (CAD), which includes the process of creating mechanical cad (computer-aided design) program that

a technical drawing with the use of computer software. runs on microsoft windows and is being developed by

dassault systèmes solidworks corp., a subsidiary of

CAD software for mechanical design uses either vector- dassault systèmes, s. A. (vélizy, france). Solidworks is

based graphics to depict the objects of traditional currently used by over 1.3 million engineers and

drafting, or may also produce raster graphics showing designers at more than 130,000 companies worldwide.

the overall appearance of designed objects. However, it Fy2009 revenue for solidworks, was 366 million dollars.

involves more than just shapes. As in the Solidworks is a parasolid-based solid modeler, and

manual drafting of technical and engineering drawings, utilizes a parametric feature-based approach to create

the output of CAD must convey information, such models and assemblies. Parameters refer to constraints

as materials, processes, dimensions, and tolerances, whose values determine the shape or geometry of the

according to application-specific conventions. model or assembly. Parameters can be either numeric

Available online: https://edupediapublications.org/journals/index.php/IJR/ P a g e | 1240

International Journal of Research p-ISSN: 2348-6848

e-ISSN: 2348-795X

Available at https://edupediapublications.org/journals

Volume 04 Issue 07

June 2017

parameters, such as line lengths or circle diameters, or

geometric parameters, such as tangent, parallel,

concentric, horizontal or vertical, etc. Numeric

parameters can be associated with each other through the

use of relations, which allows them to capture design

intent. Design intent is how the creator of the part wants

it to respond to changes and updates. For example, you

would want the hole at the top of a beverage can to stay

at the top surface, regardless of the height or size of the

can. Solidworks allows you to specify that the hole is a

feature on the top surface, and will then honor your

design intent no matter what the height you later gave to MODIFIED MODEL

the can.

Features refer to the building blocks of the part. They are

the shapes and operations that construct the part. Shape-

based features typically begin with a 2d or 3d sketch of

shapes such as bosses, holes, slots, etc. This shape is

then extruded or cut to add or remove material from the

part. Operation-based features are not sketch-based, and

include features such as fillets, chamfers, shells,

applying draft to the faces of a part, etc.

IV RESULTS AND DISCUSSION

PRESENT MODEL

2D DRAWING

2D DRAWING

Available online: https://edupediapublications.org/journals/index.php/IJR/ P a g e | 1241

International Journal of Research p-ISSN: 2348-6848

e-ISSN: 2348-795X

Available at https://edupediapublications.org/journals

Volume 04 Issue 07

June 2017

IMPACT ANALYSIS OF FRAME LESS CHASSIS Study Properties

PRESENT DESIG SPEED – 75km/hr ALLOY Study name impact_75_STEEL

STEEL Analysis type Drop Test

Mesh type Solid Mesh

Large displacement On

Result folder SolidWorks document (

6.3.3 Setup Information

Type Velocity at impact

Velocity Magnitude 20.83 m/sec

Impact Velocity Plane1

Reference

Gravity 9.81 m/s^2

Gravity Reference Top Plane

Parallel to reference Right Plane

plane

Friction Coefficient 0

Target Stiffness Rigid target

6.3.4 Result Options

Solution Time After 20 microsec

Impact

Save Results Starting 0 microsec

From

No. of Plots 25

No. of Graph Steps 20

Per Plot

Number of vertex 0

Units

Unit system: SI (MKS)

Length/Displacement mm

Temperature Kelvin

Angular velocity Rad/sec

Pressure/Stress N/m^2

Material Properties

Available online: https://edupediapublications.org/journals/index.php/IJR/ P a g e | 1242

International Journal of Research p-ISSN: 2348-6848

e-ISSN: 2348-795X

Available at https://edupediapublications.org/journals

Volume 04 Issue 07

June 2017

MESH INFORMATION

DEFORMATION

Mesh Information - Details

STRAIN

Study Results CARBON EPOXY

STRESS STUDY RESULT

STRESS

Available online: https://edupediapublications.org/journals/index.php/IJR/ P a g e | 1243

International Journal of Research p-ISSN: 2348-6848

e-ISSN: 2348-795X

Available at https://edupediapublications.org/journals

Volume 04 Issue 07

June 2017

DEFORMATION

DEFORMATION

STRAIN

STRAIN

GLASS EPOXY

STUDY RESULT RESULTS

STRESS PRESENT MODEL

Available online: https://edupediapublications.org/journals/index.php/IJR/ P a g e | 1244

International Journal of Research p-ISSN: 2348-6848

e-ISSN: 2348-795X

Available at https://edupediapublications.org/journals

Volume 04 Issue 07

June 2017

K.RAVINDRA Associate Professor,

MODIFIED MODEL

1. Material Optimization and Analysis on a

frameless chassis construction of Volvo bus Mr.

K. Eswararao M. Tech-MACHINE DESIGN

pursuing Student, SISTAM College of Engineering,

Srikakulam, Mr. S. Chandrasekhar Reddy Associate

Professor & HOD, SISTAM College of

Engineering, Srikakulam,

2. Impact analysis on a frame less chassis construction

of mini bus for variable loads mr. A.naresh, assistant

CONCLUSION professor in the department of mechanical

engineering, guru nanak institutions and technical

In our project we have designed a frameless chassis used campus (gnitc) , ibrahimpatnam, r. R. Dist

in a Volvo bus collecting data from Body construction ,hyderabad,telangana, india mr. E. Naveen kumar,

work shop in Vijayawada. Present used material for application engineer , mech engg, amberpet,

frameless chassis is Steel. We are replacing the steel hyderabad , telangana, india.

with composite materials Carbon Epoxy and E – Glass 3. Design and analysis of a bus body side frame 1

Epoxy. By replacing with composites, the weight of the sreenath s, 2k kamalakkannan 1m.tech, 2associate

frameless chassis is reduced by almost 4 times. Impact professor department of automobile engineering

analysis is done on the chassis at different speeds hindustan university, chennai

75km/hr, 150 km/hr and 300 km/hr. By observing the 4. Stabilization of city bus chassis to reduce tilt

results, the displacement and stress values are less for E effect using ansys work bench Murari Nagendra

– Glass epoxy than Steel and Carbon Epoxy. We have Babu1, S N S Maruthi Vijay2, Vinjamuri Venkata

also modified the design of frameless chassis by adding Kamesh3.

ribs at the top and bottom at the front side of the chassis. 5. Computer Aided Bus Skeleton Design (BUS-CAD)

By observing the impact analysis on modified design the H. M. A. Hussein and Alexander Harrich

displacement and stress values are reduced than the 6. TRIZ method for light weight bus body structure

present design. So we can conclude that E – Glass epoxy design S. Butdee a,*, F. Vignat b a Department of

is better material for frameless chassis and by modifying Production Engineering, Faculty of Engineering,

the design some advantages can be found (i.e) decrease Thai-French Innovation Center (TFIC) & Integrated

of stress and displacement values. Manufacturing System Research Center, King

Mongkut’s University of Technology, North

REFERENCES Bangkok, Thailand

1. Design and impact analysis of frameless chassis

of valvo bus for different speeds BOIDAPU

JASWANTH KARTHIK M. Tech-MACHINE

DESIGN pursuing Student, viswanadha institute

of technology and management, , Mr.

Available online: https://edupediapublications.org/journals/index.php/IJR/ P a g e | 1245

You might also like

- FE-based Vehicle Analysis of Heavy TrucksDocument10 pagesFE-based Vehicle Analysis of Heavy TrucksvilukNo ratings yet

- Wheel End Assembly MM1114Document71 pagesWheel End Assembly MM1114LUKAS100% (1)

- Wilson Gear BoxDocument20 pagesWilson Gear Boxsonirocks100% (1)

- 3FE Desmog GuideDocument13 pages3FE Desmog GuideKevinNo ratings yet

- System Changeover Four Possible ApproachesDocument5 pagesSystem Changeover Four Possible ApproachesArap Chito75% (8)

- Installed FilesDocument41 pagesInstalled Filesluz y amorNo ratings yet

- Measure Your DevOps JourneyDocument16 pagesMeasure Your DevOps JourneySonia Herrera UribeNo ratings yet

- Java OOP MCQ and Short QuestionsDocument10 pagesJava OOP MCQ and Short QuestionsVinod Shanker ShringiNo ratings yet

- Hypermesh Basics Tutorials-1Document40 pagesHypermesh Basics Tutorials-1api-3717939100% (8)

- Volvo vt880Document8 pagesVolvo vt880ForomaquinasNo ratings yet

- Synchromesh Gearbox Definition Construction Working Principle Advantages Application Notes PDFDocument9 pagesSynchromesh Gearbox Definition Construction Working Principle Advantages Application Notes PDFMelanie MartinssonNo ratings yet

- Chapter 01 Introduction To Servicing Heavy Duty TrucksDocument5 pagesChapter 01 Introduction To Servicing Heavy Duty TrucksRajvir GrewalNo ratings yet

- ZF Axle Systems for Coaches: 20 Years of ExperienceDocument8 pagesZF Axle Systems for Coaches: 20 Years of ExperiencewurtukukNo ratings yet

- Air Brake System: Presented By: T Pravalika 19D45A0307 Presented By: T Pravalika 19D45A0307Document24 pagesAir Brake System: Presented By: T Pravalika 19D45A0307 Presented By: T Pravalika 19D45A0307priyanka priya100% (1)

- Slides.D13A. Presentation. enDocument10 pagesSlides.D13A. Presentation. enAlex PakitoNo ratings yet

- Clutch PDFDocument12 pagesClutch PDFIzz BaharNo ratings yet

- Hydro Pneumatic Braking SytemDocument11 pagesHydro Pneumatic Braking Sytempramo_dass100% (1)

- Volvo 9400 Brochure NewDocument20 pagesVolvo 9400 Brochure Newmithun.gopinathNo ratings yet

- Fabrication of Four Wheel Steering SystemDocument14 pagesFabrication of Four Wheel Steering SystemRenju PaulNo ratings yet

- Volvo FM-Technical SpecificationsDocument10 pagesVolvo FM-Technical SpecificationsManuel La TorreNo ratings yet

- Toyota Vehicle Glossary TermsDocument31 pagesToyota Vehicle Glossary TermsEdward Ugochukwu AdighibeNo ratings yet

- B9TL RangeDocument12 pagesB9TL RangePhilippine Bus Enthusiasts SocietyNo ratings yet

- Atego 4x2 Rigid 1018 1024Document4 pagesAtego 4x2 Rigid 1018 1024neacsucristianNo ratings yet

- Proposal On Design Analysis of Composite Leaf Spring of A Light VehicleDocument13 pagesProposal On Design Analysis of Composite Leaf Spring of A Light Vehiclecobra2919No ratings yet

- See Figures 1 Thru 7: Suspension SystemDocument28 pagesSee Figures 1 Thru 7: Suspension SystembalajigandhirajanNo ratings yet

- Portal Axle Design PDFDocument5 pagesPortal Axle Design PDFUmesh JadhavNo ratings yet

- Bharat Benz - Problems Ahead (PPTminimizer)Document26 pagesBharat Benz - Problems Ahead (PPTminimizer)amitsonuksmsNo ratings yet

- Brake System - HMCDocument69 pagesBrake System - HMCDani HidayatulohNo ratings yet

- Classification of Chassis Mte1Document12 pagesClassification of Chassis Mte1Ryan CalicaNo ratings yet

- Volvo Powertrain Strategy Presentation PDFDocument26 pagesVolvo Powertrain Strategy Presentation PDFcarbasemyNo ratings yet

- Gearboxes in AutomobilesDocument34 pagesGearboxes in AutomobilesPrashant PatilNo ratings yet

- Air Brake Systems for Heavy VehiclesDocument4 pagesAir Brake Systems for Heavy VehiclesYemaneDibetaNo ratings yet

- Front and Rear Axles Bearing PN PDFDocument15 pagesFront and Rear Axles Bearing PN PDFAyman OsamaNo ratings yet

- M3I - OM 460 Engine, 6-Cyl. In-Line, 12.8 L, 290 KW (394 HP), 1900 NM - Actros Model Series 964Document2 pagesM3I - OM 460 Engine, 6-Cyl. In-Line, 12.8 L, 290 KW (394 HP), 1900 NM - Actros Model Series 964url295No ratings yet

- Preface: Practical Knowledge Leads A Man To Perfection'Document15 pagesPreface: Practical Knowledge Leads A Man To Perfection'Arpan SaxenaNo ratings yet

- THE IDIOT’S GUIDE TO TUNING SU CARBSDocument7 pagesTHE IDIOT’S GUIDE TO TUNING SU CARBSHimanshu SinghNo ratings yet

- FM13 6x4 Air Suspended Tractor FM 64T B3HP: Chassis Dimensions (MM)Document6 pagesFM13 6x4 Air Suspended Tractor FM 64T B3HP: Chassis Dimensions (MM)abhijeet7362No ratings yet

- Principle: Power Sources TransmissionDocument18 pagesPrinciple: Power Sources TransmissionGaurav Maithani100% (2)

- Techinfo Oc500rf enDocument12 pagesTechinfo Oc500rf enDanang Wiryawan AdityatamaNo ratings yet

- Automatic TransmissionDocument18 pagesAutomatic TransmissionAnandraj004No ratings yet

- Types of Axles Front Axle Rear Axle and Stub Axle PDFDocument7 pagesTypes of Axles Front Axle Rear Axle and Stub Axle PDFraghavNo ratings yet

- Automobile Electrical System Questions With AnswersDocument14 pagesAutomobile Electrical System Questions With Answersshamgoudampalli210No ratings yet

- ZF-AV110 Presentation enDocument6 pagesZF-AV110 Presentation enjasogti100% (1)

- MX Engine BrochureDocument7 pagesMX Engine BrochureGus SalazarNo ratings yet

- Tata Motors' EGR and SCR Technologies for BS IV ComplianceDocument3 pagesTata Motors' EGR and SCR Technologies for BS IV ComplianceKaranNo ratings yet

- Automatic Gearbox WorkingDocument10 pagesAutomatic Gearbox Workingsaurabhsharma1990No ratings yet

- Anti-Lock Braking System (ABS) & Electronic Brake-Force Distribution (EBD or EBFD) SystemDocument15 pagesAnti-Lock Braking System (ABS) & Electronic Brake-Force Distribution (EBD or EBFD) SystemAkshit GoyalNo ratings yet

- ATT Brakes - Example TextbookDocument15 pagesATT Brakes - Example TextbookSooraj KrishnaNo ratings yet

- Minor Sweeping Machines: Technical Operating and Basic Maintenance InstructionsDocument46 pagesMinor Sweeping Machines: Technical Operating and Basic Maintenance InstructionsBogdan NgrNo ratings yet

- 4WD System Specs & Service GuideDocument35 pages4WD System Specs & Service GuideZM OhnNo ratings yet

- Turbocharger: Presented byDocument26 pagesTurbocharger: Presented byYasewn KALAWANTNo ratings yet

- THREE AXIS PNEUMATIC MODERN TRAILER UNLOADINGDocument26 pagesTHREE AXIS PNEUMATIC MODERN TRAILER UNLOADINGjaiy12No ratings yet

- Land Rover V8: and ToolDocument56 pagesLand Rover V8: and ToolAntonio OliveiraNo ratings yet

- Connecting Rods Guide: Functions, Types & Stress ForcesDocument113 pagesConnecting Rods Guide: Functions, Types & Stress ForcesengrsurifNo ratings yet

- Prinsip Electromagnetic BrakeDocument11 pagesPrinsip Electromagnetic BrakeKiryaki FrancisNo ratings yet

- Scaniaks 2013Document126 pagesScaniaks 2013Alex Renne ChambiNo ratings yet

- Project Report: - Suspension SystemDocument33 pagesProject Report: - Suspension SystemAnil KumarNo ratings yet

- Abs & AsrDocument36 pagesAbs & Asrcoolonline0% (1)

- Ex1 LabDocument6 pagesEx1 LabRamesh Kavitha Sanjit 18BME0677No ratings yet

- Automobile Chasis: Project OnDocument41 pagesAutomobile Chasis: Project OnSai CoolNo ratings yet

- Development of Hybrid Cars-0Document4 pagesDevelopment of Hybrid Cars-0wakidNo ratings yet

- Design and Analysis of an Automobile ChassisDocument5 pagesDesign and Analysis of an Automobile ChassisAdrián Fernández AraújoNo ratings yet

- ChassisDocument5 pagesChassisSapari VelNo ratings yet

- Structural Analysis of Ladder Chassis Frame For Jeep Using AnsysDocument7 pagesStructural Analysis of Ladder Chassis Frame For Jeep Using AnsysIJMERNo ratings yet

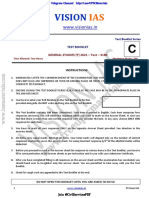

- UPSC Prelims Test 3Document18 pagesUPSC Prelims Test 3SivaKumarNo ratings yet

- UPSC Prelims Test 4Document17 pagesUPSC Prelims Test 4SivaKumarNo ratings yet

- Vision IAS CSP21T28Q SURVEYDocument18 pagesVision IAS CSP21T28Q SURVEYharshaNo ratings yet

- Position, Orientation and Coordinate TransformationsDocument27 pagesPosition, Orientation and Coordinate TransformationsVeronicaNistorNo ratings yet

- FINAL MTech - MACHINE - DEIGN Choice BasedDocument40 pagesFINAL MTech - MACHINE - DEIGN Choice BasedharshaNo ratings yet

- ROBOTICS KINEMATICSDocument56 pagesROBOTICS KINEMATICSharshaNo ratings yet

- Robotics Syllabus BreakdownDocument41 pagesRobotics Syllabus BreakdownharshaNo ratings yet

- Position, Orientation and Coordinate TransformationsDocument27 pagesPosition, Orientation and Coordinate TransformationsVeronicaNistorNo ratings yet

- Design and Analysis of Alloy Wheel Rim: I J I R S E TDocument6 pagesDesign and Analysis of Alloy Wheel Rim: I J I R S E Tkiran_sridharaNo ratings yet

- ME424 201516 Unit3Document51 pagesME424 201516 Unit3harshaNo ratings yet

- ME424 201516 Unit2Document29 pagesME424 201516 Unit2harsha100% (1)

- Syllabus APPSC Group II ExamDocument5 pagesSyllabus APPSC Group II ExamAmarnath ReddyNo ratings yet

- Joint Military ExercisesDocument5 pagesJoint Military ExercisesharshaNo ratings yet

- 6.single Point Cutting Tool PDFDocument8 pages6.single Point Cutting Tool PDFharshaNo ratings yet

- Plates 2012en p27ddDocument8 pagesPlates 2012en p27ddGinoocle OrihuelaNo ratings yet

- 2012 01 - Pipeline Route Selection Right of Way - Mustang PDFDocument3 pages2012 01 - Pipeline Route Selection Right of Way - Mustang PDFNurcahyo Djati WNo ratings yet

- Case Study CTTS - Milestone 07 Object Analysis SolutionDocument6 pagesCase Study CTTS - Milestone 07 Object Analysis SolutionAly A AlyNo ratings yet

- Using Ewa Application As A Tools For Learning English Language ReviewDocument4 pagesUsing Ewa Application As A Tools For Learning English Language Reviewikasuci 0124No ratings yet

- Stratux AHRS Sensor Board v1.1: Last Modified: 02/06/2018Document4 pagesStratux AHRS Sensor Board v1.1: Last Modified: 02/06/2018Mário MineiroNo ratings yet

- Hpe6 A42Document6 pagesHpe6 A42Brock PondputtNo ratings yet

- LAN Proposal Recommendations for School NetworkDocument6 pagesLAN Proposal Recommendations for School NetworkWhorms Martins Olushola WhenuNo ratings yet

- Access Arrangements Exam Day Form 4 2Document2 pagesAccess Arrangements Exam Day Form 4 2Fenil ShahNo ratings yet

- Siemens Siremobil 2000 PDFDocument247 pagesSiemens Siremobil 2000 PDFTeresa Rosas Guzmán100% (5)

- Project Report on Summer Training at Panasonic Battery India Co. LtdDocument53 pagesProject Report on Summer Training at Panasonic Battery India Co. LtdnaranahirNo ratings yet

- 4.2 BigHand Enterprise Core Product Technical RequirementsDocument21 pages4.2 BigHand Enterprise Core Product Technical RequirementsRob DunphyNo ratings yet

- SQL NotesDocument42 pagesSQL NoteskumarNo ratings yet

- Chidamber & Kemerer Suite of MetricsDocument12 pagesChidamber & Kemerer Suite of Metricsmanjunath dupatiNo ratings yet

- F20 User ManualDocument101 pagesF20 User ManualSevim KorkmazNo ratings yet

- CS Investigatory On Grocery ShopDocument26 pagesCS Investigatory On Grocery ShopIshika SinghNo ratings yet

- 100 Cloze Test QuestionsDocument21 pages100 Cloze Test QuestionsDeekshit KumarNo ratings yet

- Bhishek Atta: Junior Associate - TraineeDocument1 pageBhishek Atta: Junior Associate - TraineeMegha MattaNo ratings yet

- Johnny Sha ResumeDocument2 pagesJohnny Sha ResumeJohnny ShaNo ratings yet

- PA 1309 - 10. Topaz. Service Manual TRAD. Philips Electronic Manufacturing TechnologyDocument260 pagesPA 1309 - 10. Topaz. Service Manual TRAD. Philips Electronic Manufacturing TechnologyLeopoldo Medina100% (2)

- Introduction To Amazon API GatewayDocument10 pagesIntroduction To Amazon API GatewayRodrigo Zenon TrujilloNo ratings yet

- Introduction To Ict NotesDocument152 pagesIntroduction To Ict NotesRichard ScansNo ratings yet

- Ibm Sonas With VmwareDocument4 pagesIbm Sonas With VmwareprovenchNo ratings yet

- Cnc-Machining An: Engine BlockDocument4 pagesCnc-Machining An: Engine BlockКуэнка МануэлNo ratings yet

- A Case For A Single Loan Origination System For Core Banking Products PDFDocument5 pagesA Case For A Single Loan Origination System For Core Banking Products PDFansh_hcetNo ratings yet

- Oracle HRMS Question e BookDocument37 pagesOracle HRMS Question e BookSyed Farhan Ashraf100% (1)