Professional Documents

Culture Documents

Ezm 4430

Uploaded by

Egemet SatisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ezm 4430

Uploaded by

Egemet SatisCopyright:

Available Formats

Programmable Counter

EZM-4430 48 x 48 DIN 1/16

Universal Input Programmable Counter

- 6 digits Process (PV) and 6 digits Set (SV) Value Display

- Operation with 1 Set Value

- Reset , Pause and ChA-ChB Counting Inputs

- Operation with Automatic and Manual Reset

EZM-4430 48x48 DIN 1/16

- NPN/PNP Type Operation

- INC , DEC , INC / INC , INC / DEC , UP / DOWN , x1 / x2 / x4

Counting with Phase Shifting Property in Counter Function

- Multiplication Coefficient and Decimal Point Position

Introduction Manual. ENG EZM-4430 02 V03 08/14

Downloaded from www.Manualslib.com manuals search engine

ABOUT INSTRUCTION MANUAL

Instruction manual of EZM-4430 Programmable Counter consists of two main sections.

Explanation of these sections are below. Also, there are other sections which include order

information and technical specifications of the device. All titles and page numbers in instruction

manual are in “CONTENTS” section. User can reach to any title with section number.

Installation:

In this section, physical dimensions of the device, panel mounting, electrical wiring,

module mounting in the device, physical and electrical installation of the device to the system are

explained.

Operation and Parameters:

In this section, user interface of the device, how to access to the parameters, description

of parameters are explained.

Also in these sections, there are warnings to prevent serious injury while doing the

physical and electrical mounting or using the device.

Explanation of the symbols which are used in these sections are given below.

c This symbol is used for safety warnings. User must pay attention to these

warnings.

a

This symbol is used to determine the dangerous situations as a result of an electric

shock. User must pay attention to these warnings definitely.

i This symbol is used to determine the important notes about functions and usage of

the device.

Downloaded from www.Manualslib.com manuals search engine

CONTENTS

1.PREFACE..................................................................................................................Page 5

1.1 GENERAL SPECIFICATIONS

1.2 ORDERING INFORMATION

1.3 WARRANTY

1.4 MAINTENANCE

2.INSTALLATION......................................................................................................... Page 7

2.1 GENERAL DESCRIPTION

2.2 DIMENSIONS

2.3 PANEL CUT-OUT

2.4 ENVIRONMENTAL RATINGS

2.5 PANEL MOUNTING

2.6 INSTALLATION FIXING CLAMP

2.7 REMOVING FROM THE PANEL

3.ELECTRICAL WIRINGS........................................................................................... Page 12

3.1 TERMINAL LAYOUT AND CONNECTION INSTRUCTION

3.2 ELECTRICAL WIRING DIAGRAM

3.3 VIEW OF DEVICE LABEL

3.4 CONNECTION OF DEVICE SUPPLY VOLTAGE INPUT

3.5 COUNTING INPUT CONNECTION

3.5.1 PROXIMITY & SWITCH CONNECTION

3.5.2 INCREMENTAL ENCODER & SWITCH CONNECTION

3.5.3 SWITCH CONNECTION

3.6 RELAY OUTPUT WIRING DIAGRAM

3.7 GALVANIC ISOLATION TEST VALUES OF EZM-4430 PROGRAMMABLE

COUNTER

4.DEFINITION OF FRONT PANEL AND ACCESSING TO THE SET

PARAMETERS............................................................................................................ Page 20

4.1 DEFINITION OF FRONT PANEL

4.2 POWER ON OBSERVATION OF EZM - 4430 PROGRAMMABLE

COUNTER AND SOFTWARE REVISION ON THE DISPLAY

4.3 ADJUSTMENT OF SET VALUE

4.4 RESETTING COUNT VALUE

4.5 ACCESSING TO THE PROGRAM PARAMETERS

5.PROGRAM PARAMETERS...................................................................................... Page 29

6.FAILURE MESSAGES IN EZM-4430 PROGRAMMABLE COUNTER ................... Page 46

7.SPECIFICATIONS .................................................................................................... Page 47

8.OTHER INFORMATIONS..........................................................................................Page 48

Downloaded from www.Manualslib.com manuals search engine

EU DECLARATION OF CONFORMITY

Manufacturer’s Name : EMKO ELEKTRONIK A.S.

Manufacturer’s Address : DOSAB, Karanfil Sk., No:6,

16369 Bursa, TURKEY

The manufacturer hereby declares that the product:

Product Name : Programmable Counter

Type Number : EZM-4430

Product Category : Electrical equipment for measurement, control and

laboratory use

Conforms to the following directives :

2006 / 95 / EC The Low Voltage Directive

2004 / 108 / EC The Electromagnetic Compatibility Directive

has been designed and manufactured to the following specifications:

EN 61000-6-4:2007 EMC Generic Emission Standard for Industrial Environments

EN 61000-6-2:2005 EMC Generic Immunity Standard for Industrial Environments

EN 61010-1:2001 Safety Requirements for electrical equipment for measurement, control

and laboratory use

When and Where Issued Authorized Signature

th

16 October 2009 Name : Serpil YAKIN

Bursa-TURKEY Position : Quality Manager

Downloaded from www.Manualslib.com manuals search engine

1.Preface

EZM Series Programmable Counter can be used in package machines, production and

quality control rollers, in cutting and processing machine of glass, plastic, marble, sheet, iron,

fabric all measuring and controlling of dimension, productivity, and can be adapted easily to all

mechanical construction and automation system.

Some application fields which they are used are below:

Application Fields

Package machines,

Quality Control rollers,

Filling Systems,

Tool Benchs,

Measuring Dimension and Control Automation,

In Cutting and Processing machine of glass, plastic, marble, sheet, iron and fabric

Building Automation.

Production bands

1.1 General Specifications

EZM-4430

Standart

230 V V 50/60Hz Supply Voltage

Optional Supply Input Input

115V V 50/60Hz, 24V V 50/60Hz

24 V Z

Switch

Proximity Sensor(NPN,PNP) Counting Inputs

Optic Sensor (Ch A, Ch B)

Encoder

Switch Reset and Pause

Proximity Sensor(NPN,PNP) Inputs

Optic Sensor(NPN,PNP)

Switch

Proximity Sensor

Sensor Voltage (NPN,PNP)

Output Optic Sensor

Encoder

Standart

Output Control Output(Relay)

Downloaded from www.Manualslib.com manuals search engine

1.2 Ordering Information

A BC D E / FG HI / U V W Z All order information of EZM-4430

EzM-4430 ( 48x48 DIN 1/16)

Programmable Counter are given on the

00 0 1 / 00 00 / 0 0 0 0

table at left. User may form appropriate

A Supply Voltage device configuration from information and

2 24 V V (-%15;+%10) 50/60Hz or 24 VZ (-%15;+%10)

codes that at the table and convert it to the

3 24 V V (-%15;+%10) 50/60Hz ordering codes.

4 115 V V (-%15;+%10) 50/60Hz Supply voltage must be determined

5 230V V (-%15;+%10) 50/60Hz

9 Customer (Maximum 240V V (-%15;+%10))50/60Hz for your system.

Please fill the order code blanks

E Output-1 according to your needs.

1 Relay Output (5A @ 250 V V Resistive Load ) Please contact us, if your needs are

out of the standards.

c

V Symbol means Vac

Z Symbol means Vdc

W Symbol means Vac and Vdc

can be applied.

1.3 Warranty

EMKO Elektronik warrants that the equipment delivered is free from defects in material and

workmanship. This warranty is provided for a period of two years. The warranty period starts from

the delivery date. This warranty is in force if duty and responsibilities which are determined in

warranty document and instruction manual performs by the customer completely.

1.4 Maintenance

Repairs should only be performed by trained and specialized personnel. Cut power to the device

before accessing internal parts.

Do not clean the case with hydrocarbon-based solvents (Petrol, Trichlorethylene etc.). Use of

these solvents can reduce the mechanical reliability of the device. Use a cloth dampened in ethyl

alcohol or water to clean the external plastic case.

Downloaded from www.Manualslib.com manuals search engine

2.Installation

c

Before beginning installation of this product, please read the instruction

manual and warnings below carefully.

In package ,

- One piece unit

- Two pieces mounting clamps

- One piece instruction manual

A visual inspection of this product for possible damage occured during shipment is

recommended before installation. It is your responsibility to ensure that qualified

mechanical and electrical technicians install this product.

If there is danger of serious accident resulting from a failure or defect in this unit, power

off the system and separate the electrical connection of the device from the system.

The unit is normally supplied without a power switch or a fuse. Use power switch and fuse

as required.

Be sure to use the rated power supply voltage to protect the unit against damage and to

prevent failure.

Keep the power off until all of the wiring is completed so that electric shock and trouble

with the unit can be prevented.

Never attempt to disassemble, modify or repair this unit. Tampering with the unit may

results in malfunction, electric shock or fire.

Do not use the unit in combustible or explosive gaseous atmospheres.

During the equipment is putted in hole on the metal panel while mechanical installation

some metal burrs can cause injury on hands, you must be careful.

Montage of the product on a system must be done with it’s fixing clamps. Do not do the

montage of the device with inappropriate fixing clamp. Be sure that device will not fall

while doing the montage.

It is your responsibility if this equipment is used in a manner not specified in this

instruction manual.

Downloaded from www.Manualslib.com manuals search engine

2.1 General Description

Mounting Clamp

OP

EZM

-44 30

O2

Device Label

SV

S2

Coun

ter

P SET

RES

ET

Front Panel

IP65 protection

Panel surface

(maximum thickness 15 mm / 0.59 inch)

2.2 Dimensions

Maximum 5 mm / 0.2 inch

EZM-4430

OP

48 mm / 1.89 inch

O2

SV

S2

Counter

SET RESET

P

48 mm / 1.89 inch

11.1 ± 1 mm / 0.43 inch 84 mm / 3.31 inch

Downloaded from www.Manualslib.com manuals search engine

2.3 Panel Cut-out

65 mm / 2.56 inch (min)

65 mm / 2.56 inch (min)

46 mm / 1.81 inch (min)

46 mm / 1.81 inch (min)

Downloaded from www.Manualslib.com manuals search engine

2.4 Environmental Ratings

Operating Conditions

Operating Temperature : 0 to 50 °C

Max. Operating Humidity : 90% Rh (non-condensing)

Altitude : Up to 2000m.

c

Forbidden Conditions:

Corrosive atmosphere

Explosive atmosphere

Home applications (The unit is only for industrial applications)

2.5 Panel Mounting

1-Before mounting the device in

your panel, make sure that the

cut-out is the right size.

1

2-Check front panel gasket

position

3-Insert the device through the

OP

EZM

-44 cut-out. If the mounting clamps

30

O2 are on the unit, put out them

SV

before inserting the unit to the

S2

panel.

Coun

te r

P SET

RES

ET

During installation into a metal panel, care should be taken to avoid injury from

c

metal burrs which might be present. The equipment can loosen from vibration

and become dislodged if installation parts are not properly tightened. These

precautions for the safety of the person who does the panel mounting.

10

Downloaded from www.Manualslib.com manuals search engine

2.6 Installation Fixing Clamp

1 2

The unit is designed for panel

mounting.

1-Insert the unit in the panel cut-out

OP

EZM

-4430

from the front side.

O2

SV

2- Insert the mounting clamps to the

S2

holes that located top and bottom

Coun

sides of device and screw up the

ter

fixing screws until the unit

P SET

RES

completely immobile within the

ET

panel

c

Montage of the unit to a system must be done with it’s own fixing clamps. Do not

do the montage of the device with inappropriate fixing clamps. Be sure that

device will not fall while doing the montage.

2.7 Removing from the Panel

c

Before starting to remove the unit from panel, power off the unit and the related

system.

1-Loosen the screws.

OP

EZM

-4430 2-Pull mounting clamps from top

O2

SV

and bottom fixing sockets.

S2

3-Pull the unit through the front

Coun

ter

side of the panel

P SET

RES

ET

11

Downloaded from www.Manualslib.com manuals search engine

3.Electrical Wirings

c

You must ensure that the device is correctly configured for your application.

Incorrect configuration could result in damage to the process being controlled,

and/or personal injury. It is your responsibility, as the installer, to ensure that

the configuration is correct.

Parameters of the device has factory default values. These parameters must be

set according to the system’s needs.

c

Only qualified personnel and technicians should work on this equipment. This

equipment contains internal circuits with voltage dangerous to human life.

There is severe danger for human life in the case of unauthorized intervention.

c

Be sure to use the rated power supply voltage to protect the unit against

damage and to prevent failure.

c Keep the power off until all of the wiring is completed so that electric shock and

trouble with the unit can be prevented.

3.1 Terminal Layout and Connection Instructions

Max. 2.5mm / 0.098 inch

Wire Size:

14AWG/1mm²

Solid / Stranded

Torque

0,5Nm

a

Screw driver

0,8 x3mm

12

Downloaded from www.Manualslib.com manuals search engine

3.2 Electrical Wiring Diagram

c

Electrical wiring of the device must be the same as ‘Electrical Wiring Diagram’

below to prevent damage to the process being controlled and personnel injury.

Sensor

Supply Voltage Count Inputs

Max 50mA

PAUSE

RESET

NOTE-1

12 V Z

0VZ

Ch B

Ch A

1 2 3 4 5 6

cY

P/N : EZM-4430

5A@250VV

NO C NC

10 11 12 13 14

a

Relay Output Supply Voltage Output

230V V (-%15;+%10) 50/60Hz - 2.3VA

115V V (-%15;+%10) 50/60Hz - 2.3VA

24 V V (-%15;+%10) 50/60Hz - 2.3VA

24 V Z (-%15 / +%10) - 4W

(It must be determined in order.)

NOTE-1 : Sensor supply voltage: 12VZ ± 40%, 50 mA maximum with short circuit

protection

13

Downloaded from www.Manualslib.com manuals search engine

3.3 View of Device Label

8 9 10 11 12 13 14

NO C NC

N L

5A@250VV 230V V -%15;+%10

50/60Hz -1.5VA

c aY P/N : EZM-4430

Max.50mA

12 V Z

0VZ

Pause

Reset

Ch-A

Ch-B

1 2 3 4 5 6 7

14

Downloaded from www.Manualslib.com manuals search engine

3.4 Connection of Device Supply Voltage Input

Connection of Supply Connection of Supply

Voltage Input Voltage Input

Y Y

Note-1

Note-1

Fuse

Fuse

N aL N a L Note-2

13 14 13 14

External

Note-3

External

Note-3

Fuse Fuse

(1 A V T) (1 A V T)

Power Power

Supply Supply

Switch Switch

c c

Supply Voltage Supply Voltage

115VV, 230 V V 24V V (-%15;+%10) 50/60Hz

(-%15;+%10) 50/60 Hz or 24VZ (-%15;+%10)

Note-1 :

There is internal 33 R W fusible flameproof resistor in 115V V 50/60 Hz and 230VV 50/60 Hz

There is internal 4R7 W fusible flameproof resistor in 24V V 50/60Hz

Note-2 : “L” is “+”, “N” is “-” for 24VZ supply voltage.

Note-3 : External fuse is recommended

c

Make sure that the power supply voltage is the same indicated on the

instrument.

Switch on the power supply only after that all the electrical connections have

been completed.

Supply voltage range must be determined in order. While installing the unit,

supply voltage range must be controlled and appropriate supply voltage must

be applied to the unit. Controlling prevents damages in unit and system and

possible accidents as a result of incorrect supply voltage.

c There is no power supply switch on the device. So a power supply switch must

be added to the supply voltage input. In accordance with the safety regulations,

the power supply switch shall bring the identification of the relevant

instrument. Power supply switch shall be easily accessible by the user.

Power switch must be two poled for seperating phase and neutral. On/Off

condition of power switch is very important in electrical connection. On/Off

condition of power switch must be signed for preventing the wrong connection.

If an external fuse is used, it must be on phase connection in Vsupply input.

15

Downloaded from www.Manualslib.com manuals search engine

3.5 Counting Input Connection

3.5.1 Proximity & Switch Connection

= PNP type operation

PROX. PROX.

PNP PNP

Switch

Switch

1 2 3 4 5 6

PAUSE

RESET

0VZ

Max. 50mA

ChA

ChB

12 V Z

NOTE-1

= NPN type operation

PROX. PROX.

NPN NPN

Switch

Switch

1 2 3 4 5 6

PAUSE

RESET

0VZ

Max. 50mA

ChA

ChB

12 V Z

NOTE-1

NOTE-1 : Sensor supply voltage: 12VZ ± 40%, 50 mA maximum with short circuit

protection

16

Downloaded from www.Manualslib.com manuals search engine

3.5.2 Incremental Encoder & Switch Connection

= PNP type operation

INCREMENTAL ENCODER

10 to 30V Z

Switch

Switch

1 2 3 4 5 6

PAUSE

RESET

0VZ

Max. 50mA

ChA

ChB

12 V Z

NOTE-1

= NPN type operation

INCREMENTAL ENCODER

10 to 30V Z

Switch

Switch

1 2 3 4 5 6

PAUSE

RESET

0VZ

Max. 50mA

ChA

ChB

12 V Z

NOTE-1

NOTE-1 : Sensor supply voltage: 12VZ ± 40%, 50 mA maximum with short circuit

protection

17

Downloaded from www.Manualslib.com manuals search engine

3.5.3 Switch Connection

= PNP type operation

Switch

Switch

Switch

Switch

1 2 3 4 5 6

PAUSE

RESET

0VZ

Max. 50mA

ChA

ChB

12 V Z

NOTE-1

= NPN type operation Switch

Switch

Switch

Switch

1 2 3 4 5 6

PAUSE

RESET

0VZ

Max. 50mA

ChA

ChB

12 V Z

NOTE-1

NOTE-1 : Sensor supply voltage: 12VZ ± 40%, 50 mA maximum with short circuit

protection

18

Downloaded from www.Manualslib.com manuals search engine

3.6 Relay Output Wiring Diagram

L N

5A V T Fuse

C

11

NC

12 Last Control

Element

(Contactor)

NO 10

c

Fuse

Load

c Fuses must be selected according to the applications.

3.7 Galvanic Isolation Test Results of EZM-4430 Programmable Counter

500V V ( for EZM-4430.3 )

2000V V ( for EZM-4430.5 )

13

Supply Voltage

14

0VZ 2

2000V V 10 10 2000V V

11 Relay Outout 11

12 12

2000V V

12V Z Sensor

1 1

Supply Voltage

2000V V 3 3

4 4

Digital Inputs

5 5

6 6

19

Downloaded from www.Manualslib.com manuals search engine

4.Definition of Front Panel and Accessing to the Set Parameters

4.1 Definition of Front Panel

EZM-4430

OP

Displays Actual Value

and Name of Program

O2 Parameter

Led indication of output SV

is active Displays SET and

S2

Parameter Value

Counter

Led indication of SET

Value

SET RESET

P

PROG Button is

Used for accessing to the ENTER Button is used for

Program Parameters saving all changes to

memory and accessing to

the parameters.

SHIFTING Button is used for RESET and INCREMENT

Changing the cursor position Button is used to Reset the

in Programming mode and Actual Value or increment the

entering the SET Value. digit value that is selected by

SHIFTING Button.

20

Downloaded from www.Manualslib.com manuals search engine

4.2 Power On Observation of EZM - 4430 Programmable Counter and Software

Revision on the Display

When power is applied to the device, software revision number of the controller is momentarily

illuminated on actual value display. Then operation screen is observed.

When power on, view of the screen is shown below:

EZM-4430

OP

O2

SV

S2

Counter

“ rEu” Þ Revision Revision number

SET RESET

P

EZM-4430 EZM-4430

O1 O1

O2 O2

SV SV

S2 S2

Counter Counter

SET RESET SET RESET

P P

Software Revision Main screen is shown.

c If there is an unexpected situation while opening the device, power off the

device and inform a qualified personnel.

21

Downloaded from www.Manualslib.com manuals search engine

4.3 Adjustment of SET Value

Changing SET Value

O1

Operation O1

SET Screen

Screen

O2 O2

SV SV

S2 S2

Counter Counter

SET RESET SET RESET

P P

Press Shift button again.

When shift button is pressed, 6th

digit of SET value starts to flash.

O1

SET Screen O1

SET Screen

O2 O2

SV SV 4th digit of

SET value

S2 S2

starts to

Counter Counter flash.

SET RESET SET RESET

P P

5th digit of SET value starts Press Shift button again. Increase the flashing

to flash. value with increment

button.

O1

SET Screen O1

Operation

Screen

O2 O2

SV SV

S2 S2

Counter Counter

SET RESET SET RESET

P P

Save the value as SET value by

pressing Enter button.

22

Downloaded from www.Manualslib.com manuals search engine

4.4 Resetting the Count Value

OP

Operation O1

Operation

Screen Screen

O2 O2

SV SV

S2 S2

Counter Counter

SET RESET SET RESET

P P

When RESET button is pressed, Actual Value

becomes the Reset-Offset Value.

RESET operation can be realized by Reset button or applying signal to the

RESET input. These two operations are named MANUAL RESET in parameters

section.

At the end of MANUEL RESET operation, if

Value becomes Reset Offset Value.

= then Count

i If = and = then Count Value becomes

SET value. If =

Value becomes Reset Offset Value.

and = then Count

23

Downloaded from www.Manualslib.com manuals search engine

4.5 Accessing to the Program Parameters

In this section Accessing to the Program parameters process is shown.

For details on parameters refer to PROGRAM PARAMETERS section.

O1

Operation O1

Password Screen

Screen

O2 O2 The most

SV S1 significant digit

of the parameter

S2 S2

(4th digit for this

Counter Counter parameter)

flashes.

SET RESET SET RESET

P P

Enter password

When PROG button is pressed, password must with shift and

be entered to access the program parameters increment button

O1 O1

Input types and

functions

O2 O2

S1 S1

The most

significant digit

S2 S2

of the parameter

Counter Counter (1st digit for this

parameter)

flashes.

SET RESET SET RESET

P P

You can change

Press Enter Button to the parameter

Press Enter with INCREMENT

confirm password Button button, save it to

the memory and

pass to the next

parameter with

ENTER button.

The most significant digit of O1

Filter time for Ch-A and

the parameter (2nd digit for Ch-B Input

O2

this parameter) flashes.

S1

You can change the

S2

parameter with

INCREMENT button,

Counter save it to the memory and

Press PROG button to exit pass to the next

from programming section SET RESET

parameter with ENTER

P button.

without saving this

parameter.

Press Enter Button

24

Downloaded from www.Manualslib.com manuals search engine

The most significant digit of O1 Filter time for Reset and

the parameter (2nd digit for Pause Input

O2

this parameter) flashes. S1

You can change the

parameter with

S2

INCREMENT button,

Counter save it to the memory and

pass to the next

Press PROG button to exit parameter with ENTER

from programming section SET RESET

button.

P

without saving this

parameter.

Press Enter Button

The most significant digit of O1 Direction of the counting

the parameter (1st digit for O2

this parameter) flashes. S1

You can change the

parameter with

S2

INCREMENT button,

Counter save it to the memory and

pass to the next

Press PROG button to exit parameter with ENTER

from programming section P

SET RESET

button.

without saving this

parameter.

Press Enter Button

The most significant digit of O1 Sensor type selection

the parameter (1st digit for O2

this parameter) flashes. S1

You can change the

parameter with

S2

INCREMENT button,

Counter save it to the memory and

pass to the next

Press PROG button to exit parameter with ENTER

from programming section P

SET RESET

button.

without saving this

parameter.

Press Enter Button

The most significant digit of

O1 Output Functions

the parameter (1st digit for O2

this parameter) flashes. S1

You can change the

S2

parameter with

INCREMENT button,

Counter save it to the memory and

pass to the next

Press PROG button to exit

parameter with ENTER

from programming section P

SET RESET

button.

without saving this

parameter.

Press Enter Button

25

Downloaded from www.Manualslib.com manuals search engine

The most significant digit of

O1

Output Run Type

the parameter (1st digit for O2

this parameter) flashes. S1

You can change the

S2

parameter with

INCREMENT button,

Counter save it to the memory and

pass to the next

Press PROG button to exit parameter with ENTER

from programming section P

SET RESET

button.

without saving this

parameter.

Press Enter Button

The most significant digit of

O1

Output Pulse Time

the parameter (4th digit for O2

this parameter) flashes. S1

You can change the

S2

parameter with

INCREMENT button,

Counter save it to the memory and

pass to the next

Press PROG button to exit parameter with ENTER

SET RESET

from programming section P button.

without saving this

parameter.

Press Enter Button

The most significant digit of O1 Point Position

the parameter (1st digit for O2

this parameter) flashes. S1

You can change the

S2

parameter with

INCREMENT button,

Counter save it to the memory and

pass to the next

Press PROG button to exit parameter with ENTER

SET RESET

from programming section P button.

without saving this

parameter.

Press Enter Button

The most significant digit of O1 Data Record

the parameter (1st digit for O2

this parameter) flashes. S1

You can change the

S2

parameter with

INCREMENT button,

Counter save it to the memory and

pass to the next

Press PROG button to exit parameter with ENTER

RESET

from programming section P

SET

button.

without saving this

parameter.

Press Enter Button

26

Downloaded from www.Manualslib.com manuals search engine

The most significant digit of

O1

Reset and Set Protection

the parameter (1st digit for O2

this parameter) flashes. S1

You can change the

S2

parameter with

INCREMENT button,

Counter save it to the memory and

pass to the next

Press PROG button to exit parameter with ENTER

SET RESET

from programming section P button.

without saving this

parameter.

Press Enter Button

The most significant digit of O1 Multiplication Coefficient

the parameter (6th digit for O2

this parameter) flashes. S1

You can change the

S2

parameter with

INCREMENT button,

Counter save it to the memory and

pass to the next

Press PROG button to exit parameter with ENTER

SET RESET

from programming section P button.

without saving this

parameter.

Press Enter Button

The most significant digit of O1 Reset Offset

the parameter (6th digit for O2

this parameter) flashes. S1

You can change the

S2

parameter with

INCREMENT button,

Counter save it to the memory and

pass to the next

Press PROG button to exit parameter with ENTER

SET RESET

from programming section P button.

without saving this

parameter.

Press Enter Button

The most significant digit of

O1 Program Password

the parameter (4th digit for O2

this parameter) flashes. S1

You can change the

S2

parameter with

INCREMENT button,

Counter save it to the memory and

pass to the next

Press PROG button to exit parameter with ENTER

from programming section P

SET RESET

button.

without saving this

parameter.

Press Enter Button

27

Downloaded from www.Manualslib.com manuals search engine

O1 O1

O2 O2

SV S1

S2 S2

Counter Counter

SET RESET SET RESET

P P

Operation Screen Input types and functions

Continue to press ENTER

button for scanning all

parameters.

28

Downloaded from www.Manualslib.com manuals search engine

8.

5. PARAMETRELER

Program Parameters

Input types and Functions

Upcount on rising edge of Ch-A input

Ch-A

Pause

Start

Value on Value = 0 1 2 3 4

the Screen

Downcount on rising edge of Ch-A input.

Ch-A

Pause

Start

Value on Value = 8 7 6 5 4

the Screen

Upcount on rising edge of Ch-A input.

Downcount on rising edge of Ch-B input.

Ch-A

Ch-B

Start

Value on Value = 0 1 2 3 2 1 2 3 Counting to

the Screen upwards

Start

Value on Value = 8 7 6 5 6 7 6 5 Counting to

the Screen downwards

29

Downloaded from www.Manualslib.com manuals search engine

Upcount on rising edge of Ch-A input

Upcount on rising edge of Ch-B input

Ch-A

Ch-B

Start

Value on Value = 0 1 2 3 4 5 6 7 Counting to

the Screen upwards

Start

Value on Value = 8 7 6 5 4 3 2 1 Counting to

the Screen downwards

Upcount on rising edge of Ch-A input when Ch-B is at 0

Downcount on rising edge of Ch-A when Ch-B is at 1

Ch-A

UP DOWN UP

Ch-B

Start

Value on Value = 0 1 2 1 0 1 Counting to

the Screen upwards

Start Counting to

Value on Value = 8 7 6 7 8 7 downwards

the Screen

x1 Phase Shifting (for incremental encoders)

Upcount on rising edge of Ch-A input when Ch-B is at 0

Downcount on rising edge of Ch-A input when Ch-B is at 1

Encoder is travelling Ch-A

in the Reverse Direction

Encoder is travelling

Ch-A

in the Forward Direction

Ch-B

6 7 8 9

Start Counting to

Value on Value = 5 6 7 8 9 10 upwards

the Screen

7 6 5 4 Counting to

Start downwards

Value on Value = 8 7 6 5 4 3

the Screen

30

Downloaded from www.Manualslib.com manuals search engine

x2 Phase Shifting (for incremental encoders)

Upcount on rising edge of Ch-A when Ch-B is at 0

Downcount on rising edge of Ch-A when Ch-B is at 1

Upcount on falling edge of Ch-A when Ch-B is at 1

Downcount on falling edge of Ch-A when Ch-B is at 0

Encoder is travelling Ch-A

in the Reverse Direction

Encoder is travelling

Ch-A

in the Forward Direction

Ch-B

5 6 7 8 9 10

Start Counting to

Value on Value = 5 6 7 8 9 10 11 upwards

the Screen

14 13 12 11 10 9

Start Counting to

Value on Value downwards

= 14 13 12 11 10 9 8

the Screen

x4 Phase Shifting (for incremental encoders)

Upcount on rising edge of Ch-A when Ch-B is at 0

Downcount on falling edge of Ch-A when Ch-B is at 0

Downcount on rising edge of Ch-A when Ch-B is at 1

Upcount on falling edge of Ch-A when Ch-B is at 1

Downcount on rising edge of Ch-B when Ch-A is at 0

Upcount on falling edge of Ch-B when Ch-A is at 0

Upcount on rising edge of Ch-B when Ch-A is at 1

Downcount on falling edge of Ch-B when Ch-A is at 1

Encoder is travelling

Ch-A

in the Reverse Direction

Encoder is travelling Ch-A

in the Forward Direction

Ch-B

Ch-B

6 7 8 9 10 11 12 13 14 15 16

Start Counting to

Value upwards

Value = 5 6 7 8 9 10 11 12 13 14 15 16 17

on the

Screen 16 15 14 13 12 11 10 9 8 7 6

Counting to

Value Start

downwards

on the Value = 17 16 15 14 13 12 11 10 9 8 7 6 5

Screen

31

Downloaded from www.Manualslib.com manuals search engine

Filter time for Ch-A and Ch-B Inputs

It is used to protect against the electrical contact debounce or the signal

that is less than the determined pulse time.

It can be adjusted from to milisecond.

If Input types and Functions parameter; is entered , or

i then, pulse time for Ch-A and Ch-B Input parameter

can not be accessed

Filter time for Reset and Pause Inputs

It is used to protect against the electrical contact debounce or the signal

that is less than the determined pulse time.

It can be adjusted from to milisecond.

Direction of Counting

Upcount. ( 0 --> Preset )

Downcount. ( Preset --> 0 )

Input types and Functions parameter is or

i then Direction of Counting parameter can not be accessed.

Sensor Type Selection

NPN type sensor selected

PNP type sensor selected

32

Downloaded from www.Manualslib.com manuals search engine

Output Functions

Manual Reset-1.

Device continues to count till manual reset is applied.

(Output PulseTime is not considered)

Count direction : 0 --> P (Upcounting) =

Reset

Set

Reset Offset

Output = Or

=

When count value reaches the Set Value, Output Position is changed.

Counting process continues over the SET value. Output Pulse Time is

not considered. Process counts, until manual reset happens. When

Manual Reset happens, count value becomes Reset Offset value.

Counting direction : P --> 0 (Downcounting) =

Reset

Set

Reset Offset

Output = Or

=

When count value reaches the 0, Output Position is changed.

Counting process continues under the 0 value. Output Pulse Time is not

considered. Process counts, until manual reset happens. When Manual

Reset happens; if = count value becomes

SET value, if = then count value becomes

Reset Offset value.

33

Downloaded from www.Manualslib.com manuals search engine

Manual Reset-2.

(Output pulse Time is not considered)

Counting direction : 0 --> P (Upcounting) =

Reset

Set

Reset Offset

Output = Or

=

When count value reaches the Set Value, Output Position is changed.

Counting process is not continue over the SET value. Output Pulse Time

is not considered. Process counts, until manual reset happens. When

Manual Reset happens, count value becomes Reset Offset value.

Counting direction : P --> 0 (Downcounting) =

Reset

Set

Reset Offset

Output = Or

=

When count value reaches the 0, Output Position is changed.

Counting process is not continue under the 0 value. Output Pulse Time

is not considered. Process counts, until manual reset happens. When

Manual Reset happens; if = , then count value

becomes SET value, if = , then count value

becomes Reset Offset value.

34

Downloaded from www.Manualslib.com manuals search engine

Manual Reset-3.

Device continues to count till manual reset is applied.

(Output Pulse Time is considered.)

Counting direction : 0 --> P (Upcounting) =

Reset

Set

Reset Offset

Output =

Output =

When count value reaches the Set Value, Output Position is

changed. If Output Pulse time is not 0, then Output

Position is changed at the end of the Pulse time. If =

then Output Position has not change until Manual Reset happens.

Counting process continues over the SET value.

When Manual Reset happens, count value becomes Reset Offset

value.

Counting direction : P --> 0 (Downcounting) =

Reset

Set

Reset Offset

Output =

Output

=

When count value reaches the 0 Value, Output Position is changed. If

Output Pulse time is not 0, then Output Position is changed

at the end of the Pulse time. If = ,then Output Position

has not change until Manual Reset happens. Counting process

continues under the 0 value.

When Manual Reset happens; if = , then count

value becomes SETvalue, if = , then count value

becomes Reset Offset value.

35

Downloaded from www.Manualslib.com manuals search engine

Automatic Reset-1

Counting direction : 0 --> P (Upcounting) =

Reset

Set

Reset Offset

Output =

Output =

When count value reaches the Set Value, Output Position is changed.

Actual value is reset automatically. Counting starts upcounting from 0

value. If Output Pulse time is not 0, then Output Position is

changed at the end of the Pulse time. If Pulse time =

then Output Position has not changed until Manuel Reset happens.

When Manual Reset happens, count value becomes Reset Offset

value.

Counting direction : P --> 0 (Downcounting) =

Reset

Set

Reset Offset

Output =

Output

=

When count value reaches the 0 Value, Output Position is changed.

Actual value is reset automatically. Counting starts downcounting from

Set value. If Output Pulse time is not 0, then Output Position

is changed at the end of the Pulse time. If Pulse time =

then Output Position has not changed until Manuel Reset happens.

When Manual Reset happens; if = , then count

value becomes SETvalue, if = , then count value

becomes Reset Offset value.

If output functions parameter is selected Automatic Reset (

i , or

for realizing Automatic Reset.

, then must be different from zero

36

Downloaded from www.Manualslib.com manuals search engine

Automatic Reset-2

Counting direction : 0 --> P (Upcounting) =

Reset

Set

Reset Offset

Output =

Reset

Set

Reset Offset

Output =

When count value reaches the Set Value, Output Position is changed. If

Output Pulse time is not 0, then Output Position is changed

the old position at the end of the Pulse time. Actual value is reset and

counting starts from 0 value at the end of the Output Pulse time.

If output pulse time = then, output position has not

change until Manual Reset happens. Actual counting value stops at SET

value. Counting process is not continue over the SET value.

When Manual Reset happens, count value becomes Reset Offset

value.

If output functions parameter is selected Automatic Reset (

i , or

for realizing Automatic Reset.

, then must be different from zero

37

Downloaded from www.Manualslib.com manuals search engine

Counting direction : P --> 0 (Downcounting) =

Reset

Set

Reset Offset

Output =

Reset

Set

Reset Offset

Output =

When count value reaches the 0 Value, Output Position is changed. If

Output Pulse time is not 0, then Output Position is changed

the old position at the end of the Pulse time. Actual value is reset and

counting starts from SET value at the end of the Output Pulse time.

If output pulse time = , then output position has not

change until Manual Reset happens. Actual counting value stops at SET

value. Counting process is not continue under the 0 value.

When Manual Reset happens, if = , then count

value becomes SET value. If = ,then count

value becomes Reset Offset value.

If output functions parameter is selected Automatic Reset (

i , or

for realizing Automatic Reset.

, then must be different from zero

38

Downloaded from www.Manualslib.com manuals search engine

Automatic Reset-3

Counting direction : 0 --> P (Upcounting) =

Reset

Set

Reset Offset

Output

=

Reset

Set

Reset Offset

Output =

When count value reaches the SET Value, Output Position is changed.

If Output Pulse time is not 0, then Output Position is changed

the old position at the end of the Pulse time. Count value starts counting

from 0 value. But SET value is observed in actual value display. Real

counting value is shown on Actual value screen at the end of the Output

pulse time. If = ,then output position has not changed

until Manual Reset happens. Counting process has not continue over

SET value.

When Manual Reset happens, count value becomes Reset Offset

value.

If output functions parameter is selected Automatic Reset (

i , or

for realizing Automatic Reset.

, then must be different from zero

39

Downloaded from www.Manualslib.com manuals search engine

Counting direction : P --> 0 (Downcounting) =

Reset

Set

Reset Offset

Output =

Reset

Set

Reset Offset

Output =

When count value reaches the 0 Value, Output Position is changed. If

Output Pulse time is not 0, then Output Position is changed

the old position at the end of the Pulse time. Count value starts counting

from SET value. But 0 value is observed in actual value display. Real

counting value is shown on Actual value screen at the end of the Output

pulse time. If = ,then output position has not changed

until Manual Reset happens. Counting process has not continue over 0

value.

When Manual Reset happens, if = , then count

value becomes SET value. If = ,then count value

becomes Reset Offset value.

If output functions parameter is selected Automatic Reset (

i , or

for realizing Automatic Reset.

, then must be different from zero

40

Downloaded from www.Manualslib.com manuals search engine

Automatic Reset-4

Counting direction : 0 --> P (Upcounting) =

Reset

Set

Reset Offset

Output =

Reset

Set

Reset Offset

Output =

When count value reaches the SET Value, Output Position is changed.

If Output Pulse time is not 0, then Output Position is changed

at the end of the Pulse time. Counting continue over SET value.

Counting value becomes 0 and output position becomes old position. If

output pulse time = ,then output position has not

change until Manual Reset happens.

When Manual Reset happens, count value becomes Reset Offset

value.

If output functions parameter is selected Automatic Reset (

i , or

for realizing Automatic Reset.

, then must be different from zero

41

Downloaded from www.Manualslib.com manuals search engine

Counting direction : P --> 0 (Downcounting) =

Reset

Set

Reset Offset

Output =

Reset

Set

Reset Offset

Output =

When count value reaches the 0 Value, Output Position is changed. If

Output Pulse time is not 0, then Output Position is changed

at the end of the Pulse time. Counting continue under 0 value. Counting

value becomes SET and output position becomes old position. If output

pulse time = ,then output position has not change

until Manual Reset happens.

When Manual Reset happens, if = , then count

value becomes SET value. If = ,then count value

becomes Reset Offset value.

If output functions parameter is selected Automatic Reset (

i , or

for realizing Automatic Reset.

, then must be different from zero

42

Downloaded from www.Manualslib.com manuals search engine

Automatic Reset-5

is not considered.

Counting direction : 0 --> P (Upcounting) =

Reset

Set

Reset Offset

Output

= Or

=

If count value equal or greater than SET value, then output becomes

active. If count value less than SET value, then output becomes inactive.

is not considered. Counting process continues over the Set

value.

When Manual Reset happens, count value becomes Reset Offset

value.

Counting direction : P --> 0 (Downcounting) =

Reset

Set

Reset Offset

Output = Or

=

If count value is equal or less than value, then output

becomes active. If count value greater than value, then

output becomes inactive. Output Pulse time is not

considered.

When Manual Reset happens; if = , then count

value becomes SETvalue, if = , then count value

becomes Reset Offset value.

i It is preferred if upcount and downcount is performed at the same time.

43

Downloaded from www.Manualslib.com manuals search engine

Output Run Type

Output Normally non-energised

Output Normally energised

Output Pulse Time

It determines how long Output will be active.

It can be adjusted from 00.00 to 99.99 seconds.

If it is 00.00 second, then it operates indefinitely.

For details, refer to the section where output functions are

defined

Point Position for Display

No point

Between first and second digits

Between second and third digits

Between third and fourth digits

Between fourth and fifth digits

Data Record

Count value is saved to memory when power is

disconnected and restored on power up.

Count value is not saved to memory when power is

disconnected. When power up, if the direction is upcounting,

0 value is shown on the screen. If the direction is down

counting then SET value is shown on the screen.

Reset and Set Protection (for Front Panel Access)

There is no Reset and Set protection

Only RESET Button protection is active.

Actual value can not be reset by Reset button.

SET value can not be changed.

Full protection ; Reset protection is active and SET value can

not be changed.

44

Downloaded from www.Manualslib.com manuals search engine

Multiplication Coefficient

It can be adjusted from to . Changes in this

parameter is evaluated when counting starts.

If it is multiplication is not performed. So number of pulses are

displayed without having any changes.

Reset Offset

It can be adjusted from to .

For details, refer to the Output Functions section.

Program Password

It is used for accessing to the program parameters. It can be adjusted

from to .

If it is , there is no password protection while accessing to the

parameters.

When programming button is pressed, will appear on the

display.

If program password is not “0” while accessing to the program

parameters ;

1- If user does not enter the value correctly ; operation screen

will appear without entering to operator parameters.

2- When in top display and in bottom display,if user

presses ENTER button without entering password (for observing the

parameters):

User can see all parameters except Program Password but device does

not allow to do any change in the program parameters.

45

Downloaded from www.Manualslib.com manuals search engine

6. Failure Messages in EZM-4430 Programmable Counter

1-If the password is not 0, user can access to the parameters without entering the password

and by pressing ENTER button.

User can see all parameters except for programming password parameter but user

can not do any change in the program parameters. If password is entered for accessing to the

parameters correctly, most significant digit of the parameter flashes. But if the password is not

entered, flashing of the most significant digit is not realised.

O1

Operation O1

Password Screen

Screen

O2 O2

SV S1 The most

significant digit

S2 S2 of the parameter

Counter Counter (4th digit for this

parameter)

flashes.

SET RESET SET RESET

P P

Press ENTER

When PROG button is pressed, button without

password entering screen will entering the

appear. password.

O1

Input Types

and Functions

O2

S1

No digit flashes

S2

Counter

By pressing ENTER

button, user can see all

SET RESET

P parameters except for

program password

O1 Reset Offset Parameter

O2

S1

S2

Counter

Press PROG button to exit Continue to press ENTER

from programming mode. button for scanning the

P

SET RESET parameters.

46

Downloaded from www.Manualslib.com manuals search engine

O1 O1

O2 O2

SV S1

S2 S2

Counter Counter

SET RESET SET RESET

P P

Operation Screen Input Types and Functions

OV 2-If Actual Value is flashing and counting is stopped ;

It appears if any of the count value is greater than the

O2

maximum count value.

SV

To remove this warning and reset the count value press

S2

RESET button.

Counter

SET RESET

P

OV 3-If Actual Value is flashing and counting is stopped ;

It appears if any of the count value is lower than the

O2

minimum count value.

SV

To remove this warning and reset the count value press

S2

RESET button.

Counter

SET RESET

P

7. Specifications

Device Type : Programmable Counter

Housing & Mounting : 48mm x 48mm x 87.5 DIN Size 43700 plastic housing for

panel mounting. Panel cut-out is 46x46mm

Protection Class : IP65 at front, IP20 at rear.

Weight : Approximately 0.21 Kg.

Environmental Ratings : Standard, indoor at an altitude of less than 2000 meters

with none condensing humidity

Storage / Operating Temperature: -40 oC to +85 oC / 0 oC to +50 oC

Storage / Operating Humidity : 90 % max. (None condensing)

47

Downloaded from www.Manualslib.com manuals search engine

Installation : Fixed installation

Over Voltage Category : II

Pollution Degree : II, office or workplace, none conductive pollution

Operating Conditions : Continuous

Supply Voltage and Power : 230 V V (-%15 / +%10) 50/60 Hz. 2.3VA

115 V V (-%15 / +%10) 50/60 Hz. 2.3VA

24 V V (-%15 / +%10) 50/60 Hz. 2.3VA

24 V Z (-%15 / +%10) - 4W

Digital Inputs

Electrical Characteristics : Rated voltage : 16 VZ @ 5mA

Maximum continuous permissible voltage : 30 VZ

Logic 1 minimum level : 3 VZ

Logic 0 maximum level : 2 VZ

Sensor Supply Voltage : 12VZ ± %40 maximum 50mA

Maximum Input Frequency : = 0 , 1 , 2 with 20000 Hz

= 3 , 4 with 20000 Hz

= 5 , 6 with 12000 Hz

= 7 with 10000 Hz

Output Type : Relay Output 5A@250VV Resistive Load

100.000 operation (Full Load)

Actual Value Display : 8 mm Red 6 digit LED Display

Set Display : 8 mm Green 6 digit LED Display

LED Displays : SV (Set value) , OP (Control output) LEDs

Approvals : ,

8. Other Informations

Manufacturer Information:

Emko Elektronik Sanayi ve Ticaret A.Þ.

Demirtaþ Organize Sanayi Bölgesi Karanfil Sk. No:6 16369

BURSA/TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

Repair and Maintenance Service Information:

Emko Elektronik Sanayi ve Ticaret A.Þ.

Demirtaþ Organize Sanayi Bölgesi Karanfil Sk. No:6 16369

BURSA/TURKEY

Thank you very much for your preference to use Emko Elektronik

Your Technology Partner Products.

www.emkoelektronik.com.tr

48

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Limit GaugesDocument29 pagesLimit GaugesMANOJ M83% (6)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Uncertainty Analysis ofDocument10 pagesUncertainty Analysis ofEgemet SatisNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Uncertainty Analysis ofDocument10 pagesUncertainty Analysis ofEgemet SatisNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Limit GaugesDocument29 pagesLimit GaugesMANOJ M83% (6)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Astm E448 82 R02 E02 PDFDocument40 pagesAstm E448 82 R02 E02 PDFPacifier NothingfaceNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Uncertainty Analysis ofDocument10 pagesUncertainty Analysis ofEgemet SatisNo ratings yet

- Surface Texture Metrology Services Available PDFDocument2 pagesSurface Texture Metrology Services Available PDFEgemet SatisNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Matest Catalogue 6 Cement MortarDocument49 pagesMatest Catalogue 6 Cement MortarEgemet SatisNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Segmentasyon PDFDocument1 pageSegmentasyon PDFEgemet SatisNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Astm D6926 PDFDocument6 pagesAstm D6926 PDFEgemet SatisNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Aggregates CatalogueDocument10 pagesAggregates CatalogueEgemet SatisNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 05 Concretes p73 112Document40 pages05 Concretes p73 112Egemet SatisNo ratings yet

- 05 Concretes p73 112Document40 pages05 Concretes p73 112Egemet SatisNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Glukhov 2018 J. Phys.: Conf. Ser. 998 012012Document9 pagesGlukhov 2018 J. Phys.: Conf. Ser. 998 012012Egemet SatisNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 3642 01Document4 pages3642 01Egemet SatisNo ratings yet

- Analysis of Errors of The Testing Equipment For PDFDocument5 pagesAnalysis of Errors of The Testing Equipment For PDFEgemet SatisNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Analysis of Errors of The Testing Equipment For PDFDocument5 pagesAnalysis of Errors of The Testing Equipment For PDFEgemet SatisNo ratings yet

- High Accuracy Short Range Laser Meter For System Calibration and InstallationDocument8 pagesHigh Accuracy Short Range Laser Meter For System Calibration and InstallationEgemet SatisNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Calibration of Digital Level PDFDocument10 pagesCalibration of Digital Level PDFEgemet SatisNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Iso 11254-1 - 2000 PD Sudan 42 PDFDocument30 pagesIso 11254-1 - 2000 PD Sudan 42 PDFEgemet SatisNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Bachelor Project 2010: Comparison of Short Range and Long Range Laser Scanner's Accuracy DifferencesDocument27 pagesBachelor Project 2010: Comparison of Short Range and Long Range Laser Scanner's Accuracy DifferencesEgemet SatisNo ratings yet

- 3835-Article Text PDF-7593-1-10-20130718Document14 pages3835-Article Text PDF-7593-1-10-20130718Egemet SatisNo ratings yet

- FittingData PDFDocument10 pagesFittingData PDFRajeeb KunwarNo ratings yet

- Arazi Ölçüm Cihazları Ve Standartları PDFDocument9 pagesArazi Ölçüm Cihazları Ve Standartları PDFEgemet SatisNo ratings yet

- LVDT Calibration ProcedureDocument3 pagesLVDT Calibration ProcedureEgemet Satis100% (1)

- Jpconf5 13 092Document5 pagesJpconf5 13 092Egemet SatisNo ratings yet

- ASME B1.3-2007 ¿É ÓÊÜ SS Ç ÄÂÝÎÆ âÁ¿Ï Í .Ó ÖƺÍÃ×ÖÆÂÝÎÆ (UN¡ UNR¡ UNJ¡ MºÍMJ)Document22 pagesASME B1.3-2007 ¿É ÓÊÜ SS Ç ÄÂÝÎÆ âÁ¿Ï Í .Ó ÖƺÍÃ×ÖÆÂÝÎÆ (UN¡ UNR¡ UNJ¡ MºÍMJ)vivek_swati100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

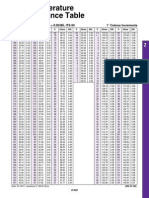

- For European Curve, Alpha 0.00385, ITS-90 1° Celsius IncrementsDocument3 pagesFor European Curve, Alpha 0.00385, ITS-90 1° Celsius IncrementsMary HarrisonNo ratings yet

- Ansi B 7 1 2000 PDFDocument155 pagesAnsi B 7 1 2000 PDFEgemet SatisNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)