Professional Documents

Culture Documents

HollySys 1000MW Coal Fired Power Plant

Uploaded by

Fitriatuzzahro AndrianiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HollySys 1000MW Coal Fired Power Plant

Uploaded by

Fitriatuzzahro AndrianiCopyright:

Available Formats

CONTACT US

SINGAPORE (INTERNATIONAL HQ) INDIA

HollySys (Asia Pacific) Pte Ltd HollySys Automation India Pvt. Ltd

200 Pandan Loop, #08-01, Pantech 21 No. 405, 4th Floor,

Singapore 128388 Sewa Corporate Park Building, MG Road

Gurgaon 122002

Tel : +65 6777 0950 Haryana, India

Fax : +65 6777 2730 Tel : +91 124 6900705

CHINA INDONESIA

HollySys Group Representative Office

Di Sheng Middle Road, No.2 The Vida 7th Floor,

Economic-Technological Development Area Jl. Raya Pejuangan No. 8, Kebon Jeruk

100176 Beijing, China Jakarta 11530

Tel : +86 10 58981000 Tel : +62 21 2977 8060 HOLLiAS MACS DCS has been used in China

Fax : +86 10 58981100 Fax : +62 21 2977 8001

Largest 1000 MW Coal-fired Power Plant

THE BACKGROUND CHALLENGES & BENEFITS

Taishan Power Plant by the Beijing Guohua Electric At a temperature of 347.15 °C and air pressure of 22.115

Power (Group) Investment Co., Ltd. located in the city MPa, the density of water vapor would be increased to

of Taishan in Tonggu Bay of Guangdong Province. The liquid water. With a temperature reaching 600 °C and air

Phase I construction of sub-critical 5 × 600 MW power pressure in between 25 to 28 MPa, you will enter the ultra

generating units had all been put into operation. For super-critical stage.

the Phase II construction of 4 × 1000 MW super-critical

power generating units. Able to reach a thermal efficiency of around 45 % by

turning wet steam into steam-gas and saturated steam

HollySys has won the contract for the first two units. delivering a lower coal consumption, environmental

Taishan Power Plant are designed to reach a total installed friendlier using a higher technological system.

capacity of 1000 MW and will become China’s largest

coal-fired power plants and the contract was delivered With lower coal consumption is its biggest advantage

on 29 March 2011 in a high-end standards. over any other super-critical thermal units in China with

about 2 to 3 % improved efficiency.

Taishan Power Plant is equipped with the most advanced

production management system and technical expertise. The development direction of the ultra super-critical

Under the leading enterprise of Beijing Guohua Electric generating units is to maintain its availability, reliability,

Power (Group), it plays an important role in the thermal flexibility and operational lifespan of the units and further its

power plant industry with numerous new technology enhancement on the steam parameters in order to achieve

implemented in Taishan Power Plant. greater efficiency and environmental performance.

All Rights Reserved. Copyright © 2016 by HollySys International.

THE SOLUTION The scope of DCS of generating units includes the boiler

main and auxiliary system, turbine main and auxiliary

system, electric generating, ECS, etc. The scope of DCS

The two current 1,000 MW super-critical power generating units was designed by Guangdong Electric Power Design

of FGD includes the desulfurization booster, absorber,

Institute. All the main control and desulfurization (FGD) system are utilizing the HollySys’s MACS DCS control system

oxidation fan, etc. The scope of DCS of Utilities includes

with a total of 36,128 I/O points.

the ECS, air conditioner system, air compressor and

ammonia store system.

No Name of System I/O Configuration Content

At the same time, DCS communicates with turbine Digital

Electro Hydraulic (DEH), generating TSI, protection

Single Unit: Boiler, Turbine, Electrical, Denitration

I/O Configuration 32000 points

Common Unit: Auxiliary Circulating Feed Water Pump, system, Balance of Plant (BOP), to achieve integrated

1 Main DCS control, monitor and manage to a generating unit.

Compressor, Ammonia Storage System, and other

DPU Configuration 96 sets

Common Electrical

The functions of DCS includes:

I/O Configuration 4128 points FGD System For Unit No. 1, Wastewater System, • Data Acquisition System (DAS)

2 Desulfurization Electrical, 10 KV Power Distribution Between Buildings,

DCS • Modulation Control System (MCS)

DPU Configuration 11 sets and other Common System

• Bypass Control System (BPCS)

Total 36128 points • Sequence Control System (SCS)

• Furnace Safety Supervisory System (FSSS)

• MEH + METS (Steam-Driven Feed Water Pump)

• Electrical Control System (ECS)

Boiler Main Parameters • Flue Gas Desulfurization (FGD)

Maximum Continuous Evaporation of Superheated Steam (B-MCR) 3091 t/h

TESTIMONIAL

Superheated Steam Pressure 27.56 MPa(a)

“The 2 × 1000 MW units DCS project in Taishan Power Plant is outstanding in terms of safety, economic efficiency

Superheated Steam Temperature 605 °C

and environmental protection, as well as investment control. It is the leading lever in China. The direct station service

power consumption rate for power supply coal consumption is 3.77 %, which takes lead in China’s 1000 MW units.

The service rate for protection devices, automation equipments and instruments is 100 %. The desulfurization and

Turbine Main Parameters denitration systems have been put into service in parallel with the main equipment. The overall performance fully

meets our design requirements.”

Power Capacity 1000 MW

From Taishan Power Plant, China

Maximum Continuous Power (T-MCR) 1053.485 MW

Frontal Main Steam: Steam Pressure Condition 26.25 MPa(a)

Frontal Main Steam: Steam Temperature Condition 600 °C

REFERENCE

1000 MW 14 units

HollySys will deliver the DCS system which includes its proprietary control of generating units; Flue Gas Desulfurization

(FGD), Utilities, Electrical Control System (ECS) for the two 1000 MW super-critical power generating units and the 600 ~ 800 MW 21 units

Distributed Control System (DCS) reserves communication interface with Management Information System (MIS),

Supervisory Information System (SIS), etc. 300 MW 204 units

Over 3000 projects ranging from 6 MW

Turbine Control

to 1000 MW

You might also like

- C - ECU Pinout - Toyota - Land Crusier 5vz-Fe (6 Cylinder - 1 Coil Control 2 Ignition Point) - 5vz-3rz-Right Manual For Lahore Landcruiser 5vz-1998Document4 pagesC - ECU Pinout - Toyota - Land Crusier 5vz-Fe (6 Cylinder - 1 Coil Control 2 Ignition Point) - 5vz-3rz-Right Manual For Lahore Landcruiser 5vz-1998Boomer Boomer100% (1)

- Siremobil PartsDocument20 pagesSiremobil PartsOscar OcañoNo ratings yet

- Liebert PFH Condensing UnitDocument121 pagesLiebert PFH Condensing UnitSnehasis DasNo ratings yet

- Digital Technologies For Thermal Power Plants Improves Performance and RoiDocument5 pagesDigital Technologies For Thermal Power Plants Improves Performance and RoineerajNo ratings yet

- Data Center Energy: The Novel Therm WayDocument7 pagesData Center Energy: The Novel Therm WayJohn WuNo ratings yet

- Ijiset V3 I10 10Document11 pagesIjiset V3 I10 10Diki PrayogoNo ratings yet

- Kawasaki v12 300 Por 380Document85 pagesKawasaki v12 300 Por 380wellington freitasNo ratings yet

- Steam Tip Sheet #12Document2 pagesSteam Tip Sheet #12Muhammad NaeemNo ratings yet

- Cleaning up the air: Industry investing in clean technology to combat air pollutionDocument5 pagesCleaning up the air: Industry investing in clean technology to combat air pollutionKishore KunalNo ratings yet

- Steam Power Plants: Mitsubishi Heavy Industries, Ltd. Energy SystemsDocument10 pagesSteam Power Plants: Mitsubishi Heavy Industries, Ltd. Energy SystemsSagar SanasNo ratings yet

- Steam Turbine RetrofitDocument8 pagesSteam Turbine RetrofitkoybasizNo ratings yet

- Mechanical Engineer CV Highlights ExperienceDocument4 pagesMechanical Engineer CV Highlights Experiencetajshah283No ratings yet

- Focus On: Gas PowerDocument44 pagesFocus On: Gas PowerStefanos DiamantisNo ratings yet

- Seminar On: Flexibilisation of Thermal Power PlantsDocument4 pagesSeminar On: Flexibilisation of Thermal Power Plantser_sanjaypatelNo ratings yet

- Resent Development PDFDocument4 pagesResent Development PDFAnurag porteNo ratings yet

- Deepthermal: Combustion Optimization For Thermal Power Generating Units Using Offline Reinforcement LearningDocument12 pagesDeepthermal: Combustion Optimization For Thermal Power Generating Units Using Offline Reinforcement LearningQuang Nguyễn MinhNo ratings yet

- Review Paper On Ultra Supercritical Power Plants Full Length PaperDocument7 pagesReview Paper On Ultra Supercritical Power Plants Full Length PaperAtul NegiNo ratings yet

- Siemens White PaperDocument10 pagesSiemens White PaperWilson Pavão100% (1)

- Article Supercritical Control en 37630Document4 pagesArticle Supercritical Control en 37630etong saturninaNo ratings yet

- Experienced Electrical Engineer ResumeDocument4 pagesExperienced Electrical Engineer ResumerameshNo ratings yet

- Training ReportPDF PDFDocument42 pagesTraining ReportPDF PDFAman RajNo ratings yet

- TripticoHydro English v01Document6 pagesTripticoHydro English v01Rajkishor YadavNo ratings yet

- Hydro & Thermal Power Plants ComparisonDocument32 pagesHydro & Thermal Power Plants ComparisonAbhishek KaleNo ratings yet

- Mal AnkaraDocument2 pagesMal AnkaraSaran KumarNo ratings yet

- Steam Turbine Replacement by High Speed Electric System Driven CompressorsDocument9 pagesSteam Turbine Replacement by High Speed Electric System Driven CompressorsJoffre BourgeoisNo ratings yet

- Steam Turbine Products: GE EnergyDocument16 pagesSteam Turbine Products: GE Energyrewr5345100% (1)

- Steam Tip Sheet #16Document2 pagesSteam Tip Sheet #16Muhammad NaeemNo ratings yet

- Plasma ignition system for oilDocument7 pagesPlasma ignition system for oiltechnicol.andrzej.budzianowskiNo ratings yet

- Fleet360 Plant Services Solutions: Customer Success StoriesDocument13 pagesFleet360 Plant Services Solutions: Customer Success StorieswinhlaingooNo ratings yet

- Energy Tips - Steam: Consider Steam Turbine Drives For Rotating EquipmentDocument2 pagesEnergy Tips - Steam: Consider Steam Turbine Drives For Rotating EquipmentMohammedBujairNo ratings yet

- Telecom Energy BrochureDocument18 pagesTelecom Energy BrochureahmedNo ratings yet

- Benefits of Variable Speed Drives in Sugar Production: White PaperDocument12 pagesBenefits of Variable Speed Drives in Sugar Production: White PaperMashudi FikriNo ratings yet

- Role of Coal Plants in India's Transition to RenewablesDocument11 pagesRole of Coal Plants in India's Transition to Renewables1pallabNo ratings yet

- Introduction to NTPC Simhadri Power PlantDocument25 pagesIntroduction to NTPC Simhadri Power PlantAkshaya Mallya BNo ratings yet

- Bozhko 2018Document13 pagesBozhko 2018sezgin bayramNo ratings yet

- ACESDocument13 pagesACESapi-26570979No ratings yet

- ToshibaDocument33 pagesToshibaJohn P KNo ratings yet

- FESTO - Case - StudyDocument2 pagesFESTO - Case - StudyI'm 27 year old, and a Graphic Designer by profession.100% (2)

- 00870-0800-6129 RevAA 2.2 UF PDFDocument14 pages00870-0800-6129 RevAA 2.2 UF PDFAnonymous hUjnXzZNo ratings yet

- Advanced Technologies of Preventive Maintenance For Thermal Power PlantsDocument6 pagesAdvanced Technologies of Preventive Maintenance For Thermal Power PlantsSubburajMechNo ratings yet

- Er. Pankaj Mittal Assistant ProfessorDocument14 pagesEr. Pankaj Mittal Assistant ProfessorPankaj MittalNo ratings yet

- Recover Heat From Boiler BlowdownDocument2 pagesRecover Heat From Boiler BlowdownJAY PARIKHNo ratings yet

- Shree Cement Limited: Case StudyDocument9 pagesShree Cement Limited: Case StudyShambhu MehtaNo ratings yet

- Carbon FootprintDocument6 pagesCarbon Footprintmtry658893No ratings yet

- Ijiset V2 I10 37Document12 pagesIjiset V2 I10 37Ram HingeNo ratings yet

- GE's TM2500+ Solution Offers Fast, Mobile and Flexible PowerDocument6 pagesGE's TM2500+ Solution Offers Fast, Mobile and Flexible PowerJorge Armando Acevedo Pinel100% (1)

- 22 Mwe Combined Heat and Power Direct Drying and CogenerationDocument2 pages22 Mwe Combined Heat and Power Direct Drying and CogenerationarmandoNo ratings yet

- Dong Fang HistoryDocument55 pagesDong Fang Historyramnadh803181No ratings yet

- Quarterly Loss in Thermal Power Plant Prevention DigestDocument20 pagesQuarterly Loss in Thermal Power Plant Prevention DigestNikhil RajanNo ratings yet

- Insulation and Thermal Design of a Hermetically Sealed Turbo-GeneratorDocument7 pagesInsulation and Thermal Design of a Hermetically Sealed Turbo-GeneratorJUAN ATALAYANo ratings yet

- NTPC LTDDocument19 pagesNTPC LTDshriyansh jainNo ratings yet

- Opcion 1Document17 pagesOpcion 1María Lucía Pérez MoralesNo ratings yet

- Training Report ON Familiarisation of Thermal Power Plant: Aakash Ranjan GhoshDocument25 pagesTraining Report ON Familiarisation of Thermal Power Plant: Aakash Ranjan GhoshAR GNo ratings yet

- NTPC InternshipDocument22 pagesNTPC Internshipaman2007_shNo ratings yet

- FINAL Renewable E-BookDocument14 pagesFINAL Renewable E-BookLiz HorusNo ratings yet

- Belitong Hybrid FPV+Wind+BioGas For GGGI 2023 Ver2Document17 pagesBelitong Hybrid FPV+Wind+BioGas For GGGI 2023 Ver2Dedi. HNo ratings yet

- In Plant Tarining Repot Adani Electricity Final VersionDocument35 pagesIn Plant Tarining Repot Adani Electricity Final VersionSiddharth MhatreNo ratings yet

- NTPC summer training reportDocument20 pagesNTPC summer training reportParveen Bairagi100% (1)

- Amit Kumar Tata Power SolarDocument38 pagesAmit Kumar Tata Power SolarEka BNo ratings yet

- Waste Heat Recovery System Operated in Midrex PlantsDocument2 pagesWaste Heat Recovery System Operated in Midrex PlantsMorteza RafieiNo ratings yet

- Carrasco2006 PDFDocument15 pagesCarrasco2006 PDFAmiir AmirNo ratings yet

- 04 PlanningandDeployingBESS FluenceDocument33 pages04 PlanningandDeployingBESS FluencePongsakorn NakkharaNo ratings yet

- Bus Bid Sheet With Cross RefDocument56 pagesBus Bid Sheet With Cross ReftylerNo ratings yet

- Longjian Road & Bridge Co., Ltd. Paira Bridge (Lebukhali Bridge) Construction ProjectDocument4 pagesLongjian Road & Bridge Co., Ltd. Paira Bridge (Lebukhali Bridge) Construction Projectarif hossain labuNo ratings yet

- Switched Reluctance Reluctance Motors and ControlDocument47 pagesSwitched Reluctance Reluctance Motors and ControlSreerag Kunnathu Sugathan100% (1)

- Air Foam Chamber: Fire Fighting Equipment Data SheetDocument8 pagesAir Foam Chamber: Fire Fighting Equipment Data SheetMihir JhaNo ratings yet

- Material and Process For NDT Technologys PDFDocument164 pagesMaterial and Process For NDT Technologys PDFwajidNo ratings yet

- Notch Cutting MachineDocument2 pagesNotch Cutting MachineAbraham RaygozaNo ratings yet

- DLM ValidationDocument7 pagesDLM ValidationSandilya KambampatiNo ratings yet

- SVP3000 Alphaplus Smart Valve PositionerDocument8 pagesSVP3000 Alphaplus Smart Valve Positioner鄭元豪No ratings yet

- Cam MechDocument24 pagesCam MechmarcglebNo ratings yet

- Structural AnalysisDocument35 pagesStructural AnalysisNagaraj RamachandrappaNo ratings yet

- RPM Tech LM220 Brochure 01 2020 en SourcewellDocument4 pagesRPM Tech LM220 Brochure 01 2020 en SourcewellPhil B.No ratings yet

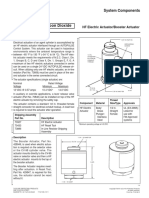

- System Components: HF Electric Actuator/Booster ActuatorDocument1 pageSystem Components: HF Electric Actuator/Booster ActuatorBryan ShanahanNo ratings yet

- Model Number Significance ChartDocument15 pagesModel Number Significance ChartSHAKEEL ISMAIL LAMBAYNo ratings yet

- Hitachi Water Pump CatalogueDocument6 pagesHitachi Water Pump CatalogueRicky al ikhsaniNo ratings yet

- Bab II Wa600Document17 pagesBab II Wa600abrisal03No ratings yet

- Retract Doc 01 (3) PDFDocument8 pagesRetract Doc 01 (3) PDFAlmeida FábioNo ratings yet

- Resistencia de Materiales - N. M. Belyaev - Strength of Materials - MirDocument650 pagesResistencia de Materiales - N. M. Belyaev - Strength of Materials - MirSandoval Rivas RafaelNo ratings yet

- Karaca-Bykakkas2018 Article MicrohardnessCharacterizationODocument10 pagesKaraca-Bykakkas2018 Article MicrohardnessCharacterizationOma ChakaNo ratings yet

- Modulo Arranque Monicon GTR17Document6 pagesModulo Arranque Monicon GTR17Rommel Chang0% (1)

- Altis MV2 (11.12.03)Document1 pageAltis MV2 (11.12.03)D Wahyu BawonoNo ratings yet

- Rsu PDFDocument8 pagesRsu PDFIsaac Galvez EscuderoNo ratings yet

- X20B3522P07F: Flange Forged Carbon Steel ASME - CL600 WNRF SA 105-N SCH80 8" NPSDocument1 pageX20B3522P07F: Flange Forged Carbon Steel ASME - CL600 WNRF SA 105-N SCH80 8" NPSSathish KumarNo ratings yet

- Avesta Nicrmo-3: Welding Wire TigDocument1 pageAvesta Nicrmo-3: Welding Wire TigKathir VelNo ratings yet

- 6M33 Training Document EPA - FA R01Document71 pages6M33 Training Document EPA - FA R01Daniel Ardila100% (1)

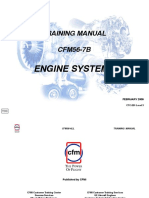

- CTC-224 Engine SystemsDocument317 pagesCTC-224 Engine Systemsalexdd39100% (2)

- Energies: Numerical Study On Thermal Hydraulic Performance of Supercritical LNG in Zigzag-Type Channel PchesDocument19 pagesEnergies: Numerical Study On Thermal Hydraulic Performance of Supercritical LNG in Zigzag-Type Channel PchesSyed Anas SohailNo ratings yet