Professional Documents

Culture Documents

MCOT 007 Chemical Injection-Doiler and Sludge Breaker

Uploaded by

Lembang ApangCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCOT 007 Chemical Injection-Doiler and Sludge Breaker

Uploaded by

Lembang ApangCopyright:

Available Formats

Operating Procedure MY SKO O 05 MCOT 007

Chemicals Injection: Sludge Breaker Rev. 0 Sept 2011

Any deviation from this procedure must follow the MANAGEMENT OF CHANGE PROCEDURE

or STANDING INSTRUCTIONS process before any deviation or change may be made.

OPERATING PROCEDURE

Contents

Foreword

Distribution List

Amendment Summary

Glossary

Reference

Section 1 Introduction

Section 2 Procedure

Appendix A Checklist

Diagram

"UNCONTROLLED WHEN PRINTED"

30/07/2012 8:35 AM PETRONAS CARIGALI SDN BHD Page 1 of 14

Operating Procedure MY SKO O 05 MCOT 007

Chemicals Injection: Sludge Breaker Rev. 0 Sept 2011

FOREWORD

Authority for original issue

Document Author

Issue of this document has been formally authored by:

Name: Mentor Solutions & Resources Sdn Bhd

Position: Technician/ Consultant/ Contractor

Date:

Issue Review

Issue of this document has been formally reviewed by:

Name:

Signature

Position: Production Supervisor/ Field Engineer

Date:

Issue Approval

Issue of this document has been formally approved by:

Name:

Signature:

Position: Head of Production

Date:

Document Custodian

The following person has been assigned as the document custodian:

Name:

Signature:

Position Onshore Installation Manager

Date

"UNCONTROLLED WHEN PRINTED"

30/07/2012 8:35 AM PETRONAS CARIGALI SDN BHD Page 2 of 14

Operating Procedure MY SKO O 05 MCOT 007

Chemicals Injection: Sludge Breaker Rev. 0 Sept 2011

Distribution List

Copy No. Title Location

01 Central Control Room MCOT

AMENDMENT SUMMARY

This sheet must be completed in detail at each revision once this document has been approved.

Details must include revision number, description and indication of which pages and

paragraphs have been revised, date of revision approval, approvers title and signature.

Rev Description Date Approver Title Name

Rev 0 Original Document

Notes: (1) Document Holders to update Amendment Record as and when

amendments/new revisions are received.

(2) For description of amendment the Document Holder should indicate

correction, modification, update or deletion issue.

(3) Document Holder to enter their company reference number, sign and date the

record of entry.

(4) Where part amendments are issued, the relevant page(s) will be identified

with a lower case letter in the revision status line in the header.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 8:35 AM PETRONAS CARIGALI SDN BHD Page 3 of 14

Operating Procedure MY SKO O 05 MCOT 007

Chemicals Injection: Sludge Breaker Rev. 0 Sept 2011

GLOSSARY

CSDS Chemical Safety Data Sheet

REFERENCE

DOC. NO TITLE

MCOT Rejuvenation Project Phase Piping & Instrumentation Diagram (P&ID)

2 Process Drawing (Rev. No. 6)

"UNCONTROLLED WHEN PRINTED"

30/07/2012 8:35 AM PETRONAS CARIGALI SDN BHD Page 4 of 14

Operating Procedure MY SKO O 05 MCOT 007

Chemicals Injection: Sludge Breaker Rev. 0 Sept 2011

Section 1

INTRODUCTION

Content Page

1.1 OBJECTIVE / PURPOSE ................................................................................................. 6

1.2 SCOPE ................................................................................................................................ 6

1.3 OP CATEGORY................................................................................................................. 6

1.4 PREREQUISITES ............................................................................................................. 6

1.5 LIMITATIONS ..................................................................................................................... 6

1.6 ROLES / RESPONSIBILITY. ........................................................................................... 6

1.7 HSE REQUIREMENTS .................................................................................................... 6

"UNCONTROLLED WHEN PRINTED"

30/07/2012 8:35 AM PETRONAS CARIGALI SDN BHD Page 5 of 14

Operating Procedure MY SKO O 05 MCOT 007

Chemicals Injection: Sludge Breaker Rev. 0 Sept 2011

1 INTRODUCTION

1.1 OBJECTIVE / PURPOSE

1.1.1 The operating procedure outlines the normal activities required to safely execute the task, as

well as action to be taken during abnormal/emergency situations during the execution of the

task.

1.1.2 The task refers to the sludge breaker injection for the slop oil treatment.

1.2 SCOPE

1.2.1 The requirements in this procedure shall apply to;

• Sludge breaker injection for slop oil treatment.

1.3 OP CATEGORY

Categories Normal / Start Up / Shutdown / Checklist Required: Yes / No

and attributes Emergency / Special / Temporary /

Abnormal / Decommissioning

1.4 PREREQUISITES

1.4.1 N/A

1.5 LIMITATIONS

1.5.1 Sludge breaker inventory.

1.6 ROLES / RESPONSIBILITY

1.6.1 Refer to Section 2: Procedure “Action party”.

1.7 HSE REQUIREMENTS

Hazards and The table below lists job hazards and the precautions that should be taken for

precautions safety, environmental, quality, ergonomics, Good Manufacturing Practices,

etcG before beginning this procedure.

Hazard Precaution

Chemical/Toxic/Thermal burns Wear appropriate PPE

"UNCONTROLLED WHEN PRINTED"

30/07/2012 8:35 AM PETRONAS CARIGALI SDN BHD Page 6 of 14

Operating Procedure MY SKO O 05 MCOT 007

Chemicals Injection: Sludge Breaker Rev. 0 Sept 2011

PPE required The following Personnel Protection Equipment (PPE) must be used to do this

activity in addition to common PPEs. List any special PPEs required,

PPE Use

Eye protection Eye protection against chemical splash

Chemical resistant apron Body protection against chemical splash

Chemical resistant boots Lower limbs protection against chemical

splash

Gas mask/Respirator Lung/respiratory protection against chemical

fume

Rubber gloves Skin protection against chemical splash

Tools and The tools and equipment listed below are needed to do this job. List any

Equipment special tools required in addition to hand tools.

Tools and/or Equipment Use

N/A

ESD / N/A

Interlocks

"UNCONTROLLED WHEN PRINTED"

30/07/2012 8:35 AM PETRONAS CARIGALI SDN BHD Page 7 of 14

Operating Procedure MY SKO O 05 MCOT 007

Chemicals Injection: Sludge Breaker Rev. 0 Sept 2011

Unit: Never

Safe Operating SOL

Exceed

Limit Excursions

Area: Limit

Equipment Inst. Consequence of Corrective

Tag # H L HH LL Deviation Actions

N/A

"UNCONTROLLED WHEN PRINTED"

30/07/2012 8:35 AM PETRONAS CARIGALI SDN BHD Page 8 of 14

Operating Procedure MY SKO O 05 MCOT 007

Chemicals Injection: Sludge Breaker Rev. 0 Sept 2011

Section 2

PROCEDURE

Content Page

2.1 PREPARATION OF SLUDGE BREAKER INJECTION FOR SLOP OIL TREATMENT .... 10

2.2 SLUDGE BREAKER INJECTION PUMP (P-6890 A/B) START UP ................................. 10

2.3 SLUDGE BREAKER INJECTION PUMP (P-200/300) SHUT DOWN ............................... 10

"UNCONTROLLED WHEN PRINTED"

30/07/2012 8:35 AM PETRONAS CARIGALI SDN BHD Page 9 of 14

Operating Procedure MY SKO O 05 MCOT 007

Chemicals Injection: Sludge Breaker Rev. 0 Sept 2011

2 PROCEDURE

2.1 PREPARATION OF SLUDGE BREAKER INJECTION FOR SLOP OIL

TREATMENT

No. Action Action Party

2.1.1 Ensure all the valves are in the correct lined up and in operating condition. Area operator

Refer to Appendix A, item 1.1, Table 1.

2.1.2 Ensure that the chemical in the ISO tank is available. Check the level in the Area operator

sight glass.

WARNING:

HANDLING OF THE CHEMICAL CAN BE HAZARDOUS AND SHOULD

BE HANDLED IN ACCORDANCE WITH THE CSDS.

2.2 SLUDGE BREAKER INJECTION PUMP (P- 6890 A/B) START UP

No. Action Action Party

2.2.1 Open the selected pump (P-6890 A/B) suction and discharge valve. Area operator

2.2.2 Inform the Panel man 2 prior to starting up of the pump. Start the pump Area operator

from local switch.

2.2.3 Monitor the pressure at the pump discharge and adjust the injection rate Area operator

according to the slop oil flow rate.

NOTE:

• The chemical injection is required when the Slop Oil Treatment is in

operation.

• Bleed off any air trapped in the piping

• Injection rate is based on laboratory analysis results

CAUTION:

• PUMP OPERATES AT HIGH DISCHARGE PRESSURE.

• EXTRA PRECAUTION WHEN OPENING THE VENT VALVE DURING

BLEEDING.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 8:35 AM PETRONAS CARIGALI SDN BHD Page 10 of 14

Operating Procedure MY SKO O 05 MCOT 007

Chemicals Injection: Sludge Breaker Rev. 0 Sept 2011

2.3 SLUDGE BREAKER INJECTION PUMP (P-200/300) SHUT DOWN

No. Action Action Party

2.3.1 Shut down the chemical injection pump from local switch and close all inlet Area operator

and outlet valves.

2.3.2 Inform Panel man 2 that the pump is already switched off. Area operator

END OF PROCEDURE

"UNCONTROLLED WHEN PRINTED"

30/07/2012 8:35 AM PETRONAS CARIGALI SDN BHD Page 11 of 14

Operating Procedure MY SKO O 05 MCOT 007

Chemicals Injection: Sludge Breaker Rev. 0 Sept 2011

Appendix

APPENDIX A

Content Page

1 CHECKLIST ............................................................................................................13

1.1 TABLE 1: NORMAL OPERATION OF THE CHEMICAL INJECTION SYSTEM ...13

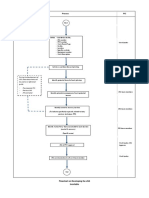

2 DIAGRAMS .............................................................................................................14

2.1 FIGURE 1: CHEMICAL INJECTION FOR THE SLOP OIL TREATMENT ............14

"UNCONTROLLED WHEN PRINTED"

30/07/2012 8:35 AM PETRONAS CARIGALI SDN BHD Page 12 of 14

Operating Procedure MY SKO O 05 MCOT 007

Chemicals Injection: Sludge Breaker Rev. 0 Sept 2011

1 CHECKLIST

1.1 TABLE 1: NORMAL OPERATION OF THE CHEMICAL INJECTION SYSTEM

LOCATION VALVE POSITION

ISO tank outlet valves Open

P-6890 A suction valve Open

Pump strainer drain valve Close

PSV-6890 A inlet valve Open

PSV-6890 A outlet valve Open

P-6890 A discharge valve Open

P-6890 B suction valve Close

P-6890 B discharge valve Close

"UNCONTROLLED WHEN PRINTED"

30/07/2012 8:35 AM PETRONAS CARIGALI SDN BHD Page 13 of 14

Operating Procedure MY SKO O 05 MCOT 007

Chemicals Injection: Sludge Breaker Rev. 0 Sept 2011

2 DIAGRAMS

2.1 FIGURE 1: CHEMICAL INJECTION FOR THE SLOP OIL TREATMENT

"UNCONTROLLED WHEN PRINTED"

30/07/2012 8:35 AM PETRONAS CARIGALI SDN BHD Page 14 of 14

You might also like

- MCOT 049tanks FiscalisationDocument18 pagesMCOT 049tanks FiscalisationLembang ApangNo ratings yet

- MCOT 011 Offshore Incoming Trunkline OperationsDocument16 pagesMCOT 011 Offshore Incoming Trunkline OperationsLembang ApangNo ratings yet

- MCOT 020 Tanker Loading Operations PDFDocument20 pagesMCOT 020 Tanker Loading Operations PDFLembang ApangNo ratings yet

- MCOT 010 Crude Receiving - Tank Switching OperationsDocument16 pagesMCOT 010 Crude Receiving - Tank Switching OperationsLembang ApangNo ratings yet

- MCOT 013 Pig Receiving From 4B 18in Crude LineDocument18 pagesMCOT 013 Pig Receiving From 4B 18in Crude LineLembang ApangNo ratings yet

- MCOT 018 Sea Loading Pump Station - SLPS - Operations PDFDocument24 pagesMCOT 018 Sea Loading Pump Station - SLPS - Operations PDFLembang ApangNo ratings yet

- MCOT 019 Bundwall Water Draining PDFDocument15 pagesMCOT 019 Bundwall Water Draining PDFLembang ApangNo ratings yet

- MCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFDocument15 pagesMCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFLembang ApangNo ratings yet

- MCOT 017 Inter Tanks Transfer OperationsDocument14 pagesMCOT 017 Inter Tanks Transfer OperationsLembang ApangNo ratings yet

- MCOT 008 WL Crude Receiving 18 InchDocument23 pagesMCOT 008 WL Crude Receiving 18 InchLembang ApangNo ratings yet

- Attachment II - Revised JHA Process FlowDocument1 pageAttachment II - Revised JHA Process FlowLembang ApangNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)