Professional Documents

Culture Documents

MCOT 017 Inter Tanks Transfer Operations

Uploaded by

Lembang ApangOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCOT 017 Inter Tanks Transfer Operations

Uploaded by

Lembang ApangCopyright:

Available Formats

Operating Procedure MY SKO O 05 MCOT 017

Inter Tanks Transfer Operations Rev. 0 Sept 2011

Any deviation from this procedure must follow the MANAGEMENT OF CHANGE PROCEDURE

or STANDING INSTRUCTIONS process before any deviation or change may be made.

OPERATING PROCEDURE

Contents

Foreword

Distribution List

Amendment Summary

Glossary

Reference

Section 1 Introduction

Section 2 Procedure

Appendix A Checklist

Diagram

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:42 AM PETRONAS CARIGALI SDN BHD Page 1 of 14

Operating Procedure MY SKO O 05 MCOT 017

Inter Tanks Transfer Operations Rev. 0 Sept 2011

FOREWORD

Authority for original issue

Document Author

Issue of this document has been formally authored by:

Name: Mentor Solutions & Resources Sdn Bhd

Position: Technician/ Consultant/ Contractor

Date:

Issue Review

Issue of this document has been formally reviewed by:

Name:

Signature

Position: Production Supervisor/ Field Engineer

Date:

Issue Approval

Issue of this document has been formally approved by:

Name:

Signature:

Position: Head of Production

Date:

Document Custodian

The following person has been assigned as the document custodian:

Name:

Signature:

Position Onshore Installation Manager

Date

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:42 AM PETRONAS CARIGALI SDN BHD Page 2 of 14

Operating Procedure MY SKO O 05 MCOT 017

Inter Tanks Transfer Operations Rev. 0 Sept 2011

Distribution List

Copy No. Title Location

01 Central Control Room MCOT

AMENDMENT SUMMARY

This sheet must be completed in detail at each revision once this document has been

approved.

Details must include revision number, description and indication of which pages and

paragraphs have been revised, date of revision approval, approvers title and signature.

Rev Description Date Approver Title Name

Rev 0 Original Document

Notes: (1) Document Holders to update Amendment Record as and when

amendments/new revisions are received.

(2) For description of amendment the Document Holder should indicate

correction, modification, update or deletion issue.

(3) Document Holder to enter their company reference number, sign and date the

record of entry.

(4) Where part amendments are issued, the relevant page(s) will be identified

with a lower case letter in the revision status line in the header.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:42 AM PETRONAS CARIGALI SDN BHD Page 3 of 14

Operating Procedure MY SKO O 05 MCOT 017

Inter Tanks Transfer Operations Rev. 0 Sept 2011

GLOSSARY

CCR Central Control Room

DCS Distributed Control System

EOV Electric Operated Valve

SFH Safe Filling High

SLPS Sea Loading Pumps Station

CIMAH Control of Industrial Major Accident Hazard

REFERENCE

DOC. NO TITLE

MY SKO O 07016 Rev.1 April 2010 MCOT Operating Procedures Manual

MCOT CIMAH Safety Report PCSB

MCOT CIMAH 2009 Rev 131109

SKO Rev. 0 November 2009

MCOT Rejuvenation Project Phase Piping & Instrumentation Diagram (P&ID)

2 Process Drawing (Rev. No. 6)

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:42 AM PETRONAS CARIGALI SDN BHD Page 4 of 14

Operating Procedure MY SKO O 05 MCOT 017

Inter Tanks Transfer Operations Rev. 0 Sept 2011

Section 1

INTRODUCTION

Content Page

1.1 OBJECTIVE / PURPOSE ............................................................................................. 6

1.2 SCOPE .......................................................................................................................... 6

1.3 OP CATEGORY ............................................................................................................ 6

1.4 PREREQUISITES ......................................................................................................... 6

1.5 LIMITATIONS ................................................................................................................ 6

1.6 ROLES / RESPONSIBILITY. ........................................................................................ 6

1.7 HSE REQUIREMENTS ................................................................................................. 6

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:42 AM PETRONAS CARIGALI SDN BHD Page 5 of 14

Operating Procedure MY SKO O 05 MCOT 017

Inter Tanks Transfer Operations Rev. 0 Sept 2011

1 INTRODUCTION

1.1 OBJECTIVE / PURPOSE

1.1.1 This operating procedure outlines activities required to execute inter-tank transfer:

• to maximize tanks storage ullage,

• to transfer of residual crude prior to tank maintenance,

• for export meter proving and calibration.

1.2 SCOPE

1.2.1 The requirements in this procedure shall apply to:

• Tank preparation

• Inter tank transfer

1.3 OP CATEGORY

Categories Normal / Start Up / Shutdown / Checklist Required: Yes / No

Emergency / Special / Temporary /

and attributes

Abnormal / Decommissioning

1.4 PREREQUISITES

1.4.1 MCOT Daily Tanks Status.

1.4.2 Options to run motor-driven pump (P-1440/50), booster pump (P-1410/20/30), gas-driven

engines crude loading pumps (P-1/10/11/1200) or combination of pumps must be planned

upfront.

1.4.3 Competent area operator with engine driver certification as per DOSH requirement is required

if gas-driven engines are to be used.

1.4.4 Maintain radio communication with the CCR during inter tank operation

1.5 LIMITATIONS

N/A

1.6 ROLES / RESPONSIBILITY

1.6.1 Refer to Section 2: Procedure “Action party”.

1.7 HSE REQUIREMENTS

Hazards and The table below lists job hazards and the precautions that should be taken for

precautions safety, environmental, quality, ergonomics, Good Manufacturing Practices,

etcH before beginning this procedure.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:42 AM PETRONAS CARIGALI SDN BHD Page 6 of 14

Operating Procedure MY SKO O 05 MCOT 017

Inter Tanks Transfer Operations Rev. 0 Sept 2011

Hazard Precaution

Loss of containment Ensure relief/breather valve is operational

Ergonomics Correct posture when opening valve

Others Beware of lightning strike

Biological hazards Beware of snakes

PPE required The following Personnel Protection Equipment (PPE) must be used to do this

activity in addition to common PPEs. List any special PPEs required,

PPE Use

N/A

Tools and The tools and equipment listed below are needed to do this job. List any

Equipment special tools required in addition to hand tools.

Tools and/or Equipment Use

Valve wrench For valve opening

ESD / N/A

Interlocks

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:42 AM PETRONAS CARIGALI SDN BHD Page 7 of 14

Operating Procedure MY SKO O 05 MCOT 017

Inter Tanks Transfer Operations Rev. 0 Sept 2011

Unit: Storage Tank Farm

Safe Operating Limit Never Exceed Limit SOL Excursions

Area: 2

Equipment Inst. Tag # H L HH LL Consequence of Deviation Corrective Actions

TK-69 LT-6901 Too high level will cause overflow Control the level through diverting flow to

10250 600 10430 500 Low low level will cause pump other tanks

cavitation

Too high level will cause overflow

Control the level through diverting flow to

TK-72 LT-7201 10250 600 10350 500 Low low level will cause pump

other tanks

cavitation

TK-79 LT-7901 Too high level will cause overflow Control the level through diverting flow to

11840 1000 12600 900 Low low level will cause pump other tanks

cavitation

TK-81 LT-8101 Too high level will cause overflow Control the level through diverting flow to

12350 800 12600 700 Low low level will cause pump other tanks

cavitation

TK-82 LT-8201 Too high level will cause overflow Control the level through diverting flow to

11950 800 12578 700 Low low level will cause pump other tanks

cavitation

TK-83 LT-8301 Too high level will cause overflow Control the level through diverting flow to

11920 800 11996 700 Low low level will cause pump other tanks

cavitation

TK-90 LT-9001 Too high level will cause overflow Control the level through diverting flow to

17320 600 17860 500 Low low level will cause pump other tanks

cavitation

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:42 AM PETRONAS CARIGALI SDN BHD Page 8 of 14

Operating Procedure MY SKO O 05 MCOT 017

Inter Tanks Transfer Operations Rev. 0 Sept 2011

Section 2

PROCEDURE

Content Page

2.1 TANK PREPARATION ................................................................................................ 10

2.2 INTER TANKS TRANSFER ........................................................................................ 10

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:42 AM PETRONAS CARIGALI SDN BHD Page 9 of 14

Operating Procedure MY SKO O 05 MCOT 017

Inter Tanks Transfer Operations Rev. 0 Sept 2011

2 PROCEDURE

2.1 TANK PREPARATION

No. Action Action Party

2.1.1 Fiscalize tanks prior to carry out inter tank transfer. Refer to Tank Area operator

Fiscalization Procedure.

NOTE:

• Independent surveyor to witness tanks fiscalization.

• Inter tank transfer operation is to:

o Maximize tanks storage ullage

o Transfer residual crude prior to tank maintenance

o Export meter proving and calibration

2.1.2 Check CCR ENTIS tank gauging display for transfer and filling tanks Panel man 1

levels

2.1.3 Set tank level alarm (minimum 1 meter) before safe filling height to Panel man 1

prevent over filling

2.1.4 Line up tank to be transferred to the filling tank via SLPS. Refer to SLPS Panel man 1 /

Operating Procedure. Area operator

NOTE:

• SLPS Booster pumps P-1410/1420/1430

• Main loading pumps gas engine driven P-1/P-10/P-11/P-1200

• Main loading pumps electric driven P-1440/P-1450.

2.2 INTER TANKS TRANSFER

No. Action Action Party

2.2.1 Open tank sides outlet manual valves of tank to be transferred out. Area operator

2.2.2 Open tank sides filling manual valves of tank to be transferred in. Area operator

2.2.3 Open transfer tank crude outlet and filling tank inlet line EOVs from CCR. Panel man 1

NOTE:

Operations of EOV, tank side valves are to be recorded in panel man

logbook in CCR.

2.2.4 Carry out pre-startup check of gas engine driven loading pump. Refer to Area

SLPS Operations procedure. operator/ ICE

Driver

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:42 AM PETRONAS CARIGALI SDN BHD Page 10 of 14

Operating Procedure MY SKO O 05 MCOT 017

Inter Tanks Transfer Operations Rev. 0 Sept 2011

No. Action Action Party

2.2.5 Line up a l l SLPS pumps and manifold valves. Check respective positions Area operator

of valves are in correct position.

2.2.6 Start booster pump and SLPS loading pumps as per SLPS OP. Area operator

/ ICE Driver

2.2.7 Engage the loading pump clutch. Commence inter tank transfer at low Area operator

flow rate and increase gradually to the required flow rate. One loading

pump rate is 1,300 kl/hr.

2.2.8 Monitor tanks levels and flow rate from CCR ENTIS. Panel man 1

2.2.9 Reduce pump flow rate manually via FIC and FCV when filling tank preset Panel man 1/

level alarm is triggered and disengage the loading pump clutch. ICE Driver

CAUTION:

• DO NOT EXCEED TANK SFH.

2.2.10 Stop SLPS loading pump engine after idling for 5 minutes. ICE Driver

2.2.11 Close transfer in and transfer out tank inlet and outlet EOVs from CCR. Panel man 1

2.2.12 Close tank sides outlet manual valves of transfer out tank. Area operator

2.2.13 Close tank sides filling manual valves of transfer in tank. Area operator

2.2.14 Fiscalise both tanks after inter tank transfer. Area operator

NOTE:

Fiscalise tank after minimum half hour settling period.

2.2.15 Update MCOT Daily Tanks Status. Shift

Production

Supervisor

2.2.16 Fill up Tank Movement forms A7 and A8. Panel man 1

END OF PROCEDURE

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:42 AM PETRONAS CARIGALI SDN BHD Page 11 of 14

Operating Procedure MY SKO O 05 MCOT 017

Inter Tanks Transfer Operations Rev. 0 Sept 2011

Appendix

APPENDIX A

Content Page

1 CHECKLIST ................................................................................................................ 13

1.1 TABLE 1: DRY TANKS SFH, MAXIMUM LEVEL, CAPACITY .................................. 13

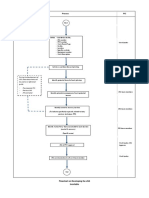

2 DIAGRAMS ................................................................................................................. 14

2.1 FIGURE 1: DRY TANKS OPERATION ...................................................................... 14

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:42 AM PETRONAS CARIGALI SDN BHD Page 12 of 14

Operating Procedure MY SKO O 05 MCOT 017

Inter Tanks Transfer Operations Rev. 0 Sept 2011

1 CHECKLIST

1.1 TABLE 1: DRY TANKS SFH, MAXIMUM LEVEL, CAPACITY

Low Level SFH Setting Maximum Max Operating

Crude Oil Tank

Setting (mm) (mm) Setting (mm) Capacity (kl)

TK-69 450 10250 10430 10781

TK-79* 998 11840 12600 23750

TK-81 900 12350 12600 23710

TK-82 878 11950 12578 22495

TK-83 370 11920 11996 22520

TK-90* 600 17320 17860 34517

*Wet And Dry (Also Known As Dual) Tank

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:42 AM PETRONAS CARIGALI SDN BHD Page 13 of 14

Operating Procedure MY SKO O 05 MCOT 017

Inter Tanks Transfer Operations Rev. 0 Sept 2011

2 DIAGRAMS

2.1 FIGURE 1: DRY TANKS OPERATION

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:42 AM PETRONAS CARIGALI SDN BHD Page 14 of 14

You might also like

- Operating Manual DAS PLTMG Sumbawa 50 MWDocument21 pagesOperating Manual DAS PLTMG Sumbawa 50 MWerick herdiawanNo ratings yet

- Wet Gas CompressionDocument122 pagesWet Gas CompressionMSNo ratings yet

- InstruCalc QuickStart Guide PDFDocument26 pagesInstruCalc QuickStart Guide PDFPatricio CopadoNo ratings yet

- BTG Ets MFT Alarm ListDocument20 pagesBTG Ets MFT Alarm ListriyantoNo ratings yet

- Liquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Document70 pagesLiquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Achmadda FebiyonoNo ratings yet

- LPG Recovery and Condensate StabilizationDocument6 pagesLPG Recovery and Condensate StabilizationWaqar AhmedNo ratings yet

- Ves 5140 R13Document23 pagesVes 5140 R13Dwiadi CahyabudiNo ratings yet

- Dehydration SOP Rev.1.Document10 pagesDehydration SOP Rev.1.jayprakashNo ratings yet

- Laporan Asset Wellness Reliabilty Adp Omu Week 11Document35 pagesLaporan Asset Wellness Reliabilty Adp Omu Week 11Luqman Hakim100% (1)

- Commissioning Procedure - FM 200Document5 pagesCommissioning Procedure - FM 200Binu SulochananNo ratings yet

- Boiler Startup Procedure PDFDocument56 pagesBoiler Startup Procedure PDFசர்வமும் சிவமயம்No ratings yet

- Prinsip Dasar M-RSDocument45 pagesPrinsip Dasar M-RSIkhsan ArifNo ratings yet

- PDB PTW 2019 Ra and WL Vol. 1 10-11 Nov 2020Document255 pagesPDB PTW 2019 Ra and WL Vol. 1 10-11 Nov 2020Syed AmzarNo ratings yet

- G-04 - KAN Guide On Internal Audits For Lab and Inspection Bodies (En)Document11 pagesG-04 - KAN Guide On Internal Audits For Lab and Inspection Bodies (En)Himma FirdausNo ratings yet

- Commissioning RRDocument32 pagesCommissioning RRAinur Bamol NamsembilanNo ratings yet

- HSSE Pack - Site Training PackDocument36 pagesHSSE Pack - Site Training Packfarhan Ali100% (1)

- Schematic Diagram NSB-NSODocument18 pagesSchematic Diagram NSB-NSOandriNo ratings yet

- Proses Konstruksi, Proteksi Turbin Dan CommisioningDocument11 pagesProses Konstruksi, Proteksi Turbin Dan CommisioningAji PrastiaNo ratings yet

- For Gas MeteringDocument24 pagesFor Gas Meteringsugeng wahyudiNo ratings yet

- Electrical T Est EquipmentDocument13 pagesElectrical T Est EquipmenthophancongnhanNo ratings yet

- User Guide For Models and Physical Properties - Multiflash 4.3Document74 pagesUser Guide For Models and Physical Properties - Multiflash 4.3GalileosaysNo ratings yet

- Guidance On Safe Operation of Boilers: Ref: BG01Document40 pagesGuidance On Safe Operation of Boilers: Ref: BG01SubburajMechNo ratings yet

- Boiler Make Up Water Pump Data SheetDocument6 pagesBoiler Make Up Water Pump Data SheetGunturMudaAliAkbarNo ratings yet

- Quotation CEMS (HG) - CO2 - SISPEK - PT Tenaga Listrik Bengkulu (1269)Document2 pagesQuotation CEMS (HG) - CO2 - SISPEK - PT Tenaga Listrik Bengkulu (1269)Muhamad JemadiNo ratings yet

- Price List Software - Updated 11 Okt 21Document6 pagesPrice List Software - Updated 11 Okt 21Rokan PipelineNo ratings yet

- Simops Test Leak / Hold Test For SCSSV / SSV North East ClusterDocument3 pagesSimops Test Leak / Hold Test For SCSSV / SSV North East ClusterHosseinNo ratings yet

- MSDS MC22Document4 pagesMSDS MC22Fhail MechanicalNo ratings yet

- Basics of Industrial Heat TransferDocument12 pagesBasics of Industrial Heat TransferPinaiNo ratings yet

- Flame ScannerDocument72 pagesFlame ScannerRavi Sankar MuthuNo ratings yet

- (KPCC) Sop - Gas BoosterDocument12 pages(KPCC) Sop - Gas BoosterWindy Nitaejun HorvejkulNo ratings yet

- Suspended & Surface Mounted Luminaires: HDK900 RangeDocument2 pagesSuspended & Surface Mounted Luminaires: HDK900 Rangesihabudin kolyubiNo ratings yet

- MSDS SFM-4728, FlexoilDocument5 pagesMSDS SFM-4728, FlexoilLeddy ZakarunaNo ratings yet

- JSA Box UpDocument7 pagesJSA Box Upimam dianiNo ratings yet

- Interleeaved Boost Converter - MOHAMADABDULRAHIMBMOHDNORDINDocument67 pagesInterleeaved Boost Converter - MOHAMADABDULRAHIMBMOHDNORDINmelzii100% (2)

- Penentuan Laju Korosi Dan Sisa Umur PakaiDocument10 pagesPenentuan Laju Korosi Dan Sisa Umur PakaifaisalNo ratings yet

- PidDocument85 pagesPidvermaakash22No ratings yet

- Trans Chapter6 PDFDocument106 pagesTrans Chapter6 PDFsammar_10No ratings yet

- PSSR Pre-Commissioning SafetyDocument6 pagesPSSR Pre-Commissioning SafetymanuNo ratings yet

- Harga Pekerjaan Repair Valve Rev1Document21 pagesHarga Pekerjaan Repair Valve Rev1sandrositohangNo ratings yet

- Compressor Wet GasDocument4 pagesCompressor Wet GasyogacruiseNo ratings yet

- SOPDocument29 pagesSOPKeniBataraNo ratings yet

- Pre-Start Up Safety Review (PSSR) : Akamigas Balongan IndramayuDocument18 pagesPre-Start Up Safety Review (PSSR) : Akamigas Balongan IndramayuRifky Haikal RamadhanNo ratings yet

- Sop BoilerDocument3 pagesSop BoilerBentar ELcNo ratings yet

- Boiler Operations - Soda BoilingDocument3 pagesBoiler Operations - Soda BoilingBasty Tejano100% (1)

- 5.3.3 Dimensioning of The Air Receiver Volume: C 1 1 Max U L 0Document1 page5.3.3 Dimensioning of The Air Receiver Volume: C 1 1 Max U L 0Nath BoyapatiNo ratings yet

- GT Tray Tower1 PDFDocument12 pagesGT Tray Tower1 PDFJose Christian Viladegut GuzmanNo ratings yet

- Adiabtaic Vs Polytropic Head Compressor - ComparisonDocument1 pageAdiabtaic Vs Polytropic Head Compressor - Comparisonvijay_jvNo ratings yet

- LPG Leakage & DetectionDocument3 pagesLPG Leakage & DetectionSravan GopuNo ratings yet

- 4.SOP Emergency Shut DownDocument5 pages4.SOP Emergency Shut DownDodik NugrohoNo ratings yet

- Technical Manual ZETA REVDocument66 pagesTechnical Manual ZETA REVAnonymous lB6SsHu5KNo ratings yet

- LCBDocument29 pagesLCBjanvi lunagariyaNo ratings yet

- SKC Rigid Polyol - SR451: For Rigid Polyurethane FoamDocument1 pageSKC Rigid Polyol - SR451: For Rigid Polyurethane FoamA MahmoodNo ratings yet

- Case Histories of Amine Plant Equipment Corrosion Problems - Part 2Document4 pagesCase Histories of Amine Plant Equipment Corrosion Problems - Part 2jdgh1986No ratings yet

- Power Plant OperationDocument5 pagesPower Plant OperationAthira NairNo ratings yet

- Feed Water ControlDocument8 pagesFeed Water Controlsihyeok kimNo ratings yet

- Jha To Perform On-Site Verification For Glycol ReboilerDocument2 pagesJha To Perform On-Site Verification For Glycol ReboilerEdha AliNo ratings yet

- MCOT 010 Crude Receiving - Tank Switching OperationsDocument16 pagesMCOT 010 Crude Receiving - Tank Switching OperationsLembang ApangNo ratings yet

- MCOT 018 Sea Loading Pump Station - SLPS - Operations PDFDocument24 pagesMCOT 018 Sea Loading Pump Station - SLPS - Operations PDFLembang ApangNo ratings yet

- MCOT 020 Tanker Loading Operations PDFDocument20 pagesMCOT 020 Tanker Loading Operations PDFLembang ApangNo ratings yet

- MCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFDocument15 pagesMCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFLembang ApangNo ratings yet

- MCOT 049tanks FiscalisationDocument18 pagesMCOT 049tanks FiscalisationLembang ApangNo ratings yet

- MCOT 011 Offshore Incoming Trunkline OperationsDocument16 pagesMCOT 011 Offshore Incoming Trunkline OperationsLembang ApangNo ratings yet

- MCOT 020 Tanker Loading Operations PDFDocument20 pagesMCOT 020 Tanker Loading Operations PDFLembang ApangNo ratings yet

- MCOT 010 Crude Receiving - Tank Switching OperationsDocument16 pagesMCOT 010 Crude Receiving - Tank Switching OperationsLembang ApangNo ratings yet

- MCOT 013 Pig Receiving From 4B 18in Crude LineDocument18 pagesMCOT 013 Pig Receiving From 4B 18in Crude LineLembang ApangNo ratings yet

- MCOT 018 Sea Loading Pump Station - SLPS - Operations PDFDocument24 pagesMCOT 018 Sea Loading Pump Station - SLPS - Operations PDFLembang ApangNo ratings yet

- MCOT 019 Bundwall Water Draining PDFDocument15 pagesMCOT 019 Bundwall Water Draining PDFLembang ApangNo ratings yet

- MCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFDocument15 pagesMCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFLembang ApangNo ratings yet

- MCOT 008 WL Crude Receiving 18 InchDocument23 pagesMCOT 008 WL Crude Receiving 18 InchLembang ApangNo ratings yet

- Attachment II - Revised JHA Process FlowDocument1 pageAttachment II - Revised JHA Process FlowLembang ApangNo ratings yet