Professional Documents

Culture Documents

MCOT Tank Operating Procedure

Uploaded by

Lembang ApangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCOT Tank Operating Procedure

Uploaded by

Lembang ApangCopyright:

Available Formats

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

Any deviation from this procedure must follow the MANAGEMENT OF CHANGE PROCEDURE or

STANDING INSTRUCTIONS process before any deviation or change may be made.

OPERATING PROCEDURE

Contents

Foreword

Distribution List

Amendment Summary

Glossary

Reference

Section 1 Introduction

Section 2 Procedure

Appendix A Checklist

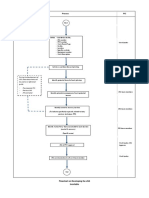

Diagram

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 1 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

FOREWORD

Authority for original issue

Document Author

Issue of this document has been formally authored by:

Name: Mentor Solutions & Resources Sdn Bhd

Position: Technician/ Consultant/ Contractor

Date:

Issue Review

Issue of this document has been formally reviewed by:

Name:

Signature

Position: Production Supervisor/ Field Engineer

Date:

Issue Approval

Issue of this document has been formally approved by:

Name:

Signature:

Position: Head of Production

Date:

Document Custodian

The following person has been assigned as the document custodian:

Name:

Signature:

Position Onshore Installation Manager

Date

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 2 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

Proprietary Information

This document contains proprietary information belonging to

PETRONAS Carigali Sdn Bhd and must not be wholly or partially reproduced nor

disclosed without prior permission from PETRONAS Carigali Sdn Bhd.

Distribution List

Copy No. Title Location

01 Central Control Room MCOT

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 3 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

AMENDMENT SUMMARY

This sheet must be completed in detail at each revision once this document has been approved.

Details must include revision number, description and indication of which pages and paragraphs

have been revised, date of revision approval, approvers title and signature.

Rev Description Date Approver Title Name

Rev 0 Original Document

Notes: (1) Document Holders to update Amendment Record as and when amendments/new

revisions are received.

(2) For description of amendment the Document Holder should indicate correction,

modification, update or deletion issue.

(3) Document Holder to enter their company reference number, sign and date the

record of entry.

(4) Where part amendments are issued, the relevant page(s) will be identified with a

lower case letter in the revision status line in the header.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 4 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

GLOSSARY

MCOT Miri Crude Oil Terminal

LEL Lower Explosive Limit

PCMS Process Control and Monitoring System

EOV Electrical Operated Valve

Reference Point Is the fixed point or mark at or near the top of a tank, from which

measurement are made. This point may be a bench mark or a small

fixed plate inside the gauging hatch, a narrow groove cut horizontally on

the inside of the hatch, or the edge of a fixed metal arm which is

attached to the tank shell and projects a short distance above the

gauging hatch but is not in contact with it

Reference Depth The distance from the reference point to the bottom of the tank.

(Gauging Height) Preferably this distance should be stamped on the fixed bench mark

plate or stenciled on the tank roof near the gauging hatch.

Datum Plate Level metal plate, preferable attached to the tank shell, located directly

under the reference point to provide a fixed contact for the innage bob.

All tanks are with Datum plate

Cut Line demarcation on the measuring scale made by the material being

measured

REFERENCE

DOC. NO TITLE

MY SKO O 07 016 MCOT Operating Procedure Manual

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 5 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

Section 1

INTRODUCTION

Content Page

1.1 OBJECTIVE/PURPOSE .................................................................................................... 7

1.2 SCOPE .............................................................................................................................. 7

1.3 OP CATEGORY ................................................................................................................ 7

1.4 PREREQUISITES ............................................................................................................. 7

1.5 LIMITATIONS .................................................................................................................... 7

1.6 ROLES / RESPONSIBILITY. ............................................................................................. 7

1.7 HSE REQUIREMENTS ..................................................................................................... 7

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 6 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

1 INTRODUCTION

1.1 OBJECTIVE/PURPOSE

1.1.1 This operating procedure defines the step-by-step instructions to carry out tanks fiscalisation

operations. It outlines the normal activities required to execute the task, as well as actions to

be taken in the event of abnormal situations that may arise during job execution.

1.1.2 The objective of fiscalisation is to measure the quantity and BS&W of crude oil in the tank:

• Before and after receiving of product into the tank

• After emulsion draining from the tank

• Before and after loading, inter tank transfer

• For calculating the monthly inventory

1.2 SCOPE

1.2.1 The requirements in this operating procedure shall apply to MCOT.

1.3 OP TYPE

Type and Normal / Start Up / Shutdown / Checklist Required: Yes / No

Emergency / Special / Temporary /

attributes

Abnormal / Decommissioning

1.4 PREREQUISITES

1.4.1 Ensure communication is established between Operation Technician and MCOT CCR at all

times during the operation

1.4.2 Ensure measuring gauge accuracy is checked as per requirements

1.4.3 Sample analyser is reliable

1.5 LIMITATIONS

1.5.1 Gauging may not be done during adverse weather condition, unless necessary.

1.6 ROLES / RESPONSIBILITY:

1.6.1 Refer to Section 2: Procedure “Action party”.

1.7 HSE REQUIREMENTS

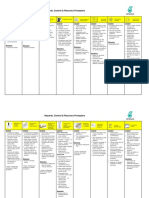

Hazards and The table below lists job hazards and the precautions that should be taken for

precautions safety, environmental, quality, ergonomics, Good Manufacturing Practices,

etcH before beginning this procedure.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 7 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

Hazard Precaution

Static Electricity Gauges to be earthed by touching

dipping hatch.

Gas Hazard Do not inhale gases, stand up

wind

Leaks Inspect tanks, connecting valves

and lines

Water intrusion Never dip tank during heavy rain

Lighting strike Do not go up the tank during

lightning

Fumes Wear face mask or stand upwind

Slip and fall Anti-slip plate in place

Hold the handrail

PPE required The following Personnel Protection Equipment (PPE) must be used to do this

activity in addition to common PPEs. List any special PPEs required,

PPE Use

Half mask respirator with organic cartridge Require to wear respirator if toxic

gas is present during dipping.

Tools and The tools and equipment listed below are needed to do this job. List any

Equipment special tools required in addition to hand tools.

Tools and/or Equipment Use

Dipping tape Product sampling and

measurement

Sampling jar

Flushing cage

Thermometer

Water paste

ESD /

Interlocks N/A

NOTE: Only where applicable

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 8 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

Unit: Never

Safe Operating SOL

Exceed

Limit Excursions

Area: Limit

Equipment Inst. Consequence of Corrective

Tag # H L HH LL Deviation Actions

NOTE: Only where applicable

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 9 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

Section 2

PROCEDURE

Content Page

2.1 INNAGE METHOD .......................................................................................................... 11

2.2 OUTAGE METHOD ......................................................................................................... 13

2.3 WATER AND SEDIMENTS GAUGING ........................................................................... 14

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 10 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

2 PROCEDURE

2.1 INNAGE METHOD

No. Action Action Party

2.1.1 Apply some water paste covering the bob at the expected level and part of the Operation

dip tape above the bob. Technician

NOTE:

• Dip tape shall conform to specifications given by IP 202/69, measured

in metric units and marked in metres, centimetres and millimetres.

• Dip-tapes shall be checked before being used for the first time and at

monthly intervals thereafter.

• The “Sub-Master” dip tape will be kept solely for the purpose of

checking the working tapes. “Sub-Master” dip tape shall be checked

every six months against a “Master Tape”, certified by SIRIM and

under custodian of Shift Operations Supervisor.

2.1.2 Lower the gauging tape and the bob until the bob touches the datum plate and Area Operator

the millimetre reading at the reference point is the same as the millimetre

reading on the gauging reference height.

2.1.3 Withdraw the tape immediately and record the reading as follows: Area Operator

a) Tank number

b) Type of sample: (e.g. Tank Fiscalisation)

c) Date/ Time

d) Liquid temperature

e) Name of the sample taker

NOTE:

• Reading of the dip tapes to the nearest millimeters.

• Obtain at least two similar readings and record immediately after

taken.

2.1.4 Record the result of the innage gauge as follows: Area Operator

a) Reference Height

b) Crude oil + water level in the tank

c) Water level as per water cut indication

d) Actual crude oil in the tank (b) –(c)

e) Available ullage in the tank (a) – (b)

2.1.5 Refer to tank’s calibration table to know the volume of crude oil in the tank at Area Operator

tank levels of (b) and (d).

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 11 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

2.1.6 Obtain the accurate volume of crude oil in the tank by calculating the actual Area Operator

Specific Gravity using the temperature correction factor.

NOTE:

Example calculation:

a) Reference Height 21,794 mm

b) Crude oil + water level in the tank 13,761 mm

c) Water level as per cut indication 561 mm

d) Actual crude oil in the tank (b) – (c) 13,200 mm

e) Available ullage in the tank (a) – (b) 8,033 mm

2.1.7 From the Actual crude reading in the tank, refer to the Tank Calibration Table Area Operator

for the actual volume in K/liters.

2.1.8 Use the Terminal Tank Gauging Ticket to determine the Corrected Tank Area Operator

Volume of the crude oil.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 12 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

2.2 OUTAGE METHOD

No. Action Action Party

2.2.1 Apply some water paste covering the bob and part of the dip tape above the Area Operator

bob.

NOTE:

• Practice will determine how much paste should be applied to obtain a

satisfactory water cut.

• At a thick coating increased the time required for the water to react

with the paste and may give erroneous readings.

2.2.2 Lower the measuring tape and bob into the tank until the bob is completely Area Operator

submerged and millimeter reading on the tape at the reference point is the

same as the millimeter reading on the gauging reference height.

2.2.3 Withdraw the tape immediately and record the reading as follows: Area Operator

a) Tank number

b) Type of sample: (e.g. Tank Fiscalisation)

c) Date/ Time

d) Liquid temperature

e) Name of the sample taker

NOTE:

• Reading of the dip tapes to the nearest millimetres

• Obtain at least two similar readings and record immediately after

taken

2.2.4 Record the result of the outage gauge for the following: Area Operator

a) Gauging Height

b) Distance from Reference Point to Crude Level

(Ullage or Empty Space or Outage)

c) Crude oil + water level in the tank: (a)-(b)

d) Water level in the tank as per water cut

e) Actual crude oil level in the tank (c)-(d)

2.2.5 Refer to tank’s calibration table to know the volume of crude oil in the tank at Area Operator

tank levels of (c).

2.2.6 Obtain the accurate volume of crude oil in the tank by calculating the actual Area Operator

Specific Gravity using the temperature and pressure correction calculation.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 13 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

2.2.7 NOTE:

Example calculation:

a) Gauging Depth (Reference Height) 21,794 mm

b) Distance from Reference Point to Crude Level 8,033 mm

(Ullage or Empty Space or Outage)

c) Crude oil + water level in the tank: (a)-(b) 13,761 mm

d) Water level in the tank as per water cut 561 mm

e) Actual crude oil level in the tank: (c)-(d) 13,200 mm

2.2.8 From the Actual crude reading in the tank, refer to the Tank Calibration Table Area Operator

for the actual volume in K/liters.

2.2.9 Use the Terminal Tank Gauging Ticket to determine the Corrected Tank Area Operator

Volume of the crude oil.

2.3 WATER AND SENDIMENTS GAUGING

No. Action Action

Party

Area

2.6.1 Apply a coat of water paste to the innage bob which will be at the interface of

Operator

water and oil to determine the reading of water cut.

NOTE:

• A good paste will either dissolve or immediately change color on

contact with free water.

2.3.1 Allow the tape and innage bob to remain in the gauging position for 5 to 10 Area

seconds for light product, and 20 to 30 seconds for heavier products. Operator

2.3.2 Read and record the layer of emulsified oil and water depths if spotted condition Area

is observed. Operator

Example :

If the paste shows continuous colour changes up to 238 mm with spotting from

238 mm to 451 mm report both readings

Water : 238 mm

Spotted : 238 mm to 451 mm

The calculation for water-cut with spotted reading is as follows:-

(451 mm – 238 mm)/2+238 mm = 345 mm

END OF PROCEDURE

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 14 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

Appendix

APPENDIX A

Content Page

1 CHECKLIST .............................................................................................................. 166

1.1 TABLE 1: WATER DIP COMPUTATION EXAMPLES ...................................................166

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 15 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

1 CHECKLIST

1.1 TABLE 1: WATER DIP COMPUTATION EXAMPLES

No. Water Dip Computation Examples Calculation

1 EXAMPLE 1

Clean oil/water interface

(a) Gauging height = 10,745 mm

(b) Tape reading at reference point = 10,445 mm

(c) Difference: (a) – (b) = 300 mm

(d) Clean cut reading on tape = 20 mm

(e) Total water dip: (c) + (d) = 320 mm

2 EXAMPLE 2

Emulsion layer present between the water and oil, showing spotted reading

on the tape

If in the above example, in an addition to a clear cut reading on the tape, a spotted

section of the tape is recorded and the average composition of the emulsion is

known, the calculation will continue unchanged until item (e) that now becomes:

(e) Bottom water dip: (c) + (d) = 320 mm

If the spotted section goes from 20 mm to 60 mm and the average water fraction of

the emulsion is 30%, the calculation continues:

(f) Emulsion layer thickness: (60-20) = 40mm

(g) Thickness spilt, water: 40 x 0.3 = 12 mm

(h) Total water dip: (e) + (g) = 332 mm

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 16 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 17 of 18

Operating Procedure - MCOT MY SKO O 05 MCOT 049

MCOT Tanks Fiscalisation Rev. 0 Sept 2011

"UNCONTROLLED WHEN PRINTED"

30/07/2012 10:42 AM PETRONAS CARIGALI SDN BHD Page 18 of 18

You might also like

- Dong-I Datos PDFDocument8 pagesDong-I Datos PDFraulNo ratings yet

- KTA 19 Parts CatalogueDocument58 pagesKTA 19 Parts CatalogueMP Vasu Raju100% (1)

- S433 GENSET SPARE LISTDocument42 pagesS433 GENSET SPARE LISTvpsales2123No ratings yet

- QuickServe Online - (3666003) C Series Troubleshooting and Repair Manual SETT VALVEDocument4 pagesQuickServe Online - (3666003) C Series Troubleshooting and Repair Manual SETT VALVEKrisman SimanjuntakNo ratings yet

- 5-650kva 60HZ en PDFDocument26 pages5-650kva 60HZ en PDFAndrésRozoNo ratings yet

- Cummins 4BT - 6BT Engine Parts Catalogue - Diesel Engine, Diesel Engine Parts, Generator Set ExporterDocument2 pagesCummins 4BT - 6BT Engine Parts Catalogue - Diesel Engine, Diesel Engine Parts, Generator Set ExporterBUI VAN CUONGNo ratings yet

- Eliminator™ FilterDocument35 pagesEliminator™ FiltertstkupdhNo ratings yet

- Manual DDFPDocument92 pagesManual DDFPCarlos VegaNo ratings yet

- M18 018 eDocument3 pagesM18 018 eFalgon IslamNo ratings yet

- Parts Catalog Cummins (150KVA), 6BTAA5.9 G12 - ESN 78641992 - CPL 4283Document135 pagesParts Catalog Cummins (150KVA), 6BTAA5.9 G12 - ESN 78641992 - CPL 4283Ari100% (1)

- GD705A Unit Parts ListDocument10 pagesGD705A Unit Parts Listirawan budi santosaNo ratings yet

- Sebp5557 00 00 All PDFDocument839 pagesSebp5557 00 00 All PDFmhmoud tweel100% (1)

- 6BT5.9-DM Non-Certified Ratings SSDocument2 pages6BT5.9-DM Non-Certified Ratings SStempro100% (1)

- Optimum ManualDocument17 pagesOptimum ManualJohn IpsilantisNo ratings yet

- J - Ponuda PDFDocument8 pagesJ - Ponuda PDFAjdin Herc AhmetovicNo ratings yet

- Seal BrochureDocument29 pagesSeal BrochureAziz AbdullahNo ratings yet

- Merchant - Condensing Unit For Ac PDFDocument14 pagesMerchant - Condensing Unit For Ac PDFAmmar RamanNo ratings yet

- V 222 TiDocument2 pagesV 222 TiTrupp2785No ratings yet

- Yangdong Not EnabledDocument4 pagesYangdong Not EnabledalawiNo ratings yet

- Genset Engine Dimensions and Technical DataDocument4 pagesGenset Engine Dimensions and Technical DatasdiamanNo ratings yet

- MT86 2018 Part BookDocument98 pagesMT86 2018 Part Bookenhbat batsuhNo ratings yet

- Engine Model Lead Time (Weeks) Engine Model Lead Time (Weeks) Engine Model Lead Time (Weeks) Engine Model Lead Time (Weeks)Document2 pagesEngine Model Lead Time (Weeks) Engine Model Lead Time (Weeks) Engine Model Lead Time (Weeks) Engine Model Lead Time (Weeks)dinduntobzNo ratings yet

- Oil ValveDocument4 pagesOil ValveGolbert GolbiNo ratings yet

- Static Injector TimingDocument12 pagesStatic Injector TimingMohamed Mohamed100% (1)

- Part Original Doosan Cuci GudangDocument18 pagesPart Original Doosan Cuci GudangIrul UmamNo ratings yet

- M25 Maintenance Schedule PDFDocument3 pagesM25 Maintenance Schedule PDFMYO WINNo ratings yet

- Parts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-55Document1 pageParts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-55Hardiansyah Simarmata100% (1)

- PVM 74 EtonDocument48 pagesPVM 74 Etoncaprit_her_771605No ratings yet

- Cat 3408c Gen SetDocument4 pagesCat 3408c Gen Setshinichie100% (1)

- 2.1 ДвигательDocument37 pages2.1 ДвигательHarlinton descalziNo ratings yet

- Motor Cummins 4bta3.9 g2Document75 pagesMotor Cummins 4bta3.9 g2Jorge SennNo ratings yet

- Piston RingsDocument1 pagePiston Ringsxtenis87No ratings yet

- 3516B Valve Lash and Valve Brigde AdjustmentDocument8 pages3516B Valve Lash and Valve Brigde Adjustmentmanu luvungaNo ratings yet

- Parts Manual - WGD185Document8 pagesParts Manual - WGD185Francisco Fernandez-Davila SainzNo ratings yet

- New Spares List SP HPCE 520 CPL 11-2012Document12 pagesNew Spares List SP HPCE 520 CPL 11-2012GMNo ratings yet

- Water PumpsDocument119 pagesWater PumpsLesly LeslyNo ratings yet

- 01 2 18 ms9-303Document13 pages01 2 18 ms9-303Rachit SharmaNo ratings yet

- Marine SiteContent en Binary Asset Attachments Products CCEC N855 CCEC Performance Curves FR11169 NT855 325 1800 IMOIIDocument3 pagesMarine SiteContent en Binary Asset Attachments Products CCEC N855 CCEC Performance Curves FR11169 NT855 325 1800 IMOIIOscar Eduardo Parra GuerreroNo ratings yet

- Cumminssec7 PDFDocument28 pagesCumminssec7 PDFjosecarlosvjNo ratings yet

- Workshop Manual Hyundai S250JDocument150 pagesWorkshop Manual Hyundai S250JwilmerNo ratings yet

- IPD - Lista de Peças Do Motor - 1 PDFDocument3 pagesIPD - Lista de Peças Do Motor - 1 PDFxxxxxxxxxxxxxxxxxxx100% (1)

- Crankshaft As 3849907 - Caterpillar d10tDocument1 pageCrankshaft As 3849907 - Caterpillar d10tgraha networkNo ratings yet

- FPT N Series Diesel Engine Data CatalogDocument14 pagesFPT N Series Diesel Engine Data CatalogMohamed Amine LimemNo ratings yet

- Media Search - SENR2824 - 3304 & 3306 VEHICULAR ENGINE PDFDocument7 pagesMedia Search - SENR2824 - 3304 & 3306 VEHICULAR ENGINE PDFMichael DavenportNo ratings yet

- Marine Engine-6170 Series: General SpecificationsDocument3 pagesMarine Engine-6170 Series: General SpecificationsTrần Hoài VinhNo ratings yet

- QSK19 M 660hkDocument2 pagesQSK19 M 660hkAinur Bamol Namsembilan100% (1)

- 丢失文件名的文件Document368 pages丢失文件名的文件313934753No ratings yet

- Kta38-M0 900@1800 FR631Document2 pagesKta38-M0 900@1800 FR631Cak Soe Bujang Periang100% (1)

- Genuine Cummins Celect PX Injectors: Better Reliability. Every TimeDocument2 pagesGenuine Cummins Celect PX Injectors: Better Reliability. Every TimeMassahiro Filho100% (1)

- 4tne98-G1a (0CR10-G45800)Document30 pages4tne98-G1a (0CR10-G45800)Alaina Sousa100% (1)

- Marine Diesel Engine Trends and Developments in 2010Document26 pagesMarine Diesel Engine Trends and Developments in 2010Khawaja JavedNo ratings yet

- Manual w200 WartsillaDocument452 pagesManual w200 Wartsillanikolasthermosolutions100% (1)

- Rubia S10 20 LT 20 LT 80 LT Castrol CRB Monograde 10W Rubia S 10W 208 LT 208 LT 4368 LTDocument6 pagesRubia S10 20 LT 20 LT 80 LT Castrol CRB Monograde 10W Rubia S 10W 208 LT 208 LT 4368 LTRovshan GasimovNo ratings yet

- Quick guide to piston ring inspection and measurementDocument7 pagesQuick guide to piston ring inspection and measurementshashirajNo ratings yet

- UC22/UC27: Aftermarket Parts ListDocument14 pagesUC22/UC27: Aftermarket Parts Listshinichie100% (1)

- Wheel Loaders PEBJ0031 PDFDocument53 pagesWheel Loaders PEBJ0031 PDFShamanich1No ratings yet

- MCOT 008 WL Crude Receiving 18 InchDocument23 pagesMCOT 008 WL Crude Receiving 18 InchLembang ApangNo ratings yet

- MCOT 020 Tanker Loading Operations PDFDocument20 pagesMCOT 020 Tanker Loading Operations PDFLembang ApangNo ratings yet

- MCOT 017 Inter Tanks Transfer OperationsDocument14 pagesMCOT 017 Inter Tanks Transfer OperationsLembang ApangNo ratings yet

- MCOT 048 Instrument and Utility Air System OperationDocument20 pagesMCOT 048 Instrument and Utility Air System OperationLembang ApangNo ratings yet

- MCOT 052 SLPS Cooling SystemDocument14 pagesMCOT 052 SLPS Cooling SystemLembang ApangNo ratings yet

- MCOT 051 Sand Washer OperationDocument17 pagesMCOT 051 Sand Washer OperationLembang ApangNo ratings yet

- MCOT 053 Sludge Farm OperationDocument16 pagesMCOT 053 Sludge Farm OperationLembang ApangNo ratings yet

- MCOT 011 Offshore Incoming Trunkline OperationsDocument16 pagesMCOT 011 Offshore Incoming Trunkline OperationsLembang ApangNo ratings yet

- MCOT 050 Baram Liquid Line Net Oil Computing - NOCDocument10 pagesMCOT 050 Baram Liquid Line Net Oil Computing - NOCLembang ApangNo ratings yet

- MCOT 020 Tanker Loading Operations PDFDocument20 pagesMCOT 020 Tanker Loading Operations PDFLembang ApangNo ratings yet

- MCOT 009 BA 16in Crude ReceivingDocument22 pagesMCOT 009 BA 16in Crude ReceivingLembang ApangNo ratings yet

- MCOT 012 Pig Receiving From BA 16 in Crude LineDocument19 pagesMCOT 012 Pig Receiving From BA 16 in Crude LineLembang ApangNo ratings yet

- MCOT 010 Crude Receiving - Tank Switching OperationsDocument16 pagesMCOT 010 Crude Receiving - Tank Switching OperationsLembang ApangNo ratings yet

- Optimize SLPS OperationsDocument24 pagesOptimize SLPS OperationsLembang ApangNo ratings yet

- Pig Receiving ProcedureDocument18 pagesPig Receiving ProcedureLembang ApangNo ratings yet

- MCOT 009 BA 16in Crude ReceivingDocument22 pagesMCOT 009 BA 16in Crude ReceivingLembang ApangNo ratings yet

- MCOT 019 Bundwall Water Draining PDFDocument15 pagesMCOT 019 Bundwall Water Draining PDFLembang ApangNo ratings yet

- MCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFDocument15 pagesMCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFLembang ApangNo ratings yet

- MCOT 006 Fuel Gas SystemDocument14 pagesMCOT 006 Fuel Gas SystemLembang ApangNo ratings yet

- Pre-prepared JHA SamplesDocument4 pagesPre-prepared JHA SamplesprinceoceanNo ratings yet

- MCOT 017 Inter Tanks Transfer OperationsDocument14 pagesMCOT 017 Inter Tanks Transfer OperationsLembang ApangNo ratings yet

- MCOT 008 WL Crude Receiving 18 InchDocument23 pagesMCOT 008 WL Crude Receiving 18 InchLembang ApangNo ratings yet

- Attachment IV - JHA Prompters - FinalDocument5 pagesAttachment IV - JHA Prompters - FinalLembang ApangNo ratings yet

- MCOT 007 Chemical Injection-Doiler and Sludge BreakerDocument14 pagesMCOT 007 Chemical Injection-Doiler and Sludge BreakerLembang ApangNo ratings yet

- Attachment I - Revised Requirement On JHADocument20 pagesAttachment I - Revised Requirement On JHALembang ApangNo ratings yet

- Attachment III - JHA Template - 09th May 2014Document2 pagesAttachment III - JHA Template - 09th May 2014Lembang ApangNo ratings yet

- Attachment II - Revised JHA Process FlowDocument1 pageAttachment II - Revised JHA Process FlowLembang ApangNo ratings yet