Professional Documents

Culture Documents

MCOT 019 Bundwall Water Draining PDF

Uploaded by

Lembang ApangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCOT 019 Bundwall Water Draining PDF

Uploaded by

Lembang ApangCopyright:

Available Formats

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

Any deviation from this procedure must follow the MANAGEMENT OF CHANGE PROCEDURE

or STANDING INSTRUCTIONS process before any deviation or change may be made.

OPERATING PROCEDURE

Contents

Foreword

Distribution List

Amendment Summary

Glossary

Reference

Section 1 Introduction

Section 2 Procedure

Appendix A Checklist

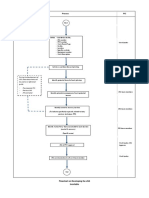

Diagram

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 1 of 15

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

FOREWORD

Authority for original issue

Document Author

Issue of this document has been formally authored by:

Name: Mentor Solutions & Resources Sdn Bhd

Position: Technician/ Consultant/ Contractor

Date:

Issue Review

Issue of this document has been formally reviewed by:

Name:

Signature

Position: Production Supervisor/ Field Engineer

Date:

Issue Approval

Issue of this document has been formally approved by:

Name:

Signature:

Position: Head of Production

Date:

Document Custodian

The following person has been assigned as the document custodian:

Name:

Signature:

Position Onshore Installation Manager

Date

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 2 of 15

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

Distribution List

Copy No. Title Location

01 Central Control Room MCOT

AMENDMENT SUMMARY

This sheet must be completed in detail at each revision once this document has been

approved.

Details must include revision number, description and indication of which pages and

paragraphs have been revised, date of revision approval, approvers title and signature.

Rev Description Date Approver Title Name

Rev 0 Original Document

Notes: (1) Document Holders to update Amendment Record as and when

amendments/new revisions are received.

(2) For description of amendment the Document Holder should indicate

correction, modification, update or deletion issue.

(3) Document Holder to enter their company reference number, sign and date the

record of entry.

(4) Where part amendments are issued, the relevant page(s) will be identified

with a lower case letter in the revision status line in the header.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 3 of 15

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

GLOSSARY

CCR Central Control Room

CIMAH Control of Industrial Major Accident Hazard

DCS Distributed Control System

Hand Wheel Operating A globe valve that is operated by a hand wheel.

Valve

Quick Opening Valve A ball valve that is operated by a handle.

OIW Oil In Water

REFERENCE

DOC. NO TITLE

MY SKO O 07016 Rev.1 April 2010 MCOT Operating Procedures Manual

P&ID

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 4 of 15

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

Section 1

INTRODUCTION

Content Page

1.1 OBJECTIVE / PURPOSE ...................................................................................................... 6

1.2 SCOPE ..................................................................................................................................... 6

1.3 OP CATEGORY...................................................................................................................... 6

1.4 PREREQUISITES .................................................................................................................. 6

1.5 LIMITATIONS .......................................................................................................................... 6

1.6 ROLES / RESPONSIBILITY. ................................................................................................ 6

1.7 HSE REQUIREMENTS ......................................................................................................... 7

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 5 of 15

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

1 INTRODUCTION

1.1 OBJECTIVE / PURPOSE

1.1.1 The objective of this procedure is to define the step-by-step instructions for carrying out tank

bundwall draining of bunded tank area safely.

1.2 SCOPE

1.2.1 The requirements in this procedure shall apply to:

• Manual Operation

• Water draining

1.3 OP CATEGORY

Categories Normal / Start Up / Shutdown / Checklist Required: Yes / No

Emergency / Special / Temporary /

and attributes

Abnormal / Decommissioning

1.4 PREREQUISITES

1.4.1 Presence of water level in the bunded area.

1.5 LIMITATIONS

1.5.1 High tide in the river during bundwall draining

1.6 ROLES / RESPONSIBILITY

1.6.1 Refer to Section 2: Procedure “Action party”.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 6 of 15

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

1.7 HSE REQUIREMENTS

Hazards and The table below lists job hazards and the precautions that should be taken for

precautions safety, environmental, quality, ergonomics, Good Manufacturing Practices,

etcH before beginning this procedure.

Hazard Precaution

Loss of containment Do not drain during high tide

Biological Beware of poisonous creature i.e. snakes,

bees etc.

Others Precaution on the soft grounds

Beware of lightning strike

PPE required The following Personnel Protection Equipment (PPE) must be used to do this

activity in addition to common PPEs. List any special PPEs required,

PPE Use

Rain boot During high tide

Rain coat During heavy raining

Tools and The tools and equipment listed below are needed to do this job. List any

Equipment special tools required in addition to hand tools.

Tools and/or Equipment Use

Valve key/wrench To open the specific valve

ESD / N/A

Interlocks

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 7 of 15

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

Unit: Storage Tank Farm

Safe Operating Never Exceed SOL

Limit Limit Excursions

Area: 2

H L HH LL Consequence of Deviation Corrective Actions

Bundwall (OIW) Bundwall drain valve to be close at all

10 ppm Non-compliance to DOE requirement

time

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 8 of 15

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

Section 2

PROCEDURE

Content Page

2.1 CONTROL ................................................................................................................... 10

2.2 WATER DRAINING ..................................................................................................... 10

2.3 OILY WATER DRAINING ............................................................................................. 10

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 9 of 15

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

2 PROCEDURE

2.1 CONTROL

No. Action Action Party

2.1.1 Fill-in Area 2 tank farm One CARE check sheet (please refer to Appendix Area operator

A, Item 1.1, Table 1)

2.1.2 Record opening and closing of valves in the control room log book Area operator

2.1.3 A red "flag" tag for each open valve must be displayed clearly in tank area Area operator

map at the control room

2.1.4 Upon completion of draining exercise, red "flag" tag at tank area map at Area operator

control room shall be removed

2.2 WATER DRAINING

No. Action Action Party

2.2.1 Open bundwall drain valve Area operator

• Refer to Appendix A, Item 1.1, Table 1: Area 2 Tank Farm One CARE

check sheet

2.2.2 Tag open valve with red “flag”

• Refer to Appendix A, Item 1.1, Table 1: Area 2 Tank Farm One CARE Area operator

check sheet

2.2.3 Carry out sampling to check drain water oil content if required (Refer Area operator

sampling operating procedure). / Lab

technician

NOTE:

If OIW content between 10 ppm to 40ppm, drain water to be divert to TPI-2

water sump by opening diversion valve. Refer to section 2.3.

If OIW content > 40 ppm manual recovery required (i.e. vacuum truck)

2.2.4 Close bundwall drain valve after draining. Area operator

2.2.5 Check and confirm all drain valves are in closed position based on physical Area operator

observation

2.2.6 Remove red “flag” and return to the control room. Area operator

2.3 OILY WATER DRAINING (10 PPM – 40 PPM)

No. Action Action Party

2.3.1 Close sluice gate valve SG-6500A to divert oily water to TPI-2 water sump. Area operator

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 10 of 15

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

2.3.2 Open EOV SG 6500 B/C. Area operator

2.3.3 Open V1 (manual valve). Area operator

2.3.4 Close SG-6500B/C and V1 after draining is completed. Area operator

2.3.5 Open sluice gate valve SG-6500A. Area operator

END OF PROCEDURE

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 11 of 15

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

Appendix

APPENDIX A

Content Page

1 CHECKLIST ................................................................................................................ 13

1.1 TABLE 1: AREA 2 TANK FARM ONE CARE CHECK SHEET.................................. 13

2 DIAGRAMS ................................................................................................................. 14

2.1 FIGURE 1: RED FLAG TAG ....................................................................................... 14

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 12 of 15

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

1 CHECKLIST

1.1 TABLE 1: AREA 2 TANK FARM ONE CARE CHECK SHEET

1. BUNDWALL VALVE STATUS

P1 P2 P3 P4 P5 P6 P7 P8

OPENED

CLOSED

VALVE

CONDITION

2. EOV’s/TSF’s/TSS’s/TSBS’s OPERABILITY

TK NO. EOV NO. REMOTE/MANUAL TSS TSF TSBS REMARKS

VALVES/HANDWHEEL/BONNET/THREAD CONDITION

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 13 of 15

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

2 DIAGRAMS

2.1 FIGURE 1: RED FLAG TAG

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 14 of 15

Operating Procedure MY SKO O 05 MCOT 019

Bundwall Water Draining Rev. 0 Sept 2011

V1

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:46 AM PETRONAS CARIGALI SDN BHD Page 15 of 15

You might also like

- Chlorine LeakDocument14 pagesChlorine LeakudayNo ratings yet

- Mantainence ManualDocument9 pagesMantainence ManualAli DiabNo ratings yet

- 7022H 400 MS 0000 828 RCDocument18 pages7022H 400 MS 0000 828 RCA.A100% (1)

- Flange Management Procedure IFUDocument32 pagesFlange Management Procedure IFUMarvan Audy Buriko100% (1)

- Positive Isolation StandardDocument21 pagesPositive Isolation Standardmadhulika100% (2)

- Pigging Head and Spool InstallationDocument38 pagesPigging Head and Spool InstallationWilliam O OkolotuNo ratings yet

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceFrom EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNo ratings yet

- Draft Method Statement For Tank Erection DTD 02.12.2019Document7 pagesDraft Method Statement For Tank Erection DTD 02.12.2019manish pathrabeNo ratings yet

- Joint Integrity Procedure - GQP-ENG-014Document32 pagesJoint Integrity Procedure - GQP-ENG-014mohd as shahiddin jafriNo ratings yet

- CCB - Rev 04Document102 pagesCCB - Rev 04Alok SinghNo ratings yet

- PCSB Inspection and Maintenance Guidelines Volume 1Document124 pagesPCSB Inspection and Maintenance Guidelines Volume 1JaiNo ratings yet

- Method Statement For Tank ErectionDocument8 pagesMethod Statement For Tank Erectionmanish pathrabeNo ratings yet

- SSG Ng01017365 Gen Cs 6180 00001 c01 River Dredging ProcedureDocument12 pagesSSG Ng01017365 Gen Cs 6180 00001 c01 River Dredging ProcedureDaniel DamboNo ratings yet

- Best Practice For Isolation - Hydrocarbon EquipmentDocument45 pagesBest Practice For Isolation - Hydrocarbon EquipmentvictorvikramNo ratings yet

- 10016-COM-020 Rev0 Procedure For Commissioning of MBF UnitDocument15 pages10016-COM-020 Rev0 Procedure For Commissioning of MBF UnitsithulibraNo ratings yet

- Procedure For Painting: Oml100 (Fso Unity)Document24 pagesProcedure For Painting: Oml100 (Fso Unity)Ezemeh NigeriaNo ratings yet

- Supervision Procedure: Oml100 (Fso Unity)Document8 pagesSupervision Procedure: Oml100 (Fso Unity)Ezemeh Nigeria100% (1)

- MCOT 011 Offshore Incoming Trunkline OperationsDocument16 pagesMCOT 011 Offshore Incoming Trunkline OperationsLembang ApangNo ratings yet

- MCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFDocument15 pagesMCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFLembang ApangNo ratings yet

- MCOT 020 Tanker Loading Operations PDFDocument20 pagesMCOT 020 Tanker Loading Operations PDFLembang ApangNo ratings yet

- MCOT 010 Crude Receiving - Tank Switching OperationsDocument16 pagesMCOT 010 Crude Receiving - Tank Switching OperationsLembang ApangNo ratings yet

- MCOT 017 Inter Tanks Transfer OperationsDocument14 pagesMCOT 017 Inter Tanks Transfer OperationsLembang ApangNo ratings yet

- MCOT 018 Sea Loading Pump Station - SLPS - Operations PDFDocument24 pagesMCOT 018 Sea Loading Pump Station - SLPS - Operations PDFLembang ApangNo ratings yet

- MCOT 049tanks FiscalisationDocument18 pagesMCOT 049tanks FiscalisationLembang ApangNo ratings yet

- MCOT 013 Pig Receiving From 4B 18in Crude LineDocument18 pagesMCOT 013 Pig Receiving From 4B 18in Crude LineLembang ApangNo ratings yet

- MCOT 008 WL Crude Receiving 18 InchDocument23 pagesMCOT 008 WL Crude Receiving 18 InchLembang ApangNo ratings yet

- Containment and Blasting ProcedureDocument20 pagesContainment and Blasting ProcedureEzemeh NigeriaNo ratings yet

- SDA-S17893-BNYC1-PX-1206-00001 C01 Bonny Equipment Sizing Calculation ReportDocument37 pagesSDA-S17893-BNYC1-PX-1206-00001 C01 Bonny Equipment Sizing Calculation ReportsegunNo ratings yet

- Hla Cha 03 GDB DC 00 005 2 PDFDocument10 pagesHla Cha 03 GDB DC 00 005 2 PDFOsman AcostaNo ratings yet

- MQ SP P 5020Document10 pagesMQ SP P 5020jaseel kNo ratings yet

- 8001-WI - 01-05-52 Towing OperationDocument7 pages8001-WI - 01-05-52 Towing OperationAgung Tri SugihartoNo ratings yet

- B-35.408 - Rev A-Calculation of Soil Bearing CapacityDocument122 pagesB-35.408 - Rev A-Calculation of Soil Bearing Capacitychukudi oguneNo ratings yet

- MQ SP P 5024Document16 pagesMQ SP P 5024jaseel kNo ratings yet

- M270HVN02 - 0 (BenQ GW2760HS) - Improved Viewing Angle VADocument34 pagesM270HVN02 - 0 (BenQ GW2760HS) - Improved Viewing Angle VAKoolkrayzeh KLNo ratings yet

- MQ SP P 5011 PDFDocument25 pagesMQ SP P 5011 PDFjaseelNo ratings yet

- AOU B121EW09 V3 Version 1.2Document35 pagesAOU B121EW09 V3 Version 1.2divubi2004No ratings yet

- SOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. NumberDocument4 pagesSOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. Numberarif rhNo ratings yet

- Power and Water Utility Company For Jubail and Yanbu (MARAFIQ) Master Specification MQ-SP-C-2016 Project Name Date: 08 Mar 2011 Contract Number Page 1 of Revision 1Document10 pagesPower and Water Utility Company For Jubail and Yanbu (MARAFIQ) Master Specification MQ-SP-C-2016 Project Name Date: 08 Mar 2011 Contract Number Page 1 of Revision 1Azhar AliNo ratings yet

- HSE Front End Loading ProcedureDocument11 pagesHSE Front End Loading ProcedureVasilica BarbarasaNo ratings yet

- V320BJ6 LD1 CmimeiDocument35 pagesV320BJ6 LD1 CmimeiNurjaman ElektroNo ratings yet

- V4-CH03-Process Interlock Description Rev 1 - SECTION 200 TO 800Document111 pagesV4-CH03-Process Interlock Description Rev 1 - SECTION 200 TO 800MohamedNo ratings yet

- MQ SP P 5022 PDFDocument17 pagesMQ SP P 5022 PDFjaseel kNo ratings yet

- MQ SP P 5002 PDFDocument44 pagesMQ SP P 5002 PDFjaseelNo ratings yet

- 8001-WI-01-05-53 Rescue Boat LaunchingDocument6 pages8001-WI-01-05-53 Rescue Boat LaunchingAgung Tri SugihartoNo ratings yet

- 7.1.E.5 Ground Bed Installation Support OkDocument4 pages7.1.E.5 Ground Bed Installation Support Okarif rhNo ratings yet

- Specification - Site Preparation, Excavation, and Backfill SpecificationDocument24 pagesSpecification - Site Preparation, Excavation, and Backfill SpecificationAzhar AliNo ratings yet

- Datasheet 2Document28 pagesDatasheet 2JEORJENo ratings yet

- Specification - Hvac Air Cooled Condensing UnitsDocument15 pagesSpecification - Hvac Air Cooled Condensing UnitsJaseelKanhirathinkalNo ratings yet

- Coagulation/ Flocculation Tank and Clarified Pond For WWT OperationDocument7 pagesCoagulation/ Flocculation Tank and Clarified Pond For WWT OperationKokian MckozenNo ratings yet

- Product Specification: (V) Preliminary Specification Final SpecificationDocument28 pagesProduct Specification: (V) Preliminary Specification Final SpecificationJorge TabaresNo ratings yet

- Man B&W: Safety PrecautionsDocument44 pagesMan B&W: Safety Precautionsroberto luckyNo ratings yet

- Ims 52 07 06Document14 pagesIms 52 07 06marcio de rossiNo ratings yet

- 110 - Startup-Shutdown & Handover of Nitric Acid Pump (02-1111 & 02-1151)Document14 pages110 - Startup-Shutdown & Handover of Nitric Acid Pump (02-1111 & 02-1151)Muhammad Umer RanaNo ratings yet

- Datasheet MosfetDocument30 pagesDatasheet Mosfetwalter andiasNo ratings yet

- P650HVN02 4Document31 pagesP650HVN02 4Ali Hamjah DeztroyerNo ratings yet

- 8001-WI-01-05-50 Personal Floating DevicesDocument7 pages8001-WI-01-05-50 Personal Floating DevicesAgung Tri SugihartoNo ratings yet

- Marcado Electroquimico Etch / Electrochemical Etch Marking: ENG ENG-00086 / HDocument14 pagesMarcado Electroquimico Etch / Electrochemical Etch Marking: ENG ENG-00086 / HlucioNo ratings yet

- SSP Grass CuttingDocument13 pagesSSP Grass CuttingNurfirman HNo ratings yet

- MQ SP C 2013Document34 pagesMQ SP C 2013Azhar AliNo ratings yet

- B-45.276 - C - Specification For Control ValvesDocument22 pagesB-45.276 - C - Specification For Control ValvesUbong P. EffiongNo ratings yet

- MCOT 049tanks FiscalisationDocument18 pagesMCOT 049tanks FiscalisationLembang ApangNo ratings yet

- MCOT 013 Pig Receiving From 4B 18in Crude LineDocument18 pagesMCOT 013 Pig Receiving From 4B 18in Crude LineLembang ApangNo ratings yet

- MCOT 018 Sea Loading Pump Station - SLPS - Operations PDFDocument24 pagesMCOT 018 Sea Loading Pump Station - SLPS - Operations PDFLembang ApangNo ratings yet

- MCOT 008 WL Crude Receiving 18 InchDocument23 pagesMCOT 008 WL Crude Receiving 18 InchLembang ApangNo ratings yet

- Attachment II - Revised JHA Process FlowDocument1 pageAttachment II - Revised JHA Process FlowLembang ApangNo ratings yet