Professional Documents

Culture Documents

PT12 Theorie in Pneumatic Conveying

PT12 Theorie in Pneumatic Conveying

Uploaded by

W MoralesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PT12 Theorie in Pneumatic Conveying

PT12 Theorie in Pneumatic Conveying

Uploaded by

W MoralesCopyright:

Available Formats

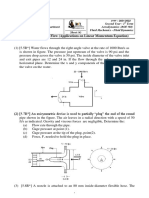

PT12/17 layout 8/9/01 10:50 AM Page 235

Introduction to the Theoretical

and Practical Principles of

Pneumatic Conveying

S C O T T N E I D I G H , Neuero Corporation, West Chicago, IL, USA

A B S T R AC T

T

he article initially explains the different types of

pneumatic systems and the conveying princi-

ples, and then analyses the flow in both vertical

and horizontal pipes. It also examines the effect of varying

air speed, and quantifies the loss of conveying pressure

when the pipe bends, showing how this can be trans-

lated into equivalent increase in pipe length.

PHYS IC AL FUND AMENTAL PRI NCI PLES

Conveying principle and design of a pneumatic

conveying system

Pneumatic conveying is based on the physical principle

that air, under certain conditions, is able to convey

heavy materials. In nature, air can carry many substances,

such as sand, snow, leaves, and seeds. Pneumatic

conveying causes air to flow by creating a pressure

difference between the beginning and end of a pipe.

From basic physics, it is known that the suction of liquid

is theoretically limited to 10m height, but for granular

material in suction mode, the conveying height is close

to unlimited – on condition that an air stream at the neces-

sary speed is available to carry the material. The first

pneumatic conveying equipment was used to unload grain

from ships before the 19th Century. Later, this new contin-

uous conveying method spread to small and middle

size systems, as well as to other bulk products.

Pneumatic conveying systems may be differentiated

as low, medium or high pressure. Blowers for industrial

applications develop a conveying pressure of approx. 0.5

to 1 bar positive pressure, which corresponds to a

vacuum of 0.3 to 0.5 bar. The three systems used are:

suction only, pressure only, and combined.

Figure 1 shows the suction only mode. A blower Typical examples of suction only mode are stationary, Figure 1 (top)

(7) at the end of the pipe creates a vacuum in order to mobile, self travelling, or floating pneumatic ship Pneumatic conveying - suc-

generate the necessary air stream in the pipe. Like in a unloaders, used for grain and oil seeds carried in ocean tion mode

vacuum cleaner, the product is picked up at the suction going and inland vessels, barges, rail wagons and trucks. Figure 2 (above)

nozzle (1) and transported through the pipes (2,3) to the Figure 2 illustrates a pressure only mode system. Here Pneumatic conveying - pres-

separation cyclone (4). Here the air and product are again air is taken directly from atmosphere and pressurised by sure mode

separated. The product is taken out from the system through the blower (1). The product to be conveyed is introduced

a rotary airlock (5). The air is exhausted from the into the system using a rotary airlock (2) which allows

blower (7) to the atmosphere, or to a filter for cleaning the material to enter the air stream in the pipe (3). At the

the air. This type of suction layout allows the product to end of the pipe, air and product is separated in a pressure

be introduced at a number of points, and be delivered to cyclone (5). The product falls downward, and the air is

a central location. exhausted out of the top.

PT12/17 layout 8/9/01 10:50 AM Page 236

Figure 3 (top) The necessary air speed w is called the suspension

Pneumatic conveying - suction speed ws. The minimal condition for conveying is that

- pressure mode

the air speed in a vertical pipe is higher than the

suspension speed, and the difference is the real speed

of each particle relative to the pipe. Thus:

ρ

S = cw * A * * w2

2

where S is the stream force, cw is the resistance coefficient

of the shape, A is the flow face area of the particle

(vertical to the flow direction), ρ is the atmospheric

ρ

density, and w the air speed. The expression –2 w2 is also

known as dynamic or impact pressure. The suspension

Pressure only systems are recommended when the speed is influenced by many factors. Primarily, atmospheric

product is introduced at one point, and optionally, using density affects the flow force – hence the conveying

diverter valves (4) transported to different delivery points. capacity will slightly increase in high pressure weather condi-

Due to the higher pressure differential and specific weight tions, or on very cold days. Furthermore, the suspension

of the air, they have a greater capacity than the suction type. speed is determined by cw, which depends on the shape

In practical applications, both modes can be combined and surface roughness of the particle. Non-spherical shaped

to get the benefits of each (Figure 3). The first section bodies tend to have an advantage, as an elongated shape

of the conveying line uses the suction mode to get the will fall with the tip down to reduce resistance, which explains

material into the pipe, and the second part uses the pressure the differences in capacity for different grain types under

mode to achieve higher capacity at longer distances. the same conditions.

The diameters of pneumatic conveying pipes vary If the chosen particle is not in the centre of the pipe,

between 10 mm (for use in the processing industry) to but close to the wall as in Figure 4(b), a force A, vertical

800 mm (for large amounts of material, such as grain from to the flow direction, arises. This lifting force comes from

ships). The conveying capacity is accordingly different, the non-symmetrical speed profile of the air close to the

and ranges from a few kg/h to 1000 t/h. Lines are pipe wall, caused by the boundary layer, and it tries to

between 10 and 1000 m in length, and the air speed varies force the particle to the centre of the pipe.

with the material, but is generally between 10 to 30 m/s. This effect is clearer in Figures 4(c), (d) and (e),

showing horizontal conveying. The particle in the

Flow analysis in the conveying pipe flow at the centre of the pipe in 4(c) is acted on by the

To allow solid matter to be transported, the driving flow flow resistance (towing force) S to the right, and the

forces of the air must be larger than the forces – weight, weight force G down. If the particle is close to the pipe

friction and inertia – acting on the particle. There are three wall, as in 4(d) and 4(e), the lifting force A starts to

influential factors: the first is the suspension speed of the act. Below the middle of the pipe, the lifting force opposes

solid matter ws; the second is the air speed w; and the third the weight of the particle.

is the mixture relation π , representing the ratio of solid Theoretically, more forces should be presented in

matter to the conveying medium. this figure – for example, inertia, friction between parti-

Figure 4(a) shows schematically the two most cles, friction between particle and wall, and momentum

important forces acting on a particle in a vertical air stream. – all of which must be overcome by the air flow. This

In airflow w, the flow resistance S of the particle acts pneumatic system is known as dilute phase conveying.

vertically up, and its weight G acts down. When both The particles move by flying, or jumping forward, and

forces, S and G, are equal, the particle stays suspended. are carried (blown), more or less in the same concen-

tration, through the conveying pipe The degree of

Figure 4 (middle) concentration is expressed through a non-dimen-

Pneumatic conveying - forces sional parameter, the mixture ratio µ. This is the ratio

acting on a particle in a pipe

of solid matter transported to the conveyed air mass,

in the same unit of time.

Figure 5 shows dilute phase conveying of solid parti-

cles in pipes, vertical and horizontal. Due to the variable

directions of the speed component, forces acting cross-

wise make the particles hit the wall of the pipe. There they

are retarded, jump back, and need to be accelerated again,

which leads to pressure loss in the pipe.

A more or less free flow of the particle is possible with

sufficient air speed for vertical conveying, and with a

mixture ratio of approximately 10 to 20, as shown in 5(a).

A separation of air and product can happen if the air flow

Figure 5 (bottom) nears the suspension speed of the particle, and the

Dilute pneumatic conveying mixture ratio is close to 30, as in 5(b). Although some

of the solid particles sink, it is possible to obtain overall

upstream conveying.

Horizontally, as in 5(c), there is separation caused by

the gravity force as soon the air speed is reduced. If the

air speed is close to the particle suspension speed, as in

5(d), a deposit, especially fines, is formed along the pipe

bottom. Most of the particles move, forming a slug of strong

separation in the pipe bends. Blockage may occur if the

pressure reserve of the blower is insufficient.

PT12/17 layout 8/9/01 10:50 AM Page 239

At any point of the conveying pipe, a minimum air speed Figure 6

– the critical speed – is needed in order to transport the Lab for determination of sus-

pension speed

product. It varies according to the characteristics of the

product to be conveyed and can be between 10 and 30 m/s.

If the air speed falls short, then material deposits on the

pipe bottom until finally a blockage occurs. It is not

possible to determine the blockage limit beforehand, as

it depends on each system’s layout and piping configuration.

Higher air speed may transport the material, but

will have the following disadvantages:

• The wear caused by the product on the pipe is

considerably higher;

• It can cause significant damage to the product

granules (product degradation); and

• Higher horsepower is required at the blower to

create the conveying pressure.

From fluid dynamics, the electrical power N of a blower Figure 7

needed to move only air can be found from the volume Suspension speed for differ-

flow of air V, the total required pressure ∆p, and the ent products

efficiency η, thus:

V∆p

N= η

The air flow is also a product of the cross section A

and air speed w, therefore:

∏ d2

V= A w =

4 w

But, from the Bernoulli energy equation, the pressure

loss in the pipe at turbulent flow is proportional to the

square of the air speed, so that:

∆p α w2.

and thus N α w3

which means a higher air speed requires a consider-

able increase in power.

over can be read on the Y-axis. Fine river sand is on the

left, and those grain types, with a smooth surface and spher-

EMP IR ICAL FOUND AT I O N S ical shape (such as peas and beans), needing higher

suspension speeds are on the right. Because each particle

Air speed in a sample does not have exactly the same shape and size,

Suspension speed plays a big role in pneumatic conveying, there is no precise suspension speed for a product. An

but only a single particle (grain) has been considered up average value can be determined when 50% of the

to now. In reality, particles will mainly appear in clouds, product remains. Wheat, for example, has an average

and tests have shown that these will sink faster than a single suspension speed of 9 m/s.

particle. One explanation is to consider the effect of the To design the pipe it is necessary to determine the

side sheltered from the wind, as in a bicycle race, where conveying air speed. It should be high enough above

the last rider profits from the lower wind force. Consequently, the suspension speed in order to avoid a blockage of

this means that higher particle concentration in the pipe the system. For example, the air speed for grain is proven

requires higher air speed to assure perfect transport. from practical experience to lie between 20 and 25

The determination of the suspension speed of a product m/s. The product (particle) speed is the difference

is possible using simple test facilities, as shown in Figure of the air speed w and the suspension speed ws, and

6. A transparent conical section is inserted in a vertical suction it has been found that the ratio of particle speed to

conveying pipe (on the left ). A blower provides the neces- air speed is about 0.6. Wheat has a suspension speed

sary vacuum. In each diameter (section) of this cone of 9 m/s and a required air speed of 23 m/s.

there will be a different air speed. At a specific diameter

in the conical section, the air speed drops so much that Pressure loss in conveying pipe

conveying is no longer possible, and the test product Figure 8 plots the principal components of the total

particles stay at a certain point of the cone. With suitable pressure loss in the conveying pipe relative to air speed.

measurement tools, and an adjustable air flow, the suspen- These factors are:

sion speed of the product can be found. • The air (without material) generates friction in the pipe

Figure 7 shows the resulting diagram of such measure- that must be overcome. This part of the conveying

ments for a number of different products. The suspension pressure is shown in the curve ∆pL. As pressure drop

speed ws is shown on the X-axis logarithmically. For each increases at a square ratio, approximately to the air

product, the percentage of the total sample that is blown speed, the latter should be kept as low as possible.

PT12/17 layout 8/9/01 10:51 AM Page 240

• The conveyed product is constantly retarded at the Adding all losses creates the total pressure loss curve,

pipe wall and needs to be accelerated again. This friction or system characteristic curve, ∆pTOT. Its shape depends

gives the pressure drop portion ∆pR. The pressure on the product, the mixture ratio, and the piping

drop increases approximately linearly with the air speed. configuration, but the parabolic shape is valid for all

pneumatic conveying systems.

• Blocking forces due to the particles are expressed with The power of the blower depends on the conveying

∆pF. If material flow is constant, with falling air speed pressure ∆p and the air speed w. A working point, with

the amount of material in the pipe increases, the mixture a minimal power consumption of Nmin is shown which

ratio changes and, consequently, the pressure loss does not coincide with the lowest conveying pressure. The

increases. This curve is hyperbolic in shape. working range of dilute phase conveying is located at higher

air speed and power consumption in order to avoid

blockage in the conveying pipe. The left dashed branch

Figure 8 (below)

of the curve only relates to dense phase conveying.

Pressure - air speed curve

Up to now, the conveying pressure needed is only valid

for the complete system. The following looks at how each

component builds over the conveying line.

Pressure loss caused by material acceleration

The solid particles must be accelerated as quickly as possible

to the minimum conveying speed. The acceleration loss

takes a large portion of the conveying pressure, which

must be generated by the blower. This loss occurs only

at the material inlet point in a suction only, or a pressure

only, system. In a combined suction/pressure system, it

occurs twice: once at the material inlet at the suction nozzle,

and again after the suction cyclone at the material re-entry

into the pressure piping.

Figure 9 (bottom)

An equivalent length of piping can be used to express

Equivalent length for particle

acceleration the magnitude of the acceleration resistance, and its portion

of the total pressure loss in the conveying pipe. It is expressed

as the length of horizontal conveying pipe that gives the

same pressure loss at constant conveying speed. Figure

9 shows the experimental curve from Segler to get the

equivalent length for the acceleration of wheat at an average

air speed of 22 m/s independent of the conveying

quantity. The asymptotic curve gets closer to a limiting

value at a material throughput of over 5 kg/s – a

conveying capacity of over 20 t/h. At this point the

equivalent length can be considered constant at about 22

m, and is independent of the conveying capacity.

In suction only systems, there is another pressure loss

Figure 10 (top) caused by the type of suction nozzle. A value may be added,

Material and air flow in a between 0 and the nozzle acceleration loss (resistance).

bend

Pressure loss in the pipe bend

During the design and construction of suction or

pressure conveying systems, it is important to keep the

number of changes of direction to a minimum. At the pipe

bend, there is a gradual braking of the product in the air

stream. An additional product acceleration is required which

increases the blower requirement. Higher wear occurs

at the bend, requiring special attention such as thicker

pipe walls. It may also cause product degradation.

Figure10 shows the product and air stream in a

bend. There are four situations:

• Before entry into the bend, up to cross section #I,

the product and air are uniformly blended;

Figure 11 (above)

Equivalent length LSK for • At cross section #I, segregation starts;

conveying bend

• Between cross sections #I and #II, the material is

directed to the outer wall because of the centrifugal

force. It is retarded by the friction at the wall, and so

the material speed ∆ KI at entry is higher than the

outgoing speed ∆ KII; and

• After cross section #II, the air and the product mix

again.

Experiments have shown that the pressure drop inside

the pipe bend while conveying material is little higher

than with only air. The real pressure loss comes only

PT12/17 layout 8/9/01 10:51 AM Page 241

after the direction change caused by the material

acceleration. The equivalent length of a pipe bend is

the length of a horizontal pipe of the same diameter,

the same surface roughness, and the same pressure loss

as the pipe bend.

Figure 11, from Segler, shows the equivalent horizontal

length of a 90° pipe bend with a normal radius of curva-

ture of four to six times the pipe diameter. Only for small

conveying quantities, of less than 4 kg/s, is there a

small dependence on pipe diameter. Over a capacity of

10 kg/s the curve gets close to a limiting value, and for

more than 30 t/h a constant equivalent length of approx-

imately 18 m can be used. This means that by saving one

bend of 90°, the horizontal conveying line could be

extended almost 20m for the same capacity.

Pipe bends of less than 90°, for example 45°, obtain

a smaller equivalent length lSK. Test results have shown

that there is very little difference between a bend in the

horizontal plane and one between the horizontal and the

vertical, so the same equivalent length is used.

Pressure loss in vertical conveying

In a vertical, rather than horizontal, pipe there is

additional lifting work to be done which generates an extra

pressure drop, and there is a rule of thumb that the pressure

drop per metre length in the vertical pipe is approximately

double the horizontal. Thus, in determining an equiva-

lent length, the vertical length is doubled when finding

the total system pressure drop.

NOTE

A more detailed paper on this subject can be downloaded

from the company’s homepage http://www.neuero.com.

ABOUT THE AUTHOR

Scott Neidigh, President of Neuero Corporation, has been

involved, since 1966, in the design and engineering of pneumatic

conveying systems for the bulk material handling industry. He is

a graduate of Southern Illinois University and the Midwest

College of Engineering, where he received Degrees in Machine

Design Technology, and Mechanical Engineering. He is also a

member of the Society of Automotive Engineers, as well as the

American Society of Agricultural Engineers.

I F Y O U H AV E A N Y E N Q U I R I E S R E G A R D I N G T H E

C O N T E N T O F T H I S A RT I C L E , P L E A S E C O N TA C T :

Scott Neidigh

Neuero Corporation

1201 Hawthorne Lane

West Chicago

Il 60185

USA

Tel: +1 (630) 231-9020

Fax: +1 (630) 231-6121

E-mail: neuero@neuero.com

Web site: www.neuero.com

You might also like

- Aerodynamics Lab ManualDocument50 pagesAerodynamics Lab Manualshibin874141No ratings yet

- Wind Tunnel Lab ReportDocument20 pagesWind Tunnel Lab Reportbrandon99960% (5)

- Authentic Ductwork CalculationDocument10 pagesAuthentic Ductwork CalculationbernardsilvanoNo ratings yet

- Aerodynamic 1Document150 pagesAerodynamic 1Abdelr100% (2)

- Duct DesignDocument18 pagesDuct Designhfguerrac95% (21)

- Hydraulic BasicsDocument189 pagesHydraulic BasicsPraful PatilNo ratings yet

- Design Air SystemsDocument40 pagesDesign Air SystemstariqNo ratings yet

- Wing Fillets in AircraftDocument12 pagesWing Fillets in AircraftNiraj BhaktwartiNo ratings yet

- All You Need To Know About FansDocument10 pagesAll You Need To Know About FansgertibajNo ratings yet

- Centrifugal CompressorDocument20 pagesCentrifugal CompressorMir Aqueel AliNo ratings yet

- Intro To Psychology by Charles StangorDocument861 pagesIntro To Psychology by Charles StangorAidan Alexis67% (9)

- Intro To Psychology by Charles StangorDocument861 pagesIntro To Psychology by Charles StangorAidan Alexis67% (9)

- Gas Turbine 3Document45 pagesGas Turbine 3KorichiKarim100% (2)

- Air Lift PumpDocument9 pagesAir Lift PumpChukwuebuka AneneNo ratings yet

- Vessel Conveyor SystemDocument4 pagesVessel Conveyor SystemleekiangyenNo ratings yet

- Air Requirements: 2004 by Marcel Dekker, Inc. All Rights ReservedDocument36 pagesAir Requirements: 2004 by Marcel Dekker, Inc. All Rights ReservedGustavo Hernandez100% (1)

- Principles of Flight PDFDocument41 pagesPrinciples of Flight PDFKammanai PhothongNo ratings yet

- Gas-Solid Flows: 2004 by Marcel Dekker, Inc. All Rights ReservedDocument36 pagesGas-Solid Flows: 2004 by Marcel Dekker, Inc. All Rights ReservedGustavo Hernandez100% (1)

- ElectrochemistryDocument65 pagesElectrochemistryAhom CK100% (2)

- CFDDocument7 pagesCFDwahtoiNo ratings yet

- Aero 2Document16 pagesAero 2sara.adnan2013No ratings yet

- Stepped Pipeline Systems: 2004 by Marcel Dekker, Inc. All Rights ReservedDocument28 pagesStepped Pipeline Systems: 2004 by Marcel Dekker, Inc. All Rights ReservedGustavo HernandezNo ratings yet

- Experiment 5 Pressure Distribution On Circular Cylinder and AirfoilDocument8 pagesExperiment 5 Pressure Distribution On Circular Cylinder and AirfoilMarilynYunLing50% (2)

- Conveying: E A. Zenz and D. F. Othmer, "Pneumatic and Hydraulic Conveying," Chapter 10, FluidizaDocument18 pagesConveying: E A. Zenz and D. F. Othmer, "Pneumatic and Hydraulic Conveying," Chapter 10, Fluidizavalerio.garibay100% (1)

- Im Paper 25 K KawakitaDocument10 pagesIm Paper 25 K KawakitaTAPAS SINGHNo ratings yet

- Gas Flow and Pressure Drop Through Moving BedsDocument7 pagesGas Flow and Pressure Drop Through Moving BedsGiovanny MateusNo ratings yet

- Stack 1933 Naca 463Document22 pagesStack 1933 Naca 463cordella_francescoNo ratings yet

- Fluid Mechanics II Lab Sheet 1 ExperimenDocument8 pagesFluid Mechanics II Lab Sheet 1 ExperimenAiman HaiqalNo ratings yet

- Wind Tunnel Experiments Procedure in UPMDocument5 pagesWind Tunnel Experiments Procedure in UPMMohd AnuarNo ratings yet

- Experiment 4Document10 pagesExperiment 4Anonymous Y3e0XfdxH1No ratings yet

- UEME 3112 Free Turbulent Jet May 2015Document5 pagesUEME 3112 Free Turbulent Jet May 2015Adam Leong0% (1)

- MECH372 Assessment 4Document12 pagesMECH372 Assessment 4joseph.mekhamerNo ratings yet

- Bubble Cap Tray Assignment: CE 428 Spring 2003Document11 pagesBubble Cap Tray Assignment: CE 428 Spring 2003Thọ NguyễnNo ratings yet

- 海洋钻井平台散料处理系统固相输运的预测模型 PDFDocument15 pages海洋钻井平台散料处理系统固相输运的预测模型 PDFbruce lianNo ratings yet

- Static&Dynamic LossDocument4 pagesStatic&Dynamic LossrazahNo ratings yet

- Effect Injection On Air Lift PumpDocument6 pagesEffect Injection On Air Lift PumpDavid Fransiskus SimarmataNo ratings yet

- Fluids Systems Practical File: Course OutcomesDocument29 pagesFluids Systems Practical File: Course Outcomes2K18/ME/192 SANCHIT DHASMANANo ratings yet

- 2D Jet Experiment: AE - 611 Laboratory ReportDocument13 pages2D Jet Experiment: AE - 611 Laboratory ReportAbhishek KanthedNo ratings yet

- Fluid Mech Sheet 4 IAETDocument11 pagesFluid Mech Sheet 4 IAET3bdo MahmoudNo ratings yet

- Aade 10 DF Ho 26Document9 pagesAade 10 DF Ho 26Trần Anh ĐứcNo ratings yet

- Module 8 (Basic Aerodynamics)Document52 pagesModule 8 (Basic Aerodynamics)AmirAli MohebbiNo ratings yet

- Wind Tunnel Testing of A Complete AircraftDocument19 pagesWind Tunnel Testing of A Complete AircraftJack WillettNo ratings yet

- 2014-Spring Ay Reu Project2 Turbine Technical-ReportDocument20 pages2014-Spring Ay Reu Project2 Turbine Technical-Reportapi-244056687No ratings yet

- Centrifugal CompressorsDocument6 pagesCentrifugal CompressorsGokulAgNo ratings yet

- 4.2.3-1 Introduction: Airfoil Endwall Heat TransferDocument11 pages4.2.3-1 Introduction: Airfoil Endwall Heat Transferm1977engNo ratings yet

- Manual of Basic Air Flow BenchDocument24 pagesManual of Basic Air Flow BenchPung Kang Qin100% (1)

- Performance Study of An Airlift Pump With Bent Riser TubeDocument10 pagesPerformance Study of An Airlift Pump With Bent Riser TubefhmollNo ratings yet

- DesignAirSystems (Part 2)Document3 pagesDesignAirSystems (Part 2)marcoo8No ratings yet

- Theoretical and Experimental Investigation of Impinging Jet Ventilation and Comparison With Wall Displacement VentilationDocument14 pagesTheoretical and Experimental Investigation of Impinging Jet Ventilation and Comparison With Wall Displacement VentilationSofiane BellabiodNo ratings yet

- Airfoil DynamicsDocument6 pagesAirfoil DynamicsGarry GeorgeNo ratings yet

- Experiment #5: Air Drag ForceDocument5 pagesExperiment #5: Air Drag ForceAhmed HassanNo ratings yet

- 09 - Chapter 1Document14 pages09 - Chapter 1naser shamsNo ratings yet

- Drag Reduction of Motor Vehicles by Active Flow Control Using The Coanda EffectDocument12 pagesDrag Reduction of Motor Vehicles by Active Flow Control Using The Coanda EffectVivek KantiNo ratings yet

- Pneumatic Conveying - GJ74, HauckDocument6 pagesPneumatic Conveying - GJ74, Hauckjfejfe100% (1)

- A Theoretical and Practical Guide To The Basics of Designing Air Flow SystemsDocument41 pagesA Theoretical and Practical Guide To The Basics of Designing Air Flow SystemsKristianto AdiNo ratings yet

- Ejsr 84 4 04Document15 pagesEjsr 84 4 04Ardian YudoNo ratings yet

- Wind Tunnel Experiments 10 11Document4 pagesWind Tunnel Experiments 10 11Kaashyap SarmaNo ratings yet

- Model aeroplanes: The building of model monoplanes, biplanes, etc., together with a chapter on building a model airshipFrom EverandModel aeroplanes: The building of model monoplanes, biplanes, etc., together with a chapter on building a model airshipNo ratings yet

- Heterogeneous Catalysis: Most Heterogeneous Catalysts Are Supported CatalystsDocument30 pagesHeterogeneous Catalysis: Most Heterogeneous Catalysts Are Supported CatalystsAhom CKNo ratings yet

- NabookDocument211 pagesNabookRohit NimeshNo ratings yet