Professional Documents

Culture Documents

Cross Reference AWG To Metric Size With Ampacity of Insulated Conductors PDF

Uploaded by

Limuel Espiritu0 ratings0% found this document useful (0 votes)

24 views1 pageOriginal Title

35662243-Cross-Reference-AWG-to-Metric-Size-With-Ampacity-of-Insulated-Conductors.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views1 pageCross Reference AWG To Metric Size With Ampacity of Insulated Conductors PDF

Uploaded by

Limuel EspirituCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

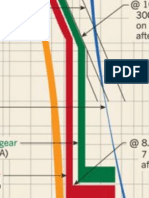

CROSS-REFERENCE - AWG TO METRIC SIZE (WITH AMPACITY) OF INSULATED CONDUCTORS

Copper Aluminum or Copper-clad Aluminum

Wire Size Temperature Rating Based on Insulation Type

(60°C ) (75°C ) (90°C ) (60°C ) (75°C ) (90°C )

TBS, SA, SIS, FEP, TBS, SA, SIS, FEP,

FEPB, MI, FEPB, MI,

RHW, THHW, THW, RHH, RHW-2, THHN, RHW, THHW, THW, RHH, RHW-2, THHN,

THHW, THHW,

AWG (/ MCM or kcmil) | mm2 TW, UF THWN, TW, UF THWN,

XHHW, USE, ZW THW-2, THWN-2, XHHW, USE, ZW THW-2, THWN-2,

USE-2, XHH, USE-2, XHH,

XHHW, XHHW-2, ZW- XHHW, XHHW-2, ZW-

2 2

14 | 2.0 20 | 20 20 | 20 25 | 25 — — —

12 | 3.5 25 | 25 25 | 25 30 | 30 20 | 20 20 | 20 25 | 25

10 | 5.5 30 | 30 35 | 35 40 | 40 25 | 25 30 | 30 35 | 35

8 | 8.0 40 | 40 50 | 50 55 | 55 30 | 30 40 | 40 45 | 45

6 | 14.0 55 | 55 65 | 65 70 | 75 40 | 40 50 | 50 60 | 60

4 | 22.0 70 | 70 85 | 85 90 | 95 55 | 55 65 | 65 75 | 80

3 | 30.0 85 |90 100 | — 110 |115 65 |65 75 | 80 85 | —

2 | 30.0 95 | — 115 | 110 130 | — 75 |— 90 |— 90 | 90

1 | 38.0 110 | 100 130 | 125 150 | 130 85 | 75 100 | 90 115| 105

1/0 (or 0 ) | 50.0 125 | 120 150 | 145 170 | 150 100 | 95 120 | 110 130 | 125

2/0 (or 00 ) | 60.0 145 | 135 170 | 160 190 | 170 115 | 100 135 | 120 150 | 135

3/0 (or 000 ) | 80.0 165 | 160 200 | 195 225 | 205 130 | 120 155 | 145 175 | 165

4/0 (or 0000 ) | 100.0 195 | 185 230 | 220 260 | 225 150 | 140 180 | 170 205 | 190

250 | 125.0 215 | 210 255 | 255 290 | 265 170 | 165 205 | 200 230 | 225

300 | 150.0 240 | 240 285 | 280 320 | 295 190 | 185 230 | 225 255 | 250

350 | 175.0 260 | 260 310 | 305 350 | 345 210 | 205 250 | 245 280 | 275

400 | 200.0 280 | 280 335 | 330 380 | 355 225 | 220 270 | 265 305 | 300

500 | 250.0 320 | 315 380 | 375 430 | 400 260 | 255 310 | 305 350 | 345

600 | 325.0 355 | 370 420 | 435 475 | 470 285 | 305 340 | 365 385 | 410

700 | 375.0 385 | 395 460 | 470 520 | 530 310| 315 375 | 380 420| 430

750 | 400.0 400 | 405 475 | 485 535 | 515 320 | 335 385| 405 435| 460

800 | — 410 | — 490 | — 555 | — 330 | — 395 | — 450 | —

900 | 500.0 435 | 445 520 | 540 585 | — 355| 370 425 | 440 480 | 495

1000 | — 455 | — 545 | — 615 | — 375 | — 445 | — 500 | —

1250 | — 495 | — 590 | — 665 | — 405 | — 485 | — 545 | —

1500 | — 520 | — 625 | — 705 | — 435 | — 520 | — 585 | —

1750 | — 545 | — 650 | — 735 | — 455 | — 545 | — 615 | —

2000 | — 560 | — 665 | — 750 | — 470 | — 560 | — 630 | —

CORRECTION FACTORS

For ambient temperatures other than 30°C, multiply the allowable ampacities shown above by the appropriate

Ambient Temp. (°C)

factor shown below.

21–26 1.08 1.05 1.04

26-30 1.00 1.00 1.00

31-35 0.91 0.94 0.96

36-40 0.82 0.88 0.91

41-45 0.71 0.82 0.87

46-50 0.58 0.75 0.82

51-55 0.41 0.67 0.76

56-60 — 0.58 0.71

61-70 — 0.33 0.58

71-80 — — 0.41

Note: Given values for wire sizes are not equivalents but give the nearest commercially available sizes between AWG and Metric standards Quantities

before the " | " is for AWG/MCM and those after the vertical bar is for Metric System. The table is most useful when available wire sizes are in Metric

System (mm2) but design specifications are given in AWG or conversely. Ampacities may overlap between AWG-Metric wire sizes using certain insulation

types. Due consideration must be practiced in selecting conductor size based on the nearest ampacity such that greater margin of safety is achieved (say,

by choosing wire size which has one step higher ampacity). Ampacities applicable to not more than three conductors are in raceway, cable, or earth,

rated up to 2000 V and at ambient temperature of 30°C. MCM is the same as kcmil . MCM to mm² conversion can use the relationship 1 kcmil =

0.5067 mm².

References: Table 310.16 of National Electrical Code 2008 Edition, Table 3.10.1.16 Philippine Electrical Code 2008 Edition, and

http://en.wikipedia.org/wiki/American_wire_gauge

Disclaimer: Effort has been made to ensure that data presented is free of any error, is provided "as is" and without warranty. Use the information

contained in this compilation at your own risk.

Compiled by JGP © 2010

You might also like

- 25 Optical Illusions That Will Make Your Brain HurtDocument26 pages25 Optical Illusions That Will Make Your Brain HurtJoeDabid100% (1)

- Brand: Schneider Price List of Miniature Circuit Breaker (MCB)Document8 pagesBrand: Schneider Price List of Miniature Circuit Breaker (MCB)helalNo ratings yet

- Polycab Cable Selection Chart & Ampere RatingDocument1 pagePolycab Cable Selection Chart & Ampere Ratingshivani77% (26)

- Electrical Design Analysis RevisionDocument3 pagesElectrical Design Analysis RevisionMarlon Habon67% (3)

- Voltage Drop Diagram: Electrical Design AnalysisDocument3 pagesVoltage Drop Diagram: Electrical Design AnalysisPaeng PaloganNo ratings yet

- Cooper Bussmann Short Circuit and Voltage Drop CalculationDocument10 pagesCooper Bussmann Short Circuit and Voltage Drop CalculationcloobpspNo ratings yet

- Meralco StandardsDocument28 pagesMeralco StandardsBenj Alvarez Capistrano67% (3)

- The Leader Who Had No Title - A Modern Fable On Real Success in Business and in Life (Book Description)Document10 pagesThe Leader Who Had No Title - A Modern Fable On Real Success in Business and in Life (Book Description)JoeDabid75% (4)

- Short Circuit Per Unit MethodDocument1 pageShort Circuit Per Unit MethodI'am Phil100% (1)

- Electrical Design Analysis: ProjectDocument3 pagesElectrical Design Analysis: ProjectMARKCHRISTMASNo ratings yet

- Ground Floor Load Schedule & ComputationsDocument3 pagesGround Floor Load Schedule & ComputationsGintoki SakataNo ratings yet

- PEC AC Resistance Reactance TableDocument1 pagePEC AC Resistance Reactance Tabledabs_orangejuice90% (20)

- 35kv Xlpe Phelps DodgeDocument2 pages35kv Xlpe Phelps DodgeCommercial One100% (2)

- NEC 316.10 Ampacity Table For Cable Conductor SizingDocument1 pageNEC 316.10 Ampacity Table For Cable Conductor SizingHumayun RazaNo ratings yet

- Engr. Florencio D. BerenguelDocument79 pagesEngr. Florencio D. BerenguelJosamy MartinezNo ratings yet

- NEC Rules For Fire PumpsDocument5 pagesNEC Rules For Fire PumpsJoeDabidNo ratings yet

- HOW TO TALK SO PEOPLE LISTEN - UMW Student Leadership Conference (2011)Document196 pagesHOW TO TALK SO PEOPLE LISTEN - UMW Student Leadership Conference (2011)JoeDabid100% (1)

- Sheet 3 AnswersDocument14 pagesSheet 3 Answerskahina100% (2)

- Eda PDFDocument6 pagesEda PDFcjay ganirNo ratings yet

- Ground Floor Plan Plot 6 (Villa 6), Electrical Earthing LayoutDocument1 pageGround Floor Plan Plot 6 (Villa 6), Electrical Earthing LayoutCSEC Uganda Ltd.No ratings yet

- Wiring Design & CalculationsDocument36 pagesWiring Design & CalculationsSerrano Ivan Jasper100% (1)

- Electrical DesignDocument6 pagesElectrical DesignxtianNo ratings yet

- Bus Bar Size For PanelDocument1 pageBus Bar Size For PanelRajendra LabadeNo ratings yet

- DHL Revised Electrical LoadDocument16 pagesDHL Revised Electrical LoadDELA PEÑA ROMEO PARDILLONo ratings yet

- Wiring Diagrams For Outdoor and Ceiling-Mounted Motion DetectorsDocument17 pagesWiring Diagrams For Outdoor and Ceiling-Mounted Motion DetectorsJoeDabidNo ratings yet

- Riser Diagram: ComputationsDocument1 pageRiser Diagram: Computationsmark dominicNo ratings yet

- Electrical Systems Design Based On Pec 2009 PDFDocument2 pagesElectrical Systems Design Based On Pec 2009 PDFLydherson SepnioNo ratings yet

- Wires Phelps Dodge Pricelist Aiti - 1620175328Document1 pageWires Phelps Dodge Pricelist Aiti - 1620175328MLB Account100% (1)

- Construction Safety Guidelines - DOLE DAO 13 PDFDocument21 pagesConstruction Safety Guidelines - DOLE DAO 13 PDFJoeDabidNo ratings yet

- Identifying Pitfalls in The Arc Flash Calculation ProcessDocument13 pagesIdentifying Pitfalls in The Arc Flash Calculation ProcessJoeDabidNo ratings yet

- Emt Pipe Pricelist PDFDocument1 pageEmt Pipe Pricelist PDFJules Milar Paguia100% (4)

- Electrical Design Analysis PDF FreeDocument2 pagesElectrical Design Analysis PDF FreeJonathan Feruelo100% (1)

- Hans-Joachim Herrmann-Under-Excitation-Protection PDFDocument18 pagesHans-Joachim Herrmann-Under-Excitation-Protection PDFSerge RINAUDONo ratings yet

- Philippine Electrical Code Table 9.1.1.9 AC Resistance Reactance TableDocument1 pagePhilippine Electrical Code Table 9.1.1.9 AC Resistance Reactance TableGlasee GoweeNo ratings yet

- Comments On DrawingsDocument8 pagesComments On Drawingsmdalt77No ratings yet

- GE Pricelist 2017Document2 pagesGE Pricelist 2017Rolando Cawaling100% (4)

- Toyota Fortuner BrochureDocument26 pagesToyota Fortuner BrochureJoeDabid100% (1)

- Voltage Drop CalculationDocument30 pagesVoltage Drop Calculationjohannie ukaNo ratings yet

- Boq ElectricalDocument22 pagesBoq Electricaleng_hosNo ratings yet

- Electrical Design Analysis: 3 Storey Commercial BuildingDocument6 pagesElectrical Design Analysis: 3 Storey Commercial Buildingcjay ganir0% (1)

- Motor Circuit, Controllers Based PEC 1 2000, Annual ConventionDocument105 pagesMotor Circuit, Controllers Based PEC 1 2000, Annual Conventionapi-376901488% (8)

- 35kv Xlpe Phelps Dodge PDFDocument2 pages35kv Xlpe Phelps Dodge PDFRodney LanagNo ratings yet

- Acsr Tree Wire 15KV PDFDocument1 pageAcsr Tree Wire 15KV PDFbertovalenNo ratings yet

- Wire Phelps DodgeDocument2 pagesWire Phelps DodgeNoli T. Caronan67% (3)

- CHAPTER 3 Voltage Drop and Short Circuit Analysis PDFDocument42 pagesCHAPTER 3 Voltage Drop and Short Circuit Analysis PDFtaufiqishak0988% (8)

- Electrical Installation GuideDocument259 pagesElectrical Installation GuideKhemraz RamduthNo ratings yet

- Transmission Pricing IndiaDocument20 pagesTransmission Pricing IndiakaynptiNo ratings yet

- NEC Tabla 310-16Document2 pagesNEC Tabla 310-16Miguel Encarnacion100% (3)

- UENR8264UENR8264-01 - SIS Manual Deif m1 MarinoDocument2 pagesUENR8264UENR8264-01 - SIS Manual Deif m1 MarinoJOHAN DAVID RODRIGUEZ100% (1)

- Sistema Electrico 928GDocument15 pagesSistema Electrico 928Gjohana ruiz cervantesNo ratings yet

- SK-Relay: Installation and Maintenance InstructionsDocument2 pagesSK-Relay: Installation and Maintenance InstructionsAbhishek ChakrabortyNo ratings yet

- Wire Ampacity TableDocument3 pagesWire Ampacity TablePaul YstianNo ratings yet

- Load ScheduleDocument2 pagesLoad Schedulelanie-lampasaNo ratings yet

- Design AnalysisDocument10 pagesDesign AnalysisRyan RamosNo ratings yet

- Shihlin Catalog 2Document23 pagesShihlin Catalog 2alvinNo ratings yet

- Staff House Shced of LoadsDocument15 pagesStaff House Shced of LoadsRoy Y. Maratas100% (1)

- PhilFlex THW Building WireDocument1 pagePhilFlex THW Building Wirerey pamelo navarro100% (1)

- Group M - BGC - Load - Rev1 - 09172015Document1 pageGroup M - BGC - Load - Rev1 - 09172015Michael Jhon MoralesNo ratings yet

- 1 Zaragoza Sample Lectrical Computation (SAMPLE)Document7 pages1 Zaragoza Sample Lectrical Computation (SAMPLE)Emarlito BunaNo ratings yet

- Cambodia Catalog Passenger Lift PDFDocument28 pagesCambodia Catalog Passenger Lift PDFaliNo ratings yet

- SizingTransformers PDFDocument1 pageSizingTransformers PDFNaveen ReddyNo ratings yet

- AP-M Series PDFDocument5 pagesAP-M Series PDFVitorio LogoNo ratings yet

- PEC 2017 Short Circuit Calculation SampleDocument8 pagesPEC 2017 Short Circuit Calculation SamplemarvinNo ratings yet

- Rice Mill Electrical Plan A4 PDFDocument1 pageRice Mill Electrical Plan A4 PDFDooting Skelly NootNootNo ratings yet

- Load SchedulesDocument6 pagesLoad Schedulesmuqtar4uNo ratings yet

- Wire Ampacity and Ocpd Rating StandardsDocument3 pagesWire Ampacity and Ocpd Rating StandardsJule LobresNo ratings yet

- Technical Specification For Supply of MCCBDocument9 pagesTechnical Specification For Supply of MCCBAhmad KalbounahNo ratings yet

- Aluminium 3.5C PVC Cable ChartDocument1 pageAluminium 3.5C PVC Cable ChartDulon22100% (1)

- 2023 CCAC Pricelist - February 1, 2023Document8 pages2023 CCAC Pricelist - February 1, 2023Raylie PaguioNo ratings yet

- Bank Transformers in Open DeltaDocument11 pagesBank Transformers in Open DeltaAndré Conhak LinsNo ratings yet

- CCTV Single Line Diagram CCTV Single Riser Diagram: Bureau of DesignDocument1 pageCCTV Single Line Diagram CCTV Single Riser Diagram: Bureau of DesignDominador Ladot Heraña Jr.No ratings yet

- Nec TablesDocument21 pagesNec TablesDelmar FerrerNo ratings yet

- 013 Stream Pe 100 Pipe Support SpacingsDocument1 page013 Stream Pe 100 Pipe Support Spacingsmih1No ratings yet

- Nec AmpacitiesDocument2 pagesNec AmpacitiesmicrajacutNo ratings yet

- HC110 Load Chart No JibDocument10 pagesHC110 Load Chart No JibRie ReiNo ratings yet

- Protection Arrangements and SettingsDocument3 pagesProtection Arrangements and SettingsJoeDabidNo ratings yet

- UPMin - BS Architecture 2018Document1 pageUPMin - BS Architecture 2018JoeDabidNo ratings yet

- IEC 61000-4-13-16-19 Immunity To Hrmnics, Inter-Hrmnics and Voltg Ripples in Public Power Grids - Seminar IEEE Schaffner 20151119 PDFDocument38 pagesIEC 61000-4-13-16-19 Immunity To Hrmnics, Inter-Hrmnics and Voltg Ripples in Public Power Grids - Seminar IEEE Schaffner 20151119 PDFJoeDabidNo ratings yet

- Web Development Tutorials Domain Name: Godaddy: Tutorial 1-1ADocument12 pagesWeb Development Tutorials Domain Name: Godaddy: Tutorial 1-1AJoeDabidNo ratings yet

- Renewable Energy - Matlab, Manning's Equation, Stream FlowDocument9 pagesRenewable Energy - Matlab, Manning's Equation, Stream FlowJoeDabidNo ratings yet

- Integrating Renewable Energy Systems in Buildings: Sheila J. Hayter, PE, FASHRAE Ashrae Region Ix CRC August 5, 2011Document43 pagesIntegrating Renewable Energy Systems in Buildings: Sheila J. Hayter, PE, FASHRAE Ashrae Region Ix CRC August 5, 2011JoeDabidNo ratings yet

- ERC Res No. 16 S2011 PDFDocument19 pagesERC Res No. 16 S2011 PDFJoeDabidNo ratings yet

- PhilDistCode PDFDocument118 pagesPhilDistCode PDFJoeDabidNo ratings yet

- SPEAK MORE EFFECTIVELY - Part One - Public Speaking A Quick and Easy Way by Dale Carnegie (2008)Document12 pagesSPEAK MORE EFFECTIVELY - Part One - Public Speaking A Quick and Easy Way by Dale Carnegie (2008)JoeDabidNo ratings yet

- Mitsubishi Montero Sport BrochureDocument7 pagesMitsubishi Montero Sport BrochureJoeDabid100% (1)

- Portable Battery For Night PhotographyDocument16 pagesPortable Battery For Night PhotographyJoeDabidNo ratings yet

- BDX - User's ManualDocument9 pagesBDX - User's ManualRonald PiedrahitaNo ratings yet

- Assignment No. 3: Three-Phase Transformer ConnectionsDocument13 pagesAssignment No. 3: Three-Phase Transformer ConnectionsAmiel Ohween AnayNo ratings yet

- Automatic Changeover Switch Using Ne555 TimerDocument7 pagesAutomatic Changeover Switch Using Ne555 TimerNick Owusu-debrahNo ratings yet

- Basic Electrical and Electronics EngineeringDocument2 pagesBasic Electrical and Electronics EngineeringDharani KumarNo ratings yet

- BNB 31403 Electrical & Energy SupplyDocument18 pagesBNB 31403 Electrical & Energy SupplyAidi RedzaNo ratings yet

- Deployment of Microgrids in IndiaDocument34 pagesDeployment of Microgrids in IndiaNayan MannaNo ratings yet

- SMK0965F: Switching Regulator ApplicationsDocument8 pagesSMK0965F: Switching Regulator ApplicationsFale MensNo ratings yet

- Sub Engg Annexure-II PDFDocument3 pagesSub Engg Annexure-II PDFRacherla Mega RaniNo ratings yet

- 2 - المحاضرة الثانية 2020Document21 pages2 - المحاضرة الثانية 2020سجاد عباسNo ratings yet

- Example Problem in Computing For A Single FamilyDocument19 pagesExample Problem in Computing For A Single FamilyBreillan SerranoNo ratings yet

- Klea 220P - Powys3121 - Eng - 30092015Document57 pagesKlea 220P - Powys3121 - Eng - 30092015Azito JumNo ratings yet

- Mitsubishi MSCA12YV ManualDocument32 pagesMitsubishi MSCA12YV Manualsansegundo79No ratings yet

- VACON NX Liquid Cooled Drives User Manual DPD00887J UKDocument273 pagesVACON NX Liquid Cooled Drives User Manual DPD00887J UKMohamed ElsayedNo ratings yet

- SuperDocument10 pagesSuperrobert_lascuNo ratings yet

- B767 L3 ATA 24 Electrical PowerDocument232 pagesB767 L3 ATA 24 Electrical PowerOliver IrrazabalNo ratings yet

- SpecificationsDocument3 pagesSpecificationsvenkat0236No ratings yet

- Class Notes For ResistorsDocument2 pagesClass Notes For ResistorsCedric MontianoNo ratings yet

- Array Box-Installation and User Manual and SchematicDocument16 pagesArray Box-Installation and User Manual and SchematicLê Đình LậpNo ratings yet

- AST I-O Port CommunicationDocument2 pagesAST I-O Port Communicationanand100% (1)

- DEIF Completo PDFDocument121 pagesDEIF Completo PDFNelson ColinaNo ratings yet

- 1 s2.0 S2352152X20319307 MainDocument13 pages1 s2.0 S2352152X20319307 Mainenta elektroNo ratings yet

- TeSys Deca - Frame 2 - GV2P22Document9 pagesTeSys Deca - Frame 2 - GV2P22l1f3b00kNo ratings yet

- Ahf ManualDocument30 pagesAhf Manualdpack4798No ratings yet