Professional Documents

Culture Documents

Lesson Plan PDF

Uploaded by

syed aliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lesson Plan PDF

Uploaded by

syed aliCopyright:

Available Formats

IE-313 – Work Study & Methods Engineering (Theory)

B.Sc. Industrial Engineering & Management, 5th Semester (Batch 2017-21)

IQTM – University of the Punjab, Lahore.

Instructor: Zahid Shah

Office: Office F-16, IQTM, University of the Punjab, Lahore.

Lecture Timings: Tuesday, 01:00 p.m. to 03:00 p.m.

Office Hours: By appointment

Contact Email: zahid.iqtm@pu.edu.pk

COURSE BASICS

Pre-Requisite Nil

Co-Requisite Work Study & Methods Engineering (Lab)

Credit Hrs. 2

Lecture / Week 1

Lecture Duration / Week 2 hrs.

Quizzes 8

Practice Questions / Reading Material Will be provided for different topics.

COURSE DESCRIPTION

In 2nd semester you were taught Basic Manufacturing Processes that focused on the shape conversion aspect

of a manufacturing process. In the terminology of lean manufacturing we call this step as value-adding. In

WS & ME we will analyse the processes with a broader perspective and will also include activities before as

well as after shape conversion step. This course takes a holistic picture of industrial processes especially

those performed in manufacturing organizations and focuses on designing and improving them. Students

will learn how to address famous 3 Ms i.e. muda, mura, and muri that can hamper the productivity of any

organization. We will start the course with the main focus on muda and will gradually move to addressing

the other two Ms. As no design (of process) is perfect, we will discuss a number of concepts and techniques

to continuously measure and improve processes. We will learn to make sure that this improvement

contributes to the improvement in the overall system the process being analyzed is a part of.

Module 1 will focus on understanding the basic features of industrial processes from Quality, Cost, and

Productivity perspectives and will introduce the basics of muda, mura, and muri. Module 2 will mainly focus

on recording and analysing the processes to reduce or eliminate muda. Module 3 will set the tone for module

4 and here we will discuss different work measurement (time study) techniques. In module 4, the concepts

discussed in the first three modules will converge and we will discuss how to address mura and muri and a

number of tools of continuous improvement and lean manufacturing.

IE–313: WS & ME IQTM – University of the Punjab, Lahore. Page 1 of 5

COURSE LEARNING OUTCOMES (CLOs)

Level of learning

CLOs Description

(C = Cognitive)

1 Understand the basic features of an industrial process. C2

2 Analyse and design industrial processes. C4

3 Continuously improve industrial processes and systems. C4

4 Contribute to class discussion based on reading material. C2

CLOs AND THEIR MAPPING TO PLOs:

PLO 03: Design/Development of Solutions

PLO 07: Environment and Sustainability

PLO 09: Individual and Team Work

PLO 06: The Engineer and Society

IE-313 – Work Study & Methods Engineering (Th.)

PLO 01: Engineering Knowledge

PLO 11: Project Management

PLO 05: Modern Tool Usage

PLO 02: Problem Analysis

PLO 12: Lifelong Learning

PLO 10: Communication

Course Learning Outcomes

PLO 04: Investigation

PLO 08: Ethics

1. Understand the basic

features of an industrial

process.

2. Analyse and design industrial

processes.

3. Continuously improve

industrial processes and

systems.

4. Contribute to class

discussion based on reading

material.

IE–313: WS & ME IQTM – University of the Punjab, Lahore. Page 2 of 5

TENTATIVE WEEKLY COURSE PLAN

Weekly Course Content, Its Mapping to CLOs, and Reference Material

Week CLOs’

Description Reference Material

Mapping

01 Introduction to the course CLO1 Chapter 1 from Niebel’s book

Module 1: The Basics Practice questions

Four major performance indicators of a

process: QCPS

Productivity and cost perspectives of a

process

02 Muda, mura, and muri CLO1 Chapter 2 from Pascal’s book

Process types Handouts

Quiz 1

03 Module 2: Method Study CLO1 Chapter 2 from Niebel’s book

Selecting the process to improve Chapter 9 from Groover’s book

Recording the details of a process

(conventional tools)

04 Recording the details of a system CLO1 Handouts

(VSM) Case studies

Quiz 2

05 Critically examining the recorded CLO2 Chapter 3 from Niebel’s book

details of a process Chapter 10 from Groover’s book

(for therbligs)

06 Developing a better method / process CLO2 Chapter 3 from Niebel’s book

Case studies

07 Defining, installing, and maintaining CLO2 Chapter 9 from Niebel’s book

the new method / process

Quiz 3

08 Developing a better layout CLO2 Chapter 11 from Groover’s book

Quiz 4 Practice questions

Mid-Term Exam.

09 Module 3: Work Measurement CLO2 Chapter 10 and 11 from Niebel’s

Stop-watch based time study book

Quiz 5 Practice questions

10 Pre-determined motion time systems CLO2 Chapter 13 from Niebel’s book

(PMTS) Practice questions

11 Work sampling CLO2 Chapter 14 from Niebel’s book

Quiz 6 Practice questions

12 Module 4: Continuous Improvement CLO3 Chapter 3 and 4 from Cachon’s book

Evaluating process capacity and labor Practice questions

productivity

Line balancing

IE–313: WS & ME IQTM – University of the Punjab, Lahore. Page 3 of 5

13 Assembly line design CLO3 Chapter 6 from Cachon’s book

Batch production system Handouts

Quiz 7 Practice questions

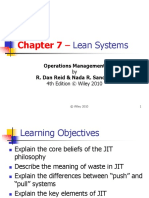

14 5S CLO3 Chapter 3 and 5 from Pascal’s book

Just-in-time production

15 Jidoka CLO3 Chapter 6 from Pascal’s book

Handouts

16 Total productive maintenance (TPM) CLO3 Handouts

Quiz 8

End-Term Exam

COURSE RESOURCES

Textbook:

1. Niebel's Methods, Standards and Work Design by Andris Freivalds, 13th ed. Publisher: McGraw-Hill.

References:

1. Work Systems: The Methods, Measurement & Management of Work by Mikell P. Groover.

Publisher: Pearson – Prentice Hall.

2. Lean Production Simplified: A Plain-Language Guide to the World’s Most Powerful Production

System, by Pascal Dennis. Publisher: Productivity Press.

3. Motion and Time Study – Design and Measurement of Work by Ralph M. Barnes. Publisher: John

Wiley and Sons.

4. Matching Supply with Demand – An Introduction to Operations Management by G. Cachon and C.

Terwiesch. Publisher: McGraw-Hill International Edition.

GRADING POLICY

Class grade is based on the following components:

Component Marks

Mid–Term Exam. 35

End–Term Exam. 40

Quizzes 15

Class Participation 10

IE–313: WS & ME IQTM – University of the Punjab, Lahore. Page 4 of 5

MAPPING OF CLOs TO DIRECT ASSESSMENTS

Quiz

CLOs CP Mid-Term End-Term

1 2 3 4 5 6 7 8

1

2

3

4

STUDENTS’ RESPONSIBILITIES

1. Be regular. Attend all lectures.

2. The use of cell phone, whispering, and cross-talk are strictly prohibited during the lecture.

3. Participate actively in class. Raise your hand in order to ask/answer a question.

4. Check your emails regularly for announcements related to the course.

5. Send an email in case of any query. Follow these points for convenience:

a. Mention a precise ‘subject’ of your email

b. Be specific in asking questions

c. Do mention your name and roll number

6. Never miss your quizzes as they are part of your overall grade. They are meant to keep you in touch

with the course on regular basis. There will be no make-up quizzes.

** Happy Learning **

IE–313: WS & ME IQTM – University of the Punjab, Lahore. Page 5 of 5

You might also like

- Critical Success Factor of LEANDocument5 pagesCritical Success Factor of LEANThanh TrinhNo ratings yet

- 743 Lesson Plan - Bba-302 (BPS)Document7 pages743 Lesson Plan - Bba-302 (BPS)Harsh SaxenaNo ratings yet

- NLGI Grease Technical DocumentDocument10 pagesNLGI Grease Technical Documentho-faNo ratings yet

- LubricantsDocument21 pagesLubricantsGourav KumarNo ratings yet

- Chapter Three Lubricants & Mechanism of LubricationDocument28 pagesChapter Three Lubricants & Mechanism of LubricationMuket AgmasNo ratings yet

- STD 11 Eng WorkbookDocument167 pagesSTD 11 Eng Workbookalparamani420% (1)

- Chapter Two - 2 LubricationDocument29 pagesChapter Two - 2 LubricationBaslielNo ratings yet

- How To Design Lubrication Task RoutesDocument8 pagesHow To Design Lubrication Task RoutesHector JNo ratings yet

- Lubrication 160826150651Document78 pagesLubrication 160826150651santoshNo ratings yet

- GreasesDocument4 pagesGreasesAnil BalanNo ratings yet

- Tribology InternationalDocument9 pagesTribology InternationalBragasNo ratings yet

- Chemistry Manual NewDocument44 pagesChemistry Manual NewRACHETA BHARATNo ratings yet

- A Review On Grease Lubrication in Rolling BearingsDocument12 pagesA Review On Grease Lubrication in Rolling Bearingsfeni4kaNo ratings yet

- Aadhyatmic Sandesh Year 5 Issue 1Document16 pagesAadhyatmic Sandesh Year 5 Issue 1ssdhamNo ratings yet

- Machinery Lubrication Jan Feb 2021Document40 pagesMachinery Lubrication Jan Feb 2021Freddy ZambranoNo ratings yet

- Grease 2Document4 pagesGrease 2arunNo ratings yet

- Polyurea Greases TLT Article March14Document1 pagePolyurea Greases TLT Article March14ivan agustinoNo ratings yet

- Grease Selection ChartDocument4 pagesGrease Selection Chartmirali74No ratings yet

- Fatty Acids and Antioxidant Effects On Grease MicrostructuresDocument7 pagesFatty Acids and Antioxidant Effects On Grease MicrostructuresAlex RichardNo ratings yet

- SKF Bearing Grease Selection Chart: LGMT 3Document1 pageSKF Bearing Grease Selection Chart: LGMT 3compaore dramaneNo ratings yet

- Using Lean PrinciplesDocument17 pagesUsing Lean PrinciplesJose Mendelle Murry TombadoNo ratings yet

- Machinery Lubrication Brochure EDocument2 pagesMachinery Lubrication Brochure Eho-faNo ratings yet

- YS April 10 EnglishDocument58 pagesYS April 10 EnglishmkghaiNo ratings yet

- Lubricant Base Stocks: OutlineDocument23 pagesLubricant Base Stocks: OutlineJahmia Coralie100% (1)

- Ys Jan Eng 2017Document68 pagesYs Jan Eng 2017upnishda100% (1)

- Yog Sandesh English Jan11Document68 pagesYog Sandesh English Jan11Yogesh BansalNo ratings yet

- Lean EvenortDocument4 pagesLean EvenortAdelina Roman0% (1)

- LGLT 2: Grease SelectionDocument4 pagesLGLT 2: Grease SelectionNguyen ChuyenNo ratings yet

- Shovel Lubrication PDFDocument2 pagesShovel Lubrication PDFSounak SasmalNo ratings yet

- Professor of Economics: Abdul JalilDocument13 pagesProfessor of Economics: Abdul JalilTanveerNo ratings yet

- Yog Sandesh Feb 09 EnglishDocument60 pagesYog Sandesh Feb 09 EnglishManmohan Gupta100% (1)

- Lubrication ChartDocument4 pagesLubrication Chartjorge DiazNo ratings yet

- Weekly Choice - November 20, 2014Document18 pagesWeekly Choice - November 20, 2014Baragrey DaveNo ratings yet

- Lubrication SystemsDocument9 pagesLubrication SystemsCeno EdwinNo ratings yet

- YogSandesh May Eng2010Document37 pagesYogSandesh May Eng2010Manmohan Gupta100% (1)

- Fieldwire-How To Begin Your Lean JourneyDocument9 pagesFieldwire-How To Begin Your Lean JourneyEricGustavoPrinceMaldonadoNo ratings yet

- Edristi Navatra June 2021Document221 pagesEdristi Navatra June 2021Ayushi jainNo ratings yet

- Lean Six Sigma Master Black Belt: Prepared by Julian Kalac, P.EngDocument45 pagesLean Six Sigma Master Black Belt: Prepared by Julian Kalac, P.EngRobertoPaizNo ratings yet

- BookLife November 2018Document27 pagesBookLife November 2018Publishers WeeklyNo ratings yet

- YogSandesh March Eng2010Document60 pagesYogSandesh March Eng2010Manmohan Gupta100% (1)

- LubricationDocument22 pagesLubricationEvílBoyViswaNo ratings yet

- YogSandesh October Eng2011Document66 pagesYogSandesh October Eng2011Manmohan Gupta100% (1)

- LEC5 Lubrication 2022Document37 pagesLEC5 Lubrication 2022mohamed hodiriNo ratings yet

- Lubricants Lubrication FinalDocument56 pagesLubricants Lubrication FinalArushi SthapakNo ratings yet

- 2014 609 - Mobil SHC 524 Synthetic Hydraulic Oil Success StoryDocument1 page2014 609 - Mobil SHC 524 Synthetic Hydraulic Oil Success StoryMudabbir Shan Ahmed100% (1)

- Patanjali CaseDocument1 pagePatanjali CaseDhruti BhatiaNo ratings yet

- SHELL Product Data Guide Industry 2013Document78 pagesSHELL Product Data Guide Industry 2013Edgar Real ViúlaNo ratings yet

- DSA (Course Outlines) Spring24Document4 pagesDSA (Course Outlines) Spring24Swaira RiazNo ratings yet

- Fluid Mechanics Lab ManualDocument70 pagesFluid Mechanics Lab ManualMuhammad Naveed 952-FET/BSME/F20No ratings yet

- MGT 3202 - Engineering Management - Obe Based Course OutlineDocument13 pagesMGT 3202 - Engineering Management - Obe Based Course OutlineMr cookNo ratings yet

- Text and Material: Text Book: Upon Completion of This Course, The Student Should Be Able ToDocument4 pagesText and Material: Text Book: Upon Completion of This Course, The Student Should Be Able ToRafi UllahNo ratings yet

- Professional Practices - 2 CurriculumDocument12 pagesProfessional Practices - 2 CurriculumH512 Abhijeet KhanzodeNo ratings yet

- Third & Final Year SyllabusDocument80 pagesThird & Final Year SyllabusMerlin Linda GNo ratings yet

- Course Outline BSIT - Prog Fundamental Using C++Document2 pagesCourse Outline BSIT - Prog Fundamental Using C++qkhanzada33No ratings yet

- 7.inplant Training-15AR67PDocument6 pages7.inplant Training-15AR67PVidya ShreeNo ratings yet

- B - Tech Syllabus PDFDocument31 pagesB - Tech Syllabus PDFkaran5singh-12No ratings yet

- Instrument Student VersionDocument67 pagesInstrument Student VersionUsman AliNo ratings yet

- Computer Networks - Course Guide (BSDS-AI-IV, Spring 2024)Document6 pagesComputer Networks - Course Guide (BSDS-AI-IV, Spring 2024)Anas IshaqNo ratings yet

- Co-Creation & Interpersonal AbilitiesDocument5 pagesCo-Creation & Interpersonal Abilitiesrashmin tannaNo ratings yet

- OS Course Outline May2022 OKDocument6 pagesOS Course Outline May2022 OKaqeelmhar7No ratings yet

- Facility Location Decision Examples (For Students)Document15 pagesFacility Location Decision Examples (For Students)syed ali100% (1)

- Flow ChartDocument1 pageFlow Chartsyed aliNo ratings yet

- NIOSH Lifting Equation: Submitted by William A. GrovesDocument30 pagesNIOSH Lifting Equation: Submitted by William A. Grovessyed aliNo ratings yet

- Simulation of Honda Bikes Repairing Shop: Group MembersDocument33 pagesSimulation of Honda Bikes Repairing Shop: Group Memberssyed aliNo ratings yet

- Niosh Lifting Equation: Presented byDocument25 pagesNiosh Lifting Equation: Presented bysyed aliNo ratings yet

- Metro Logy: B.Sc. Industrial Engineering and ManagementDocument4 pagesMetro Logy: B.Sc. Industrial Engineering and Managementsyed aliNo ratings yet

- Metro Logy: B.Sc. Industrial Engineering and ManagementDocument4 pagesMetro Logy: B.Sc. Industrial Engineering and Managementsyed aliNo ratings yet

- CH 1 Solution PDFDocument2 pagesCH 1 Solution PDFsyed aliNo ratings yet

- Quality ToolsDocument5 pagesQuality Toolssyed aliNo ratings yet

- Metro Logy: B.Sc. Industrial Engineering and ManagementDocument3 pagesMetro Logy: B.Sc. Industrial Engineering and Managementsyed aliNo ratings yet

- 27 Syed Ali (HSEE ASSIGNMENT 1)Document6 pages27 Syed Ali (HSEE ASSIGNMENT 1)syed aliNo ratings yet

- Process Layout Design - Practice QuestionsDocument2 pagesProcess Layout Design - Practice Questionssyed aliNo ratings yet

- 27 Syed Ali (HSEE ASSIGNMENT 1)Document6 pages27 Syed Ali (HSEE ASSIGNMENT 1)syed aliNo ratings yet

- Assignment 4Document4 pagesAssignment 4syed aliNo ratings yet

- Principles of Motion Economy - Practice QuestionDocument1 pagePrinciples of Motion Economy - Practice Questionsyed aliNo ratings yet

- Line Balancing and Labor Productivity - Practice Questions: WS & ME (2020) 5 Semester IqtmDocument7 pagesLine Balancing and Labor Productivity - Practice Questions: WS & ME (2020) 5 Semester Iqtmsyed aliNo ratings yet

- Assignment 2 Fishbone DiagramDocument1 pageAssignment 2 Fishbone Diagramsyed aliNo ratings yet

- Intro of Computer: - : First Generation (1937 To 1946)Document4 pagesIntro of Computer: - : First Generation (1937 To 1946)syed aliNo ratings yet

- Developing and Defining A Method - Practice QuestionsDocument2 pagesDeveloping and Defining A Method - Practice Questionssyed aliNo ratings yet

- HR AnnaDocument4 pagesHR AnnaWassen Hejjawi50% (2)

- Assignment For Topic 01-01: Productivity and CostDocument3 pagesAssignment For Topic 01-01: Productivity and Costsyed aliNo ratings yet

- 0339 Faizan AmirDocument24 pages0339 Faizan Amirsyed aliNo ratings yet

- Lesson Plan PDFDocument5 pagesLesson Plan PDFsyed aliNo ratings yet

- Minorities Under Constitution(s) of PakistanDocument12 pagesMinorities Under Constitution(s) of PakistanMehar UsmanNo ratings yet

- 1st Semester ResultDocument2 pages1st Semester Resultsyed aliNo ratings yet

- 1st Semester ResultDocument2 pages1st Semester Resultsyed aliNo ratings yet

- CH 07Document37 pagesCH 07syed aliNo ratings yet

- Outline Process Chart (A)Document1 pageOutline Process Chart (A)syed aliNo ratings yet

- Radio Electronics Annual 1986 PDFDocument98 pagesRadio Electronics Annual 1986 PDFhfalanizNo ratings yet

- 2018 Case Study Novartis Global Environmental-Impact WifORDocument11 pages2018 Case Study Novartis Global Environmental-Impact WifORBlue CliffNo ratings yet

- Commented (Frl1) : Pos Como Que No Entendí Muy Bien La Commented (Udw2R1)Document2 pagesCommented (Frl1) : Pos Como Que No Entendí Muy Bien La Commented (Udw2R1)Isabella Mercado DíazNo ratings yet

- Reciprocal Teaching Lesson PlanDocument6 pagesReciprocal Teaching Lesson Planapi-585028313No ratings yet

- Nursing AuditDocument36 pagesNursing AuditPhebeDimpleNo ratings yet

- DOCUMENT: Prosecution of Offences in Nigeria GomDocument35 pagesDOCUMENT: Prosecution of Offences in Nigeria GomSahara ReportersNo ratings yet

- IsuDocument13 pagesIsuEliz SawNo ratings yet

- Gt101: Learning and Information Technology Tu107: Computing EssentialsDocument18 pagesGt101: Learning and Information Technology Tu107: Computing EssentialsabdoulqadirNo ratings yet

- IB Source Catalog 2013-2014Document112 pagesIB Source Catalog 2013-2014eibsource0% (1)

- Episode 1to5Document69 pagesEpisode 1to5Dex Ramirez100% (5)

- 21CLD Learning Activity Cover SheetDocument9 pages21CLD Learning Activity Cover SheetMariana VoloshynNo ratings yet

- "Sales Promotion OF Nokia Products": Presented byDocument25 pages"Sales Promotion OF Nokia Products": Presented byVishal DangNo ratings yet

- Purchasing and ProcurementDocument2 pagesPurchasing and ProcurementMarie Jeannie Intal100% (1)

- Wa0008Document19 pagesWa0008YashasiviNo ratings yet

- Introduction To World Religion and Belief SystemDocument25 pagesIntroduction To World Religion and Belief SystemKristina Angelina100% (12)

- Channel FinancingDocument28 pagesChannel FinancingP VENKATA HARSHA VARDHAN REDDYNo ratings yet

- Using Patterns of Development in Writing Across DisciplinesDocument15 pagesUsing Patterns of Development in Writing Across Disciplinesbaby jane omabay50% (4)

- BS Iso 10005-2005 PDFDocument32 pagesBS Iso 10005-2005 PDFIbrahim Sirpi100% (1)

- Employee Green BehaviorDocument13 pagesEmployee Green BehaviorDeep KhatiNo ratings yet

- Department of Labor: AppealsDocument6 pagesDepartment of Labor: AppealsUSA_DepartmentOfLabor100% (1)

- Air India Air Transport Services LimitedDocument5 pagesAir India Air Transport Services LimitedSumit KumarNo ratings yet

- Marriott BriefDocument4 pagesMarriott Briefjuliette_ogerNo ratings yet

- Apj Abdul Kalam Technological UniversityDocument2 pagesApj Abdul Kalam Technological Universitynandu jNo ratings yet

- Rubric For Research PresentationDocument1 pageRubric For Research Presentationjoseph082281100% (3)

- AdhicsDocument116 pagesAdhicstimvrghs123No ratings yet

- Saep 120Document4 pagesSaep 120Demac Saud0% (1)

- Indian Air Force: Air Force Common Admission Test Admit Card - Afcat 01/2022Document6 pagesIndian Air Force: Air Force Common Admission Test Admit Card - Afcat 01/2022Ajay SinghNo ratings yet

- Narrative Report - TalaDocument3 pagesNarrative Report - TalaRichmond Lloyd Menguito JavierNo ratings yet

- Control of AirDocument71 pagesControl of Airajay ahlawatNo ratings yet

- Entry Strategy and Strategic Alliances: Mcgraw-Hill/IrwinDocument40 pagesEntry Strategy and Strategic Alliances: Mcgraw-Hill/IrwinMardhiah RamlanNo ratings yet