Professional Documents

Culture Documents

01 5 Design and Function

Uploaded by

Extra EmailOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 5 Design and Function

Uploaded by

Extra EmailCopyright:

Available Formats

DESIGN AND FUNCTION

WÄRTSILÄ W50DF

STANDARD ENGINE

1 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

INTRODUCTION

Compact design of Wärtsilä 50DF

2 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

INTRODUCTION

Ancillary equipment and connections

Turbocharger

Gas manifold

HT water air vent from air

Gas filter cooler

Power module HT water air vent

Charge air receiver LT water air vent from air

cooler

Inert gas inlet

Charge air cooler

Gas inlet

HT water inlet

LT water inlet

Lubricating oil inlet

HT water to alternator Lubricating oil outlet

LT water outlet HT water outlet

3 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

INTRODUCTION

All ancillary equipment mounted at engine free end

Water separator

Centrifugal filter

HT water pump

LT water pump

Fuel filter

Pressure regulating valve

Pilot injection pump

Lubricating oil pump

Pilot fuel outlet

Oil from LO pump

Pilot fuel inlet

Running in-filter

4 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

GENERAL DESING

Core design values

Proven gas system, pilot fuel system and

engine control system technology with

safety aspects included

Integrated and modular design based on

Wärtsilä 46

Wärtsilä 50DF engine is manufactured in

configurations from 6L up to 18V

Engine block always fitted on common base

frame

Latest and the most advanced

environmental solutions are integrated into

engine basic design

Low operating costs by dual-fuel technology

Easy access for easy maintenance

Resilient mounting with rubber elements

5 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

GENERAL DESING

Design philosophy

The Wärtsilä 50DF is a four-stroke dual-fuel engine that can be run either on natural gas or light fuel

oil (LFO) and, with certain modifications, also on heavy fuel oil (HFO). The engine combines the highly

successful Wärtsilä 46 engine strengths to the economical dual-fuel technologies. Reliability is still

the guiding principle for Wärtsilä 50DF engine. Low maintenance costs, environmental issues with

proven emission control options and installation easiness are also strongly in focus.

The main features of the Wärtsilä 50DF

High thermal efficiency and low emissions

The lean-burn concept

The air-fuel ratio in combustion is very high since the same specific heat quantity released by combustion is used to

heat up a larger mass of air. Thus the maximum temperature and consequently NOx formation are lower

Flexibility with emission control

The Wärtsilä 50DF can be run either on natural gas or LFO and also on HFO

Designed to give the same output whether it is running on natural gas or on LFO/HFO

Output ranges for the Wärtsilä 50DF engines and generating sets

Output ranges for Wärtsilä 50DF engines and generating sets

Output 50 Hz, 60 Hz

Engine configuration

Engine [kW] Generating set [kWe]

6L50DF 5700 5500

8L50DF 7600 7330

9L50DF 8550 8250

12V50DF 11400 11000

16V50DF 15200 14670

18V50DF 17100 16500

6 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

GENERAL DESING

Design philosophy

The main features of the Wärtsilä 50DF

Dual-fuel technology

Divided in to two systems: gas system and diesel oil system

Gas system

Lean-burn technology with pilot fuel ignited Otto-principle

combustion

Low pressure natural gas and LFO

Diesel oil system

Divided in to two systems: pilot fuel system and back-up fuel system

LFO/HFO

Operation mode transfer

The engine can be switched automatically from fuel oil to gas

operation at loads below 80 % of the full load

Twin-needle injection valve with electronically controlled pilot injection and

hydro-mechanically controlled main diesel injection

High reliability with low maintenance costs

Increased component lifetime and time between overhauls

Common components with Wärtsilä 32DF and Wärtsilä 46

Ancillaries; pumps, filters, coolers located to facilitate easy accessibility

Safe bearing technology

The big-end bearing housing is hydraulically tightened, resulting in a

distortion-free bore for the corrosion-resistant precision bearing

Installation easiness

All ancillaries are built on the engines

Optionally with separate ancillaries

All connections are concentrated to few points

7 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

GENERAL DESING

Design philosophy

Compliance with SOLAS fire safety regulations

Wärtsilä 50DF engines are designed keeping in mind existing SOLAS requirements already in basic

design phase.

Design concept is based on the SOLAS rules:

SOLAS II-2/15.2.9 - 15.2.12.

Arrangements for oil fuel, lubricating oil

and other flammable oils

8 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

GENERAL DESING

Summary of SOLAS requirements SOLAS II-2/15.2.9 - 15.2.12. Arrangements for oil fuel,

lubricating oil and other flammable oils

SOLAS Description of requirements

Requirement

(1) High pressure fuel pipes

”All external high-pressure fuel delivery lines between the high-pressure fuel pumps and fuel injectors shall be protected with a jacketed

piping system capable of containing fuel from a high-pressure line failure. A jacketed pipe incorporates an outer pipe into which the high-

pressure fuel pipe is placed, forming a permanent assembly. The jacketed piping system shall include a means for collection of leakages

and arrangements shall be provided for an alarm to be given of a fuel line failure.”

(2) Hot surfaces

”All surfaces with temperatures above 220 °C which may be impinged as a result of a fuel system failure shall be properly insulated.”

(3) Low pressure fuel oil pipes

”Oil fuel lines shall be screened or otherwise suitably protected to avoid, as far as praticable, oil spray or oil leakages onto hot surfaces,

into machinery air intake, or other sources of ignition. The number of joints in such piping system shall be kept to a minimum.”

(4) Lubricating oil arrangements

”The arrangements for the storage, distribution and utilization of oil used in pressure lubrication systems shall be such as to ensure the

safety of the ship and persons on board. The arrangements made in machinery spaces of category A, and whenever practicable in other

machinery spaces, shall at least comply with the provisions of paragraphs 2.1, 2.4, 2.5, 2.6, 2.7, 2.8, 2.10 and 2.11 ”screened or

otherwise suitably protected”.

9 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

GENERAL DESING

Summary of SOLAS requirements SOLAS II-2/15.2.9 - 15.2.12. Arrangements for oil fuel,

lubricating oil and other flammable oils

Guidelines to SOLAS

Shielding is only required for piping systems

under pressure exceeding 0.18N/mm2 [1.8 bar]

which are located above or near units of high temperature,

including boilers, steam pipes, exhaust manifold, silencers

or other equipment required to be insulated by SOLAS reg. II-2/15.2.10.

It is further required if oil spray or oil leakages may reach machinery

intakes or other sources of ignition.

10 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

GENERAL DESING

Sectional view of

Wärtsilä 50DF

Fig. name: Sectional view of engine

11 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

TERMINOLOGY

Designation of cylinders

Designation of engine sides and ends

Manoeuvring side and rear side. Details

located on the manoeuvring side may be

marked with "M" and correspondingly "B"

for the back of the engine (B - bank on a

V - engine).

Clockwise rotating engine. When looking

at the engine from the driving end the shaft

rotates clockwise.

Counter - clockwise rotating engine.

When looking at the engine from the driving

end the shaft rotates counter - clockwise.

Fig. name: Designation of cylinders

12 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

TERMINOLOGY

Designation of bearings

Main bearings: The flywheel bearing is No. 0, the

first standard main bearing is No. 1, the second No.

2 etc.

Thrust bearings: The thrust bearing rails are

located at the flywheel bearing. The outer rails

close to the flywheel are marked with 00 and the

inner rails with 0.

Camshaft bearings: The camshaft bearings are

designated the same as the main bearings and the

thrust bearing bushings are designated; the outer

00 and the inner 0

Camshaft gear bearings: The bearings located on

the flywheel side and are designated 00 and the

inner bearings 0.

Upper and lower bearing shells: In bearings

where both bearing shells are identical, the upper

one is marked with UP.

Fig. name: Designation of bearings

13 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

TERMINOLOGY

Designation of valves

Fig. name: Designation of valves

14 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

TERMINOLOGY

Example of reading the flywheel

Marking of the flywheel:

The flywheel is divided into 360º, starting from TDC

at firing for cylinder 1. TDC at firing for every cylinder

is marked on the flywheel. There is a common

marking for the cylinders in engines with even

cylinder numbers, one cylinder is at TDC at firing and

the other is at TDC at scavenging. There are

separate scales for A - and B - bank in a V - engine.

Firing intervals, in crank angles, can be determined

by dividing 720° with the number of cylinders. On an

example engine, the fuel timing is read to 17° for

cylinder A2 when the flywheel is in the position

shown in the figure.

System components

01 Flywheel indicator

02 Flywheel graduation

Fig. name: Example of reading the flywheel

15 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

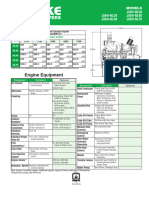

TERMINOLOGY

W50DF engines, in-line engine

Cylinder bore: 500 mm

Piston stroke: 580 mm

Speed: 500 rpm 514 rpm

Mean effective pressure: 20.0 bar 19.5 bar

Piston speed: 9.7 m/s 9.9 m/s

Output/cylinder: 950 kW

Fuel specification:

Fuel oil 730 cSt/50 °C

ISO 8217, category ISO-F-DMX, DMA and DMB

Natural gas Methane Number: 80

LHV: min. 28 MJ/nm³, 5.5 bar

BSEC 7410 kJ/kWh

Rated power

Engine configuration Output [kW]* Output [Bhp]* Weight [ton]**

6L50DF 5700 7750 96

8L50DF 7600 10340 128

9L50DF 8550 11630 148

12V50DF 11400 15500 175

16V50DF 15200 20670 220

18V50DF 17100 23260 240

*) At flywheel

**) Dry weight

16 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

TERMINOLOGY

Calculating of Mean Effective Pressure

Mean Effective Pressure

P (kW/cyl.) P (hp/cyl.)

or

Rpm * 0,08033 Rpm * 0,10921

Firing order

Engine configuration Firing orders of clockwise rotating engines

6L50DF 1-5-3-6-2-4

I: 1-3-2-5-8-6-7-4

8L50DF

II: 1-6-2-4-8-3-7-5

I: 1-2-4-6-8-9-7-5-3

9L50DF

II: 1-7-4-2-8-6-3-9-5

12V50DF A1-B1-A5-B5-A3-B3-A6-B6-A2-B2-A4-B4

16V50DF A1-B1-A3-B3-A2-B2-A5-B5-A8-B8-A6-B6-A7-B7-A4-B4

18V50DF A1-B8-A7-B6-A4-B3-A2-B9-A8-B5-A6-B1-A3-B7-A9-B4-A5-B2

17 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

MAIN TECHNICAL DATA

Wärtsilä 50DF

L-engine

Principle engine dimensions [mm ] and weights [tonnes]**

Engine

A B C D F Weight (dry)

configuration

6L50DF 8115 3580 2850 3820 1455 96.0

8L50DF 9950 3600 3100 3820 1455 128.0

9L50DF 10800 3600 3100 3820 1455 148.0

**) =

Subject to revision without notice

A = Total length

C = Total breadth

B+F = Total height (from the bottom of the oil sump to the exhaust outlet)

18 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

MAIN TECHNICAL DATA

Wärtsilä 50DF

V-engine

Principle engine dimensions [mm ] and weights [tonnes]**

Engine

A B C D F Weight (dry)

configuration

12V50DF 10465 4055 3810 3600 1500 175.0

16V50DF 12665 4055 4530 3600 1500 220.0

18V50DF 13725 4280 4530 3600 1500 240.0

**) =

Subject to revision without notice

A = Total length

C = Total breadth

B+F = Total height (from the bottom of the oil sump to the exhaust outlet)

19 © Wärtsilä 27 September 2007 W50DFA1V00BTM01A Rev. 01

You might also like

- KD2000 FDocument7 pagesKD2000 FTrần Quang TuyênNo ratings yet

- Industrial Diesel Generator Set - 50 HZ - Fuel Consumption OptimizedDocument6 pagesIndustrial Diesel Generator Set - 50 HZ - Fuel Consumption OptimizedMetin VaranNo ratings yet

- Auto Sueco P 17201 Kd1000f enDocument6 pagesAuto Sueco P 17201 Kd1000f enjmcfeNo ratings yet

- KD900 FDocument6 pagesKD900 Fb400013No ratings yet

- 50HZ SMI1815 CHINA Mitsubishi GeneratorDocument4 pages50HZ SMI1815 CHINA Mitsubishi GeneratorsunshinemachineryNo ratings yet

- Kohler Sdmo Kd2250-EDocument6 pagesKohler Sdmo Kd2250-EMartin KratkyNo ratings yet

- Cummins 125 KVADocument4 pagesCummins 125 KVAZein Ardha101No ratings yet

- SM1700 50HZ MTU GeneratorDocument4 pagesSM1700 50HZ MTU GeneratorChen CarolineNo ratings yet

- Mitsubishi Diesel Engine - S16R2-PTAW2-EDocument2 pagesMitsubishi Diesel Engine - S16R2-PTAW2-EHeni HasanahNo ratings yet

- AD 220Document7 pagesAD 220b400013No ratings yet

- Reliable 20kVA Generating Set FeaturesDocument4 pagesReliable 20kVA Generating Set Featuressayful ykNo ratings yet

- Service Manual FD100Document236 pagesService Manual FD100Hải TiếnNo ratings yet

- IBG.T.145 Specs 220V 60Hz 150W60 150WS60 Rev1-1Document6 pagesIBG.T.145 Specs 220V 60Hz 150W60 150WS60 Rev1-1Mohamed ShafeeqNo ratings yet

- Wärtsilä 50DF: Key Benefits Typical Application AreasDocument2 pagesWärtsilä 50DF: Key Benefits Typical Application AreasMuhammad Arsyad El FarobbyNo ratings yet

- Brochure o e w50df PDFDocument2 pagesBrochure o e w50df PDFRonald Bienemi PaezNo ratings yet

- IBG.U.253 Rev0 127WS60 3phase 220VDocument6 pagesIBG.U.253 Rev0 127WS60 3phase 220VMohamed ShafeeqNo ratings yet

- Yanmar 20 KvaDocument4 pagesYanmar 20 KvaRurizwan Syahru WibisanaNo ratings yet

- PC200-8 ImprovementDocument57 pagesPC200-8 Improvementdedy imran100% (1)

- PC200-8 ImprovementDocument57 pagesPC200-8 Improvementdedy imran100% (10)

- SD500 50HZ Deutz Generator-Ilovepdf-CompressedDocument4 pagesSD500 50HZ Deutz Generator-Ilovepdf-CompressedsunshinemachineryNo ratings yet

- Sdo385 50hz Doosan GeneratorDocument4 pagesSdo385 50hz Doosan GeneratorsunshinemachineryNo ratings yet

- FH235 & FH236 Series Diesel Pro FlyerDocument2 pagesFH235 & FH236 Series Diesel Pro FlyercharisNo ratings yet

- High-quality generator sets with comprehensive testing and protection featuresDocument4 pagesHigh-quality generator sets with comprehensive testing and protection featuresfirman harianjaNo ratings yet

- Perkins 650 KVADocument4 pagesPerkins 650 KVASulistiani ArlimNo ratings yet

- 38LB - catalog แคเรียDocument2 pages38LB - catalog แคเรียPiyawat JirateanthumNo ratings yet

- Volvo Ec 300 D Service ListDocument2 pagesVolvo Ec 300 D Service ListSanjay DuttaNo ratings yet

- QSL9-G3 CoolpackDocument3 pagesQSL9-G3 Coolpackmohsen_cumminsNo ratings yet

- SMI1650 50HZ CHINA Mitsubishi GeneratorDocument4 pagesSMI1650 50HZ CHINA Mitsubishi GeneratorsunshinemachineryNo ratings yet

- WPG110Document4 pagesWPG110Kevin AndrianNo ratings yet

- CAT G3512TA Spec SheetDocument3 pagesCAT G3512TA Spec SheetMantmetalsNo ratings yet

- Bitzer DataDocument27 pagesBitzer Databookslover1No ratings yet

- Manual - Bba SP 750Document32 pagesManual - Bba SP 750Leopoldo Wille100% (1)

- SD22 50HZ Deutz GeneratorDocument4 pagesSD22 50HZ Deutz GeneratorsunshinemachineryNo ratings yet

- 38LHU - Catalog (CU - Air Cooled-Med)Document2 pages38LHU - Catalog (CU - Air Cooled-Med)Kyaw KoNo ratings yet

- Reliable 100kVA Generator Set FeaturesDocument4 pagesReliable 100kVA Generator Set Featuresgirindra yudhaNo ratings yet

- Fawde 30 KVA (4DW92 - 39D) - 3 PhaseDocument4 pagesFawde 30 KVA (4DW92 - 39D) - 3 PhaseckondoyNo ratings yet

- Wärtsilä 50DF Product Guide 101-200Document100 pagesWärtsilä 50DF Product Guide 101-200Jose LlainNo ratings yet

- Sumitomo SH130-5 EMDocument79 pagesSumitomo SH130-5 EMLin Lin100% (2)

- Sullivan Palatek M SeriesDocument2 pagesSullivan Palatek M SeriesLeonardo BarrancoNo ratings yet

- General Features Prime StandbyDocument3 pagesGeneral Features Prime StandbyHabibNo ratings yet

- 250kw 50HZ Cummins Marine GeneratorDocument3 pages250kw 50HZ Cummins Marine GeneratorChen Caroline100% (1)

- VTA28-G5: Fuel OptimizedDocument3 pagesVTA28-G5: Fuel OptimizedIslam HemdanNo ratings yet

- SD46.5 50HZ Deutz GeneratorDocument4 pagesSD46.5 50HZ Deutz GeneratorsunshinemachineryNo ratings yet

- Reliable 30kVA Generating Set FeaturesDocument4 pagesReliable 30kVA Generating Set Featuresfirman harianjaNo ratings yet

- Hoja de Especificaciones JX6H-NLDocument2 pagesHoja de Especificaciones JX6H-NLosvaldoNo ratings yet

- Reliable 100kVA Generating Set Features Comprehensive ProtectionDocument4 pagesReliable 100kVA Generating Set Features Comprehensive Protectiongirindra yudhaNo ratings yet

- Lovol 100 KVADocument4 pagesLovol 100 KVAgirindra yudhaNo ratings yet

- VTA28G6Document3 pagesVTA28G6chanchan100% (1)

- 010 - RT-flex - W-X Design Aspect - Rev - 002Document13 pages010 - RT-flex - W-X Design Aspect - Rev - 002Alok KumarNo ratings yet

- 100 KvaDocument4 pages100 KvaAndi AnchaNo ratings yet

- Data - BCC 1010P-50Document3 pagesData - BCC 1010P-50Osanebi Chukwudi LuckyNo ratings yet

- Ficha Técnica Daily 55S17H - W WB 3.400 MMDocument14 pagesFicha Técnica Daily 55S17H - W WB 3.400 MMRodrigo San MartinNo ratings yet

- 08CC05150258 Assembly SchemeDocument1 page08CC05150258 Assembly SchemeBishoo ShenoudaNo ratings yet

- 280kw Cummins GeneratorDocument3 pages280kw Cummins GeneratorChen CarolineNo ratings yet

- Turbine Presentation ForgetDocument97 pagesTurbine Presentation ForgetavtarsinghsandhuNo ratings yet

- 55S17H W New Daily Euro Vi (F1C 3.0L) : Engineering Profile 1 31 Mar 2015Document14 pages55S17H W New Daily Euro Vi (F1C 3.0L) : Engineering Profile 1 31 Mar 2015emiliqn velikovNo ratings yet

- 15kW Diesel Generator Set Technical SpecificationsDocument1 page15kW Diesel Generator Set Technical SpecificationsJesús David Pesántez BalarezoNo ratings yet

- Genset Perkins 30 KVADocument4 pagesGenset Perkins 30 KVAJay InsNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Gamma Beta Functions Math - 2 Integral Calculus and Ordinary Differential Equations AIUB14ENGGDocument17 pagesGamma Beta Functions Math - 2 Integral Calculus and Ordinary Differential Equations AIUB14ENGGExtra EmailNo ratings yet

- Ex - 3.5 Math - 2 Differential Equations AIUB14ENGG PDFDocument13 pagesEx - 3.5 Math - 2 Differential Equations AIUB14ENGG PDFExtra EmailNo ratings yet

- Ex - 3.5 Math - 2 Differential Equations AIUB14ENGG PDFDocument13 pagesEx - 3.5 Math - 2 Differential Equations AIUB14ENGG PDFExtra EmailNo ratings yet

- Ex - 2.2 Math - 2 Differential Equations AIUB14ENGGDocument8 pagesEx - 2.2 Math - 2 Differential Equations AIUB14ENGGExtra EmailNo ratings yet

- Ex - 2.1 Math - 2 Differential Equations AIUB14ENGGDocument10 pagesEx - 2.1 Math - 2 Differential Equations AIUB14ENGGExtra EmailNo ratings yet

- Yamaha 20C Service Manual (En)Document284 pagesYamaha 20C Service Manual (En)bernabel pirela50% (2)

- PDF 1Document45 pagesPDF 1Deepak ShoriNo ratings yet

- CAT Engine Specifications: G3306B TA Gas Petroleum EngineDocument4 pagesCAT Engine Specifications: G3306B TA Gas Petroleum EngineSrija sagiNo ratings yet

- Linear Combustion Engine As Main Energy Unit For Hybrid VehiclesDocument9 pagesLinear Combustion Engine As Main Energy Unit For Hybrid Vehiclesgamer777No ratings yet

- Troubleshooting Power Train: Replacing the Carrier in a Swing ReductionDocument13 pagesTroubleshooting Power Train: Replacing the Carrier in a Swing ReductionFaizSaifanyNo ratings yet

- Air Compressor - Notes and QuestionnarieDocument89 pagesAir Compressor - Notes and QuestionnariedevNo ratings yet

- NSF250R PRESS INFORMATIONDocument24 pagesNSF250R PRESS INFORMATIONGuy ProcterNo ratings yet

- Mar PowerDocument29 pagesMar PowerSeilfred SanggoNo ratings yet

- Stanadyne de Pump Timing Instructions PDFDocument1 pageStanadyne de Pump Timing Instructions PDFSMITINo ratings yet

- 2 Steam TurbineDocument46 pages2 Steam TurbineWahyu MxNo ratings yet

- 5 Protective DevicesDocument44 pages5 Protective DevicesAdrian CamasosaNo ratings yet

- 3516 BlekDocument9 pages3516 BlekAna María AcostaNo ratings yet

- ON-BOARD DIAGNOSTICS FOR V8 ENGINESDocument124 pagesON-BOARD DIAGNOSTICS FOR V8 ENGINESJennifer Lynn HutsonNo ratings yet

- Kit 1630258704197Document1,247 pagesKit 1630258704197R SuMmOnNo ratings yet

- Guidance On Continuous Machinery Survey Cms eDocument15 pagesGuidance On Continuous Machinery Survey Cms eKaptan Leventcum100% (1)

- VW CNG Manual SSP 373 d2Document23 pagesVW CNG Manual SSP 373 d2Oskó József100% (2)

- Cylinder Head Gasket - Installation (08 - 2013 - ) (Cylinder Head Assembly) - Toyota Sienna 3.5ltsDocument8 pagesCylinder Head Gasket - Installation (08 - 2013 - ) (Cylinder Head Assembly) - Toyota Sienna 3.5ltsFran SanchezNo ratings yet

- Iae V2500-A5 LTM NeuDocument80 pagesIae V2500-A5 LTM Neuhussainsagarshaik89% (9)

- 1 SMDocument18 pages1 SMYogi Kawar Ganga NathNo ratings yet

- HONDA 1.6 L i-DTEC DIESEL ENGINEDocument1 pageHONDA 1.6 L i-DTEC DIESEL ENGINEPedroNo ratings yet

- Measurement Record AnalysisDocument1 pageMeasurement Record Analysistomi100% (1)

- Torque Specs for 1KD-FTV Diesel Engine PartsDocument1 pageTorque Specs for 1KD-FTV Diesel Engine PartsTAMIRU TESFAYE100% (1)

- 10 Aleson Shipping Inc. Anika Gayle 1 PDFDocument1 page10 Aleson Shipping Inc. Anika Gayle 1 PDFAlan Tul-idNo ratings yet

- Subaru-Legacy 2005 EN Manual de Taller Control de Emisiones 17fbaf51b7Document9 pagesSubaru-Legacy 2005 EN Manual de Taller Control de Emisiones 17fbaf51b7miguelNo ratings yet

- Gas Turbine Power Plant PDFDocument28 pagesGas Turbine Power Plant PDFPao CastillonNo ratings yet

- PARTS CATALOGDocument28 pagesPARTS CATALOGHalim BessoufNo ratings yet

- Austin Cars From 1932Document103 pagesAustin Cars From 1932Chris ThorleyNo ratings yet

- Chapter 2: Compressible Flow: But Use R 287Document5 pagesChapter 2: Compressible Flow: But Use R 287MikeMichaelNo ratings yet

- Pulkit PPT Steam Turbine3Document42 pagesPulkit PPT Steam Turbine3Abhishek KumarNo ratings yet

- Om 457 La Bluetec /om 457 La Om 460 La Bluetec /om 460 La: Operator'S ManualDocument104 pagesOm 457 La Bluetec /om 457 La Om 460 La Bluetec /om 460 La: Operator'S Manualhicham belallamNo ratings yet