Professional Documents

Culture Documents

Fina Ponya-Model PDF

Uploaded by

Nursyarafina Binti SulaimanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fina Ponya-Model PDF

Uploaded by

Nursyarafina Binti SulaimanCopyright:

Available Formats

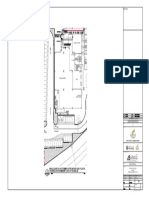

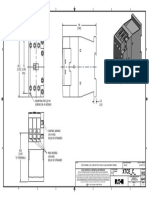

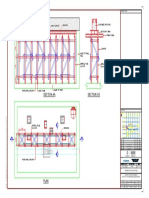

CROSS SECTIONAL VIEW OF

TUBE BUNDLES

TOP VIEW OF KETTLE REBOILER

C:\Users\user\Desktop\UKM_logo_4C_teks-hitam.png

Faculty of Engineering & Built Environment

Chemical Engineering Programme

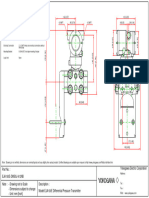

CROSS SECTIONAL VIEW OF

WELDING NECK FLANGE Project Title:

Production of Bio-hydrogen &

Polyhydroxylbutyrate (PHB) from POME

Drawing Title:

Mechanical Design of Kettle Reboiler

Heater HE-102

Prepared By:

KK 5

FRONT VIEW OF KETTLE REBOILER

Group Members:

SADDLE SUPPORT OF

1.) Nursyarafina binti Sulaiman (A158566)

HEATER

2.) Chong Shin Yie (A159130)

3.) Thivagaran A/L Veeraiya (A157583)

4.) Vennisha Thevy A/P Parmusuan (A158752)

5.) Nur Afiqah binti Othman (A158752)

Scale:

t1 Drawing Not to Scale

120° All Dimensions in mm

Drawn By:

V

Nursyarafina binti Sulaiman (A158566)

t1

Submission Date:

6th March 2020

J

E Design Specifications:

C - Design temperature: 300 °C

- Design pressure: 3 bar

- MAWP vessel:

SADDLE SIZING

- No. of tube: 32

Bolt Bolt

VESSEL DIAMETER V C E J t1 t2

diameter holes - Type of material: SA-216 Type WCA

269 245 250 220 60 5 6 20 25 Carbon Steel

WELDING NECK FLANGES - Joint: Double welded with full radiograph

DIMENSION (MM) - Flange: Joint with welding-neck flange

NO. NOMINAL PIPES SIZES (MM) d1 D b h1 d4 f Bolting d2 k h2 No. bolt class 150 for all pipes

S1/S2/S3/S4 80 88.9 190 16 42 128 3 M16 18 150 10 8

You might also like

- Standard Two-Storey SCHL BLDG POWDocument160 pagesStandard Two-Storey SCHL BLDG POWKaren Balisacan Segundo Ruiz100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Aramco Standard List (Total)Document188 pagesAramco Standard List (Total)Norman Morales100% (5)

- 13-3 FMDS Steam TurbinesDocument38 pages13-3 FMDS Steam TurbinesAnonymous LwH2t4100% (2)

- Surge ArrestorDocument47 pagesSurge ArrestorKlayNo ratings yet

- 5555 FT141121 Teslastuff 4 Inch Tesla Coil Plans Vs 1.3sDocument33 pages5555 FT141121 Teslastuff 4 Inch Tesla Coil Plans Vs 1.3sedgarpol100% (1)

- Booty C Girls NutritionDocument41 pagesBooty C Girls NutritionMargarita Kotova100% (6)

- Hayward Baker GroutingDocument43 pagesHayward Baker GroutingfiqNo ratings yet

- Standard Four-Storey SCHL BLDG POWDocument152 pagesStandard Four-Storey SCHL BLDG POWAl Patrick Dela CalzadaNo ratings yet

- State of The Art Atrium Smoke ControlDocument12 pagesState of The Art Atrium Smoke ControlBasil OguakaNo ratings yet

- 2023-Pow-Qecdtr-Ultimate FinalDocument235 pages2023-Pow-Qecdtr-Ultimate FinalEvaresto Cole MalonesNo ratings yet

- AR0500B5521DDocument3 pagesAR0500B5521DLUKAS100% (1)

- Inc MCC 400Document14 pagesInc MCC 400Fatholla SalehiNo ratings yet

- SR - Single Package - CO (Const) - Saudi (R410A60Hz) - MFL67452911 - 6CUK0-01A (June 2015) - (7.5 To 15 TR) .Technical DataDocument41 pagesSR - Single Package - CO (Const) - Saudi (R410A60Hz) - MFL67452911 - 6CUK0-01A (June 2015) - (7.5 To 15 TR) .Technical DataShaikhMazharAhmedNo ratings yet

- ATA 71 Eng Operating LimitsDocument13 pagesATA 71 Eng Operating Limitsanarko arsipelNo ratings yet

- Ceramic Mold (Cover Heater) - Rev3Document12 pagesCeramic Mold (Cover Heater) - Rev3Kristanto WahyudiNo ratings yet

- PW-01-100 1 Ground Floor Containment Layout-Pw-01-1001-B PDFDocument1 pagePW-01-100 1 Ground Floor Containment Layout-Pw-01-1001-B PDFfarshidNo ratings yet

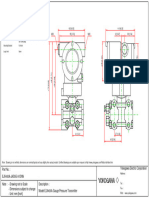

- Part No.: EJA110E-JVS4G-93CEN/FU1/D1 Description: Model EJA110E Differential Pressure Transmitter Yokogawa Electric CorporationDocument1 pagePart No.: EJA110E-JVS4G-93CEN/FU1/D1 Description: Model EJA110E Differential Pressure Transmitter Yokogawa Electric CorporationJuan ShunaNo ratings yet

- Part No.: EJX110A-JVS4G-917EB/D3/X2/HC/N4 Description: Model EJX110A Differential Pressure Transmitter Yokogawa Electric CorporationDocument1 pagePart No.: EJX110A-JVS4G-917EB/D3/X2/HC/N4 Description: Model EJX110A Differential Pressure Transmitter Yokogawa Electric Corporationv_serrano_yNo ratings yet

- PW 01 310 PW 03 310Document1 pagePW 01 310 PW 03 310farshidNo ratings yet

- Shop Drawing List Mechanical: Remarks Scale Drawing Title DWG No. NODocument1 pageShop Drawing List Mechanical: Remarks Scale Drawing Title DWG No. NORafik MaulanaNo ratings yet

- PW-01-100 1 Ground Floor Containment Layout-Pw-01-1001-2b PDFDocument1 pagePW-01-100 1 Ground Floor Containment Layout-Pw-01-1001-2b PDFfarshidNo ratings yet

- Gammon Construction Limited Central Police Station Conservation and Revitalisation Project Management Organization ChartDocument1 pageGammon Construction Limited Central Police Station Conservation and Revitalisation Project Management Organization ChartBob ChinNo ratings yet

- SZ - DF20A-DF15A Product Info-View1Document4 pagesSZ - DF20A-DF15A Product Info-View1Yamahauki SusukiNo ratings yet

- Part List of Main SubstationDocument6 pagesPart List of Main SubstationFatholla SalehiNo ratings yet

- DD DNV Gardu PLN Alt1 ModelDocument1 pageDD DNV Gardu PLN Alt1 ModelPaijo TejoNo ratings yet

- Nawcpf Msbi NCPF 360 Me DRW 32042 000 Typical Pipeline MarkerDocument1 pageNawcpf Msbi NCPF 360 Me DRW 32042 000 Typical Pipeline MarkernizardsouissiNo ratings yet

- Outline, Genset: A055J590 ArrowDocument2 pagesOutline, Genset: A055J590 ArrowmahranNo ratings yet

- Muhammad Raihan Budiman - Tugas 4 - SI-3121Document1 pageMuhammad Raihan Budiman - Tugas 4 - SI-3121M Raihan BudimanNo ratings yet

- Recommendation Drawing Upgrade Relay SEPAM2000 To SR745 (By Dimas)Document7 pagesRecommendation Drawing Upgrade Relay SEPAM2000 To SR745 (By Dimas)DanaNo ratings yet

- Steel CalculationDocument43 pagesSteel Calculationmoonelise9No ratings yet

- EJA130E DMS5J 912NB YokogawaFieldInstrumentDivision 2DSalesDrawing 03 26 2024Document1 pageEJA130E DMS5J 912NB YokogawaFieldInstrumentDivision 2DSalesDrawing 03 26 2024wega deNo ratings yet

- Mh.43a DesignDocument3 pagesMh.43a DesignAry CivilNo ratings yet

- Mundipharma MSB 05 01 Control As BuiltDocument4 pagesMundipharma MSB 05 01 Control As BuiltKarushan R.MNo ratings yet

- Eeaa090571-2 - r0.24.02.2022 - Layout and RCC Details of Columns 1Document1 pageEeaa090571-2 - r0.24.02.2022 - Layout and RCC Details of Columns 1Mohd RosleeNo ratings yet

- Double P Land Co., LTD.: For ConstructionDocument1 pageDouble P Land Co., LTD.: For ConstructionSarut WanamkangNo ratings yet

- Annex 01Document11 pagesAnnex 01rukshan jayasingheNo ratings yet

- B Tech-CompressedDocument1 pageB Tech-Compressedumesh uikeyNo ratings yet

- Wistron DW50 Winery15 - 48.4et05.0sa 09289-Sa PDFDocument88 pagesWistron DW50 Winery15 - 48.4et05.0sa 09289-Sa PDFWillian AngeloNo ratings yet

- Wistron Winery N11m-Ge - Rev x01Document91 pagesWistron Winery N11m-Ge - Rev x01art techNo ratings yet

- Cut Out For Drilling Template: Drawing TitleDocument2 pagesCut Out For Drilling Template: Drawing TitleJd DibrellNo ratings yet

- HP 15-J 15cru 6050a2548201-Mb-X01 Si 2012-10-03Document58 pagesHP 15-J 15cru 6050a2548201-Mb-X01 Si 2012-10-03Abnesis NesisNo ratings yet

- Tu Phu Tai 22kV (Giai Doan 2)Document119 pagesTu Phu Tai 22kV (Giai Doan 2)Nguyễn Minh ĐứcNo ratings yet

- HP 15-J 15CRU 6050A2548201-MB-A02 MV 2013-01-18 Schematic DiagramDocument58 pagesHP 15-J 15CRU 6050A2548201-MB-A02 MV 2013-01-18 Schematic Diagramrishi vaghelaNo ratings yet

- fbdd6 - Sony mbx250 z50 hr1m0302Document74 pagesfbdd6 - Sony mbx250 z50 hr1m0302Double HelixNo ratings yet

- Daily Report Hydro 5 AprilDocument1 pageDaily Report Hydro 5 Aprildeny fajarNo ratings yet

- Detail"A": Elevation SectionDocument1 pageDetail"A": Elevation Sectionlebanese.intlNo ratings yet

- XTCE C .IdwDocument1 pageXTCE C .IdwSilverio LeonNo ratings yet

- Trim and Stability BookletDocument336 pagesTrim and Stability BookletPanagiotis RappasNo ratings yet

- Toll Collection System Reflected Ceiling Plan (S2-001) : Metro Manila SkywayDocument1 pageToll Collection System Reflected Ceiling Plan (S2-001) : Metro Manila SkywayRhowelle TibayNo ratings yet

- LOT 1 - Annex 03 - Civil Drawings Batteries RoomDocument6 pagesLOT 1 - Annex 03 - Civil Drawings Batteries RoomMhmd almualmNo ratings yet

- Loc-5 - B1 - Fromwork SupportDocument1 pageLoc-5 - B1 - Fromwork SupportSubhash SugathanNo ratings yet

- NORMAN MYANMAR - CATWALK FACTORY No 01 & 08 - PPD - 28 Apr 2021Document3 pagesNORMAN MYANMAR - CATWALK FACTORY No 01 & 08 - PPD - 28 Apr 2021thang TranNo ratings yet

- 01 DrawingDocument1 page01 DrawingAbm Faruk E MonjurNo ratings yet

- Manual For SP1Document19 pagesManual For SP1Mai Huong Bui ThiNo ratings yet

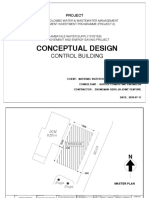

- Contractor Employer Palembang City Sewerage Project Package A2 Construction of A Domestic Wastewater Treatment Plant & Pump StationDocument1 pageContractor Employer Palembang City Sewerage Project Package A2 Construction of A Domestic Wastewater Treatment Plant & Pump StationDoni TriatmojoNo ratings yet

- Third Floor (Lvl. +11870mm) Beam Layout Plan Top Beam Layout PlanDocument1 pageThird Floor (Lvl. +11870mm) Beam Layout Plan Top Beam Layout PlanLatip KrSharmaNo ratings yet

- B&G Round Floor Bath TileDocument3 pagesB&G Round Floor Bath TileUmair HassanNo ratings yet

- EJX430A JAS5G 91DNN YokogawaFieldInstrumentDivision 2DSalesDrawing 12 22 2023Document1 pageEJX430A JAS5G 91DNN YokogawaFieldInstrumentDivision 2DSalesDrawing 12 22 2023Arash SepahvandNo ratings yet

- Concrete LCDA - Technical Data Panbeton OriginDocument8 pagesConcrete LCDA - Technical Data Panbeton OriginGeneral RobertNo ratings yet

- Tiempo de Impresión VT3500Document5 pagesTiempo de Impresión VT3500AgostinhoNo ratings yet

- M12 - Data Sheet - Fire Dampers: Index of Revisions Rev. Description And/Or Revised SheetsDocument3 pagesM12 - Data Sheet - Fire Dampers: Index of Revisions Rev. Description And/Or Revised SheetsReno MeatShopNo ratings yet

- Building # 28 Chlorination Room Package - 57 - Substructure - Controlled Copy-1Document6 pagesBuilding # 28 Chlorination Room Package - 57 - Substructure - Controlled Copy-1sk mukhtarNo ratings yet

- Seci-Dvc-Ktps6mw-Dwg-Civ-34 - MCR - Foundation General Arrangement and Reinforcement Details - R02 - Cat-IDocument2 pagesSeci-Dvc-Ktps6mw-Dwg-Civ-34 - MCR - Foundation General Arrangement and Reinforcement Details - R02 - Cat-Ipravin singhNo ratings yet

- Bore Hole Log: Hole No: BBL 2ADocument4 pagesBore Hole Log: Hole No: BBL 2AEvvy MarchiantoNo ratings yet

- W3SE 5702 Tower Foundation-T1Document1 pageW3SE 5702 Tower Foundation-T1ankitrj297No ratings yet

- Layer Flag (Differentiate From Assy P/N) Layer Name (See Module Table) Base Number D92-1371-9 000000Document12 pagesLayer Flag (Differentiate From Assy P/N) Layer Name (See Module Table) Base Number D92-1371-9 000000carlosar1477No ratings yet

- RAPPORT 8D SoverepDocument7 pagesRAPPORT 8D SoverepSarah ADNANENo ratings yet

- Dewatering Adz CombinedDocument11 pagesDewatering Adz CombinedJhonnel PunzalanNo ratings yet

- Feasibility of A Mushroom Farm in The Bunkers in El Buey: Sarah Muse, Serena Soltero, Matthew SuarezDocument28 pagesFeasibility of A Mushroom Farm in The Bunkers in El Buey: Sarah Muse, Serena Soltero, Matthew SuarezRahul SharmaNo ratings yet

- Science Notes For Class9th CbseDocument3 pagesScience Notes For Class9th CbseMithilesh Kr PremNo ratings yet

- NQ Specification 01Document8 pagesNQ Specification 01Jose MonroyNo ratings yet

- Aeg L82470bi PDFDocument72 pagesAeg L82470bi PDFCecília PerdigãoNo ratings yet

- PHILIPS WT120C L1500 1xLED60S 840 PDFDocument3 pagesPHILIPS WT120C L1500 1xLED60S 840 PDFNavneet SinghNo ratings yet

- IntJAdhesAdhes67 (2016) 38-43 BoutarYDocument6 pagesIntJAdhesAdhes67 (2016) 38-43 BoutarYPaulo UtargNo ratings yet

- Boiler Inspector TRAINING - 2021Document8 pagesBoiler Inspector TRAINING - 2021SUNIL BABURAO GAVADENo ratings yet

- 2012 Polymer-Composite Materials For Radiation ProtectionDocument10 pages2012 Polymer-Composite Materials For Radiation Protectionduque_stradaNo ratings yet

- 02 ExplorationDocument50 pages02 ExplorationYernar TiyntayevNo ratings yet

- Automatic Tank Cleaning STS English BrochureDocument4 pagesAutomatic Tank Cleaning STS English BrochureVerghese OommenNo ratings yet

- Magnesium and Hydrochloric Acid Reaction LabDocument7 pagesMagnesium and Hydrochloric Acid Reaction LabDavid Michie0% (1)

- Water Irrigation System ThesisDocument8 pagesWater Irrigation System Thesiscarolinafoxpembrokepines100% (2)

- Petromoc, SA Petr Ó Leos de Mo Ç AmbiqueDocument16 pagesPetromoc, SA Petr Ó Leos de Mo Ç AmbiqueFredNo ratings yet

- Komatsu Crawler Doozer D37pxi 23 Shop ManualDocument20 pagesKomatsu Crawler Doozer D37pxi 23 Shop Manualrodney100% (35)

- Samsung Moteur FrigoDocument27 pagesSamsung Moteur Frigomeone99No ratings yet

- Water Supply NoteDocument17 pagesWater Supply NoteMithun KanishkaNo ratings yet

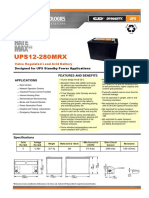

- UPS12-280MRX: Valve Regulated Lead Acid BatteryDocument2 pagesUPS12-280MRX: Valve Regulated Lead Acid BatteryCristopher JayloNo ratings yet

- 7.4.6 SMC-209-C - enDocument22 pages7.4.6 SMC-209-C - enShahbazZahidNo ratings yet

- Report On Air PollutionDocument3 pagesReport On Air PollutionpriyanshiNo ratings yet

- User Manual: PBLH™ SeriesDocument11 pagesUser Manual: PBLH™ SeriesAxel BelzitiNo ratings yet

- Nitrogen Gas Charging Kits Brochure PDFDocument12 pagesNitrogen Gas Charging Kits Brochure PDFluisedonossaNo ratings yet