Professional Documents

Culture Documents

Types of Millling Machines

Uploaded by

Lester Sadia Panit0 ratings0% found this document useful (0 votes)

47 views4 pagesOriginal Title

Types of Millling machines.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views4 pagesTypes of Millling Machines

Uploaded by

Lester Sadia PanitCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

Types of Millling machines:

For general shop work, the most used type of milling machine is

the column and knee type machine.

The column and knee type milling machines are classified.

According to the various methods of

supplying power to the table.

Different movements of the table.

The different axis of rotation of the main spindle.

1. Hand Milling Machine

It simplest of all types of milling machine

in which table feeding is controlled by

hand. The cutter is mounted on a

horizontal arbour and is rotated by power.

This type of milling machine is of small in

size and suitable for light and simple

milling operations. For Example,

machining slots, grooves, and keyway.

2. Plain Milling Machine

These are much stronger than hand millers. The table

feeding is done either by hand or power. the plain

milling machine having a horizontal spindle is also

called as a horizontal spindle milling machine. The

table may be fed in a longitudinal, cross or vertical

directions.

The feed is:

Longitudinal – when the table is moved at right

angles to the spindle.

Cross – when the table is moved parallel to the

spindle.

Vertical – when the table is adjusted in the vertical

plane.

3. Universal Milling Machine

It can be adapted to a wide range of milling

operations. Here the table can be swivelled to any

angle up to 45-degrees on either side of the normal

position.

In addition to 3 movements as mentioned earlier in

a plain milling machine, the table may have the

fourth movement when it is fed at an angle to the

milling cutter. Helical milling operation can also be

performed. The capacity of this type of machine is

increased by using special attachments such as

Dividing head or index head.

Vertical milling attachment.

Rotary attachment.

Slotting attachment.

4. Ominversal Milling Machine

Here the table also has four movements of the

universal milling machine. It can also be tilted in

a vertical plane by providing a swivel

arrangement at the knee.

The additional swivelling arrangement of the

table helps in machining spiral grooves in

reamers and bevel gears.

5. Vertical Milling Machine

Here the position of the spindle is

vertical or perpendicular to the

table. This type of machine is

adapted for machining grooves,

slots, and flat surfaces.

The spindle head is clamped to

the vertical column which is

swivelled at an angle. It allowing

the milling cutter fixed on the

spindle to work on angular

surfaces. In some machines, the

spindle can also be adjusted up

or down relative to the work.

6.Planer-style Milling Machine

This machine type is basically the same as the bed

mill. However, the planner-style includes cutters

and heads that allow for a wider range of milling

actions. In a planer, the table moves to give the

cutting speed.

You might also like

- 003 MillingDocument59 pages003 MillingKalikene MwambeloNo ratings yet

- Milling Machines and CuttersDocument15 pagesMilling Machines and CuttersPamela SidicNo ratings yet

- Milling: History of The Milling MachineDocument11 pagesMilling: History of The Milling MachineNikhil PrasannaNo ratings yet

- Milling Machines: Milli e Ains A Ause e H Ma - Why A - Up Rio e E, MD IsDocument10 pagesMilling Machines: Milli e Ains A Ause e H Ma - Why A - Up Rio e E, MD Isnitin gaikwadNo ratings yet

- Column and Knee Type MillingDocument17 pagesColumn and Knee Type Millingsatishbandla1991100% (2)

- MillingDocument37 pagesMillingKemba DonyeNo ratings yet

- MTDMDocument14 pagesMTDMsree_guruNo ratings yet

- Milling MachineDocument15 pagesMilling MachineAfif Adnan AbdurrahmanNo ratings yet

- Drilling MachinesDocument68 pagesDrilling MachinesDeenaKriShnanNo ratings yet

- Manufacturing Processes-1 (131903) : Ch-3 Drilling Machines Meet PatelDocument68 pagesManufacturing Processes-1 (131903) : Ch-3 Drilling Machines Meet PatelPawan Kumar GoyalNo ratings yet

- ch8 1Document1 pagech8 1Dumisani SitholeNo ratings yet

- Attachments For MillingDocument59 pagesAttachments For MillingLibin AbrahamNo ratings yet

- Milling Machine PresentationDocument30 pagesMilling Machine PresentationYash Jain100% (1)

- Milling MachineDocument6 pagesMilling MachineAnand BalajiNo ratings yet

- Mamam601 Part IIDocument55 pagesMamam601 Part IIHirwa jean de DieuNo ratings yet

- MillingmachineDocument46 pagesMillingmachineAmman ButtNo ratings yet

- (Print 3) Milling MachineDocument32 pages(Print 3) Milling MachineMunem Shahriar100% (1)

- 2 Machine Tools - Milling, & ShaperDocument73 pages2 Machine Tools - Milling, & ShaperGAURAV DEVNo ratings yet

- MP GTU Study Material E-Notes Unit-5 06042020034257PMDocument36 pagesMP GTU Study Material E-Notes Unit-5 06042020034257PMChandresh RanaNo ratings yet

- Prepared by S.sanyasirao, Assistant Professor, VITS College of Engg., Sontyam, VizagDocument14 pagesPrepared by S.sanyasirao, Assistant Professor, VITS College of Engg., Sontyam, Vizagsanyasirao1No ratings yet

- Handout131Milling Machines and CuttersDocument23 pagesHandout131Milling Machines and CuttersPamela SidicNo ratings yet

- 5 - Shaping Machine ME 46 Machine Shop Theory and PracticeDocument38 pages5 - Shaping Machine ME 46 Machine Shop Theory and PracticeCHRISTIAN JAY TESNADONo ratings yet

- Milling MachineDocument21 pagesMilling MachineZahra BatoolNo ratings yet

- Milling Machine & Operations (PROF GHW)Document35 pagesMilling Machine & Operations (PROF GHW)VINEET VYASNo ratings yet

- Pe Day 10Document6 pagesPe Day 10Libin AbrahamNo ratings yet

- MT IiDocument211 pagesMT Iiboopathi rajaNo ratings yet

- Sigma Institute of Engineering Mechanical Engineering DepartmentDocument37 pagesSigma Institute of Engineering Mechanical Engineering DepartmentSHIVAM PARIHARNo ratings yet

- WS Expt7Document4 pagesWS Expt7shwetaNo ratings yet

- Milling Machine PDFDocument64 pagesMilling Machine PDFJhon Ashley NahibuanNo ratings yet

- Machine Shop Theory and Practi Ce: Mechanical EngineeringDocument9 pagesMachine Shop Theory and Practi Ce: Mechanical EngineeringJohn BorjaNo ratings yet

- Lec 2 MillingDocument51 pagesLec 2 MillingHammad RazaNo ratings yet

- Experiment 5 PTDocument3 pagesExperiment 5 PTJanvi TomarNo ratings yet

- Report 2 - MillingDocument34 pagesReport 2 - Millingمحمد طه100% (1)

- Machine Shop TheoryDocument28 pagesMachine Shop Theoryjulito paquitNo ratings yet

- Drillingmachines 150429104000 Conversion Gate01 PDFDocument57 pagesDrillingmachines 150429104000 Conversion Gate01 PDFTushar PatelNo ratings yet

- Unit III Milling Machine and Slotter 4SEM MP GCOE S N GANDHAREDocument20 pagesUnit III Milling Machine and Slotter 4SEM MP GCOE S N GANDHARE40 siddhesh petkarNo ratings yet

- Planing and Slotting OperationsDocument4 pagesPlaning and Slotting Operationsmanish kumarNo ratings yet

- Milling Machine Report DelyDocument10 pagesMilling Machine Report DelyFazdly Azilan0% (2)

- MFT 2 Lab Manual-SasiDocument46 pagesMFT 2 Lab Manual-Sasisikkandar faizNo ratings yet

- MC-MT R16 - Unit-3Document63 pagesMC-MT R16 - Unit-3Anonymous GEHeEQlajbNo ratings yet

- Milling Machines & Operations: Presented By: Dcrust, MurthalDocument11 pagesMilling Machines & Operations: Presented By: Dcrust, MurthalfauzijmtiNo ratings yet

- MILLINGDocument5 pagesMILLINGArun Prasad100% (1)

- Drill PressDocument50 pagesDrill PressLovely Jaze SalgadoNo ratings yet

- Boring MachineDocument49 pagesBoring MachineRohit Ghulanavar100% (3)

- WTP Shaper Machine AssignmentDocument2 pagesWTP Shaper Machine AssignmentRonnick De La TongaNo ratings yet

- Millingmachinehusain 151003135158 Lva1 App6891 PDFDocument49 pagesMillingmachinehusain 151003135158 Lva1 App6891 PDFpatlninadNo ratings yet

- Grinding MachineDocument2 pagesGrinding MachinekiranappuNo ratings yet

- MillingDocument47 pagesMillingAvinash KankipatiNo ratings yet

- Drilling: Drilling Is A Cutting Process That Uses A Drill Bit To Cut or Enlarge A Hole of Circular Cross-Section inDocument9 pagesDrilling: Drilling Is A Cutting Process That Uses A Drill Bit To Cut or Enlarge A Hole of Circular Cross-Section inAekanshNo ratings yet

- Lec4 MillingDocument38 pagesLec4 MillingFELIX KEUYA100% (1)

- NR MillingDocument36 pagesNR MillingSapna VyasNo ratings yet

- Name: Hamza Mahmoud Salah ID: 20162750 Supervisor: DR - Nazieh Hasan /eng. Ahmad AL-dalo Class: Workshop 2Document13 pagesName: Hamza Mahmoud Salah ID: 20162750 Supervisor: DR - Nazieh Hasan /eng. Ahmad AL-dalo Class: Workshop 2Hamza MahmoudNo ratings yet

- Lecture PPT Planer MachinesDocument26 pagesLecture PPT Planer MachinesS S PatelNo ratings yet

- Topic: Milling MachineDocument47 pagesTopic: Milling MachineViasNo ratings yet

- Shaping: OrkingDocument6 pagesShaping: OrkingDevesh TiwariNo ratings yet

- Metal Cutting Lab ManualDocument54 pagesMetal Cutting Lab ManualAbhay Sharma 2K20PE02No ratings yet

- Milling MachiningDocument13 pagesMilling MachiningAshwin KumarNo ratings yet

- Grinding Machines and TypesDocument10 pagesGrinding Machines and TypesNaveen luckyNo ratings yet

- Finaly Work: Cilco Ii SenatiDocument18 pagesFinaly Work: Cilco Ii Senatiomar daniel gonzales ramosNo ratings yet

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingFrom EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNo ratings yet

- Precious Science PDFDocument6 pagesPrecious Science PDFLester Sadia PanitNo ratings yet

- Who Is Sigmund FreudDocument1 pageWho Is Sigmund FreudLester Sadia PanitNo ratings yet

- Science ReviewerDocument1 pageScience ReviewerLester Sadia PanitNo ratings yet

- Origami PDFDocument2 pagesOrigami PDFLester Sadia PanitNo ratings yet

- 12/31/20 DESIGN NO. - SECTION 15985 Sequence of Operation Part 1 - General 1.1. Description of WorkDocument367 pages12/31/20 DESIGN NO. - SECTION 15985 Sequence of Operation Part 1 - General 1.1. Description of WorkJhoNo ratings yet

- Emco Unimat SL and DB Manual (English)Document61 pagesEmco Unimat SL and DB Manual (English)kriskee13100% (28)

- Common Tools and Materials Used in DOMRAC ServicingDocument15 pagesCommon Tools and Materials Used in DOMRAC ServicingAlice100% (1)

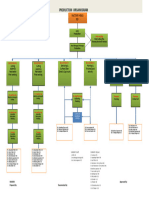

- Production OrganogramDocument1 pageProduction Organogrammd habibur rahman shamimNo ratings yet

- VX SAK Catalogue 2015 enDocument71 pagesVX SAK Catalogue 2015 enCarolDiasNo ratings yet

- Everything You Need To Know About VictorinoxDocument27 pagesEverything You Need To Know About Victorinoxotaviopaulino100% (1)

- Noble Stationery CatalogueDocument5 pagesNoble Stationery Cataloguerads9802No ratings yet

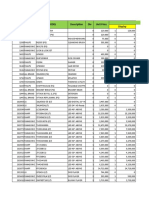

- All Air Filters QPO Eligible Parts Listing Version 2Document243 pagesAll Air Filters QPO Eligible Parts Listing Version 2꧁ Anime TV ꧂No ratings yet

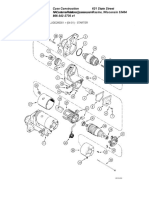

- (04-01) - StarterDocument3 pages(04-01) - StartereduardoNo ratings yet

- APW Technical Drafting 8 W2 3Document10 pagesAPW Technical Drafting 8 W2 3Kyle Cruz100% (1)

- ELS ONE39 EL+Retarder-Prover 208-60 US1 GIACDocument11 pagesELS ONE39 EL+Retarder-Prover 208-60 US1 GIACFreddy MayorgaNo ratings yet

- "Open Sesame": By: Ysms Lecturer: Sir Aliff Farhan Bin Mohd YaminDocument85 pages"Open Sesame": By: Ysms Lecturer: Sir Aliff Farhan Bin Mohd YaminFakhrurrazi HizalNo ratings yet

- Sharpening Knives by Mike CaseyDocument8 pagesSharpening Knives by Mike CaseySteve Wilby100% (1)

- Home Gardener: Outdoor Power EquipmentDocument5 pagesHome Gardener: Outdoor Power EquipmentjamesNo ratings yet

- Worm GearsDocument31 pagesWorm GearsYose MustNo ratings yet

- Hydraulic Seat Puller KitDocument2 pagesHydraulic Seat Puller KitPurwanto ritzaNo ratings yet

- Surface Grinder: Internal Grinding and External GrindingDocument4 pagesSurface Grinder: Internal Grinding and External GrindingMuhammad HaiderNo ratings yet

- Recover TurretDocument2 pagesRecover TurretMichael Naím Dévora QuintanarNo ratings yet

- LG01 - LiuGong Wheel Loader 835H - Product KnowledgeDocument43 pagesLG01 - LiuGong Wheel Loader 835H - Product KnowledgeMUHAMMAD FAUZINo ratings yet

- Tool and Shop Supplies CatalogDocument346 pagesTool and Shop Supplies CatalogLuis MartinezNo ratings yet

- Simple Table Saw Sled v1Document7 pagesSimple Table Saw Sled v1Becon AjoonuNo ratings yet

- PMR Machine Shop KitsDocument1 pagePMR Machine Shop KitsPeanut d. DestroyerNo ratings yet

- PYI Floor Anchor Fitting InstructionsDocument8 pagesPYI Floor Anchor Fitting InstructionsLa Corriente del GolfoNo ratings yet

- Atlas Axillia Product CatalougeDocument30 pagesAtlas Axillia Product CatalougeElijah BayleyNo ratings yet

- Price List of Amwoodo Eco-Products Pvt. LTD.: Bamboo ToothbrushDocument1 pagePrice List of Amwoodo Eco-Products Pvt. LTD.: Bamboo Toothbrushkriti chauhanNo ratings yet

- Be 2Document44 pagesBe 2Muhamad Rakha RadityaNo ratings yet

- Differential SteeringDocument9 pagesDifferential SteeringLucky OkoteNo ratings yet

- Mauser VergueiroDocument10 pagesMauser VergueiroRui GonçalvesNo ratings yet

- Sealmaster MFC SeriesDocument1 pageSealmaster MFC SeriesCardoso MalacaoNo ratings yet

- Baker Wireline CatalogeDocument317 pagesBaker Wireline Catalogesong LiNo ratings yet