100% found this document useful (1 vote)

236 views5 pagesMILLING

Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece through cutting action. There are several types of milling including peripheral, face, and end milling depending on the orientation of the cutter. Milling can be performed using up milling or down milling depending on whether the cutter rotation is in the same or opposite direction of the workpiece feed. The main components of a milling machine include the work table, saddle, knee, head and cutters which can be arranged horizontally or vertically. Common milling machines include column and knee mills, bed mills, rotary table mills, and CNC mills.

Uploaded by

Arun PrasadCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

236 views5 pagesMILLING

Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece through cutting action. There are several types of milling including peripheral, face, and end milling depending on the orientation of the cutter. Milling can be performed using up milling or down milling depending on whether the cutter rotation is in the same or opposite direction of the workpiece feed. The main components of a milling machine include the work table, saddle, knee, head and cutters which can be arranged horizontally or vertically. Common milling machines include column and knee mills, bed mills, rotary table mills, and CNC mills.

Uploaded by

Arun PrasadCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Introduction to Milling: Explains the milling process, its significance, and the classification of milling including face and end milling.

- Methods of Milling: Describes different milling methods such as up milling and down milling, including their characteristics and differences.

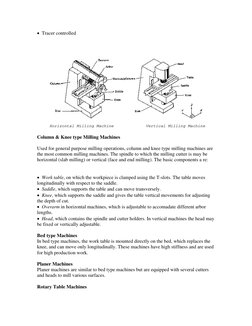

- Types of Milling Machines: Details types of milling machines including column, knee, bed type, and more specialized machines.

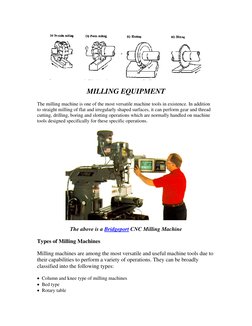

- Milling Equipment: Introduces various milling machines, highlighting their versatility and different specific operations they perform.

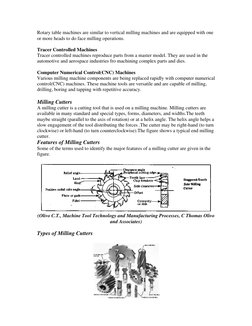

- Features of Milling Cutters: Explores the features and functions of milling cutters and their importance in milling processes.