Professional Documents

Culture Documents

Littelfuse PTC TSM250 130F Datasheet - pdf-1650463 PDF

Uploaded by

geoffffOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Littelfuse PTC TSM250 130F Datasheet - pdf-1650463 PDF

Uploaded by

geoffffCopyright:

Available Formats

PolySwitch® Resettable PPTCs

Telecom > Surface Mount > TS Series

TS Series RoHS

Description

Littelfuse PolySwitch products for telecommunication and

networking devices help to meet the growing demand

for resettable overcurrent protection. They also provide

protection against damage caused by power cross and

induced power surges as defined by ITU, Telcordia

GR1089, and IEC 62368-1. Littelfuse offers chip, surface-

mount, and radial-leaded configurations.

Applications

Networking Machines and Systems:

• Modem • Analog and digital line card

Features

• Phone set • xDSL modem and splitter

• Resettable overcurrent protection • Fax machine • Powered Ethernet system

• Fast time-to-trip • Phone wall outlet • VoIP (Voice over Internet

• Resistance sorted and matched devices available • Alarm system Protocol) equipment

• Low parasitic capacitance/flat impedance with frequency • PBX system • LAN, WAN equipment

• Recognized to UL 1434, approved to CSA TIL No. CA-3A • MDF module • Customer premise equipment

and EN 60730-1. • Access network hardware

• T1/E1 equipment

Agency Approvals Additional Information

AGENCY AGENCY FILE/CERTIFICATE NUMBER

E74889* Datasheet Resources Samples

78166*

72161787*

* See Electrical Characteristic Table for approved part numbers.

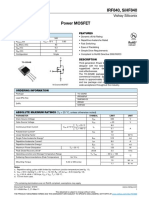

Electrical Characteristics

VMAX IMAX

Part

IH IT Operating Interrupt Interrupt PD Typ Max Time-to-trip RMIN RMAX R1MAX Agency Approvals

Number

(A) (A) (VDC) (VRMS) (A) (W) (A) (s) (Ω) (Ω) (Ω)

TS250/TSL250/TSM250/TSV250 – Surface-mount — 250VAC

TSL250-080F 0.080 0.240 80 250 3.0 1.2 1.0 0.8 5.0 11.0 20.0** x x x

TSL250-130F 0.130 0.260 60 250 3.0 1.5 1.0 2.0 4.0 8.0 12.0** — — —

0.130 0.260 60 250 3.0 1.1 1.0 0.9 6.5 12.0 20.0**

TS250-130F x x x

— — 60 600 1.0 — — — — — —

0.130 0.260 60 250 3.0 1.1 1.0 1.4 6.5 9.0 15.0**

TS250-130F-RA x x —

— — 60 600 1.0 — — — — — —

0.130 0.260 60 250 3.0 1.1 1.0 0.7 9.0 12.0 20.0**

TS250-130F-RB x x —

— — 60 600 1.0 — — — — — —

0.130 0.260 60 250 3.0 1.1 1.0 1.1 7.0 10.0 17.0**

TS250-130F-RC x x —

— — 60 600 1.0 — — — — — —

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 09/27/19

PolySwitch® Resettable PTCs

Telecom > Surface Mount > TS Series

Electrical Characteristics

VMAX IMAX

Part

IH IT Operating Interrupt Interrupt PD Typ Max Time-to-trip RMIN RMAX R1MAX Agency Approvals

Number

(A) (A) (VDC) (VRMS) (A) (W) (A) (s) (Ω) (Ω) (Ω)

TS250/TSL250/TSM250/TSV250 – Surface-mount — 250VAC

TSM250-130F 0.130 0.260 60 250 3.0 1.5 1.0 2.4 4.0 9.0 15.0 x — —

TSV250-130F 0.130 0.260 60 250 3.0 1.5 1.0 2.0 4.0 7.0 12.0** x x x

TSV250-184F 0.184 0.690 100 250 10.0 0.9 3.0 0.5 1.2 3.0 4.0** x — —

TS600 – Surface-mount — 600VAC (Single Channel)

TS600-170F 0.170 0.400 60 600 3.0 2.5 1.0 10.0 4.0 9.0 18.0 x x —

TS600-200F-RA-B-0.5 0.200 0.400 60 600 3.0 2.5 1.0 12.0 4.0 7.5 13.5 x x —

TS600-400F 0.400 1.000 60 600 3.0 2.0 3.0 5.0 0.5 1.1 2.0 x x —

TSM600 – Surface-mount — 600VAC (Dual Channel)

TSM600-250F 0.250 0.860 250 600 3.0 2.0 3.0 0.8 1.0 3.5 7.0 x x —

TSM600-250F-RA 0.250 0.860 250 600 3.0 2.0 3.0 1.0 1.0 3.0 5.0 x x —

TSM600-400F 0.400 1.000 250 600 3.0 2.0 3.0 5.0 0.5 1.1 2.0 x — —

Notes:

IH : Hold current: maximum current device will pass without interruption in 20°C still air.

IT : Trip current: minimum current that will switch the device from low resistance to high resistance in 20°C still air.

VMAX Operating : Maximum continuous voltage device can withstand without damage at rated current. This voltage is used for component Recognition under UL1434.

VMAX Interrupt : Maximum voltage that can be safely placed across a device in its tripped state.

IMAX Interrupt : Maximum fault current device can withstand without damage at rated operating voltage. This current is used for component Recognition under UL1434. Devices may trip

safely under higher level power cross conditions to assist equipment in meeting the appropriate ITU, UL60950 or GR1089 industry requirements.

PD : Power dissipated from device when in the tripped state in 20°C still air.

RMIN : Minimum resistance of device as supplied at 20°C unless otherwise specified.

RMAX : Maximum resistance of device as supplied at 20°C unless otherwise specified.

R1MAX : Maximum resistance measured one hour post-trip or post-reflow at 20°C.

** Applies to all products which share the same prefix.

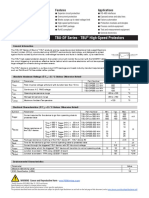

Typical Time-to-Trip Curves at 25°C

100 1000

B B

C

100

10 D A A

Time–to–Trip (s)

Time–to–Trip (s)

10

A 1

B A

C

0.1 D B

0.1

0.01 0.01

0.0 0.5 1.0 1.5 2.0 2.5 3.0 0 1 2 3 4 5 6 7

Fault Current (A) Fault Current (A)

TS250 TS600/TSM600

A = TSV250-184F C = TS250-130F A = TS600-400/TSM600-400F

B = TSV250-130F/TSL250-130F/ D = TSL250-080F B = TSM600-250F/TS600-170F/200F

TSM250-130F

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 09/27/19

PolySwitch® Resettable PPTCs

Telecom > Surface Mount > TS Series

Temperature Rerating

Maximum Ambient Temperature

Part Number** -40°C -20°C 0°C 20°C 40°C 50°C 60°C 70°C 85°C

Hold Current (A)

TS250/TSL250/TSM250/TSV250 – Surface-mount*— 250VAC

TSL250-080F 0.124 0.110 0.095 0.080 0.066 0.059 0.051 0.044 0.033

TSL250-130F 0.208 0.182 0.156 0.130 0.104 0.091 0.078 0.065 0.045

TS250-130F 0.208 0.182 0.156 0.130 0.104 0.091 0.078 0.065 0.045

TSM250-130F 0.208 0.182 0.156 0.130 0.104 0.091 0.078 0.065 0.045

TSV250-130F 0.208 0.182 0.156 0.130 0.104 0.091 0.078 0.065 0.045

TSV250-184F 0.286 0.252 0.218 0.184 0.150 0.134 0.118 0.102 0.075

†

TS600 – Surface-mount — 600VAC (Single Channel)

TS600-170F 0.264 0.230 0.200 0.170 0.140 0.125 0.109 0.094 0.070

TS600-200F 0.310 0.275 0.238 0.200 0.165 0.147 0.128 0.110 0.083

TS600-400F 0.640 0.560 0.480 0.400 0.320 0.270 0.230 0.190 0.130

TSM600 – Surface-mount†— 600VAC (Dual Channel)

TSM600-250F 0.400 0.350 0.300 0.250 0.198 0.170 0.140 0.117 0.083

TSM600-400F 0.640 0.560 0.480 0.400 0.320 0.270 0.230 0.190 0.130

* 250VAC interrupt products may help equipment pass ITU K.20, K.21 and K.45 recommendations and Telcordia GR-1089 Port Type 2 and 4 requirements.

† 600VAC interrupt products may help equipment pass UL60950, TIA-968-A and GR1089 Port Type 1, 3 and 5 requirements.

** Applies to all products which share the same prefix.

TSx250/TS600/TSM600 – Temperature Rerating Curve

200

% of Rated Hold and Trip Current

150

100

50

0

-40 -20 0 20 40 60 80

Device’s Ambient Temperature (˚C)

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 09/27/19

PolySwitch® Resettable PTCs

Telecom > Surface Mount > TS Series

TS250/TSV250/TSM250/TSL250 – Physical Specifications

Tin-plated Brass, Nickel Under-plating (TS250/TSV250/TSL250)

Terminal Material

Tin-plated Copper (TSM250)

Soldering Characteristics IEC 60068-2-58

Note: Devices are not intended to be placed through a reflow process.

TS250/TSV250/TSM250/TSL250 – Environmental Specifications

Test Conditions

60°C, 1000 hrs

Passive Aging

85°C, 1000 hrs

Humidity Aging 85°C, 85% R.H., 500 hrs

Thermal Shock 125°C, -55°C (10 Times)

Solvent Resistance MIL-STD-202, Method 215F

Moisture Resistance Level Level 1, J-STD-020

40°C max, 70% RH max; devices should remain in original sealed bags prior to use.

Storage Conditions

Devices may not meet specified values if these storage conditions are exceeded.

TS600 – Physical Specifications

Terminal Material Tin-plated Brass

Insulating Material Nylon Resin (UL94V-0), 1000V Dielectric Rating

Soldering Characteristics ANSI/J-STD-002, Category 3

Solder Heat Withstand IEC 60068-2-58, Test Tb, Section 8

TS600 – Environmental Specifications

Test Conditions

60°C, 1000 hrs

Passive Aging

85°C, 1000 hrs

Humidity Aging 85°C, 85% R.H., 1000 hrs

Thermal Shock 125°C, -55°C (10 Times)

Solvent Resistance MIL-STD-202, Method 215F

Moisture Resistance Level Level 1, J-STD-020

40°C max, 70% RH max; devices should remain in original sealed bags prior to use.

Storage Conditions

Devices may not meet specified values if these storage conditions are exceeded.

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 09/27/19

PolySwitch® Resettable PPTCs

Telecom > Surface Mount > TS Series

TSM600 – Physical Specifications

Terminal Material Tin-plated Brass

Insulating Material Nylon Resin (UL94V-0), 1000V Dielectric Rating

Soldering Characteristics IEC 60068-2-58, Method 7

Solder Heat Withstand IEC 60068-2-58, Test Tb, Section 5 Method 1a

TSM600 – Environmental Specifications

Test Conditions

60°C, 1000 hrs

Passive Aging

85°C, 1000 hrs

Humidity Aging 85°C, 85% R.H., 1000 hrs

Thermal Shock 125°C, -55°C (10 Times)

Solvent Resistance MIL-STD-202, Method 215J

Moisture Resistance Level Level 2A, J-STD-020

40°C max, 70% RH max; devices should remain in original sealed bags prior to use.

Storage Conditions

Devices may not meet specified values if these storage conditions are exceeded.

Solder Reflow Recommendations

Profile Feature Pb-Free Assembly tp

Tp Critical Zone

Ramp Up TL to Tp

Average ramp up rate (TsMAX to Tp) 3°C/s max

TL

Preheat TsMAX tL

Temperature

• Temperature min (TsMIN) 150°C TsMIN

• Temperature max (TsMAX) 200°C ts

Preheat Ramp Down

• Time (tsMIN to tsMAX) 60-180 s

25

Time maintained above: t 25˚C to Peak

Reflow Profile Time

• Temperature (TL) 217°C

• Time (tL) 60-150 s Solder Reflow

Peak/Classification temperature (Tp) 260°C • Recommended reflow method: IR, vapor phase oven, hot air oven.

• Surface-mount devices are not intended to be wave soldered to

Time within 5°C of actual peak temperature the bottom side of the board.

• Recommended maximum paste thickness of 0.25mm (0.010in).

Time (tp) 20-40 s

• Devices can be cleaned using standard industry methods and solvents.

Ramp down rate 6°C/s max

Rework

Time 25°C to peak temperature 8min max

• If a device is removed from the board, it should be discarded

Note: All temperatures refer to topside of the package, measured on the package body

surface. and replaced with a new device.

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 09/27/19

D E

A

PolySwitch® Resettable PTCs

Telecom > Surface Mount > TS Series

A C

C

C

Dimension Figures C B

C

B

D F

A A C C B

B F

A C D D E E

F E E

A GD D

C C B A C

E D C

C B B

A C

D D D B

A E B B

D

B

F F E E D D D D E E

B B E E

F DA A D

B A

D D E E

A A

D E

A

Figure 1 Figure 2 Figure 3

C B

F

B

E

B F

D D E E

C C A G

D

C E D A C

C C B B

A F F

C B

F

B B Figure

F F 4 D

Figure

D

5

D DE E E E

B F A A G G

D D E E

E E D D A G

Dimensions Aand

EA

Weights D

A

Dimensions in Millimeters (Inches)

Device Mass (g)

Part Number A B C D E F Figure

(Only for Reference)

Min Max Min Max Min Max Min Max Min Max Min Max

TS250/TSL250/TSM250/TSV250 – Surface-mount*— 250VAC

6.7 7.9 2.7 3.7 4.8 5.3 0.2 0.4 2.5 3.1

TSL250-080F — — 3 2.80

(0.27) (0.31) (0.11) (0.15) (0.19) (0.21) (0.01) (0.02) (0.10) (0.12) B

E

6.7 7.9 2.7 3.7 4.8 5.3 0.2 0.4 2.5 3.1

TSL250-130F — — 3 2.80

(0.27) (0.31) (0.11) (0.15) (0.19) (0.21) (0.01) (0.02) (0.10)

D

(0.12)

‡ ‡A C

8.5 9.4 3.4 7.4 0.3 3.8

TS250-130F — — — — — — 1 3.60

(0.34) (0.37) (0.14) (0.29) (0.01) (0.15) B B

E E B

8.2 8.9 9.0 7.8 8.6 3.9 E

0.7

TSM250-130F — — — — — 5 0.64

(0.323) (0.35) (0.354) (0.307) (0.339) D D

(0.154) (0.026)

A A C C

6.10 6.90 3.20 0.56

D 1.90 1.60 2.30

TSV250-130F — — — A — — C 2 2.80

(0.24) (0.27) (0.13) (0.02) (0.08) (0.07) (0.09)

6.10 6.90 3.20 0.56 1.90 1.60 2.30

TSV250-184F — — — — — 2 2.80

(0.24) (0.27) (0.13) (0.02) (0.08) (0.07) (0.09)

TS600 – Surface-mount†— 600VAC (Single Channel)

18.3 19.4 11.6 12.3 7.2 8.3 1.7 2.4 9.9 10.4 1.5 2.3

TS600-170F 4 23.6

(0.72) (0.77) (0.46) (0.49) (0.29) (0.33) (0.07) (0.10) (0.39) (0.41) (0.06) (0.09)

18.3 19.4 11.6 12.3 7.2 8.3 1.7 2.4 9.9 10.4 1.5 2.3

TS600-200F 4 23.6

(0.72) (0.77) (0.46) (0.49) (0.29) (0.33) (0.07) (0.10) (0.39) (0.41) (0.06) (0.09)

18.3 19.4 11.6 12.3 7.2 8.3 1.7 2.4 9.9 10.4 1.5 2.3

TS600-400F 4 19.8

(0.72) (0.77) (0.46) (0.49) (0.29) (0.33) (0.07) (0.10) (0.39) (0.41) (0.06) (0.09)

† 600VAC interrupt products may help equipment pass UL60950, TIA-968-A and GR1089 Port Type 1, 3 and 5 requirements.

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 09/27/19

B

B

F

PolySwitch

E ®

Resettable

D

A

PPTCs

D E

E

Telecom > Surface Mount > TS Series

A

Dimension Figures

C B

F

F

D D E E

A G

E D

A

Figure 6

Dimensions and Weights

Dimensions in Millimeters (Inches)

Device Mass (g)

Part Number A B C D E F G Figure

(Only for Reference)

Min Max Min Max Min Max Min Max Min Max Min Max Min Max

†

TSM600 – Surface-mount — 600VAC (Dual Channel)

17.0 17.60 11.20 11.70 10.40 11.20 4.80 5.20 2.50 2.80 0.60 1.0 2.2 3.1

TSM600-250F 6 31.2

(0.67) (0.69) (0.44) (0.46) (0.41) (0.44) (0.19) (0.20) (0.10) (0.11) (0.02) (0.04) (0.09) (0.12)

17.0 17.60 11.20 11.70 10.40 11.20 4.80 5.20 2.50 2.80 0.60 1.0 2.2 3.1

TSM600-400F B 6 31.2

(0.67) (0.69) (0.44) (0.46) (0.41) (0.44) (0.19) (0.20) (0.10) (0.11) (0.02) (0.04) (0.09) (0.12)

E

† 600VAC interrupt products may help equipment pass UL60950, TIA-968-A and GR1089 Port Type 1, 3 and 5 requirements.

D

A C

Packaging and Marking Information

Part Bag Tape and Reel Standard Package Part Agency

Number Quantity Quantity Quantity Marking Approvals

TS250/TSL250/TSM250/TSV250 – Surface-mount — 250VAC

TSL250-080F-2 — 1,500 7,500 T08 UL, CSA,TÜV

TSL250-130F-2 — 1,500 7,500 T13 —

TS250-130F-2 — 1,500 7,500 T13 UL, CSA, TÜV

TSM250-130F-2 — 600 3,000 T13M UL

TSV250-130F 2500 — 10,000 T13V UL, CSA, TÜV

TSV250-130F-2 — 1,200 6,000 T13V UL, CSA, TÜV

TSV250-184F 2500 — 10,000 T18V UL

TS600 – Surface-mount — 600VAC (Single Channel)

TS600-170F-2 — 300 900 T20 UL, CSA

TS600-200F-RA-2 — 300 900 T20 UL, CSA

TS600-400F-2 — 300 900 T40 UL, CSA

TSM600 – Surface-mount — 600VAC (Dual Channel)

TSM600-250F-2 — 200 600 TSM600 UL, CSA

TSM600-250F-RA-2 — 200 600 TSM600 UL, CSA

TSM600-400F-2 — 200 600 TSM600-4 UL

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 09/27/19

PolySwitch® Resettable PTCs

Telecom > Surface Mount > TS Series

B

B B

A

D

A A A A

D D

A A A A A

B B A A

B B B B

B C B C

B B C C B B C C C D

C CD D

Figure 1 Figure 2

B D

D D

A

D

A A

A E G A A

B B

F B

C B B E

C D

E E F

F F C

C C

Figure 3 Figure 4

Recommended Pad Layouts in millimeters (inches) Nominal

D

Device A B C D E F G Figure

A 4.6 1.80 6.10

TS250 (All) — — — — 1

(0.180) (0.070) (0.240)

B

E 3.20 2.00 6.70 8.20 2.60 3.90

TSM250 (All) — 4

F (0.126) (0.079) (0.264) (0.323) (0.102) (0.154)

C

2.29 2.41 6.35 3.43

TSV250 (All) — — — 2

(0.090) (0.095) (0.250) (0.135)

3.6 1.80 5.50

TSL250 (All) — — — — 1

(0.140) (0.070) (0.220)

10.42 3.30 3.35

TS600 (All) — — — — 1

(0.410) (0.130) (0.132)

5.2 17.80 5.54 6.75 2.08 3.12 8.39

TSM600 (All) 3

(0.205) (0.701) (0.218) (0.266) (0.082) (0.123) (0.331)

Part Ordering Number System

TSx -200 F -RA -B-0.5 -2

Packaging

2 = Tape and Reel

(Blank) = Bulk

B-x.x = Resistance Matched in Bins of x.xΩ (Optional)

Rx = Resistance Range (Optional)

aRoHS Compliant, ELV Compliant

Hold Current (mA)

Product Series

(TS250, TSM250, TSV250, TSL250, TS600, TSM600)

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 09/27/19

PolySwitch® Resettable PPTCs

Telecom > Surface Mount > TS Series

TS250/TSV250/TSM250/TSL250 – Tape and Reel Specifications

TS devices are packaged per EIA 481 and EIA 481-2 standards.

See Figures 1 and 2 for details.

TS250 TSM250 TSV250 TSL250

Dimension Tolerance Dimension Tolerance Dimension Tolerance Dimension Tolerance

Description EIA Mark (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

Carrier Tape Width W 16 ±0.30 24.0 ±0.50 16.0 ±0.30 16 ±0.30

Sprocket Hole Pitch P0 4.0 ±0.10 4.0 ±0.10 4.0 ±0.10 4.0 ±0.10

P1 12.0 ±0.10 16.0 ±0.10 8.0 ±0.10 8.0 ±0.10

P2 2.0 ±0.10 2.0 ±0.10 2.0 ±0.10 2.0 ±0.10

A0 6.9 ±0.23 7.05 ±0.20 5.5 ±0.10 5.5 ±0.10

B0 9.6 ±0.15 8.85 ±0.20 6.2 ±0.10 7.9 ±0.10

B1 max 12.1 — 12.45 — 8.0 — 9.2 —

Sprocket Hole D0 1.5 -0/+0.1 1.5 -0/+1.0 1.55 ±0.05 1.55 ±0.05

Diameter

F 7.5 ±0.10 11.5 ±0.10 7.5 ±0.10 7.5 ±0.10

E1 1.75 ±0.10 1.75 ±0.10 1.75 ±0.10 1.75 ±0.10

E2 min 14.25 — 22.25 — — — — —

Tape Thickness T max 0.4 — 0.5 ±0.50 0.45 — 0.35 —

Tape Thickness with T1 max 0.1 — 0.1 — 0.1 — 0.1 —

Splice Cover Tape

Thickness K0 3.4 ±0.15 8.55 ±0.20 7.0 ±0.10 3.70 ±0.10

Leader min 300 — 300 — 390 — 390 —

Trailer min 300 — 160 — 160 — 160 —

Reel Dimensions

Reel Diameter A max 340 — 390 — 340 — 340 —

Core Diameter N min 50 — 75 — 50 — 50 —

Space between

W1 16.4 -0/+2.0 25.4 ±0.5 16.4 -0/+2.0 16.4 -0/+2.0

Flanges-less Device

Reel Width W2 max 22.4 — 30.4 — 22.4 — 22.4 —

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 09/27/19

PolySwitch® Resettable PTCs

Telecom > Surface Mount > TS Series

TS600/TSM600 – Tape and Reel Specifications

TS devices are packaged per EIA 481 and EIA 481-2 standards.

See Figures 1 and 2 for details.

TS600 TSM600

Dimension Tolerance Dimension Tolerance

Description EIA Mark (mm) (mm) (mm) (mm)

Carrier Tape Width W 32 ±0.3 32 ±0.3

Sprocket Hole Pitch P0 4.0 ±0.1 4.0 ±0.1

P1 16 ±0.1 24 ±0.1

P2 2.0 ±0.1 2.0 ±0.1

A0 10 ±0.1 11.2 ±0.1

B0 19.2 ±0.1 17.8 ±0.1

B1 max 21.6 — 23.45 —

Sprocket Hole Diameter D0 1.5 -0/+1.0 1.5 -0/+1.0

F 14.2 ±0.1 14.2 ±0.1

E1 1.75 ±0.1 1.74 ±0.1

E2 min 28.4 ±0.1 28.4 ±0.1

Tape Thickness T max 0.50 ±0.5 0.5 ±0.5

Tape Thickness with Splice T1 max 0.1 — 0.1 —

K0 13.2 ±0.1 11.9 ±0.1

Leader min 390 — 390 —

Trailer min 160 — 160 —

Reel Dimensions

Reel Diameter A max 360 — 360 —

Core Diameter N min 50 — 50 —

Space between Flanges-less Device W1 32.4 -0/+2.0 32.4 -0/+2.0

Reel Width W2 max 40 — 40 —

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 09/27/19

PolySwitch® Resettable PPTCs

Telecom > Surface Mount > TS Series

Tape and Reel Diagrams

Embossment

P0

T D0 P2

E1

Cover Tape

A0

F

W

E2

B1 K0 B0

T1 P1

Center Lines

of Cavity

Figure 1

W2 (Measured at Hub)

A N (Hub Dia.)

Cover Tape

W1 (Measured at Hub)

Carrier Tape

Embossed Cavity

Figure 2

WARNING

• Users should independently evaluate the suitability of and test each product selected for their own application.

• Operation beyond the maximum ratings or improper use may result in device damage and possible electrical arcing and flame.

• These devices are intended for protection against damage caused by occasional overcurrent or overtemperature fault conditions and should

not be used when repeated fault conditions or prolonged trip events are anticipated.

• Contamination of the PPTC material with certain silicone-based oils or some aggressive solvents can adversely impact the performance

of the devices.

• Device performance can be impacted negatively if devices are handled in a manner inconsistent with recommended electronic, thermal, and

mechanical procedures for electronic components.

• PPTC devices are not recommended for installation in applications where the device is constrained such that its PTC properties are inhibited,

for example in rigid potting materials or in rigid housings, which lack adequate clearance to accommodate device expansion.

• Operation in circuits with a large inductance can generate a circuit voltage (Ldi/dt) above the rated voltage of the device.

Disclaimer Notice - Information furnished is believed to be accurate and reliable. However, users should independently evaluate the suitabil-

ity of and test each product selected for their own applications. Littelfuse products are not designed for, and may not be used in, all applica-

tions. Read complete Disclaimer Notice at www.littelfuse.com/disclaimer-electronics.

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 09/27/19

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Littelfuse:

TSM250-130F-2 TSM250-130F-RA-2

You might also like

- Detailed Lesson Plan Boyle's LawDocument9 pagesDetailed Lesson Plan Boyle's LawTeacher Derick Daet86% (7)

- Concise Guide to OTN optical transport networksFrom EverandConcise Guide to OTN optical transport networksRating: 4 out of 5 stars4/5 (2)

- Datasheet 7090-15Document2 pagesDatasheet 7090-15joseavanegasNo ratings yet

- PCS 9705Document3 pagesPCS 9705elkhalfi50% (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Shadows On The Moon by Zoe Marriott ExtractDocument20 pagesShadows On The Moon by Zoe Marriott ExtractWalker Books100% (1)

- BARACARBDocument2 pagesBARACARBYudha Satria50% (2)

- DataSMART 656Document2 pagesDataSMART 656bakh777196No ratings yet

- Pacsystems Industrial Ethernet Switches: Provide Fast, Seamless, and Resilient ConnectivityDocument12 pagesPacsystems Industrial Ethernet Switches: Provide Fast, Seamless, and Resilient ConnectivityAnthony InostrozaNo ratings yet

- ISO1050Document40 pagesISO1050mar_barudjNo ratings yet

- Product Features: The Industrial Network CompanyDocument4 pagesProduct Features: The Industrial Network CompanyLuiyi Lazcano MontalvoNo ratings yet

- HST-3000 RFC-2544 Ethernet Testing Guide V1.2 PDFDocument24 pagesHST-3000 RFC-2544 Ethernet Testing Guide V1.2 PDFnguyenaituyenNo ratings yet

- JDSU HST-3000 RFC-2544 Testing GuideDocument24 pagesJDSU HST-3000 RFC-2544 Testing GuideMarvin HernandezNo ratings yet

- 99Document3 pages99arf.infinixNo ratings yet

- 7.- QuickServer FS-QS-2X10Document3 pages7.- QuickServer FS-QS-2X10Pio Wilde Quispe GarciaNo ratings yet

- Airlink Rv50X: Peak D/L Peak U/L Frequency Bands Frequency Bands Frequency Bands Regulatory CarrierDocument3 pagesAirlink Rv50X: Peak D/L Peak U/L Frequency Bands Frequency Bands Frequency Bands Regulatory CarrierSolusi MonitoringNo ratings yet

- Industrial Ethernet Switches DatasheetDocument9 pagesIndustrial Ethernet Switches DatasheetHadi KhajoueinejadNo ratings yet

- 716TX Data SheetDocument3 pages716TX Data SheetJosé Raúl Aguilar ArreolaNo ratings yet

- snls551b PDFDocument131 pagessnls551b PDFDaniel Hernández MartínNo ratings yet

- 2819Document1 page2819bibitNo ratings yet

- RS6300Document9 pagesRS6300TB Mohammad Reva ReyhantNo ratings yet

- Moxa PT 7528 Series Datasheet v2.0Document9 pagesMoxa PT 7528 Series Datasheet v2.0lverenzuelaNo ratings yet

- SRWF-1028 Wireless Transceiver Data Module User ManualDocument12 pagesSRWF-1028 Wireless Transceiver Data Module User ManualAndersonNo ratings yet

- MRD-405 Industrial 4G RouterDocument3 pagesMRD-405 Industrial 4G RouterJuan PerezNo ratings yet

- ASCO 5150 Connectivity ModuleDocument2 pagesASCO 5150 Connectivity ModuleYulian Arlex Granda PérezNo ratings yet

- Gateways / Sr360N: Adsl2+ 4-Port Gateway With WifiDocument2 pagesGateways / Sr360N: Adsl2+ 4-Port Gateway With Wifijosh gobinNo ratings yet

- 1283618Document4 pages1283618Trung Pham VanNo ratings yet

- DMR TB9300 BaseStation SpecificationsDocument4 pagesDMR TB9300 BaseStation SpecificationsAlaa NoorNo ratings yet

- Saab-R60-Vdes-Base-Station Datasheet 7000 120 006dDocument2 pagesSaab-R60-Vdes-Base-Station Datasheet 7000 120 006dSameer Abu-AnnadiNo ratings yet

- TS4-A-F (700W) (15A and 25A) (Fire Safety Add-On) Datasheet ENDocument2 pagesTS4-A-F (700W) (15A and 25A) (Fire Safety Add-On) Datasheet ENĐức MinhNo ratings yet

- TR WMX 58 XX DatasheetDocument2 pagesTR WMX 58 XX DatasheetcristhianNo ratings yet

- CJ1W-ETN21: Organically Connect The Production Site and ManagementDocument8 pagesCJ1W-ETN21: Organically Connect The Production Site and ManagementTonyNo ratings yet

- IEEE802Document18 pagesIEEE802api-3829437100% (1)

- Dia 6 Ed 1090112 enDocument14 pagesDia 6 Ed 1090112 enJorge BarrosoNo ratings yet

- Automotive Plant Surge Protection GuideDocument2 pagesAutomotive Plant Surge Protection GuideJuan Carlos Medina GNo ratings yet

- Carver School DatabaseDocument5 pagesCarver School DatabaseLost ContactNo ratings yet

- 304TX DataSheetDocument2 pages304TX DataSheetcarlosorizabaNo ratings yet

- Powerful 2X2 Mimo Airmax Basestation: Models: Rm2-Ti, Rm5-TiDocument8 pagesPowerful 2X2 Mimo Airmax Basestation: Models: Rm2-Ti, Rm5-TiDavid HernandezNo ratings yet

- MRV304Document4 pagesMRV304songacoNo ratings yet

- RCMS2601-30 - Rev.A - User Manual Ver200507Document15 pagesRCMS2601-30 - Rev.A - User Manual Ver200507SpbPavelNo ratings yet

- Amc 1306 e 25Document45 pagesAmc 1306 e 25Girish KantharajuNo ratings yet

- AMC1306x Small, High-Precision, Reinforced Isolated Delta-Sigma Modulators With High CMTIDocument44 pagesAMC1306x Small, High-Precision, Reinforced Isolated Delta-Sigma Modulators With High CMTICristian Elieser Avila RojasNo ratings yet

- Metrodata Solutions CatalogueDocument16 pagesMetrodata Solutions CatalogueMetrodataLtdNo ratings yet

- PT-7528 Series: IEC 61850-3 28-Port Layer 2 Managed Rackmount Ethernet SwitchesDocument8 pagesPT-7528 Series: IEC 61850-3 28-Port Layer 2 Managed Rackmount Ethernet SwitchesCsaba DonáthNo ratings yet

- Cisco Routers 1941 Series DatasheetDocument9 pagesCisco Routers 1941 Series DatasheetMeela ZengNo ratings yet

- Westermo Ds mrd-455 2303 en ReviDocument3 pagesWestermo Ds mrd-455 2303 en ReviBlesson P VargheseNo ratings yet

- DS QuickServer 3X10-FDocument3 pagesDS QuickServer 3X10-FMario Girasole JuniorNo ratings yet

- Nokia Wavence: MSS-1 MSS-4 MSS-8Document2 pagesNokia Wavence: MSS-1 MSS-4 MSS-8Moh Yunan100% (1)

- Am Superheterodyne Receiver: ApplicationsDocument4 pagesAm Superheterodyne Receiver: ApplicationscaptainNo ratings yet

- Ads 8320Document32 pagesAds 8320rROMULO MOREIRANo ratings yet

- Manial Del Equipo de Comunicaciones OPLAT GRIDCOM T390Document498 pagesManial Del Equipo de Comunicaciones OPLAT GRIDCOM T390EDMUNDO HAYASHINo ratings yet

- R&S®TS8980 Test System Analyzes LTE Quality Indicators: CQI, PMI and RIDocument4 pagesR&S®TS8980 Test System Analyzes LTE Quality Indicators: CQI, PMI and RIForu MophiliaNo ratings yet

- Nport 5100A Series: 1-Port Rs-232/422/485 Serial Device ServersDocument7 pagesNport 5100A Series: 1-Port Rs-232/422/485 Serial Device ServersElectrical JKFMNo ratings yet

- AX7000-4096 DatasheetDocument5 pagesAX7000-4096 Datasheetsolution regional5No ratings yet

- KSZ8061 PDFDocument64 pagesKSZ8061 PDFsaberNo ratings yet

- Moxa Nport P5150a Series Datasheet v1.5Document5 pagesMoxa Nport P5150a Series Datasheet v1.5Manoj SutharNo ratings yet

- ABB String Inverters: UNO-DM-3.3/3.8/4.6/5.0-TL-PLUS-US 3.3 To 5 KWDocument4 pagesABB String Inverters: UNO-DM-3.3/3.8/4.6/5.0-TL-PLUS-US 3.3 To 5 KWDS ComputersNo ratings yet

- PT-508 Series - Layer 2 Managed Switches - MOXADocument1 pagePT-508 Series - Layer 2 Managed Switches - MOXABoudam BoudjemaNo ratings yet

- High Voltage Solid State Relays PDFDocument21 pagesHigh Voltage Solid State Relays PDFlazarosNo ratings yet

- Moxa 5150A Data SheetDocument7 pagesMoxa 5150A Data SheetDhanush MSNo ratings yet

- Multifunction Telecom Switch: DescriptionDocument8 pagesMultifunction Telecom Switch: DescriptionPhong DoNo ratings yet

- Protect Motorola Canopy CMM3 from Surges with ALPU-CMM3Document2 pagesProtect Motorola Canopy CMM3 from Surges with ALPU-CMM3peruingenierosNo ratings yet

- tsw200 Datasheet 2023 v11Document8 pagestsw200 Datasheet 2023 v11SimenaNo ratings yet

- Littelfuse PTC 0805L Datasheet - pdf-693356 PDFDocument6 pagesLittelfuse PTC 0805L Datasheet - pdf-693356 PDFgeoffffNo ratings yet

- 91070Document9 pages91070atomdNo ratings yet

- Infineon IPB60R040C7 DS v02 - 00 EN 1622423Document15 pagesInfineon IPB60R040C7 DS v02 - 00 EN 1622423geoffffNo ratings yet

- MFNSHT 1128480 PDFDocument7 pagesMFNSHT 1128480 PDFgeoffffNo ratings yet

- Bourns 10232018 TBU-DF-1489325Document8 pagesBourns 10232018 TBU-DF-1489325geoffffNo ratings yet

- Ds CP 0zcf Series 1633784 PDFDocument5 pagesDs CP 0zcf Series 1633784 PDFgeoffffNo ratings yet

- An11158 PDFDocument29 pagesAn11158 PDFgeoffffNo ratings yet

- Littelfuse PTC TSM250 130F Datasheet - pdf-1650463Document12 pagesLittelfuse PTC TSM250 130F Datasheet - pdf-1650463geoffffNo ratings yet

- 91070Document9 pages91070atomdNo ratings yet

- Rfp30N06Le, Rf1S30N06Lesm: 30A, 60V, Esd Rated, 0.047 Ohm, Logic Level N-Channel Power Mosfets FeaturesDocument8 pagesRfp30N06Le, Rf1S30N06Lesm: 30A, 60V, Esd Rated, 0.047 Ohm, Logic Level N-Channel Power Mosfets Featuresfahmi1987No ratings yet

- 91070Document9 pages91070atomdNo ratings yet

- Littelfuse PTC 0805L Datasheet - pdf-693356 PDFDocument6 pagesLittelfuse PTC 0805L Datasheet - pdf-693356 PDFgeoffffNo ratings yet

- Rfp30N06Le, Rf1S30N06Lesm: 30A, 60V, Esd Rated, 0.047 Ohm, Logic Level N-Channel Power Mosfets FeaturesDocument8 pagesRfp30N06Le, Rf1S30N06Lesm: 30A, 60V, Esd Rated, 0.047 Ohm, Logic Level N-Channel Power Mosfets Featuresfahmi1987No ratings yet

- An11158 PDFDocument29 pagesAn11158 PDFgeoffffNo ratings yet

- An11158 PDFDocument29 pagesAn11158 PDFgeoffffNo ratings yet

- Rfp30N06Le, Rf1S30N06Lesm: 30A, 60V, Esd Rated, 0.047 Ohm, Logic Level N-Channel Power Mosfets FeaturesDocument8 pagesRfp30N06Le, Rf1S30N06Lesm: 30A, 60V, Esd Rated, 0.047 Ohm, Logic Level N-Channel Power Mosfets Featuresfahmi1987No ratings yet

- SFP CompatibilityDocument7 pagesSFP CompatibilitygeoffffNo ratings yet

- 91070Document9 pages91070atomdNo ratings yet

- SFP CompatibilityDocument7 pagesSFP CompatibilitygeoffffNo ratings yet

- Measurement of Level in A Tank Using Capacitive Type Level ProbeDocument13 pagesMeasurement of Level in A Tank Using Capacitive Type Level ProbeChandra Sekar100% (1)

- Determine PH by PH Indicator and Universal IndicatorDocument3 pagesDetermine PH by PH Indicator and Universal IndicatorhaleelNo ratings yet

- Kraby System 2018Document22 pagesKraby System 2018soga010178No ratings yet

- Heliflex Hose CatalogueDocument119 pagesHeliflex Hose CatalogueAugustine DharmarajNo ratings yet

- 2011 02 Huijben Spie Why Every Urea Plant Needs A Continuous NC Meter PDFDocument9 pages2011 02 Huijben Spie Why Every Urea Plant Needs A Continuous NC Meter PDFfawadintNo ratings yet

- Biologic License ApplicationDocument16 pagesBiologic License ApplicationJean Sandra PintoNo ratings yet

- Browning Belt Tension GaugeDocument2 pagesBrowning Belt Tension GaugeJasperken2xNo ratings yet

- A Drop of Blood: Casting Time Range Components Duration Casting Time Range Components DurationDocument6 pagesA Drop of Blood: Casting Time Range Components Duration Casting Time Range Components DurationCristobal RencoretNo ratings yet

- Belazo Elastomeric Roof PaintDocument2 pagesBelazo Elastomeric Roof PaintrumahsketchNo ratings yet

- Roland Berger Hot Trends InconstructionDocument24 pagesRoland Berger Hot Trends InconstructionJavier ContrerasNo ratings yet

- Mvf404 Mhn-Seh2000w 956 b4 SiDocument2 pagesMvf404 Mhn-Seh2000w 956 b4 SiluisneiralopezNo ratings yet

- Revision 2 Pages Grammar Drills 106078Document3 pagesRevision 2 Pages Grammar Drills 106078Ligia Dragomir100% (1)

- Line Pack Presentation - Dec 2018Document7 pagesLine Pack Presentation - Dec 2018Goran JakupovićNo ratings yet

- FV10 Excel Flux Tutorial en 2Document36 pagesFV10 Excel Flux Tutorial en 2Ahcene BouzidaNo ratings yet

- KND 3200 eDocument0 pagesKND 3200 eGianna FrolaNo ratings yet

- TheologicalDiscipleship English 2011-1Document144 pagesTheologicalDiscipleship English 2011-1bilnyangnatNo ratings yet

- Imsa Catalog Imsa CatDocument16 pagesImsa Catalog Imsa CatDaniel TelloNo ratings yet

- Catalog INSIZE - Instrumente de MasuraDocument32 pagesCatalog INSIZE - Instrumente de MasuraSculegero0% (1)

- Jacobi Progressive Speed Agility Training For High School Middle School AthletesDocument39 pagesJacobi Progressive Speed Agility Training For High School Middle School AthletesAnthony Mckay100% (1)

- 22 Imobilisasi Pada Usia LanjutDocument34 pages22 Imobilisasi Pada Usia LanjutGian KalalembangNo ratings yet

- BMK PDFDocument8 pagesBMK PDFHuỳnh Minh SángNo ratings yet

- Final Nasir GlassDocument57 pagesFinal Nasir GlassShuvo Taufiq Ahmed100% (2)

- ZTE UMTS KPI Optimization Analysis Guide V1 1 1Document62 pagesZTE UMTS KPI Optimization Analysis Guide V1 1 1GetitoutLetitgo100% (1)

- Physical Activity Guidelines Advisory Committee ReportDocument683 pagesPhysical Activity Guidelines Advisory Committee Reportyitz22100% (1)

- EKO75 KW VST Air Cooled Electrical DiagramDocument13 pagesEKO75 KW VST Air Cooled Electrical DiagramBerat DeğirmenciNo ratings yet

- Separation and Purification TechnologyDocument10 pagesSeparation and Purification TechnologyPedro Henrique MagachoNo ratings yet

- Understanding Revit Architecture - BeginnersDocument56 pagesUnderstanding Revit Architecture - BeginnersBudega100% (95)