Professional Documents

Culture Documents

Alloy Chart

Uploaded by

elias attalahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alloy Chart

Uploaded by

elias attalahCopyright:

Available Formats

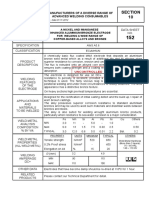

Permanent Mold: HIGH CONDUCTIVITY COPPER ALLOY (CU)

SPECIFICATION CHEMICAL CDA BRITISH DIN YIELD TENSILE ELONGATION BRINELL MODULUS ELECTRICAL ELECTRICAL CHARACTERISTICS

COMPOSITION STANDARD STANDARD STANDARD STRENGTH STRENGTH % 2" HARDNESS OF ELASTICITY CONDUCTIVITY CONDUCTIVITY

EQUIVALENT EQUIVALENT EQUIVALENT PSI x 103 (MIN) PSI x 103 (MIN) (MIN) PSI x 106 % IACS m/mm2h

BC-CU-110 CU – 99.9% 811 B5 1400 17655 5.1 – 6.0 27 – 30 28 – 35 10MM/500KG 17.6 97 MIN 56 MIN Pure electrolytic copper, excellent electrical and thermal conductivity.

HCC1 GK-CUL50 40 – 46 Alloy can be hard and soft soldered, limited weldability.

BC-CU-100 CU – 99.9% 811 B5 1400 17655 3.5 – 5.1 26 – 29 44 – 48 10MM/500KG 17.6 93 MIN 52 MIN Pure electrolytic copper with oxygen contents, excellent electrical and

HCC1 GK-SCUL50 33 – 38 thermal conductivity. Material can be processed in hydrogen atmosphere.

BC-CU-210 CU-CR 815 B5 1400 17655 39.5 – 44 54 – 59 20 – 25 10MM/500KG 17.5 77 MIN 44.5 MIN Heat treated chromium copper with excellent strength and conductivity.

CC1-TF GK-CUCRF35 100 – 140 Good hard and soft solderability.

BC-CU-300 CU-NI-SI SIMILAR B5 1400 SIMILAR 50 – 55 63 – 66 8 – 15 10MM/3000KG 17.5 35 – 44 22.6 – 25.5 Heat treated copper alloy with good thermal and electrical conductivity.

821 17666 135-160 MIN Alloy is resistant to stress corrosion.

CUN1251

BC-CU-310 CU-NI-SI SIMILAR B5 1400 SIMILAR 74 – 79 77 – 83 3–4 10MM/3000KG 17.3 26 – 35 15.6 – 20.2 Heat treated copper alloy (Same as BC-CU-300), but has higher mechanical

822 17666 190 – 205 properties, and lower conductivity readings. Alloy is resistant to stress

CUN1351 corrosion.

Permanent Mold: BRASS & SPECIAL BRASS ALLOYS (B & SB)

BC-B-100 CU-ZN 855 B5 1400 1709 20 – 24 57 – 64 40 – 56 10MM/500KG 13.5 23 – 25.5 13.3 – 14.8 Excellent alloy for thin wall, complex and complicated casting

HTB1 GK-CUZN38AL 70 – 90 requirements. Alloy resists stress and atmospheric corrosion.

BC-B-300 CU-ZN-PB 857 B5 1400 1709 19 – 24 41 – 45 16 – 20 10MM/500KG 13.6 20 – 23.5 11.6 – 13.6 Brass alloy with good machinability. Alloy is not recommended for

HTB1 GK-CUZN37PB 70 – 90 complicated casting design.

BC-SB-100 CU-ZN-AL 864 B5 1400 1709 23 – 30 61 – 71 30 – 49 10MM/500KG 13.6 17 – 20 9.8 – 11.6 Excellent alloy with outstanding mechanical properties. Alloy has good

HTB1 GK-CUZN37AL1 100 – 120 resistance to stress corrosion in industrial atmosphere.

BC-SB-120 CU-ZN NONE NONE NONE 12 – 13 66 – 69 31 – 34 10MM/500KG 11.5 35 – 38 20.3 – 22 Alloy with high electrical conductivity suitable for use in electrical

90 – 95 equipment. Alloy cannot be tin plated. Alloy does not resist stress

corrosion. Part surfaces need protection from atmospheric corrosion.

BC-SB-120-1 CU-ZN NONE NONE NONE 19 – 24 60 – 78 28 – 36 10MM/500KG 11.8 29 – 32 17.4 – 18.5 Same as alloy BC-SCB-120 except alloy can be soldered and tin plated.

88 – 95

BC-SB-200 CU-ZN-PB-MN NONE NONE NONE 22 – 25 40 – 44 8 – 10 10MM/500KG 14.7 7.5 – 9 4.3 – 4.3 Alloy with excellent sliding properties. Good bearing material with high

70 – 76 mechanical loads.

BC-SB-300 CU-ZN-FE-NI-AL 867 B5 1400 1709 34 – 42 79 – 87 16 – 20 10MM/3000KG 15.8 18 – 20 10.4 – 11.6 High-strength yellow brass, good bearing material for large loads. Material

HTB1 GK-CUZN34AL2 130 – 150 suitable for high pressure valve parts. Limited castability.

BC-SB-310 CU-ZN-FE-AL 865 B5 1400 1709 22 – 30 65 – 74 28 – 36 10MM/500KG 13.5 23 – 25 13.3 – 14.5 Same as alloy BC-SB-300 except with lesser hardness and strength, but

HTB1 GK-CUZN37AL1 100 – 125 greater conductivity.

BC-SB-340 CU-ZN-FE-AL-MN 865 B5 1400 1709 21 – 35 63 – 76 25 – 45 10MM/500KG 13.8 17 – 19 9.8 – 11 High-strength yellow brass with good corrosion resistance in marine

HTB1 GK-CUZN35AL1 110 – 130 atmosphere.

Permanent Mold: ALUMINUM BRONZE ALLOYS (AB)

BC-AB-100 CU-AL 953 B5 1400 1714 20 – 23 63 – 72 52 – 65 10MM/500KG 15.0 15 – 18 8.7 – 10.4 Alloy has good corrosion resistance. Little property change in –200°C tem-

AB1 GK-CUAL10 75 – 95 perature. Good alloy for chemical industry and food handling equipment.

BC-AB-110 CU-AL-FE 952 B5 1400 1714 27 – 30 76 – 85 30 – 35 10MM/500KG 16.0 10 – 12 5.8 – 6.9 Excellent resistance to chemical agents such as H2SO4 and H3PO4. Good

AB1 GK-CUAL10FE 95 – 110 resistance to cold salt water, weldable, and suitable for non-magnetic application.

BC-AB-120 CU-AL-FE 952 B5 1400 1714 32 – 42 80 – 95 23 – 35 10MM/3000KG 16.5 10 – 12 5.8 – 6.9 Good corrosion resistance in salt water and other water applications.

AB1 GK-CUAL10FE 135 – 155 Alloy can be welded and heat treated.

BC-AB-200 CU-AL-FE-NI 955 B5 1400 1714 58 – 68 95 – 108 6 – 10 10MM/3000KG 17.5 8.0 MAX 4.6 MAX High-strength nickel-aluminum bronze with excellent corrosion resistance.

AB2 GK-CUAL11NI 190 – 210 Excellent in hot and cold salt applications. Alloy with high mechanical

loading capacity and very good erosion and wear resistance properties.

BC-AB-210 CU-AL-FE-NI 955 B5 1400 1714 45 – 50 88 – 98 14 – 20 10MM/3000KG 17.2 8.0 MAX 4.6 MAX Good mechanical properties, excellent resistance against hot and cold salt

AB2 GK-CUAL10NI 160 – 185 water, good corrosive resistance. Alloy performs excellently in O2 and H2S

environment. Alloy used in electrical, machine, mining and marine industry.

BC-AB-220 CU-AL-FE-NI 954 B5 1400 1714 35 – 42 82 – 92 20 – 30 10MM/3000KG 16.9 8.0 MAX 4.6 MAX Alloy similar to BC-AB-110 except better mechanical properties. Alloy

AB2 GK-CUAL9NI 125 – 160 can be welded and heat treated.

BC-AB-230 CU-AL-FE-NI 955 B5 1400 1714 64 – 78 98 – 113 5–7 10MM/3000KG 18.0 8.0 MAX 4.6 MAX Extreme high wear and corrosion resistance. Properties similar to BC-AB-

AB2 GK-CUAL11NI 210 – 230 200. Alloy can be heat treated and welded.

BC-AB-240 CU-AL-FE-NI 955 B5 1400 1714 45 – 52 88 – 98 12 – 18 10MM/3000KG 17.1 8.0 MAX 4.6 MAX Alloy similar to BC-AB-210. Alloy specially tailored for disc and valve

AB2 GK-CUAL10NI 150 – 195 applications.

BC-AB-300 CU-AL-MN-NI NONE B5 1400 1714 28 – 32 70 – 75 33 – 40 10MM/500KG 16.8 8.0 MAX 4.6 MAX Aluminum-nickel-manganese bronze with very good corrosion resistance.

CMA1 GK-CUAL8MN 100 – 110 Good application where low magnetic properties are required.

NOTE: Where there are ranges indicated, the higher number can be exceeded but will not go below the lower number.

You might also like

- Chapter 4: AC Network Analysis Instructor NotesDocument60 pagesChapter 4: AC Network Analysis Instructor Notessong100% (1)

- 22Document50 pages22physicsdocs87% (15)

- 2015 - Commercial - M Cubed Technologies, Inc - Aluminum Alloy Reinforced With Ceramic ParticlesDocument2 pages2015 - Commercial - M Cubed Technologies, Inc - Aluminum Alloy Reinforced With Ceramic ParticlesMahmood KhanNo ratings yet

- CAD-CAM PRACTICE DRAWINGS For BEGINNERS PDFDocument232 pagesCAD-CAM PRACTICE DRAWINGS For BEGINNERS PDFelias attalah100% (2)

- Force Polygon Equilibrium ExperimentDocument1 pageForce Polygon Equilibrium ExperimentRatala GepNo ratings yet

- Dual Shield 9000-B3 Flux Cored Wire for 2.25% Cr-1% Mo SteelsDocument1 pageDual Shield 9000-B3 Flux Cored Wire for 2.25% Cr-1% Mo SteelsqaNo ratings yet

- Copper Nickel Alloy 7030 E28093 UNS C71500 E28093 CupronickelDocument6 pagesCopper Nickel Alloy 7030 E28093 UNS C71500 E28093 CupronickelSantosh TiwariNo ratings yet

- Aluminium PCMDocument25 pagesAluminium PCMKarthi Kaiean100% (2)

- Data Sheet CuZn20Al2AsDocument1 pageData Sheet CuZn20Al2AsJean Carlos Reyna PascualNo ratings yet

- Kanthal Af Tube - S Kaxxx Ps Eng - 0Document2 pagesKanthal Af Tube - S Kaxxx Ps Eng - 0Chia Sze KiatNo ratings yet

- Alloy Cuni 70-30Document2 pagesAlloy Cuni 70-30didiethardoyoNo ratings yet

- Copperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloysDocument1 pageCopperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloyssatnamNo ratings yet

- PART 92 Cu-Ni Welding - Part 1 Cu-Ni Material PropertiesDocument16 pagesPART 92 Cu-Ni Welding - Part 1 Cu-Ni Material Propertiesravindra_jivaniNo ratings yet

- Copper Tubes for Plumbing and Heating SystemsDocument10 pagesCopper Tubes for Plumbing and Heating SystemsDeepak kumarNo ratings yet

- Manufacturers of advanced welding consumables data sheet for cobalt alloy NS-ECo-6Document1 pageManufacturers of advanced welding consumables data sheet for cobalt alloy NS-ECo-6yadi_baeNo ratings yet

- M.M.A. welding electrode for Martensitic stainless steelsDocument1 pageM.M.A. welding electrode for Martensitic stainless steelscwiksjNo ratings yet

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- Automig 70S-61Document1 pageAutomig 70S-61tarun kaushalNo ratings yet

- Properties of Copper and Copper AlloysDocument1 pageProperties of Copper and Copper Alloysankesh_ghoghariNo ratings yet

- AB0034 Alloy25Document12 pagesAB0034 Alloy25Scott LongmireNo ratings yet

- SL Basis Materials en PDFDocument1 pageSL Basis Materials en PDFarmin_kunosic9871No ratings yet

- Engineering Alloys (Non Ferrous)Document52 pagesEngineering Alloys (Non Ferrous)Sukhwinder Singh GillNo ratings yet

- Aluminum Data SheetDocument15 pagesAluminum Data Sheetabdalla el-saadaneyNo ratings yet

- Material Datasheet Cu-OFDocument2 pagesMaterial Datasheet Cu-OFmohsen_267No ratings yet

- Carbonsteel SteelmetalguidebookDocument18 pagesCarbonsteel SteelmetalguidebookEyob AdNo ratings yet

- Page - 5Document1 pagePage - 5Bharat KumaneNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Nicalloy Mo-12: NON FERROUS (Ni Alloys)Document1 pageNicalloy Mo-12: NON FERROUS (Ni Alloys)krupesh patelNo ratings yet

- Worksheet 11 2015136Document14 pagesWorksheet 11 2015136Eleazar GarciaNo ratings yet

- Armco Pure Iron PDFDocument12 pagesArmco Pure Iron PDFsmith willNo ratings yet

- Knowledge Tit-Bits On Transformer Electrical Steels-Part 2Document13 pagesKnowledge Tit-Bits On Transformer Electrical Steels-Part 2salemg82No ratings yet

- COPPER-110: Nearest StandardDocument3 pagesCOPPER-110: Nearest StandardPS Pinturas pinturasNo ratings yet

- AMENDMENT 2 (500 KV) (Rev2, Apr2016)Document7 pagesAMENDMENT 2 (500 KV) (Rev2, Apr2016)Jed SrisuthumNo ratings yet

- 2594 TigDocument1 page2594 TigAnonymous skBAwexNo ratings yet

- 1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NBDocument1 page1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NBRodrigo TeodoroNo ratings yet

- Advanced welding electrode for aluminium bronzesDocument1 pageAdvanced welding electrode for aluminium bronzesAris WicaksonoNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- 2-Conduction in SolidDocument46 pages2-Conduction in SolidRichard Adventus HutasoitNo ratings yet

- Copper Alloy NotesDocument5 pagesCopper Alloy NotesSalem GarrabNo ratings yet

- Cuznpb2 leadedDocument3 pagesCuznpb2 leadedwjjt6chgtmNo ratings yet

- Alloy Cross Reference Table PDFDocument4 pagesAlloy Cross Reference Table PDFChad MitchellNo ratings yet

- Betanox D Welding ElectrodeDocument1 pageBetanox D Welding ElectrodearavindpeetaNo ratings yet

- 1 4509Document2 pages1 4509Umesh KotadiaNo ratings yet

- Copper and Copper Alloy Ingots and CastingsDocument2 pagesCopper and Copper Alloy Ingots and CastingspoopNo ratings yet

- Cu-HCP: C10300 Industrial RolledDocument7 pagesCu-HCP: C10300 Industrial RolledpierocarnelociNo ratings yet

- EN1A Carbon Steel - EN1A Forging - EN1A Flat - Saaj SteelDocument4 pagesEN1A Carbon Steel - EN1A Forging - EN1A Flat - Saaj SteelNaiduNo ratings yet

- Aluminium Alloy 1050 H14 TDSDocument1 pageAluminium Alloy 1050 H14 TDSfaria1969No ratings yet

- The Rotating Cylinder Electrode PDFDocument11 pagesThe Rotating Cylinder Electrode PDFbuvanseaNo ratings yet

- Cored Wires for High Toughness Welding of C-Mn and Low-Alloy SteelsDocument1 pageCored Wires for High Toughness Welding of C-Mn and Low-Alloy SteelsCristian BoselliNo ratings yet

- LATONDocument1 pageLATONAlan GutierrezNo ratings yet

- Wilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200Document2 pagesWilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200williamNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- PBN DatasheetDocument1 pagePBN DatasheetLove MishraNo ratings yet

- Copper & Its AlloysDocument16 pagesCopper & Its AlloysNataliyaNo ratings yet

- CastingDocument19 pagesCastingMohd SyafiqNo ratings yet

- Applications: Hpalloys Cobalt 6B Product DescriptionDocument4 pagesApplications: Hpalloys Cobalt 6B Product DescriptionJSH100No ratings yet

- 954 - Bronze Aluminio PDFDocument2 pages954 - Bronze Aluminio PDFivanoliveira3261No ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- AW - Datasheet - ALLOY 20 CB 3Document2 pagesAW - Datasheet - ALLOY 20 CB 3.xNo ratings yet

- CuZn30-PNA 226 - ENDocument2 pagesCuZn30-PNA 226 - ENNHadesNo ratings yet

- Strength of Metals and Alloys: Proceedings of the 5th International Conference, Aachen, Federal Republic of Germany, August 27-31, 1979From EverandStrength of Metals and Alloys: Proceedings of the 5th International Conference, Aachen, Federal Republic of Germany, August 27-31, 1979P. HaasenRating: 5 out of 5 stars5/5 (1)

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Design and Optimization of Scissor Jack: ISSN (PRINT) :2394-6202, (ONLINE) :2394-6210, VOLUME-2, ISSUE-1,2016Document6 pagesDesign and Optimization of Scissor Jack: ISSN (PRINT) :2394-6202, (ONLINE) :2394-6210, VOLUME-2, ISSUE-1,2016abebeNo ratings yet

- Technical specifications for sewerage systemsDocument38 pagesTechnical specifications for sewerage systemsEngr Asad SufyanNo ratings yet

- Sewer Connection and Repair Manual: Version 1.1 September 2017Document58 pagesSewer Connection and Repair Manual: Version 1.1 September 2017elias attalahNo ratings yet

- Full Sewerage Report FDocument40 pagesFull Sewerage Report Felias attalahNo ratings yet

- Syed Ibrahim Dilawer Portfolio PDFDocument34 pagesSyed Ibrahim Dilawer Portfolio PDFNíthìsh GøwdåNo ratings yet

- Alloy ChartDocument1 pageAlloy Chartelias attalahNo ratings yet

- Materials Science and Engineering C: Laura Tamayo, Manuel Azócar, Marcelo Kogan, Ana Riveros, Maritza PáezDocument19 pagesMaterials Science and Engineering C: Laura Tamayo, Manuel Azócar, Marcelo Kogan, Ana Riveros, Maritza PáezErika AriasNo ratings yet

- SolidWorks For Sheet MetalDocument15 pagesSolidWorks For Sheet MetalCodreanu Petru100% (2)

- NCPI Vitrified Clay Pipe Engineering Manual 08-11-2015Document145 pagesNCPI Vitrified Clay Pipe Engineering Manual 08-11-2015elias attalahNo ratings yet

- Cu OverviewDocument38 pagesCu OverviewDejan DjokićNo ratings yet

- BIMCO-Cyber Security Guidelines 2018Document56 pagesBIMCO-Cyber Security Guidelines 2018Kim HalavakoskiNo ratings yet

- Materials Science & Engineering A: SciencedirectDocument10 pagesMaterials Science & Engineering A: Sciencedirectelias attalahNo ratings yet

- PH DpropDocument6 pagesPH Dpropelias attalahNo ratings yet

- Materials Science and Engineering C: Laura Tamayo, Manuel Azócar, Marcelo Kogan, Ana Riveros, Maritza PáezDocument19 pagesMaterials Science and Engineering C: Laura Tamayo, Manuel Azócar, Marcelo Kogan, Ana Riveros, Maritza PáezErika AriasNo ratings yet

- GearDocument22 pagesGearelias attalahNo ratings yet

- 01 Dujv UE Presentation 2018 PDFDocument69 pages01 Dujv UE Presentation 2018 PDFelias attalahNo ratings yet

- Good Practices For The Maritime Security Report PDFDocument61 pagesGood Practices For The Maritime Security Report PDFKim HalavakoskiNo ratings yet

- Primary Education InternshipDocument4 pagesPrimary Education Internshipelias attalahNo ratings yet

- AGM1 ENG 1stHW Information-1Document2 pagesAGM1 ENG 1stHW Information-1elias attalahNo ratings yet

- Summer Jobs 2020 PDFDocument6 pagesSummer Jobs 2020 PDFelias attalahNo ratings yet

- Participle Adjectives Long List: Past Participle (-Ed) Present Participle (-Ing)Document13 pagesParticiple Adjectives Long List: Past Participle (-Ed) Present Participle (-Ing)elias attalahNo ratings yet

- Weldability Questions PDFDocument1 pageWeldability Questions PDFelias attalahNo ratings yet

- Woodworking Machinery General ChecklistDocument3 pagesWoodworking Machinery General ChecklistShakil KhanNo ratings yet

- Some AnyDocument6 pagesSome Anyelias attalahNo ratings yet

- Participle Adjectives Short List PDFDocument3 pagesParticiple Adjectives Short List PDFelias attalahNo ratings yet

- Prediction of Propeller Forces During Ship ManeuveDocument23 pagesPrediction of Propeller Forces During Ship Maneuveelias attalahNo ratings yet

- Some and Any Exercise 1 PDFDocument2 pagesSome and Any Exercise 1 PDFelias attalahNo ratings yet

- A Smartphone Is A Mobile Phone Built On A Mobile Operating SystemDocument2 pagesA Smartphone Is A Mobile Phone Built On A Mobile Operating Systemelias attalahNo ratings yet

- Curvilinear Coordinates: OutlineDocument18 pagesCurvilinear Coordinates: Outlinealagarg137691No ratings yet

- Structural Optimization of Composite Helicopter Rotor BladesDocument142 pagesStructural Optimization of Composite Helicopter Rotor BladesyigitilgazNo ratings yet

- THESIS - C. JAYASREE - Jayasree ChakkamalayathDocument282 pagesTHESIS - C. JAYASREE - Jayasree ChakkamalayathraviNo ratings yet

- JEE Main Sample Question Paper 7Document29 pagesJEE Main Sample Question Paper 7Tanvir ShafalNo ratings yet

- Dixell XR40CDocument4 pagesDixell XR40Cminhdung76np100% (1)

- Performance Standards For Transmission (PST) Philippine Grid Code Performance Standards For Transmission (PST) PST 3.1. PurposeDocument10 pagesPerformance Standards For Transmission (PST) Philippine Grid Code Performance Standards For Transmission (PST) PST 3.1. PurposeBhea Grace Del-oNo ratings yet

- Fluid MechanicsDocument27 pagesFluid MechanicsKarl Radison AbreaNo ratings yet

- Eng3 Q4 M2 L1Document6 pagesEng3 Q4 M2 L1Jhon Kristoffer GabutNo ratings yet

- Lesson Notes Installing Alarm and Signal CircuitDocument6 pagesLesson Notes Installing Alarm and Signal CircuitHezron gibronNo ratings yet

- Fractional Calculus For Scientis and Engineers - M. Duarte O. - SpringerDocument159 pagesFractional Calculus For Scientis and Engineers - M. Duarte O. - SpringerPuig123100% (1)

- ETY155 Lab10 SuperpositionDocument4 pagesETY155 Lab10 SuperpositionprantiNo ratings yet

- Ieee1 - 2 - 4 Hardware Support v2Document7 pagesIeee1 - 2 - 4 Hardware Support v2anandNo ratings yet

- 9203 Mark Scheme Paper2 International Gcse Physics Nov21Document20 pages9203 Mark Scheme Paper2 International Gcse Physics Nov21Shagu100% (1)

- Lect 1 Limit State DesignDocument31 pagesLect 1 Limit State DesignWaleed Yahia100% (1)

- Cold Formed Steel Sections - IiDocument63 pagesCold Formed Steel Sections - IiJethalal Champaklal GadaNo ratings yet

- Moocs Lecture On Experimental Stress Analysis by Prof.K.Ramesh, Iit Madras 27-1Document29 pagesMoocs Lecture On Experimental Stress Analysis by Prof.K.Ramesh, Iit Madras 27-1muhammad hamzaNo ratings yet

- 1 - Thermal SpringDocument10 pages1 - Thermal SpringMannanNo ratings yet

- 17 Differential Equations Ma102Document3 pages17 Differential Equations Ma102Salim ShahulNo ratings yet

- IIR Educational Course Refrigeration Fundamentals: Prof. A. Pilatte Faculté Polytechnique de Mons - BelgiumDocument197 pagesIIR Educational Course Refrigeration Fundamentals: Prof. A. Pilatte Faculté Polytechnique de Mons - BelgiumnasierrasNo ratings yet

- Acronal V210 Na AdhesivesDocument3 pagesAcronal V210 Na AdhesivesCanchindoNo ratings yet

- Application Data Sheet: General InformationDocument5 pagesApplication Data Sheet: General InformationAugusto PenessiNo ratings yet

- Block 4 MCO 3 Unit 2Document35 pagesBlock 4 MCO 3 Unit 2Tushar SharmaNo ratings yet

- General Aptitude - Student'sDocument22 pagesGeneral Aptitude - Student'sAghaashNo ratings yet

- The Endocrown - A Different Type of All-Ceramic Reconstruction For Molars - JcdaDocument10 pagesThe Endocrown - A Different Type of All-Ceramic Reconstruction For Molars - Jcdaabcder1234No ratings yet

- Waves - Booklet 1 (New IAL) AnsDocument10 pagesWaves - Booklet 1 (New IAL) AnsfedNo ratings yet

- 05.01.24 SR - Star Co-Sc (Model A, B&C) Jee Main Gtm-7 (N) - QPDocument23 pages05.01.24 SR - Star Co-Sc (Model A, B&C) Jee Main Gtm-7 (N) - QPReddyNo ratings yet

- Gordon, Sementsov-Ogievskii - A Course in Descriptive Geometry - Mir - 1980Document387 pagesGordon, Sementsov-Ogievskii - A Course in Descriptive Geometry - Mir - 1980spicybinga100% (1)