Professional Documents

Culture Documents

Otis 2000 Hyd Rescue PDF

Uploaded by

Satheesh RamaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Otis 2000 Hyd Rescue PDF

Uploaded by

Satheesh RamaCopyright:

Available Formats

KONE Maintenance instruction for

OTIS 2000 (hydraulic elevator)

RESCUE INSTRUCTION FOR OTIS 2000 HYDRAULIC ELEVATOR

KONE

©

AS-21.01.005

All

(-) 2008

2009-03-02

rights

Maintenance

KONE

reserved.

Corporation

instruction for

This document is intended to be used by people who are familiar with elevator maintenance and

installation and have received proper training on methods and safety as specified by KONE.

© 2008 KONE Corporation AS-21.01.005

All rights reserved. 1 (12) (-) 2009-03-02

Disclosure prohibited

KONE Maintenance instruction for

OTIS 2000 (hydraulic elevator)

Application Notice

This document does not replace or substitute any instructions or manuals provided by the original

manufacturer of the equipment. The user of this document must always ensure that all equipment

specific instructions are taken into consideration when working with the elevator.

AUTHORIZATION NOTICE

This publication is for informational purposes only. All persons participating and using these

instructions must be qualified to perform such work, are required to have received training

as specified by KONE.

Confidentiality Notice

This confidential KONE document is provided to you only for purposes of supporting the

maintenance of equipment under KONE service contract and it may not be used or its contents

disclosed for any other purpose without KONE's prior written permission. Neither this document nor

its contents may be copied or disclosed to third parties for any reason. KONE reserves the right to

prosecute any breach of this obligation.

DISCLAIMER OF WARRANTIES AND LIABILITIES

KONE reserves the right at any time to alter the procedures reflected in this document. No statement

contained in this document is to be construed as a warranty or condition, express or implied, as to

any product, specification or procedure, its merchantability or fitness for any particular purpose or

quality, or as a modification or representation of the terms of any purchase agreement.

This document is intended for the internal use of KONE only. Any outside party using this document

or relying on the accuracy of or disclosing any of the information contained herein assumes all risks

associated therewith. KONE disclaims any liability resulting from or in connection with any outside

use or disclosure of any part of the information in this document. KONE shall not be held liable for

any typographical, factual, or other errors or omissions contained in this document, nor for any

outside party's interpretation or use of the instructions.

Trademark Notices

OTIS and OTIS 2000 are registered trademarks of Otis Elevator Company.

"KONE, MonoSpace, MiniSpace, EcoDisc, TranSys, Alta, KoneXion, KONE ECO3000 and all other

product names are trademarks or registered trademarks of KONE Corporation in various countries."

Copyright Notice

Copyright ©2008 KONE Corporation

All rights reserved. No part of the contents of this document may be copied, reproduced or

transmitted in any form or by any means, or translated into another language or format, in whole or

part, without prior written permission of KONE Corporation.

© 2008 KONE Corporation AS-21.01.005

All rights reserved. 2 (12) (-) 2009-03-02

Disclosure prohibited

KONE Maintenance instruction for

OTIS 2000 (hydraulic elevator)

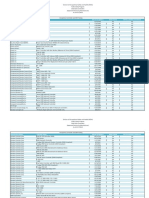

CONTENTS

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 RESCUE EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Main Board LCB II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Hand crank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Emergency lowering valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 RESCUE OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Selection chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Preparations for moving the car . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 Moving the car by using ERO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.4 Moving the car by using landing door jumper block and ERO . . . . . . . . . . . . . . . . . 10

4.5 Moving the car by using emergency opening valve . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.6 Rescue procedures when car is in door zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 APPROVALS AND VERSION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

© 2008 KONE Corporation AS-21.01.005

All rights reserved. 3 (12) (-) 2009-03-02

Disclosure prohibited

KONE Maintenance instruction for

OTIS 2000 (hydraulic elevator)

1 INTRODUCTION

This instruction describes actions needed to rescue trapped passengers safely out of OTIS 2000

hydraulic type elevator.

Rescue operations are divided into three different categories:

• Normal rescue - allowed for trained maintenance persons of the building or professional elevator

engineers.

• Technical rescue - allowed only for professional elevator engineers.

• Emergency rescue - special emergency personnel, for example firefighters.

NOTE! This instruction was compiled using only few elevators. Units manufactured in different years or

installed in different countries may have technical details or special features, which makes

them different from the units used to create this instruction. Therefore it is not always possible

to describe every procedure in detail, some elevators will need to be assessed on a case-by-

case basis locally.

2 SAFETY

These safety rules are mandatory for all rescue operations on an OTIS 2000 hydraulic type elevators.

• Only trained personnel are allowed to rescue passengers.

• On your way to the control panel, check where the elevator car is stopped and ensure that no one

is already working there. Do not open landing doors unless it is absolutely necessary.

• Do not leave any open landing door unguarded.

• Follow the local safety regulation and KONE safety rules. No exceptions because of an unusual

situation are allowed.

• Do not move the car, if it is in door zone.

• Do not move the car without supervision, if passengers can open the doors.

• Be careful when lowering the car with emergency valve.

• Always inform the passengers before using the emergency valve or moving the car with

other rescue methods!

© 2008 KONE Corporation AS-21.01.005

All rights reserved. 4 (12) (-) 2009-03-02

Disclosure prohibited

KONE Maintenance instruction for

OTIS 2000 (hydraulic elevator)

3 RESCUE EQUIPMENT

The following equipment and devices are used in the rescue operations:

• controller

• user interface board (UIB)

• portable hand crank (optional)

• ERO buttons (located either in control cabinet or in hand crank)

• landing door jumper blocks (optional)

• emergency lowering valve

• door zone LED (located either in control cabinet or in hand crank)

3.1 Controller

The controller is located in the machine room. The manual operating devices of the elevator are

located in controller or on a separate hand unit.

Illustration

1 Fuse block

2 Main Board LCB II

3 Landing door jumper

block (optional)

© 2008 KONE Corporation AS-21.01.005

All rights reserved. 5 (12) (-) 2009-03-02

Disclosure prohibited

KONE Maintenance instruction for

OTIS 2000 (hydraulic elevator)

3.2 Main Board LCB II

The user interface board is located in the control cabinet. It contains devices for operating the elevator

and other indicator lights.

USER INTERFACE BOARD

Brake current (BC) Inspection mode (INS) Door open limit (DOL)

(VLC) Emergency stop (ES) Door open button (DOB)

Group (GP) All landing doors closed (DW) Door zone LED (DZ)

Normal mode (NOR) Door fully closed (DFC) Motor protection (MP)

© 2008 KONE Corporation AS-21.01.005

All rights reserved. 6 (12) (-) 2009-03-02

Disclosure prohibited

KONE Maintenance instruction for

OTIS 2000 (hydraulic elevator)

3.3 Hand crank

The ERO buttons and door zone LED can be located in a portable hand crank or in the control cabinet.

Button / Switch. Illustration

1 Normal / ERO switch

2 UP button

3 DOWN button 1 2 3 4

4 Door zone LED (optional)

3.4 Emergency lowering valve

Button / Switch etc. Illustration

1 Emergency lowering valve

2 Hand pump

2

NOTE! GMV hydraulic valve in the picture.

Also other manufacturers’ valves can be

in use.

© 2008 KONE Corporation AS-21.01.005

All rights reserved. 7 (12) (-) 2009-03-02

Disclosure prohibited

KONE Maintenance instruction for

OTIS 2000 (hydraulic elevator)

4 RESCUE OPERATIONS

4.1 Selection chart

4.2 Preparations for

moving the car

Car is in a door zone?

YES NO

Main power supply is?

ON OFF 4.5 Moving the car

using emergency

opening valve and

hand pump

4.3 Moving the car

using ERO

Car moves?

Car moves? YES NO

YES NO

Landing door jumper

block is available?

YES NO

4.4 Moving the car

using ERO and landing

door jumper block

Car moves?

YES NO

Move the car to the nearest door zone. Emergency rescue is needed.

Contact special personnel.

4.6 Rescue procedures when car is in

door zone.

© 2008 KONE Corporation AS-21.01.005

All rights reserved. 8 (12) (-) 2009-03-02

Disclosure prohibited

KONE Maintenance instruction for

OTIS 2000 (hydraulic elevator)

4.2 Preparations for moving the car

Step Action Note / Illustration

1 Inform the passengers that you are about to Remind them to stay clear of the doors.

let them out and they must not try to do

anything themselves.

2 Open the control cabinet.

3 Switch ON the shaft lights.

4 Ensure that the car is not already in door Door zone LED does not illuminate.

zone. If the LED illuminates, finalize the rescue

operation according to section 4.6 on page

12.

5 Ensure that all doors are closed and

securely locked.

4.3 Moving the car by using ERO

Step Action Note / Illustration

1 Switch the Normal / ERO switch (1) to ERO

position.

2 Push the ERO UP button (2) to drive the

elevator car to the nearest door zone.

If the car does not move upwards, push the

ERO DOWN button (3). Try to move it

downwards to the nearest door zone.

3 When the car has reached a door zone, Door zone LED illuminates.

finalize the rescue operation according to

section 4.6 on page 12.

© 2008 KONE Corporation AS-21.01.005

All rights reserved. 9 (12) (-) 2009-03-02

Disclosure prohibited

KONE Maintenance instruction for

OTIS 2000 (hydraulic elevator)

4.4 Moving the car by using landing door jumper block and ERO

WARNING

Use extreme caution when you move the car and the landing doors safety chain is temporarily

bypassed.

Step Action Note / Illustration

1 Switch the Normal / ERO switch (1) to ERO

position.

2 Switch the landing door jumper block to

inspection position.

NOTE! Use a screwdriver to remove the

landing door jumper block.

Turn it around and place it back in

the inspection position.

WARNING!Before moving the car,

ensure visually that all landing

doors are closed. Warn

passengers not to try to exit the

car while you are moving it. The

car moves even if doors are

open.

3 Push the ERO UP button (2) to drive the car

to the nearest landing door zone.

If the car does not move upwards, push the

ERO DOWN button (3). Try to move it

downwards to the nearest door zone.

NOTE! The car has reached a door zone

when the door zone LED (4)

illuminates.

5 Remove the landing door jumper block and

put it back in the Normal position. Fasten the

screw.

© 2008 KONE Corporation AS-21.01.005

All rights reserved. 10 (12) (-) 2009-03-02

Disclosure prohibited

KONE Maintenance instruction for

OTIS 2000 (hydraulic elevator)

Step Action Note / Illustration

6 Finalize the rescue operation according to

section 4.6 on page 12.

4.5 Moving the car by using emergency opening valve

WARNING

Use extreme caution when moving the car.

Step Action Note / Illustration

1 Push the emergency lowering valve button When the car is off the safety gear, try again

(1) to lower the car to door zone.

NOTE! Instead of a button, emergency

valve can be operated by a lever. 2

NOTE! GMV hydraulic valve in the picture.

Also other manufacturers’ valves

can be in use.

2 Watch the pressure gauge: If the pressure 1

goes to zero, the car may be stuck on safety

gear. If the pressure is lost and the car has

not moved down, try to lift the car up by

pumping pressure up with the hand pump

(2).

to lower it down by pushing the emergency

lowering valve button (1).

3 When the car has reached a door zone, Door zone LED illuminates.

finalize the rescue operation according to

section 4.6 on page 12.

© 2008 KONE Corporation AS-21.01.005

All rights reserved. 11 (12) (-) 2009-03-02

Disclosure prohibited

KONE Maintenance instruction for

OTIS 2000 (hydraulic elevator)

4.6 Rescue procedures when car is in door zone

Step Action Note / Illustration

1 Ensure that car is in door zone (Door zone

LED illuminates).

2 Switch OFF the main switch.

Lock and tag the main switch.

3 Close the control cabinet.

Lock the machine room door.

4 Open the doors with the emergency opening

key and help the passengers out.

5 Close and lock the doors.

5 APPROVALS AND VERSION HISTORY

Compiled by: Information Product Author Janne Kaskimies

Checked by: 3rd Party Competence Center Director Fabien Fargnier

SEB Maintenance Specialist Jukka Lindberg

Approved by: SEB Maintenance Development Manager Seppo Valliovuo

Translation approved by:

Issue Date Description of Change Ref CR Approved by

- 2009-03-02 First issue Seppo Valliovuo

© 2008 KONE Corporation AS-21.01.005

All rights reserved. 12 (12) (-) 2009-03-02

Disclosure prohibited

You might also like

- SVT GreskeDocument17 pagesSVT GreskePeter100% (6)

- Elevator Mechanic's Helper: Passbooks Study GuideFrom EverandElevator Mechanic's Helper: Passbooks Study GuideNo ratings yet

- DOSH Approved Solid State Elevator ControllersDocument11 pagesDOSH Approved Solid State Elevator ControllersMohammed Qaid AlathwaryNo ratings yet

- TK-50 Installation Manual Rev 1.1 - EVO1Document20 pagesTK-50 Installation Manual Rev 1.1 - EVO1anh trong0% (1)

- FMI Pulse™ Installation & Start-Up: P ™ CSB M SDocument32 pagesFMI Pulse™ Installation & Start-Up: P ™ CSB M SLucas AndradeNo ratings yet

- HYDRODocument4 pagesHYDROPolinho Donacimento100% (1)

- Modu SoftDocument2 pagesModu Softhabibulla100% (1)

- Gen2 MadridDocument24 pagesGen2 MadridCristal CristalNo ratings yet

- Brake Tool ManualDocument50 pagesBrake Tool ManualKevin SinghNo ratings yet

- TocDocument16 pagesTocHoon Miew Jie33% (3)

- T10019EN 5.0 QuickstartDocument12 pagesT10019EN 5.0 Quickstartalex1807100% (1)

- AM-12.20.026 en D.1 MainDocument196 pagesAM-12.20.026 en D.1 MainvitoNo ratings yet

- Popular Woodworking - 016 - 1984 PDFDocument52 pagesPopular Woodworking - 016 - 1984 PDFKawchhar Ahammed100% (1)

- Hydroware Troubleshooting PDFDocument44 pagesHydroware Troubleshooting PDFSatheesh Rama100% (2)

- GAA30328BAA Dcss5 Service Tool Reference List PDFDocument19 pagesGAA30328BAA Dcss5 Service Tool Reference List PDFTaufik Hidayat KurniansyahNo ratings yet

- MRL E-Pack Assay Instructions For Tests and VerificationsDocument35 pagesMRL E-Pack Assay Instructions For Tests and VerificationsLe Huynh LongNo ratings yet

- GAA 24350 AW11 IVa PDFDocument31 pagesGAA 24350 AW11 IVa PDFEvgeniyNo ratings yet

- Instruction Manual For Diesel Generator DOOSAN MAN DIESEL 5L23 30H 720RPMDocument1,058 pagesInstruction Manual For Diesel Generator DOOSAN MAN DIESEL 5L23 30H 720RPMdionpanag94% (16)

- District Quality Assurance Unit: Republic of The Philippines Department of Public Works and HighwaysDocument21 pagesDistrict Quality Assurance Unit: Republic of The Philippines Department of Public Works and HighwaysNovelyn AlmojuelaNo ratings yet

- ASG-10 20 008 - Main - en A 1Document10 pagesASG-10 20 008 - Main - en A 1Polinho Donacimento100% (2)

- Otis - Nec Gien: Field Industrial EngineeringDocument10 pagesOtis - Nec Gien: Field Industrial EngineeringAlexis MauricioNo ratings yet

- Button ID CodesDocument6 pagesButton ID Codesyones0% (2)

- Remote Serial Link Training for Otis Elevator TechniciansDocument69 pagesRemote Serial Link Training for Otis Elevator TechniciansSamuel AcevedoNo ratings yet

- Fundamentals of V3F18: 6.4 Load Weighing Device (LWO)Document1 pageFundamentals of V3F18: 6.4 Load Weighing Device (LWO)Osman ElmaradnyNo ratings yet

- Gen2MR 31173Document12 pagesGen2MR 31173gtravaNo ratings yet

- RCBII RSL Parameters - 4767764251226047386845665916 PDFDocument67 pagesRCBII RSL Parameters - 4767764251226047386845665916 PDFBartz Santos0% (1)

- Billing EngineerDocument2 pagesBilling EngineerMahesh KurkundaNo ratings yet

- 812-000-000 SDS AC-VVVF Brushless HV - MV - E 2011-02-04 - ENG PDFDocument52 pages812-000-000 SDS AC-VVVF Brushless HV - MV - E 2011-02-04 - ENG PDFResta SativaNo ratings yet

- Contract CostingDocument18 pagesContract CostingAnant Jain100% (2)

- Orion - Gulliver Vertical Platform Lift: User ManualDocument24 pagesOrion - Gulliver Vertical Platform Lift: User ManualSuraj Yadav100% (1)

- Genius 20 en Ver 1.2Document307 pagesGenius 20 en Ver 1.2Kristoffer BarkmanNo ratings yet

- Kone Nanospace PDFDocument45 pagesKone Nanospace PDFgustavo sanchezNo ratings yet

- V3F18 Fault CodeDocument7 pagesV3F18 Fault CodeRaja DuraiNo ratings yet

- Schindler Mx Gc ManualDocument4 pagesSchindler Mx Gc Manualخالد التريكي0% (8)

- AS-11.65.031 KDL32 RepairDocument48 pagesAS-11.65.031 KDL32 RepairMike Rushe100% (1)

- Escalator PDFDocument44 pagesEscalator PDFDouglasNo ratings yet

- Start Up Routine OVF10 PDFDocument12 pagesStart Up Routine OVF10 PDFEng M ElseaidyNo ratings yet

- Adjusting The E311MV E411MV LMCSS Ward-Leonard Modernization ControllerDocument19 pagesAdjusting The E311MV E411MV LMCSS Ward-Leonard Modernization ControllerSamuel Acevedo100% (1)

- Otis GEN2 - Techna DO2000 Car DoorDocument46 pagesOtis GEN2 - Techna DO2000 Car DoorGregory BottiNo ratings yet

- Gen2™ Comfort Lift. Taking Ride Quality To A Higher LevelDocument10 pagesGen2™ Comfort Lift. Taking Ride Quality To A Higher LevelJitendra DwivediNo ratings yet

- Controllers Elevonic SeriesDocument58 pagesControllers Elevonic SeriesSamuel Acevedo100% (1)

- As-Ii: AR-II .65.034, KDL16 (KDL16R)Document4 pagesAs-Ii: AR-II .65.034, KDL16 (KDL16R)Moskac MoskacNo ratings yet

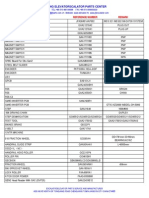

- Jufeng Elevator and Escalator Parts Center Product CatalogDocument48 pagesJufeng Elevator and Escalator Parts Center Product CatalogMelina Labor92% (13)

- Inspector's Guide: Gen2 Machine Room-Less Elevator System - The Next Generation of ElevatorsDocument16 pagesInspector's Guide: Gen2 Machine Room-Less Elevator System - The Next Generation of Elevatorsbugse100% (2)

- Adb Organization Chart 20190820 PDFDocument1 pageAdb Organization Chart 20190820 PDFToan LuongkimNo ratings yet

- Mtmtipmbprima30gb 091020035130 Phpapp01Document49 pagesMtmtipmbprima30gb 091020035130 Phpapp01Udo Iheanacho100% (4)

- Manual 40.10 PM-01.2016Document28 pagesManual 40.10 PM-01.2016Anonymous Mike100% (1)

- Autodialler PTU 8028 V2 and PTU 8028 D06 Installation ManualDocument19 pagesAutodialler PTU 8028 V2 and PTU 8028 D06 Installation ManualderbalijalelNo ratings yet

- MPDK136 Commissioning Manual Setup GuideDocument280 pagesMPDK136 Commissioning Manual Setup GuideSatheesh Rama80% (5)

- 3300 AP ReportDocument14 pages3300 AP ReportWiratama PutraNo ratings yet

- Hidra CRONO - EN81-72 AS1735 - 1-2003 - Configuration Guide - enDocument8 pagesHidra CRONO - EN81-72 AS1735 - 1-2003 - Configuration Guide - engianfrancoNo ratings yet

- (Mech. Safety System) K 602673-07Document38 pages(Mech. Safety System) K 602673-07Ali Diab100% (1)

- (PDF) BD Advands Diagnostic and Trouble Shooting GECB-LV - 2013!06!17Document17 pages(PDF) BD Advands Diagnostic and Trouble Shooting GECB-LV - 2013!06!17boneyNo ratings yet

- 10 Aaa21700xDocument17 pages10 Aaa21700xasdfNo ratings yet

- Atlas Basic SP Instalation Manual enDocument39 pagesAtlas Basic SP Instalation Manual enISHAQNo ratings yet

- Unidrive SP Elevator Issue 2Document174 pagesUnidrive SP Elevator Issue 2Andrew Lachica JacangNo ratings yet

- Guide Load Global Drive ToolDocument5 pagesGuide Load Global Drive ToolPio RodolfoNo ratings yet

- Gcs - Gecb: List of Installation ParametersDocument58 pagesGcs - Gecb: List of Installation ParametersAlexis Mauricio100% (1)

- Guide Lines: Field Component ManualDocument21 pagesGuide Lines: Field Component ManualOsman ElmaradnyNo ratings yet

- Schindler 5500 Layout Data Sheet Seismic PDFDocument4 pagesSchindler 5500 Layout Data Sheet Seismic PDFน๊อกคิโอ้ ฅนพันช่างNo ratings yet

- Sap PP SopDocument35 pagesSap PP SopMarbs GraciasNo ratings yet

- IFR Communications (131 Soru)Document18 pagesIFR Communications (131 Soru)Havva SahınNo ratings yet

- Diagnosticos y Soluc Problemas Gen2.es - en PDFDocument44 pagesDiagnosticos y Soluc Problemas Gen2.es - en PDFSatheesh Rama50% (4)

- Dossier 6170 (1) .FR - enDocument48 pagesDossier 6170 (1) .FR - enSatheesh Rama100% (1)

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- Schindler 7000 MaintainDocument16 pagesSchindler 7000 MaintainMahmoud MagdyNo ratings yet

- Modu-Tool Basic Operating Instructions PDFDocument2 pagesModu-Tool Basic Operating Instructions PDFAliRouyouNo ratings yet

- Asanoor Compact IranDocument51 pagesAsanoor Compact IranSatheesh RamaNo ratings yet

- Asanoor Compact IranDocument51 pagesAsanoor Compact IranSatheesh RamaNo ratings yet

- Ba TW45C 08 12 enDocument64 pagesBa TW45C 08 12 enangela1590100% (1)

- MCS - LCB Ii, TCB, HCB, TCBCDocument77 pagesMCS - LCB Ii, TCB, HCB, TCBCHabboula MouradNo ratings yet

- FIM Micro Instructions MOI GCS 222 MMR - 2006-10-27Document1 pageFIM Micro Instructions MOI GCS 222 MMR - 2006-10-27МихаилNo ratings yet

- MOVILIFT BR100 V1.8 Manual InglesDocument67 pagesMOVILIFT BR100 V1.8 Manual InglesSatheesh Rama88% (8)

- 100-184 ManualDocument72 pages100-184 ManualMohamedElsawiNo ratings yet

- Cedees Aps PDFDocument28 pagesCedees Aps PDFSatheesh RamaNo ratings yet

- Four Stages of Operational Competitiveness and Service BlueprintingDocument18 pagesFour Stages of Operational Competitiveness and Service BlueprintingAmanda Samaras0% (1)

- Buhler Rice Processing Catalogue SOA MEA 2015 V6Document28 pagesBuhler Rice Processing Catalogue SOA MEA 2015 V6Jibin Rajan VargheseNo ratings yet

- Distributed Database Sample QuestionsDocument3 pagesDistributed Database Sample QuestionsNhb SohelNo ratings yet

- Megas Architectural Services PVT LTD,: Risk Control Plan - Hazard Identification & Risk AssessmentDocument2 pagesMegas Architectural Services PVT LTD,: Risk Control Plan - Hazard Identification & Risk AssessmentMd jawedNo ratings yet

- Personal Skills Worksheet for Coding Career OptionsDocument2 pagesPersonal Skills Worksheet for Coding Career OptionsLucky ManNo ratings yet

- PQMDocument26 pagesPQMharoon mehmoodNo ratings yet

- The Spiral ModelDocument5 pagesThe Spiral ModelMary Ann RebloraNo ratings yet

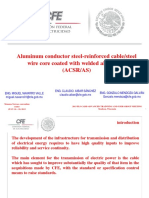

- CFE Regulations For Cables PDFDocument39 pagesCFE Regulations For Cables PDFEdward FernandezNo ratings yet

- Tax Reassessment Ordered: Preparing For The Big LeaguesDocument16 pagesTax Reassessment Ordered: Preparing For The Big LeagueselauwitNo ratings yet

- Geomiq Air Bending Chart PDFDocument2 pagesGeomiq Air Bending Chart PDFhrcozgNo ratings yet

- (Why We Need) An Operations Paradigm For ServicesDocument42 pages(Why We Need) An Operations Paradigm For ServicesdeepaksinghmbaNo ratings yet

- Technical Terms: Bug: Bug Is An Error, Flaw, or A Problem With The Functionality of AnDocument15 pagesTechnical Terms: Bug: Bug Is An Error, Flaw, or A Problem With The Functionality of AnsridharkotteNo ratings yet

- List Active NTTC Region VIII June 2013Document5 pagesList Active NTTC Region VIII June 2013Chell Cres GarcianoNo ratings yet

- IT Risk Assessment: City Auditor'S OfficeDocument14 pagesIT Risk Assessment: City Auditor'S OfficeOmerZiaNo ratings yet

- Seamless Stainless Tubes For Hydraulic and Instrumentation SystemsDocument10 pagesSeamless Stainless Tubes For Hydraulic and Instrumentation Systemsfezzeh kabiri kenariNo ratings yet

- Difference Between Oracle Apps 11i and R12Document5 pagesDifference Between Oracle Apps 11i and R12Srinivasa Rao AsuruNo ratings yet

- Uscg 009623 PDFDocument383 pagesUscg 009623 PDFAnbarasan AnandhanNo ratings yet

- 3 Ways To Extract Unique Values From A Range in Excel Listen DataDocument19 pages3 Ways To Extract Unique Values From A Range in Excel Listen DataIcank HusenNo ratings yet

- Budget 2023 - ElectricalDocument3 pagesBudget 2023 - ElectricalMaintenance MechanicalNo ratings yet

- GAMMA - Glass InsulatorsDocument4 pagesGAMMA - Glass InsulatorsMauricio SilveraNo ratings yet

- Aircraft VHF Communication Systems ReliabilityDocument2 pagesAircraft VHF Communication Systems ReliabilityAmir AsadyNo ratings yet