Professional Documents

Culture Documents

WPS Flat Butt T Butt PDF

WPS Flat Butt T Butt PDF

Uploaded by

scandalthegoodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS Flat Butt T Butt PDF

WPS Flat Butt T Butt PDF

Uploaded by

scandalthegoodCopyright:

Available Formats

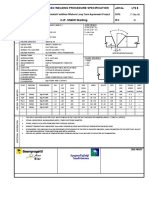

WELDING PROCEDURE SPECIFICATION WPS N°: DATE:

STRUCTURAL INSTALLATION AIDS

BUTT WELDS & T BUTT WELDS DOUBLE SIDED REV: 00

DOCUMENT REF. : AWS D1.1 JOINT DESIGN

RF = 1 ± 1 mm

PQR No : SL.E.127 RF = 1 ± 1 mm RG = 0 ‐ 5 mm

:

RG = 0 ‐ 4 mm

+ 5° α = 45°

SPEC. : α1 = 30° ‐ 2.5° + 10°

API 5L X65 ASTM A694 F65 S460 G2 + M + 10° ‐ 5°

BASE MATERIAL : α2 = 45° ‐ 5°

any combination of the followin :

SUPPLY CONDITION : N/A N/A N/A

Ceq / Pcm : N/A N/A N/A Double Side

Welds

OD RANGE FOR T joints (mm: Ø ≥ 177 Ø ≥ 177 Ø ≥ 177

WALL THICKNESS WT (mm) : 47,6 ≥ WT ≥ 3 47,6 ≥ WT ≥ 3 47,6 ≥ WT ≥ 3

PREPARATION METHOD : OXYCUTTING OR GRINDING / GRIND TO WHITE BEFORE WELDING

ALIGNMENT METHOD : TACK WELDING WITH ROOT PASS PARAMETERS

Max Hi / Lo : 0.1 x T OR 3mm (WHICHEVER LESS) WHEN APPLICABLE FILL SEQUENCE Double Side Welds

ALIGNMENT REMOVED : TACK WELDING REMOVED PROGRESSIVELY DURING ROOT PASS

Cap

PREHEAT TEMPERATURE : 100°C

T°C FOR REPAIR : See note 9 Caps Caps

Fill

INTERPASS TEMPERATURE : Max 250°C

PREHEAT METHOD : PROPANE Hot

Root

Cap Fills Hot Fills

MEASUREMENT BY : CONTACT THERMOMETER / TEMPILSTIK

BEFORE WELDING BACK PASSES,

WELDING POSITION : ALL Fill ROOT PASS MUST BE GOUGED

FROM BACK SIDE. GOUGING

WELDING DIRECTION : UPHILL WHEN VERTICAL Hot SHALL BE DONE BY GRINDING OR

ARC AIR.

NUMBER OF WELDERS : NO RESTRICTION Root

INTER-PASSES CLEANING : GRINDING IF NEEDED (Start & Stop, Silicates) IF ARC AIR IS USED, HEAT AFFECTED ZONE SHOULD BE REMOVED BY GRINDING AT

FINAL CLEANING METHOD : GRIND / POWER BRUSH / HAND TOOLS LEAST 2mm OF METAL. SEE NOTE 11.

POS. PASS WELDING WELDING AWS Standard & Class Electrod POLARITY SHIELDING GAS AMPS VOLTS TRAVEL HEAT

PROCESS CONSUMABLE eØ Ar CO2 FLOW (A) (V) SPEED INPUT

DC+ / DC-

mm (%) (%) (L/min) (cm/min) (kJ/mm)

root SMAW 2,5 - 3,2 DC - N.A N.A N.A 85 - 95 21 - 23 7 1,53 - 1,87

5G / 6G

hot SMAW TENAX 88S or 3,2 - 4 DC + N.A N.A N.A 100 - 110 22 - 27 6,8 1,94 - 2,62

(PH / A5.5 E80XX

Fill SMAW equivalent 3,2 - 4 DC + N.A N.A N.A 125 - 145 21 - 28 6,8 - 7,6 2,07 - 3,58

HL045)

Cap SMAW 3,2 DC + N.A N.A N.A 105 - 115 21 - 25 6,9 - 7 1,89 - 2,50

1 AMPERAGE / VOLTAGE / TRAVEL SPEED ARE FOR GUIDANCE ONLY. ONLY HEAT INPUT IS ESSENTIAL VARIABLE

2 MAXIMUM WAVING ALLOWED = 3 x ELECTROD Ø

3 STRIP PASS IF ANY MAY BE DONE ACCORDING TO THE FILL PASS PARAMETERS

4 PREHEAT T°C : MEASURED AT MIN 50mm AWAY FROM BEVEL EDGE USING INFRARED / CONTACT THERMOMETERS. TEMPIL

5 INTERPASS T°C : MEASURED ON THE BEVEL EDGE STICK ALLOWED OUTSIDE BEVEL

6 TACK WELD : REFER TO WELDING BOOK

7 WELD PROFILE (WELD REINFORCEMENT (WR)): • FOR T ≤ 25mm WR ≤ 3 mm • FOR 25 < T ≤ 50mm WR ≤ 4 mm • FOR 50 < T WR ≤ 5 mm

8 REPAIR WELDING : THIS WPS IS ALSO APPLICABLE FOR REPAIR. MAXIMUM N° OF REPAIR = 2. PREHEATING TEMPERATURE FOR REPAIR IS +50° ABOVE MAIN WELD.

GRINDING MAY BE USED TO REMOVE NOTCHES UP TO 5mm DEEP. NOTCHES DEEPER THAN 5mm SHALL BE GROUND OUT AND THE FACE BUTTERED

9 BACK GOUGING/GRINDING : IF ARC GOUGING IS PERFORMED, SURFACE SHALL BE MT/PT TESTED

10 STEP 2 : AFTER BACK GOUGING/GRINDING: WELDING SHALL BE DONE WITH A MINIMUM OF 2 PASSES WITH CAP PASSE PARAMETERS AS SHOWN ON STEP 2

11 FOR DOUBLE SIDED WELDS, BACK SIDE PASSES (IN GREY) WELDED WITH FILL AND CAP PARAMETERS ONLY

CLIENT :

You might also like

- On Amanda Tremblay at Citrine Software SolutionsDocument3 pagesOn Amanda Tremblay at Citrine Software SolutionssanjaanNo ratings yet

- Nuke12.2v3 ReferenceGuide PDFDocument1,093 pagesNuke12.2v3 ReferenceGuide PDFGeonan GuevaraNo ratings yet

- Contact Stresses and DeformationsDocument10 pagesContact Stresses and DeformationsSwamy BabuNo ratings yet

- MKMB 2603 Materials Testing and Quality Control: Yap Pui Yee MKM 171013Document12 pagesMKMB 2603 Materials Testing and Quality Control: Yap Pui Yee MKM 171013Penny YapNo ratings yet

- DVS 1619Document50 pagesDVS 1619Tamási BélaNo ratings yet

- Lesson 1 Checklist and Rating ScalesDocument5 pagesLesson 1 Checklist and Rating ScalesCivlerf Naej DaZo SetnobNo ratings yet

- Numerical Analysis On The Effect of Welding Parameters in TIG Welding For INCONEL 625 AlloyDocument7 pagesNumerical Analysis On The Effect of Welding Parameters in TIG Welding For INCONEL 625 AlloyErin BarryNo ratings yet

- Finite Element Analysis and Opmization of Weld Distortion ChassisDocument6 pagesFinite Element Analysis and Opmization of Weld Distortion ChassisJuan Sebastian CameroNo ratings yet

- Cadweld Welded Electrical Connections: MetricDocument56 pagesCadweld Welded Electrical Connections: MetricDonato GaloisNo ratings yet

- Residual Stress in Metal Additive ManufacturingDocument6 pagesResidual Stress in Metal Additive ManufacturingAli NasserNo ratings yet

- WeldDecayTesting TechSheet Sfs PDFDocument0 pagesWeldDecayTesting TechSheet Sfs PDFNooruddin SheikNo ratings yet

- Autocad 2d General ExercisesDocument39 pagesAutocad 2d General Exercises9700216256No ratings yet

- PEGS-0710-COR-038 - External Cathodic Protection of Onshore Deep Well CasingDocument34 pagesPEGS-0710-COR-038 - External Cathodic Protection of Onshore Deep Well CasingĐiệnBiênNhâm0% (1)

- Ca1a Cadweld Cathodic Protection Connections Catalog Lt0398Document22 pagesCa1a Cadweld Cathodic Protection Connections Catalog Lt0398Jose Luis ZimicNo ratings yet

- Study On Welding Temperature Distribution in Thin Welded Plates Through Experimental Measurements and Finite Element SimulationDocument7 pagesStudy On Welding Temperature Distribution in Thin Welded Plates Through Experimental Measurements and Finite Element SimulationManuel CarreñoNo ratings yet

- Resistance Spot Welding Fundamentals and Applications For The Automotive IndustryDocument123 pagesResistance Spot Welding Fundamentals and Applications For The Automotive IndustryIsrael Vazquez100% (1)

- Aws WJ 201705Document165 pagesAws WJ 201705Fabricio TarulloNo ratings yet

- Msc-Marc-manual Volome ADocument832 pagesMsc-Marc-manual Volome AE.HennesNo ratings yet

- Step by Step For ButtJoint - NEWDocument26 pagesStep by Step For ButtJoint - NEWMuhammad Luqman100% (1)

- WJ 2012 12 PDFDocument148 pagesWJ 2012 12 PDFMarcelo AlbeNo ratings yet

- Welding Engineering: M.Tech. DegreeDocument16 pagesWelding Engineering: M.Tech. DegreerubilNo ratings yet

- Gmaw Guide PDFDocument54 pagesGmaw Guide PDFJorge perezNo ratings yet

- Plate Analysis: Floor and Deck SlabsDocument20 pagesPlate Analysis: Floor and Deck SlabsDobromir DinevNo ratings yet

- BS en 13775-6-2004Document18 pagesBS en 13775-6-2004Abu Alhassan A.No ratings yet

- 06 NGubeljakDocument6 pages06 NGubeljakvahid_shoeibiNo ratings yet

- S 23820 ENG Sanicro 60Document2 pagesS 23820 ENG Sanicro 60Koshy JohnNo ratings yet

- Welding Metallurgy,: Flux Core Arc WeldingDocument28 pagesWelding Metallurgy,: Flux Core Arc WeldingAhmed El MorsyNo ratings yet

- SG TheoryDocument10 pagesSG TheoryvigneshwarimahamuniNo ratings yet

- Norme For WeldingDocument3 pagesNorme For Weldingsirambo1No ratings yet

- Detection and Evaluation of Rail Defects With Nondestructive Testing MethodsDocument9 pagesDetection and Evaluation of Rail Defects With Nondestructive Testing MethodsPunkajGuptaNo ratings yet

- Steel Tube Handbook WebDocument122 pagesSteel Tube Handbook WebAlejandroBolanos100% (1)

- CMAA 70 2000 Structure DesignDocument19 pagesCMAA 70 2000 Structure DesignmishikhanNo ratings yet

- ATB BrochureDocument2 pagesATB BrochureAbu Dzulqornain Tulus100% (1)

- Avoidance of Discontinuities in The Joint HardoxDocument10 pagesAvoidance of Discontinuities in The Joint HardoxfsfunbNo ratings yet

- Arclog X Manual 1.19Document55 pagesArclog X Manual 1.19davmac79No ratings yet

- Böhler Folder Strip Cladding EN WEB PDFDocument0 pagesBöhler Folder Strip Cladding EN WEB PDFCarlos Bermejo AlvarezNo ratings yet

- UDocument1 pageUmohd as shahiddin jafriNo ratings yet

- GS52Document3 pagesGS52S.Hasan MirasadiNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationMark Jason M. BrualNo ratings yet

- 8 WeldingDocument43 pages8 WeldingLopez BetoNo ratings yet

- Weld Repair of Manganese Frogs For Enhanced Safety Shared Service PDFDocument20 pagesWeld Repair of Manganese Frogs For Enhanced Safety Shared Service PDFpumud pumudNo ratings yet

- ThesisDocument48 pagesThesismuhammad amir100% (1)

- Sintap British Energy Ne-07Document61 pagesSintap British Energy Ne-07Roman KrautschneiderNo ratings yet

- Aws WJ 201901Document137 pagesAws WJ 201901Reynaldo GarciaNo ratings yet

- Foundation - Impact Testing MCDocument26 pagesFoundation - Impact Testing MCsidhesh87No ratings yet

- Manual Técnico de Parafusos - BOSSARDDocument85 pagesManual Técnico de Parafusos - BOSSARDRenato Caldas100% (1)

- 1Document9 pages1Shoaib A JamalNo ratings yet

- RESIDUAL STRESSES, Distortion and Weld Defects DISTORTION & WELD DEFECTSDocument18 pagesRESIDUAL STRESSES, Distortion and Weld Defects DISTORTION & WELD DEFECTSManoj NirgudeNo ratings yet

- Arc Welding - Calculator ChartDocument3 pagesArc Welding - Calculator ChartDr. Ladeesh V GopinathNo ratings yet

- Plasma Arc Welding MachiningDocument10 pagesPlasma Arc Welding MachiningAvinash AviNo ratings yet

- Numerical Simulation of Sleeve Repair Welding On In-Service 16Mn Crude Oil PipelinesDocument5 pagesNumerical Simulation of Sleeve Repair Welding On In-Service 16Mn Crude Oil PipelinesjangdiniNo ratings yet

- Paper Verity Weld Fatigue Method in FEADocument16 pagesPaper Verity Weld Fatigue Method in FEARich PetersonNo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Wps SmawDocument1 pageWps SmawFedericoC67% (3)

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya Barani100% (1)

- WPS-CR 01-06-15Document1 pageWPS-CR 01-06-15majdi jerbiNo ratings yet

- WPS & PQR VVSPLDocument3 pagesWPS & PQR VVSPLBhargav BbvsNo ratings yet

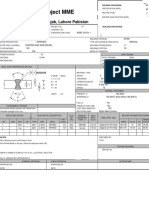

- Final Year Project MME: CEET University of The Punjab, Lahore PakistanDocument9 pagesFinal Year Project MME: CEET University of The Punjab, Lahore PakistanAhmad HasanNo ratings yet

- Sample Seal Pot DWGDocument1 pageSample Seal Pot DWGsandesh sadvilkarNo ratings yet

- Sample Seal Pot DWGDocument1 pageSample Seal Pot DWGsandesh sadvilkarNo ratings yet

- PWPS 005Document2 pagesPWPS 005Mehrdad RezaeiNo ratings yet

- Psychrometric Chart - ASHRAE - PDF: ACH (K) (NL)Document5 pagesPsychrometric Chart - ASHRAE - PDF: ACH (K) (NL)Yhan SombilonNo ratings yet

- WPS Flat Butt T Butt PDFDocument1 pageWPS Flat Butt T Butt PDFscandalthegoodNo ratings yet

- LPI Course Notes Rev 1.9Document105 pagesLPI Course Notes Rev 1.9scandalthegood100% (1)

- Coating QuestionsDocument68 pagesCoating Questionsscandalthegood100% (1)

- 1.ewf Iiw Diploma March 2015 PDFDocument1 page1.ewf Iiw Diploma March 2015 PDFscandalthegoodNo ratings yet

- Guide To ISO14731Document8 pagesGuide To ISO14731scandalthegoodNo ratings yet

- 2008-04-25 Pieter Schelte Heerema - Offshore EngineerDocument6 pages2008-04-25 Pieter Schelte Heerema - Offshore EngineerscandalthegoodNo ratings yet

- TR ISO 15608 Steel Grouping Avskrift PDFDocument5 pagesTR ISO 15608 Steel Grouping Avskrift PDFscandalthegoodNo ratings yet

- DNV OSS 401technology Qualification Manangement July 2006Document24 pagesDNV OSS 401technology Qualification Manangement July 2006scandalthegoodNo ratings yet

- En 1435 1997Document24 pagesEn 1435 1997scandalthegoodNo ratings yet

- PROJECT WORK - XII EnglishDocument4 pagesPROJECT WORK - XII English11F10 RUCHITA MAARANNo ratings yet

- Gen 003 Introduction and HistoryDocument3 pagesGen 003 Introduction and HistoryŪkkiNo ratings yet

- Bomba de Vacio Sihi LPHX 40516Document12 pagesBomba de Vacio Sihi LPHX 40516Dante Coloma JimenezNo ratings yet

- Gec 115 Lec 1 - 2 Pre MidDocument3 pagesGec 115 Lec 1 - 2 Pre MidArchjune Aubrey AbellaNo ratings yet

- Xcell Ammonia (NH) Sensor: Technical Data SheetDocument2 pagesXcell Ammonia (NH) Sensor: Technical Data SheetPaulo HeideckeNo ratings yet

- Erased Log by SosDocument3 pagesErased Log by SosJeremy LuriciNo ratings yet

- 87-10245-RevB DT4030N DigTransceiver PDFDocument2 pages87-10245-RevB DT4030N DigTransceiver PDFVíctor MayaNo ratings yet

- Overview of Social Sciences FinalDocument19 pagesOverview of Social Sciences FinalDhaf DadullaNo ratings yet

- 2-Wheel Profile Measuring System-WPMSDocument19 pages2-Wheel Profile Measuring System-WPMSVictor Manuel BonettoNo ratings yet

- CW5045 Wiring Diagram PDFDocument18 pagesCW5045 Wiring Diagram PDFhaikalNo ratings yet

- Control and Optimization of Distributed Generation Systems: Magdi S. Mahmoud Fouad M. AL-SunniDocument599 pagesControl and Optimization of Distributed Generation Systems: Magdi S. Mahmoud Fouad M. AL-Sunniasad khan100% (1)

- Quality AwardsDocument9 pagesQuality AwardsCalton MungofaNo ratings yet

- Booking Confirmation On IRCTC, Train: 12218, 06-Apr-2022, 3A, NDLS - MAODocument1 pageBooking Confirmation On IRCTC, Train: 12218, 06-Apr-2022, 3A, NDLS - MAOMohit YoungmanNo ratings yet

- TpackcanvaDocument2 pagesTpackcanvaapi-557991875No ratings yet

- GIZ ResursiDocument4 pagesGIZ ResursiAleksandar VidakovicNo ratings yet

- 2.Pdms Gridline Creation ManualDocument8 pages2.Pdms Gridline Creation ManualTran ThienNo ratings yet

- BIBLIOGRAPHYDocument3 pagesBIBLIOGRAPHYMark Anthony AlcantaraNo ratings yet

- Toilet Details R1 A2Document1 pageToilet Details R1 A2Irshad KhanNo ratings yet

- 03.master List of Procedure YI-ID NDocument1 page03.master List of Procedure YI-ID NFendiNo ratings yet

- Earth Science: Quarter 2 - Module 6: Seafloor SpreadingDocument23 pagesEarth Science: Quarter 2 - Module 6: Seafloor Spreadingqueancy euleNo ratings yet

- 2 - Inst Chem Lec Calibration of Instrumental Methods PTTDocument8 pages2 - Inst Chem Lec Calibration of Instrumental Methods PTTJoudNo ratings yet

- Public Spanish 2 Course Map - Spanish 2Document2 pagesPublic Spanish 2 Course Map - Spanish 2api-534094065No ratings yet

- Module 8Document8 pagesModule 8Dethzaida AsebuqueNo ratings yet

- Corporate Strategy SpeechDocument2 pagesCorporate Strategy SpeechJessuel Larn-epsNo ratings yet

- Speech ExamplesDocument6 pagesSpeech Examplesjayz_mateo9762100% (1)

- Section 16.14: Colligative Properties of SolutionsDocument3 pagesSection 16.14: Colligative Properties of SolutionsCatalina Perry100% (1)

- Success Comes in Many Different Shapes and FormsDocument7 pagesSuccess Comes in Many Different Shapes and FormsRagunathan srinivasan100% (1)

- Reflection Paper Elective 3Document2 pagesReflection Paper Elective 3ChaskieNo ratings yet