Professional Documents

Culture Documents

AS3788 Appendix N - Assessment of Wall Thinning: Input Data Calculations

Uploaded by

Ganesh0 ratings0% found this document useful (0 votes)

85 views5 pagesOriginal Title

ATTAR-AS3788-Assessment-of-Wall-Thinning (1).xlsx

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

85 views5 pagesAS3788 Appendix N - Assessment of Wall Thinning: Input Data Calculations

Uploaded by

GaneshCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 5

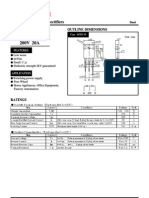

AS3788 Appendix N - Assessm

Input data Calculations

La 400 mm t1 30.00 mm

Lh 400 mm t2 15.00 mm

Dm 1500 mm Ls 116.67 mm

p 4 MPa t1&t2<5LS 583.36 Pass

f 100 MPa t1&2<2/3dm 999 Pass

tm 32 mm L 400 mm

tm axis a a or h t 30.00 mm

Cos Ø 1 1 for cylinders tm/t 1.067

Corrosion 0 Rate L/Ls 3.428

1.2

AS3788-2006 Figure N2

0.1 0

1

0.4 0.6

0.8 0.9

0.8

1 1

5

0.6

1

0.4

0.2

0

0.1 1

Basic Example Only - For ATTAR Training Use Only

ppendix N - Assessment of Wall Thinning

Results Other Data

Minimum Thickness Required (mm) Standard

Harmful/Lethal Content 9.00 Class

Transport/Impact Risk 18.00 Safety Factor

Other 6.00 Weld Efficiency

Nominal Thickness (mm)

Thickness Minimum (mm)

Graph Compliance Max Operating Temperature °c

Pass

Assumptions (use drop down to select)

Not subject to cyclic loading

Loss area not located near welds, opening or support

Positive Pressure Vessel

Thin wall vessel

Cos Ø = 1 , cylindrical vessel

No cracking or planar discontinuities evident

-

-

-

-

-

-

-

TAR Training Use Only Created by P.Grosser

AS1210 -1989

3

4

0.7

40

24

65

n to select)

ading

pening or support

sel

essel

uities evident

ated by P.Grosser

You might also like

- ATTAR AS3788 Assessment of Wall Thinning V1.02Document5 pagesATTAR AS3788 Assessment of Wall Thinning V1.02Ashraf BottaniNo ratings yet

- Nord Lock Washers InfoDocument8 pagesNord Lock Washers InfoMaclean ArthurNo ratings yet

- Sequential Lifting of Tank Shell Used To Repair FloorsDocument4 pagesSequential Lifting of Tank Shell Used To Repair FloorsBIPIN BALANNo ratings yet

- Vertical CompressDocument47 pagesVertical CompressSivi NallamothuNo ratings yet

- Flexpipe Systems Brochure AustraliaDocument6 pagesFlexpipe Systems Brochure AustraliapenjualgasNo ratings yet

- Refinery InspectionDocument44 pagesRefinery InspectiongamadiyaNo ratings yet

- Slewing Bearing Installation and Maintenance Manual: Yantai Haoyang Machinery Co.,LtdDocument22 pagesSlewing Bearing Installation and Maintenance Manual: Yantai Haoyang Machinery Co.,Ltddony ramdhaniNo ratings yet

- Thread Types and UsesDocument1 pageThread Types and UsesJDPNetoNo ratings yet

- Abrasive BlastingDocument52 pagesAbrasive Blastinglwin_oo2435100% (1)

- Flange Insulation Kit Installation and Torque GuideDocument4 pagesFlange Insulation Kit Installation and Torque Guidemashudi_fikriNo ratings yet

- Butterfly Valve Operation Manual PDFDocument16 pagesButterfly Valve Operation Manual PDFLuis GonzalezNo ratings yet

- Datasheet Wear PadDocument3 pagesDatasheet Wear PadGILBERTO YOSHIDANo ratings yet

- Technical Specification: GID-PIP-TS-630 - (E)Document41 pagesTechnical Specification: GID-PIP-TS-630 - (E)santiagoNo ratings yet

- Normas de Referencia - Fibra de VidroDocument12 pagesNormas de Referencia - Fibra de Vidroricardobor100% (1)

- What TitleDocument17 pagesWhat TitleBernathTurnipNo ratings yet

- What is a Foam Pig and how is it usedDocument4 pagesWhat is a Foam Pig and how is it usedyogacruiseNo ratings yet

- Belzona Coating Guide For CUI and Atmospheric CorrosionDocument2 pagesBelzona Coating Guide For CUI and Atmospheric CorrosionfraemddNo ratings yet

- Cement - API Oilwell Cement, Class 'G', Moderate Sulphate Resistant - Lehigh Cement Limited 2014 PDFDocument6 pagesCement - API Oilwell Cement, Class 'G', Moderate Sulphate Resistant - Lehigh Cement Limited 2014 PDFAMSNo ratings yet

- Inspection and Assessment of Damaged Subsea PipelinesDocument9 pagesInspection and Assessment of Damaged Subsea PipelinesВалерий ГерасимовичNo ratings yet

- As 3571.2-2009 Plastics Piping Systems - Glass-Reinforced Thermoplastics (GRP) Systems Based On Unsaturated PDocument8 pagesAs 3571.2-2009 Plastics Piping Systems - Glass-Reinforced Thermoplastics (GRP) Systems Based On Unsaturated PSAI Global - APACNo ratings yet

- Effect of Corrosion On Mild Steel in Food Processing Industry: A ReviewDocument8 pagesEffect of Corrosion On Mild Steel in Food Processing Industry: A ReviewIJAERS JOURNALNo ratings yet

- 14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFDocument11 pages14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFVladimir Rodriguez LeonNo ratings yet

- Van Stone BellowsDocument1 pageVan Stone BellowsSeungmin PaekNo ratings yet

- Ingress Protection (IP)Document2 pagesIngress Protection (IP)nileshb1985No ratings yet

- Dust Collector Installation ProcedureDocument9 pagesDust Collector Installation Procedureadil shidiq100% (1)

- CNC Oxyacetylene Flame Cutting MachineDocument12 pagesCNC Oxyacetylene Flame Cutting MachineNaman JoharNo ratings yet

- Galvanizing HistoryDocument6 pagesGalvanizing HistorySreedhar Patnaik.MNo ratings yet

- Marine Painting FundamentalsDocument57 pagesMarine Painting FundamentalsMin SoeNo ratings yet

- Properties of Polyester Polymer Concrete With GlassDocument12 pagesProperties of Polyester Polymer Concrete With GlassMohammad AasimuddinNo ratings yet

- Flange Bolt Torque Calculation and Pipe Flange Bolt Torque ChartDocument6 pagesFlange Bolt Torque Calculation and Pipe Flange Bolt Torque ChartArya0% (1)

- Troubleshooting Pumps: Pump Failure AnalysisDocument19 pagesTroubleshooting Pumps: Pump Failure Analysispankaj vermaNo ratings yet

- ZA0-2 35,0ae-03 00Document15 pagesZA0-2 35,0ae-03 00Marcos Dos Santos VieiraNo ratings yet

- Pig Handling System Brochure PDFDocument6 pagesPig Handling System Brochure PDFKRUNAL SHAHNo ratings yet

- Gasket Materials - Seal & Design IncDocument9 pagesGasket Materials - Seal & Design Incnuvvnak nachaNo ratings yet

- 7-12-0005 Rev6 (Skirt Opening Details)Document2 pages7-12-0005 Rev6 (Skirt Opening Details)sumit kumarNo ratings yet

- Sample2 DrawingDocument1 pageSample2 DrawingganeshNo ratings yet

- Manhole Technical GuideDocument56 pagesManhole Technical Guidekyekwa2No ratings yet

- Gasket Material, Packing & SealsDocument27 pagesGasket Material, Packing & SealsDinesh AdwaniNo ratings yet

- Lifting Lug Calculation Rev - 1Document2 pagesLifting Lug Calculation Rev - 1WijayantoNo ratings yet

- Corrosion Evaluation of Reboiler Tube PDFDocument11 pagesCorrosion Evaluation of Reboiler Tube PDFOwais MalikNo ratings yet

- Pontoon IFR Technical Specifications 07-18-06 PDFDocument15 pagesPontoon IFR Technical Specifications 07-18-06 PDFdndudcNo ratings yet

- FRP Pipe BrochureDocument8 pagesFRP Pipe BrochurecrisjhairNo ratings yet

- FRP DesignDocument17 pagesFRP DesignRUSTSHIELD IndonesiaNo ratings yet

- Leak Testing and Rehabilitation PDFDocument72 pagesLeak Testing and Rehabilitation PDFjsenadNo ratings yet

- ETL Pressure Relief Valves Datasheet PDFDocument6 pagesETL Pressure Relief Valves Datasheet PDFNanasaheb PatilNo ratings yet

- Recommended Testing Procedures For HDPE PipeDocument1 pageRecommended Testing Procedures For HDPE Pipeosto72No ratings yet

- SRT-13 Stops Rust Cold Galvanizing Spray TDSDocument2 pagesSRT-13 Stops Rust Cold Galvanizing Spray TDSIngeniero CivilNo ratings yet

- Breather Valve - PV Valve - CNC380Document2 pagesBreather Valve - PV Valve - CNC380mhidayat108No ratings yet

- Slewing Bearing Slewing Ring Slewing Gear Swing CircleDocument15 pagesSlewing Bearing Slewing Ring Slewing Gear Swing Circlezczc32z5No ratings yet

- Hot Tapping Procedure Into Existing PLEMDocument1 pageHot Tapping Procedure Into Existing PLEMBalanNo ratings yet

- Tank Truck Equipment CatalogDocument133 pagesTank Truck Equipment CatalogluisfernandoaliNo ratings yet

- Operating Instructions - Standard Shoring - SBH Series 600 Manhole Shoring BoxDocument8 pagesOperating Instructions - Standard Shoring - SBH Series 600 Manhole Shoring BoxAmr Adel HameedNo ratings yet

- Denso Valve Flange Tape Wrapping SpecDocument3 pagesDenso Valve Flange Tape Wrapping SpecNaufal Firmansyah100% (1)

- Europe's Longest Marine PE Pipe ProjectDocument8 pagesEurope's Longest Marine PE Pipe Projectmidhun1986No ratings yet

- App10 Fundamentals of ConnectionsDocument23 pagesApp10 Fundamentals of ConnectionsjdmacbookNo ratings yet

- 760C Tapping MachineDocument6 pages760C Tapping MachineTunjung Wicaksana RanukusumaNo ratings yet

- AS3788 Appendix N Wall Thinning AssessmentDocument5 pagesAS3788 Appendix N Wall Thinning Assessmentأحمد حسنNo ratings yet

- Annex 3 JV TARLEPLAST 24,0g Rev 2Document1 pageAnnex 3 JV TARLEPLAST 24,0g Rev 2Алексей ЧаусовNo ratings yet

- SJ MEPLA Calculation Protocol: Geometry:: Project: Frameless Glass - Glass 3 16-02-2024Document6 pagesSJ MEPLA Calculation Protocol: Geometry:: Project: Frameless Glass - Glass 3 16-02-2024alex robinNo ratings yet

- En NTN 6208ZZC3 5KDocument3 pagesEn NTN 6208ZZC3 5Krozzaq dhmgroupNo ratings yet

- Ultrasonics Accoustic ImpedanceDocument2 pagesUltrasonics Accoustic ImpedanceGaneshNo ratings yet

- Ultrasonics Accoustic ImpedanceDocument2 pagesUltrasonics Accoustic ImpedanceGaneshNo ratings yet

- Acoustic EmissionDocument39 pagesAcoustic Emissiongovindarajan017No ratings yet

- AS3788 Appendix N - Assessment of Wall Thinning: Input Data CalculationsDocument5 pagesAS3788 Appendix N - Assessment of Wall Thinning: Input Data CalculationsGaneshNo ratings yet

- Mechanized Coal Handling SystemDocument1 pageMechanized Coal Handling SystemGaneshNo ratings yet

- Petroleum Refining Overview: Crude Oil Characterization & Refinery ProcessesDocument83 pagesPetroleum Refining Overview: Crude Oil Characterization & Refinery ProcessespadalakirankumarNo ratings yet

- Condition Assessment of BoilerDocument8 pagesCondition Assessment of BoilerEzhil Vendhan PalanisamyNo ratings yet

- Gareth Hughes - Materials of Crude Oil RefiningDocument12 pagesGareth Hughes - Materials of Crude Oil RefiningZakiyya HannaNo ratings yet

- Analysis of Self Supported Steel ChimneysDocument81 pagesAnalysis of Self Supported Steel ChimneysrodrigoperezsimoneNo ratings yet

- Presentations Oil Refinery ProcessesDocument36 pagesPresentations Oil Refinery ProcessesGururaj SreepatharaoNo ratings yet

- Life Assessment of High Temperature HeadersDocument31 pagesLife Assessment of High Temperature HeadersAnonymous UoHUag100% (1)

- Condition Assessment of BoilerDocument8 pagesCondition Assessment of BoilerEzhil Vendhan PalanisamyNo ratings yet

- Inspection Manual For PipingDocument183 pagesInspection Manual For PipingMartin Zaballa100% (3)

- Boilers RLADocument60 pagesBoilers RLAGanesh100% (1)

- Presentations Oil Refinery ProcessesDocument36 pagesPresentations Oil Refinery ProcessesGururaj SreepatharaoNo ratings yet

- Boiler RLADocument4 pagesBoiler RLAGaneshNo ratings yet

- Ageing Plant Summary GuideDocument53 pagesAgeing Plant Summary GuideEyoma EtimNo ratings yet

- Cor Cop N India 2004Document10 pagesCor Cop N India 2004abhi_luvme03No ratings yet

- Requirements For Life Extension of Ageing Offshore Production InstallationsDocument54 pagesRequirements For Life Extension of Ageing Offshore Production InstallationsGaneshNo ratings yet

- Direct Assessment Techniques for Pipeline IntegrityDocument11 pagesDirect Assessment Techniques for Pipeline IntegrityJuliyan PujakesumaNo ratings yet

- Stress Corrosion Cracking Recommended Practices 2007Document205 pagesStress Corrosion Cracking Recommended Practices 2007Vicknesh Thanabal80% (5)

- Vessel Integrity Management (VIM) Using API579 PDFDocument5 pagesVessel Integrity Management (VIM) Using API579 PDFGaneshNo ratings yet

- User Exits in Oracle Reports for AOL IntegrationDocument2 pagesUser Exits in Oracle Reports for AOL Integrationnagarajuvcc123No ratings yet

- CLORIOUS - ControlsDocument4 pagesCLORIOUS - ControlsRM HaroonNo ratings yet

- Dairy Farm Group Case StudyDocument5 pagesDairy Farm Group Case Studybinzidd007No ratings yet

- Electraquip 2015-4Document1 pageElectraquip 2015-4Anonymous M0OEZEKoGiNo ratings yet

- Mud Construction KeralaDocument9 pagesMud Construction Keralaincridable patnaNo ratings yet

- National Post, Saturday, February 6, 2010Document1 pageNational Post, Saturday, February 6, 2010api-25940859No ratings yet

- Maruti Celerio ReviewDocument18 pagesMaruti Celerio ReviewKamal Yagami100% (1)

- CS Pipe Metric Dimensions As Per Asme B36-10Document20 pagesCS Pipe Metric Dimensions As Per Asme B36-10havocs havenNo ratings yet

- Baker, BachourDocument178 pagesBaker, BachourHoward BrandonNo ratings yet

- R Stahl Corporate InformationDocument8 pagesR Stahl Corporate InformationGeo ThaliathNo ratings yet

- ME96NSR Power MeterDocument11 pagesME96NSR Power MeterAndrew MaverickNo ratings yet

- TOC - Table of Compliance Arsitek SimDocument40 pagesTOC - Table of Compliance Arsitek SimImran nasution0% (1)

- Chap014 - JIT and Lean OperationsDocument31 pagesChap014 - JIT and Lean OperationsAgentSkySkyNo ratings yet

- Gas Appliance Pressure Regulators with Integrated FilterDocument8 pagesGas Appliance Pressure Regulators with Integrated FilterAlEjAnDrO CoNtReRaSNo ratings yet

- S20LC20U S20LC20U: Shindengen ShindengenDocument6 pagesS20LC20U S20LC20U: Shindengen ShindengendaocongdablNo ratings yet

- Articles For HandphoneDocument11 pagesArticles For HandphoneMimiMichelleMichaelNo ratings yet

- Primary and Secondary Cells PPDocument12 pagesPrimary and Secondary Cells PPJavier DavisNo ratings yet

- Understand Api PDFDocument332 pagesUnderstand Api PDFgopiipog786No ratings yet

- Struxureware PME BrochureDocument2 pagesStruxureware PME BrochureSky BysNo ratings yet

- Sow Form 1 KSSM 2017 EnglishDocument23 pagesSow Form 1 KSSM 2017 Englishwhy daNo ratings yet

- HP Notebook BIOS Setup GuideDocument8 pagesHP Notebook BIOS Setup GuideBalaRajKumarNo ratings yet

- Atlas Metals HandbookDocument45 pagesAtlas Metals HandbookJim GrayNo ratings yet

- Research Literature ReviewDocument13 pagesResearch Literature ReviewDiya1991No ratings yet

- DHP453Document4 pagesDHP453wzsdqciqNo ratings yet

- Laboratory Manual: Concrete and AggregateDocument20 pagesLaboratory Manual: Concrete and AggregateBatepola BacNo ratings yet

- CEMBC75 Wheel BalancerDocument6 pagesCEMBC75 Wheel BalancerSimranjeet SinghNo ratings yet

- L&T QuestionsDocument19 pagesL&T QuestionsVALLI NNo ratings yet

- Pulsar DTSi Parts ListDocument68 pagesPulsar DTSi Parts ListSushil Kumar67% (9)

- Dehumidifier Manual With Wiring DiagramDocument102 pagesDehumidifier Manual With Wiring DiagramMd.Rasel MiaNo ratings yet

- Parts List of Engine Assy of FMX 440 (PC-24) - TP-836Document1 pageParts List of Engine Assy of FMX 440 (PC-24) - TP-836Cws0% (1)