Professional Documents

Culture Documents

Leak Testing For Closure Welds of Pressure Piping PDF

Uploaded by

ezzataOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Leak Testing For Closure Welds of Pressure Piping PDF

Uploaded by

ezzataCopyright:

Available Formats

THE PRESSURE NEWS

Volume 9, Issue 3, September 2004

F LARE L INES AND F LARE K NOCKOUTS

Flare lines, flare knockouts and Lines to the flare should be sloped corrosion and metal deterioration due

associated equipment are typically back to the flare knockout so that to high temperature from possible

open to atmosphere and exempted liquids will drain back to the flare flame impingement. Material

from the Safety Codes Act. However, knockout. selection for the construction of flare

if not installed, maintained and stacks is important. The flare pilot

operated properly, they could pose The flame arrestor should be checked should be checked to ensure that it

considerable safety hazards as well at every opportunity to ensure that it will be dependable.

as impacting on pressure equipment. is clean.

Flare systems should not be used as

Earlier this spring, a fatality occurred On some installations, a larger liquid collection systems. Many times

at a sour battery site. Investigation diameter line is installed at the base these liquids are corrosive. If the flare

noted that sour gas escaping from a of the flare. This line will act as a system tends to gather large amounts

manway on a flare knockout drum debris trap. This line should be of liquids, then the flare knockout

might have contributed to the incident. checked as it will eventually build up should be coated to protect it from

Flare knockout drums are designed with debris to the point where it could corrosion.

for limited pressure. Any restriction be blocked off.

downstream of the flare knockout There is always the question of

drum will result in a pressure buildup Most plants have a flare line that runs personal protective equipment

in the drum and possibly an over- the full length of the plant. The line in whenever working on gas and oil

pressure situation. The most common the plant needs to be sloped to the facilities. Personal gas monitors and

problems that occur at the bottom of knockout drum so that moisture does working in pairs are both important

the flare stacks are that the line might not stay in the line, causing freezing considerations.

freeze due to moisture in the line or or corrosion problems. In many

the flame arrester plugs off from cases, the discharges from the relief Remember that any restriction in the

carbon products generated from valves are tied into this line. Any flare line or flare stack may cause

combustion that occurs near the moisture that should happen to stay overpressure of the system, to the

flame arrestor. in the discharge port of the safety point where gases could be released

valve will cause corrosion of the relief from the flare knockout drum or

This article will point out some of the valve spindle to the point where the anywhere else in the system. Also

areas that should be checked during relief valve may seize and not backpressure in the system could

initial installation of flares and flare function when required. affect the operation of the relief

knockouts and also what should be valves that are discharging into the

checked during each turnaround. The flare stack itself should be flare line.

checked regularly for signs of

ABSA UPDATE SEMINAR

October 5 - Edmonton / October 7 - Calgary

Once again, ABSA is offering a seminar for the pressure equipment industry to address the impact of the most recent

ASME Code changes on designers, quality control inspectors and other users of the Codes. The 2004 ASME Boiler

and Pressure Vessel Codes are about to be published and will become mandatory on March 31, 2005.

The meetings have been set for October 5 at the Nisku Inn in Nisku, and October 7 at the Blackfoot Inn in Calgary.

As before, we will take the opportunity to discuss other items of interest such as findings from recent design reviews or

ASME shop reviews.

As seating may be limited, we would request that the number of attendees from any one company initially be restricted

to two. More openings may become available closer to the meeting dates. Registrations will be accepted on a first-

come, first-served basis. Applications may be obtained from your nearest ABSA office or from our website. The

deadlines for registration will be September 28 for Edmonton and September 30 for Calgary .

Have you visited us on the Internet yet? - www.absa.ca

The Pressure News Page 2 Volume 9, Issue 3, September 2004

SPECIAL CONSIDERATIONS FOR A LTERNATIVE Company Annual

L EAK T ESTING FOR CLOSURE W ELDS OF Renewal

of

PRESSURE PIPING F ABRICATED TO ASME B31.3 Power Engineering

In a previous article (Testing Pressure a written test procedure must be Certificates of Competency

Piping, Volume 2, Issue 4, August prepared to address fully the

1997) we explained the regulatory technical and safety considerations In 1994, the annual renewal of Power

requirements for pressure testing for the test, Engineer and Operator Certificates of

piping systems, as well as some of the owner of the piping system Competency came into legislation in

the considerations for alternative must review the circumstances and the Engineers Regulations and that

testing or waiving of the hydrostatic decide to accept the risk of not requirement continues in the Power

test. This article provides more hydrostatically testing the piping Engineers Regulation (AR 85/2003).

information about alternative leak system, Power engineers are responsible for

testing. We also explain the an ABSA SCO must have an the renewal of their certificates. Plant

application in Alberta of special opportunity to review and accept owners are responsible for ensuring

provisions for closure welds published the proposed written alternative test that the requirements of the Act and

in the ASME B31.3. procedure prior to testing, as regulations are met including that the

required by Sections 58(3) and power engineers are holding valid

Leak testing of pressure piping 7(2)(f) of the Design, Construction certificates. Some companies set up

systems is performed prior to placing and Installation of Boilers and a group renewal with ABSA and pay

the system in service. The purpose of Pressure Vessels Regulations. the annual renewal fee for their

the leak test is to verify the integrity of employees.

the piping system. The test is the last In addition to the listed alternative test

physical quality test in the fabrication methods, ASME B31.3 includes ABSA has changed the process for

process to verify the system is safe to provisions for exempting certain welds company renewals and the new

operate. from the required leak test. Paragraph process is as follows.:

345.2.3(c) states:

The hydrostatic test method is Annually, a company may initiate

preferred mainly due to safety "Closure Welds. renewal of their employees

considerations and for ease of finding The final weld connecting piping certificates by providing, to ABSA, the

leaks. Hydrostatic testing is required systems or components which following information on ABSA Form

by regulation and by B31.3, unless have been successfully leak AB-73 (Annual Renewal of Engineers

specific approval to use another type tested in accordance with para. and Operators Certificates) for each

of test procedure or to waive the leak 345 need not be leak tested employee :

test has been accepted by ABSA and provided the weld is examined in-

the Owner. Compared with air, water process in accordance with para. File Number

at ambient temperature has less 344.7 and passes with 100% Name of Employee

stored energy per unit of volume at radiographic examination in Date of Birth

equal pressures. Should a component accordance with para. 344.5 or

Class of Certificate

fail during a hydrostatic test, the 100% ultrasonic examination in

Certificate Number

energy stored in the water is quickly accordance with para. 344.6".

Home Address

dissipated. Conversely, in view of the

As with the alternative leak test E-mail address

considerable stored energy involved

procedures discussed above, use of Signature of Employee

with air testing, the consequence of

failure of a system under a pneumatic this exemption in Alberta requires

specific acceptance of the written ABSA will accept renewals for a

test can be significant.

procedure by an ABSA Safety Codes maximum of 3 years in advance. The

Officer. The company responsible for renewal cards will be sent to the

It is recognised that there may be

construction of the pressure piping individual. The certificate holder is

occasions when it is impracticable to

system must request acceptance prior responsible to post the card with his/

conduct a hydrostatic test. Therefore,

to construction. Requests are her certificate at the plant.

Alberta regulations allow for, and

ASME B31.3 provides, alternatives. reviewed by ABSA on a case-by-case

Alternative test methods include basis. The review includes verification

pneumatic testing and sensitive leak that all Code requirements will be CORRECTION

testing. Certain conditions must be satisfied, and that the ultimate owner

Volume 9, Issue 2, June 2004

satisfied if an alternative test is to be is in agreement with the proposed

Incident Involving Over-

used in lieu of the required hydrostatic alternative.

Pressure

test:

In-process examination in accordance

with B31.3 para. 344.7 necessitates Under the 3rd paragraph .....

there must be valid technical

that there be accept-reject criteria plant air at over 100 psig

justification for selecting an

established for the things that are (1034)kPa to the tank .... should

alternative test. For example, if

being examined. Unlike RT or UT, read ..... plant air at over 100

water would contaminate the

process, such criteria have not been psig (689 kPa) to the tank ....

(Continued on page 3)

The Pressure News Page 3 Volume 9, Issue 3, September 2004

PRESSURE PIPING CONSTRUCTION D OCUMENTS

Despite their being in use for many form is to be completed by the pressure, but also that the necessary

years, questions still arise about the contractor when the final pressure controls, instrumentation and

use of Construction Data Report for test specified in the engineering safety devices have been installed

Piping Systems forms (ABSA form design has been completed. and verified as functional to maintain

AB-83) and the Completion of the conveyed fluid within safe

Construction Declaration forms What if the contractor is only operating parameters.

(ABSA form AB-81). Here are some building part of the piping

common questions. system? When is the AB-81 form to be

completed?

Who completes the forms? In the case of piping spools

fabricated by third parties The AB-81 is to be completed before

AB-83 forms are to be completed by (subcontractors) and shipped to the the pressure piping system is put into

the contractor and delivered to the job site for assembly and testing by operation.

owner. the primary contractor, and no

pressure test has been specified in When is a pressure piping system

AB-81 forms are to be completed by the engineering design (to the considered to be in operation ?

the person responsible for the subcontractor), then the AB-83 would A pressure piping system is " in

construction, installation, testing and be completed as a "partial data operation " any time it is being used

inspection of the pressure piping report" by the subcontractor when the to convey, for any purpose, an

system and forwarded to the subcontractor's work is complete and expansible fluid under pressure after

Administrator/Chief Inspector. provided to the primary the final pressure test specified in the

contractor. The primary contractor engineering design has been

What is the purpose of the would then sign off a final data completed.

Construction Data Report for report when the final pressure test

Piping Systems (AB-83)? specified in the engineering design What happens to the completed

The purpose of the AB-83 document has been completed.

forms?

is to provide assurance that pressure

What is the purpose of the The owner must retain completed

piping has been constructed, tested

Completion of Construction AB-83 the forms on file for a period

and inspected in accordance with the

Declaration (AB-81) of not less than 5 years and produce

contractors quality system,

them on request of a Safety Codes

engineering design, construction The purpose of the AB-81 is to Officer. Completed AB-81 forms are

code and Safety Codes Act provide assurance the system is safe retained on file by ABSA. Copies of

requirements. to operate. This means not only that these completed forms must also be

the system has been constructed, maintained in accordance with the

When is the AB-83 to be inspected and tested in accordance contractors quality system.

completed? with the engineering design, thus

A construction and test data report deemed safe to be placed under

(Continued from page 2) CHANGES TO THE

established by Code and must be

realistically established by the I NFORMATION B ULLETINS W EB PAGES

designer. Note also that para. 342.2

states For in-process examination, The Information Bulletins web pages Background

the examinations shall be performed (www.absa.ca / Technical

by personnel other than those Information) have been revised to The Chief Inspector and Administrator

performing the production work. provide clearer information. We have issues Variances, Directives and

That is to say that the welder cannot categorized the bulletins and Interpretations regarding pressure

assess his own fit-up, etc. identified the bulletins that are equipment under the Safety Codes

outdated or are no longer relevant. Act.

Pressure piping systems can present The information bulletins have been

a very significant safety hazard so it categorized into six (6) types: Alert, Since 1998, a total of 42 Variances,

Directive, Exemption, Information, Directives, Interpretations, Alerts and

is extremely important that their

Interpretation and Variance. As well, other information were issued as

design, construction, installation,

where applicable, related regulations Information Bulletins. Some

operation, inspection and testing be

are identified. Information Bulletins are outdated or

carried out in strict accordance with

are no longer relevant due to changes

recognized standards. When In addition, the Act and Regulation in the Act and Regulations, ASME

considering any alternative to the web page will be revised to reference Codes, or other codes and standards.

hydrostatic test prescribed under the the applicable information bulletins. People have difficulty identifying

Safety Codes Act, all risks and This page is a good resource to check which Information Bulletins are still

consequences must be carefully and whether you are using the latest valid and associating them with the

thoroughly evaluated. regulation and also to see if there are applicable regulations.

any variances that can apply to a

(Continued on page 4)

specific regulation.

The Pressure News Page 4 Volume 9, Issue 3, September 2004

(Continued from page 3) ABSA is committed to providing the

latest information regarding pressure ABSA OFFICES

ABSA is committed to providing equipment safety to the public. To

information help us to serve you better, you can Edmonton - Head Office

provide your feedback and #200, 4208 - 97th Street

Effective communication between the suggestions to ABSA by emailing Edmonton, Alberta T6E 5Z9

public and ABSA is essential to Tel (780) 437-9100

webmaster@absa.ca. Fax (780) 437-7787

promote pressure equipment safety.

Calgary

Tower 3, #590 1212-31st Avenue N.E.

Calgary, Alberta T2E 7S8

PRESSURE E QUIPMENT SAFETY T RAINING Tel (403) 291-7070

Fax (403) 291-4545

As the pressure equipment safety assessment on the training page. Fort McMurray

authority, ABSA is committed to Industry and individual input is critical #204, 9913 Biggs Avenue

Fort McMurray, Alberta T9H 1S2

helping individuals and industry meet to identifying training requirements Tel (780) 714-3067

their training needs in pressure and we value your comments and Fax (780) 714-2380

equipment safety. ABSA currently feedback. To put forward ideas for

future training, to contact us for Grande Prairie

hosts seminars by the National Board #203, 10109 - 97th Avenue

of Boiler and Pressure Vessel customized training sessions or if you Grande Prairie, Alberta T8V 0N5

Inspectors and provides seminars, have any concerns with regard to Tel (780) 538-9922

with the use of ABSA subject training, please contact the training Fax (780) 538-9400

specialists, on topics such as the department at training@absa.ca. Lethbridge

upcoming Pressure Equipment Safety #300, 515 - 7th Street South

th

Legislation Seminar on October 26 Please indicate if you or your Lethbridge, Alberta T1J 2G8

th

and 27 . For course information and company would like to be included on Tel (403) 394-1011

Fax (403) 327-2483

upcoming training inquiries, please our electronic mailing list to be

see our listings on the absa.ca notified of upcoming seminars and Medicine Hat

website. training programs. Keep watching #103, 346 - 3rd Street S.E.

The Pressure News for Medicine Hat, Alberta T1A 0G7

Tel (403) 529-3514

We are developing the ABSA training announcements from the training Fax (403) 529-3632

page to be introduced with our department, and look for the

redesigned website, and will be revamped website launch! Red Deer

including an industry needs #304, 4406 Gaetz Avenue

Red Deer, Alberta T4N 3Z6

Tel (403) 341-6677

Fax (403) 341-3377

CONTENTS St. Paul

Please note that our St. Paul office has

been closed. All services will be provided

Flare Lines and Flare Knockouts .................................................................... 1 through the Edmonton Office.

ABSA Update Seminar ................................................................................... 1

Special Considerations for Alternative Leak Testing and Closure Welds ........ 2

Internet address

Company Annual Renewal of Power Engineering Certificates ....................... 2 http://www.absa.ca

Pressure Piping Construction Documents ...................................................... 3

Changes to the Information Bulletins Web Pages .......................................... 3

Pressure Equipment Safety Training .............................................................. 4

This Newsletter is a publication of #200, 4208-97 Street

Alberta Boilers Safety Association Edmonton, Alberta

(ABSA). ABSA grants readers T6E 5Z9

permission to make photocopies of

this Newsletter for free distribution to

employees and business associates. Return undeliverable Canadian

addresses to the above address

Articles may be copied in part or in

whole provided credit be given to

ABSA.

Subscription Change

If the newsletter subscriber s status with

your company has changed, please advise

ABSA by:

phone (780) 437-9100

fax (780) 437-7787, or

e-mail webmaster@absa.ca

You might also like

- 1.API 570 & Asme DefinitionsDocument59 pages1.API 570 & Asme DefinitionsAMAL VISHNUNo ratings yet

- Vacuum Box Inspection ProcedureDocument9 pagesVacuum Box Inspection ProcedureOsilonya HenryNo ratings yet

- ch4 - API 574 PDFDocument6 pagesch4 - API 574 PDFRAMADOSSNo ratings yet

- NDT As Per B31.3Document2 pagesNDT As Per B31.3invilink87No ratings yet

- API 510 Inspector Certification RequirementsDocument2 pagesAPI 510 Inspector Certification RequirementsINSTECH ConsultingNo ratings yet

- API 510 Pressure Vessel Inspector: Training Description Training ObjectivesDocument6 pagesAPI 510 Pressure Vessel Inspector: Training Description Training ObjectivesPrashant KumarNo ratings yet

- Api 570Document2 pagesApi 570Andriani 'andin' Karunia PrameiswariNo ratings yet

- Daily Points To Recall (Day 5) : Professional Training and ConsultationDocument3 pagesDaily Points To Recall (Day 5) : Professional Training and Consultationraobabar21No ratings yet

- API 510 Section 8 QuizDocument17 pagesAPI 510 Section 8 Quizamalhaj2013No ratings yet

- API-570 SAMPLE EXAM (Open BOOKDocument8 pagesAPI-570 SAMPLE EXAM (Open BOOKAshish PatelNo ratings yet

- CKRC API 510 WORKBOOK MODULE 1 Rev 1Document7 pagesCKRC API 510 WORKBOOK MODULE 1 Rev 1morneNo ratings yet

- Reapir and Altertaion Section 8Document52 pagesReapir and Altertaion Section 8waqas pirachaNo ratings yet

- API 570 Point Recall 4Document3 pagesAPI 570 Point Recall 4Ravindra S. Jivani100% (2)

- API 510 Pressure Vessel Inspection CodeDocument1 pageAPI 510 Pressure Vessel Inspection CodeaezeadNo ratings yet

- API 510 Exam Study GuideDocument6 pagesAPI 510 Exam Study GuidetayyabNo ratings yet

- API 510 Study GuideDocument3 pagesAPI 510 Study GuidedanikakaNo ratings yet

- Inspection, Repair, Alteration, and Rerating of In-Service Piping SystemsDocument3 pagesInspection, Repair, Alteration, and Rerating of In-Service Piping Systemskhaled saadnehNo ratings yet

- API 510 Preparatory Training Exam QuestionsDocument13 pagesAPI 510 Preparatory Training Exam QuestionsCss SfaxienNo ratings yet

- Heat Exchanger InspectionDocument15 pagesHeat Exchanger InspectionroyNo ratings yet

- API 570, Piping Inspection Code (June 2006) .: (DAY 2 - Sections 1 To 6)Document5 pagesAPI 570, Piping Inspection Code (June 2006) .: (DAY 2 - Sections 1 To 6)vishal bailur100% (1)

- Intro API 570Document2 pagesIntro API 570Javier Eduardo Morales MelgarNo ratings yet

- API 570 ReviewDocument1 pageAPI 570 ReviewRajkumar ANo ratings yet

- API RP 572 QuizDocument17 pagesAPI RP 572 Quizamalhaj2013No ratings yet

- API-570 SAMPLE Closed Book ExamDocument12 pagesAPI-570 SAMPLE Closed Book ExamuttamNo ratings yet

- API 653 Tank Inspector Exam Prep Course AnswersDocument5 pagesAPI 653 Tank Inspector Exam Prep Course Answersanisanis100% (1)

- Assessment 1 API 570Document5 pagesAssessment 1 API 570Mohamed ZainNo ratings yet

- Api 510 Study Guide Practice Questions PDFDocument2 pagesApi 510 Study Guide Practice Questions PDFPrashant KumarNo ratings yet

- ASME B16.5 practice questions and answersDocument66 pagesASME B16.5 practice questions and answersAbdul Qhadeer AnsariNo ratings yet

- API 510 QUIZ No.4Document5 pagesAPI 510 QUIZ No.4Hatem RagabNo ratings yet

- Uphill Versus Downhill Welding PDFDocument4 pagesUphill Versus Downhill Welding PDFPatrick DominguezNo ratings yet

- Boost Your API-570 Piping Inspectors Exam ScoreDocument6 pagesBoost Your API-570 Piping Inspectors Exam Scorejaire esparzaNo ratings yet

- API 570 Piping Inspector Training SyllabusDocument2 pagesAPI 570 Piping Inspector Training SyllabusBidari MediNo ratings yet

- Guidelines For Pressure Boundary Bolted Flange Joint AssemblyDocument9 pagesGuidelines For Pressure Boundary Bolted Flange Joint AssemblycristinelbNo ratings yet

- API 570 Exam Prep TrainingDocument3 pagesAPI 570 Exam Prep Trainingalouis100% (1)

- API 653 PC 15may04 Exam 2 ClosedDocument8 pagesAPI 653 PC 15may04 Exam 2 ClosedShaalan AliNo ratings yet

- Api 653 (CB-109)Document37 pagesApi 653 (CB-109)Naveen RajNo ratings yet

- General welding requirements for technical standardDocument11 pagesGeneral welding requirements for technical standardKunal SrivastavaNo ratings yet

- Standard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodDocument7 pagesStandard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodMauricio FernándezNo ratings yet

- 01-B. - API STD 510 10th Ed (May 2014) + (Addendum 2 March 2018)Document3 pages01-B. - API STD 510 10th Ed (May 2014) + (Addendum 2 March 2018)PelifullHDNo ratings yet

- M.engineering - Piping SystemsDocument55 pagesM.engineering - Piping SystemsKordalhs KyriakosNo ratings yet

- API 570 Final Practice ExamDocument23 pagesAPI 570 Final Practice ExamAndiappan PillaiNo ratings yet

- API 510 Data Sheet Study GuideDocument1 pageAPI 510 Data Sheet Study Guideads_1203No ratings yet

- API 653 Recertification Quiz - Questions and Answers (Updated April 2021)Document2 pagesAPI 653 Recertification Quiz - Questions and Answers (Updated April 2021)Amani ReidNo ratings yet

- SAUDI ARAMCO PUMP ALIGNMENT CHECKLISTDocument1 pageSAUDI ARAMCO PUMP ALIGNMENT CHECKLISTesutjiadiNo ratings yet

- Open Book Testing - API 653Document9 pagesOpen Book Testing - API 653EdisonCorderoNo ratings yet

- Standard For AWS Certification of Welding InspectorsDocument24 pagesStandard For AWS Certification of Welding InspectorsFrancisco Eduardo SouzaNo ratings yet

- Definition of Terms API 510Document5 pagesDefinition of Terms API 510DeepakNo ratings yet

- Case Study - 7: Numerical in API 510 CodeDocument4 pagesCase Study - 7: Numerical in API 510 CodeVishal BailurNo ratings yet

- Nondestructive Measurement of Dry Film Thickness of Applied Organic Coatings Using An Ultrasonic GageDocument4 pagesNondestructive Measurement of Dry Film Thickness of Applied Organic Coatings Using An Ultrasonic GageAdrian OrtizNo ratings yet

- Pressure Vessel Dimension InspectionDocument3 pagesPressure Vessel Dimension InspectionAnas Sarkiah0% (1)

- API 510 - Book 5Document48 pagesAPI 510 - Book 5Hamza AlamNo ratings yet

- 2 Welding Procedure 2 PDFDocument6 pages2 Welding Procedure 2 PDFMustafa MubderNo ratings yet

- Open Book API 510 Practice Exam B Do Not Mark On Your Exam, Use The Answer Sheets ProvidedDocument16 pagesOpen Book API 510 Practice Exam B Do Not Mark On Your Exam, Use The Answer Sheets ProvidedBeantickNo ratings yet

- Asme B16 (1) .48-2005 PDFDocument50 pagesAsme B16 (1) .48-2005 PDFSusan Sue Berrospi MerinoNo ratings yet

- API-510 Closed Book (Vérifié Lors Du Test) FLASH CARDSDocument31 pagesAPI-510 Closed Book (Vérifié Lors Du Test) FLASH CARDSfathiNo ratings yet

- Flare Lines AbsaDocument4 pagesFlare Lines Absadtmgo1No ratings yet

- Fire Hydrant System Design Installation Commisioning and TestingDocument5 pagesFire Hydrant System Design Installation Commisioning and Testingjaianit89No ratings yet

- 15 Saip 50Document5 pages15 Saip 50malika_00No ratings yet

- 74 Samss 001Document7 pages74 Samss 001Cherukunnon JubuNo ratings yet

- Chemical Technology-Mod3 PDFDocument83 pagesChemical Technology-Mod3 PDFSata AjjamNo ratings yet

- Introduction To PetrochemicalsDocument49 pagesIntroduction To PetrochemicalsezzataNo ratings yet

- Overview On Petrochemical IndustriesDocument30 pagesOverview On Petrochemical IndustriesezzataNo ratings yet

- OilDocument60 pagesOilSadakat AliNo ratings yet

- Ammonia PlantDocument16 pagesAmmonia Plantganeshan67% (6)

- Ethylene PropyleneDocument40 pagesEthylene PropyleneSiva KumarNo ratings yet

- Petroleum StandardsDocument116 pagesPetroleum StandardsMark AnthonyNo ratings yet

- Steel Standards PDFDocument50 pagesSteel Standards PDFstallone21No ratings yet

- Urea Plaqnt Life Study Paper20Document19 pagesUrea Plaqnt Life Study Paper20ezzataNo ratings yet

- Steel-HardnessDocument1 pageSteel-HardnessNoir HamannNo ratings yet

- Praxair Shielding Gas ManualDocument70 pagesPraxair Shielding Gas ManualjanedrunkerNo ratings yet

- Comparison Table of Steel GradesDocument1 pageComparison Table of Steel GradesezzataNo ratings yet

- Field Heat Treatment Technician Competency Profile PDFDocument17 pagesField Heat Treatment Technician Competency Profile PDFezzataNo ratings yet

- LNG Safety & Security PDFDocument81 pagesLNG Safety & Security PDFezzataNo ratings yet

- Local PWHT of Branch ConnectionsDocument37 pagesLocal PWHT of Branch ConnectionsezzataNo ratings yet

- Hot Tap ProcedureDocument21 pagesHot Tap ProcedureImanuel Sitepu100% (1)

- Hydrotest FormulaDocument17 pagesHydrotest FormulaEarnest007100% (2)

- Influence of Welding Speed & Power On Residual Stress During GTAWDocument12 pagesInfluence of Welding Speed & Power On Residual Stress During GTAWezzataNo ratings yet

- Heat Affected Zone Hardness Limits For In-Service WeldingDocument9 pagesHeat Affected Zone Hardness Limits For In-Service Weldingezzata100% (1)

- Effect of Heat Treatment On Preventing Hydrogen Cracking of Pipeline in Hot Tapping PDFDocument8 pagesEffect of Heat Treatment On Preventing Hydrogen Cracking of Pipeline in Hot Tapping PDFezzataNo ratings yet

- Preheat and PWHT codesDocument4 pagesPreheat and PWHT codesezzataNo ratings yet

- Pneumatic Test PDFDocument4 pagesPneumatic Test PDFezzataNo ratings yet

- Pressure Vessel Failure During Hydro Test PDFDocument4 pagesPressure Vessel Failure During Hydro Test PDFezzataNo ratings yet

- Hydro Test InfoDocument5 pagesHydro Test Infospadafora77100% (1)

- Hydrostatic Pressure Testing of Plastic Piping SystemsDocument12 pagesHydrostatic Pressure Testing of Plastic Piping SystemsezzataNo ratings yet

- On Hydrostatic Testing Heat Exchangers PDFDocument7 pagesOn Hydrostatic Testing Heat Exchangers PDFRaju GummaNo ratings yet

- Arc Welding of Steel Pipe Connections On Steel Gas Pipeline in ServiceDocument10 pagesArc Welding of Steel Pipe Connections On Steel Gas Pipeline in ServiceezzataNo ratings yet

- Hydrotesting Not Required Under New API-653 Procedure: TechnologyDocument4 pagesHydrotesting Not Required Under New API-653 Procedure: Technologyamirreza_eng3411No ratings yet

- The Pressure News: I B N - IB02-002 R - 1Document4 pagesThe Pressure News: I B N - IB02-002 R - 1Sukanto BarmanNo ratings yet

- Presentation - Fire Protection Regulations - EnGDocument19 pagesPresentation - Fire Protection Regulations - EnGoctyabrovaNo ratings yet

- Quantium 510 AW 2016Document4 pagesQuantium 510 AW 2016mohsenNo ratings yet

- PTW 6.0 EnhancementsDocument36 pagesPTW 6.0 EnhancementsBreno AlmeidaNo ratings yet

- Baudouin - PowerKit Brochure - EN - 02.17Document8 pagesBaudouin - PowerKit Brochure - EN - 02.17storkbNo ratings yet

- WCAIM2051 - EN - AQ Atomising Air ValveDocument2 pagesWCAIM2051 - EN - AQ Atomising Air ValveMohammed YasinNo ratings yet

- Strategic Management Final Project AnalysisDocument33 pagesStrategic Management Final Project AnalysisEmad AttiaNo ratings yet

- SFP Catalog 1 Metal BellowsDocument92 pagesSFP Catalog 1 Metal BellowshalongvanNo ratings yet

- Nuclear Proliferation and The NPTDocument20 pagesNuclear Proliferation and The NPTgoricaaaPNo ratings yet

- W 3000Document30 pagesW 3000sarokihNo ratings yet

- GIS 8DQ1 DS eDocument18 pagesGIS 8DQ1 DS esachinkudachiNo ratings yet

- Some of The Organizations / Universities Offering Summer Training / Internship (Listed Department-Wise)Document8 pagesSome of The Organizations / Universities Offering Summer Training / Internship (Listed Department-Wise)Asis DasNo ratings yet

- D 9 MHDocument2 pagesD 9 MHDante FloresNo ratings yet

- Chapter 2 PDFDocument20 pagesChapter 2 PDFCatherineNo ratings yet

- 977 Sample PDFDocument6 pages977 Sample PDFAdrianNo ratings yet

- Electrical Machines Lab March 16 UpdateDocument53 pagesElectrical Machines Lab March 16 Updatepeter vanderNo ratings yet

- gg1 Engineer S Controls Classic TrainsDocument1 pagegg1 Engineer S Controls Classic Trainsbaron mNo ratings yet

- Chapter 2 - Principles of Electromechanical Energy ConversionDocument22 pagesChapter 2 - Principles of Electromechanical Energy Conversionchibssa alemayehuNo ratings yet

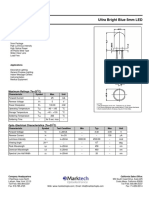

- Ultra Bright Blue 5mm LED: FeaturesDocument2 pagesUltra Bright Blue 5mm LED: FeaturesJhon LaricoNo ratings yet

- BHA PROPOSAL FOR SERD-N2 ST WELLDocument1 pageBHA PROPOSAL FOR SERD-N2 ST WELLPinggir KaliNo ratings yet

- GCP-HARP-1004 - College of Magics PDFDocument127 pagesGCP-HARP-1004 - College of Magics PDFMartin Gualdarrama50% (2)

- Yanmar MOTOR L48N-DDocument15 pagesYanmar MOTOR L48N-DAndre FilipeNo ratings yet

- Stycast 2850FTDocument4 pagesStycast 2850FTKhôi NguyênNo ratings yet

- Work Centre M15 Service ManualDocument380 pagesWork Centre M15 Service ManualMarcos GarciaNo ratings yet

- Drilling horizontal wells with electric downhole motorsDocument10 pagesDrilling horizontal wells with electric downhole motorsGregory DemerjiNo ratings yet

- Research Paper A Novel Method For Near State Pulse Width Modulation (NSPWM) Based Chopper DrivesDocument4 pagesResearch Paper A Novel Method For Near State Pulse Width Modulation (NSPWM) Based Chopper Drivesdivyamanikandan007No ratings yet

- Microsoft Word - E003 Main QuizDocument6 pagesMicrosoft Word - E003 Main QuizwarrenronaldNo ratings yet

- BS 00489-1999 PDFDocument10 pagesBS 00489-1999 PDFNayan jainNo ratings yet

- TC 10 19 PDFDocument159 pagesTC 10 19 PDFamare addisNo ratings yet

- SRU Reaction Furnace Waste Heat Boiler Tube Failure Causing Unscheduled Shutdown (Rev. 1) (FINAL)Document11 pagesSRU Reaction Furnace Waste Heat Boiler Tube Failure Causing Unscheduled Shutdown (Rev. 1) (FINAL)MubeenNo ratings yet

- Dulhunty Power LinksDocument13 pagesDulhunty Power Linksryan_jay55No ratings yet